304L Stainless Steel Pipe Description

304L stainless steel pipe--S30403 (American AISI, ASTM) 304L corresponds to the Chinese grade 00Cr19Ni10.

304L stainless steel, also known as ultra-low carbon stainless steel, is a versatile stainless steel material that is widely used in the manufacture of equipment and parts that require good comprehensive performance (corrosion resistance and formability). The lower carbon content minimizes the precipitation of carbides in the heat-affected zone near the weld, and the precipitation of carbides may cause intergranular corrosion (welding erosion) of stainless steel in certain environments.

Under normal conditions, the corrosion resistance of 304L stainless steel pipe is similar to that of 304 steel, but after welding or stress, its resistance to intergranular corrosion is excellent. Without heat treatment, it can also maintain good corrosion resistance and is generally used below 400 degrees (non-magnetic, operating temperature -196 degrees Celsius to 800 degrees Celsius).

304L stainless steel is used in outdoor machinery, building materials, heat-resistant parts and parts with difficult heat treatment in the chemical, coal and oil industries with high requirements for resistance to intergranular corrosion.

| Product | Youfa brand 304L stainless steel pipe |

| Material | Stainless Steel 304L |

| Specification | Diameter : DN15 TO DN300 (16mm - 325mm)

Thickness : 0.8mm TO 4.0mm Length : 5.8meter/ 6.0meter/ 6.1meter or custimized |

| Standard | ASTM A312

GB/T12771, GB/T19228

|

| Surface | Polishing,annealing,pickling,bright |

| Surface Finished | No.1, 2D, 2B, BA, No.3, No.4, No.2 |

| Packing | 1. Standard seaworthy export packing. 2. 15-20MT can be loaded into 20'container and 25-27MT is more suitable in 40'container. 3. The other packing can be made based on the customer requirement |

Characteristics of 304L Stainless Steel

Excellent Corrosion Resistance: The corrosion resistance of 304L stainless steel is significantly improved compared to ordinary stainless steel, making it suitable for use in chemical processes.

Good Low-Temperature Strength: 304L stainless steel maintains strong strength and toughness even at low temperatures, which is why it is widely used in low-temperature equipment.

Good Mechanical Properties: Stainless steel 304L has high tensile strength and yield strength, and its hardness can be increased through cold working.

Excellent Machinability: 304L stainless steel is easy to process, weld, and cut, and it has a high surface finish.

No Hardening After Heat Treatment: Stainless steel 304L does not undergo hardening during the heat treatment process.

Types of 304L Stainless Steel Tube

1. Stainless heat exchanger tubes

Performance characteristics: smooth inner wall, low water resistance, can withstand erosion of high water flow rate, after solution treatment, the mechanical properties and corrosion resistance of the weld and the substrate are basically the same, and the deep processing performance is excellent.

2. Thin-walled stainless steel tubes

Use: Mainly used for direct drinking water projects and other fluid transportation with high requirements.

Main features: long service life; low failure rate and water leakage rate; good water quality, no harmful objects will be precipitated into the water; the inner wall of the tube is not rusted, smooth, and has low water resistance; high cost performance, with a service life of up to 100 years, no maintenance required, and low cost; can withstand erosion of high water flow rate of more than 30m/s; open pipe laying, beautiful appearance.

3. Food hygiene tubes

Use: milk and food industry, pharmaceutical industry, and industries with special inner surface requirements.

Process features: internal weld bead leveling treatment, solution treatment, inner surface electrolytic polishing.

4. Stainless steel fluid pipe

Carefully manufactured stainless steel internal flat welded pipe, widely used in dairy products, beer, beverages, pharmaceuticals, biology, cosmetics, fine chemicals. Compared with ordinary sanitary steel pipes, its surface finish and inner wall are smooth and flat, the flexibility of the steel plate is better, the coverage is wide, the wall thickness is uniform, the precision is higher, there are no pitting, and the quality is good.

| Nominal | Kg/m Materials:304L (Wall Thickness,Weight) | |||||||

| Pipes Size | OD | Sch5s | Sch10s | Sch40s | ||||

| DN | In | mm | In | mm | In | mm | In | mm |

| DN15 | 1/2’’ | 21.34 | 0.065 | 1.65 | 0.083 | 2.11 | 0.109 | 2.77 |

| DN20 | 3/4’’ | 26.67 | 0.065 | 1.65 | 0.083 | 2.11 | 0.113 | 2.87 |

| DN25 | 1’’ | 33.4 | 0.065 | 1.65 | 0.109 | 2.77 | 0.133 | 3.38 |

| DN32 | 1 1/4’’ | 42.16 | 0.065 | 1.65 | 0.109 | 2.77 | 0.14 | 3.56 |

| DN40 | 1 1/2’’ | 48.26 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.68 |

| DN50 | 2’’ | 60.33 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.91 |

| DN65 | 2 1/2’’ | 73.03 | 0.083 | 2.11 | 0.12 | 3.05 | 0.203 | 5.16 |

| DN80 | 3’’ | 88.9 | 0.083 | 2.11 | 0.12 | 3.05 | 0.216 | 5.49 |

| DN90 | 3 1/2’’ | 101.6 | 0.083 | 2.11 | 0.12 | 3.05 | 0.226 | 5.74 |

| DN100 | 4’’ | 114.3 | 0.083 | 2.11 | 0.12 | 3.05 | 0.237 | 6.02 |

| DN125 | 5’’ | 141.3 | 0.109 | 2.77 | 0.134 | 3.4 | 0.258 | 6.55 |

| DN150 | 6’’ | 168.28 | 0.109 | 2.77 | 0.134 | 3.4 | 0.28 | 7.11 |

| DN200 | 8’’ | 219.08 | 0.134 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 |

| DN250 | 10’’ | 273.05 | 0.156 | 3.4 | 0.165 | 4.19 | 0.365 | 9.27 |

| DN300 | 12’’ | 323.85 | 0.156 | 3.96 | 0.18 | 4.57 | 0.375 | 9.53 |

| DN350 | 14’’ | 355.6 | 0.156 | 3.96 | 0.188 | 4.78 | 0.375 | 9.53 |

| DN400 | 16’’ | 406.4 | 0.165 | 4.19 | 0.188 | 4.78 | 0.375 | 9.53 |

| DN450 | 18’’ | 457.2 | 0.165 | 4.19 | 0.188 | 4.78 | 0.375 | 9.53 |

| DN500 | 20’’ | 508 | 0.203 | 4.78 | 0.218 | 5.54 | 0.375 | 9.53 |

| DN550 | 22’’ | 558 | 0.203 | 4.78 | 0.218 | 5.54 | 0.375 | 9.53 |

| DN600 | 24’’ | 609.6 | 0.218 | 5.54 | 0.250 | 6.35 | 0.375 | 9.53 |

| DN750 | 30’’ | 762 | 0.250 | 6.35 | 0.312 | 7.92 | 0.375 | 9.53 |

304L Stainless Steel Tubes Test And Certificates

Strict Quality Control:

1) During and after production, QC staffs with more than 5 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

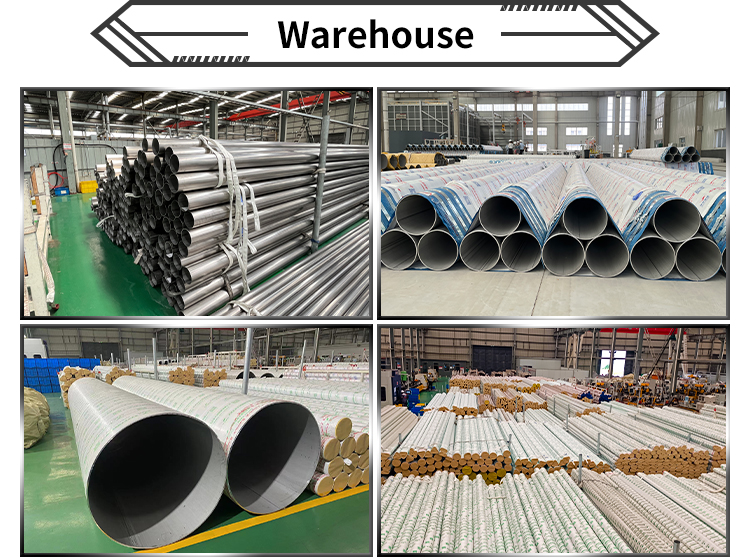

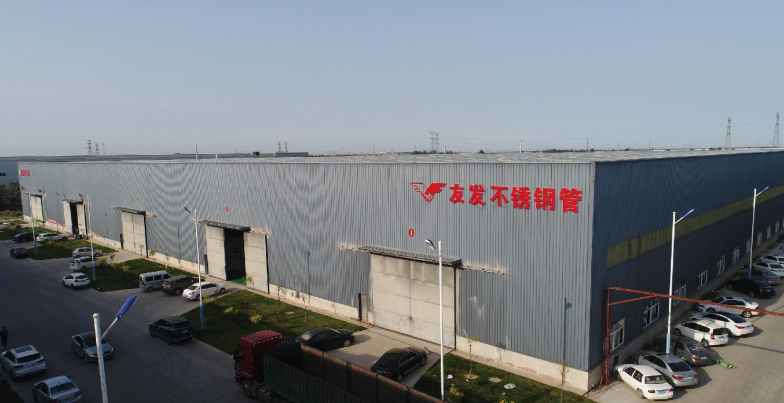

Stainless Steel Tubes Youfa Factory

Tianjin Youfa Stainless Steel Pipe Co., Ltd. is committed to the R & D and production of thin-walled stainless steel water pipes and fittings.

Product Characteristics : safety and health, corrosion resistance, firmness and durability, long service life, maintenance free, beautiful, safe and reliable, fast and convenient installation, etc.

Products Usage : tap water engineering, direct drinking water engineering, construction engineering, water supply and drainage system, heating system, gas transmission, medical system, solar energy, chemical industry and other low-pressure fluid transmission drinking water engineering.

All pipes and fittings fully comply with the latest national product standards and are the first choice for purifying water source transmission and maintaining a healthy life.