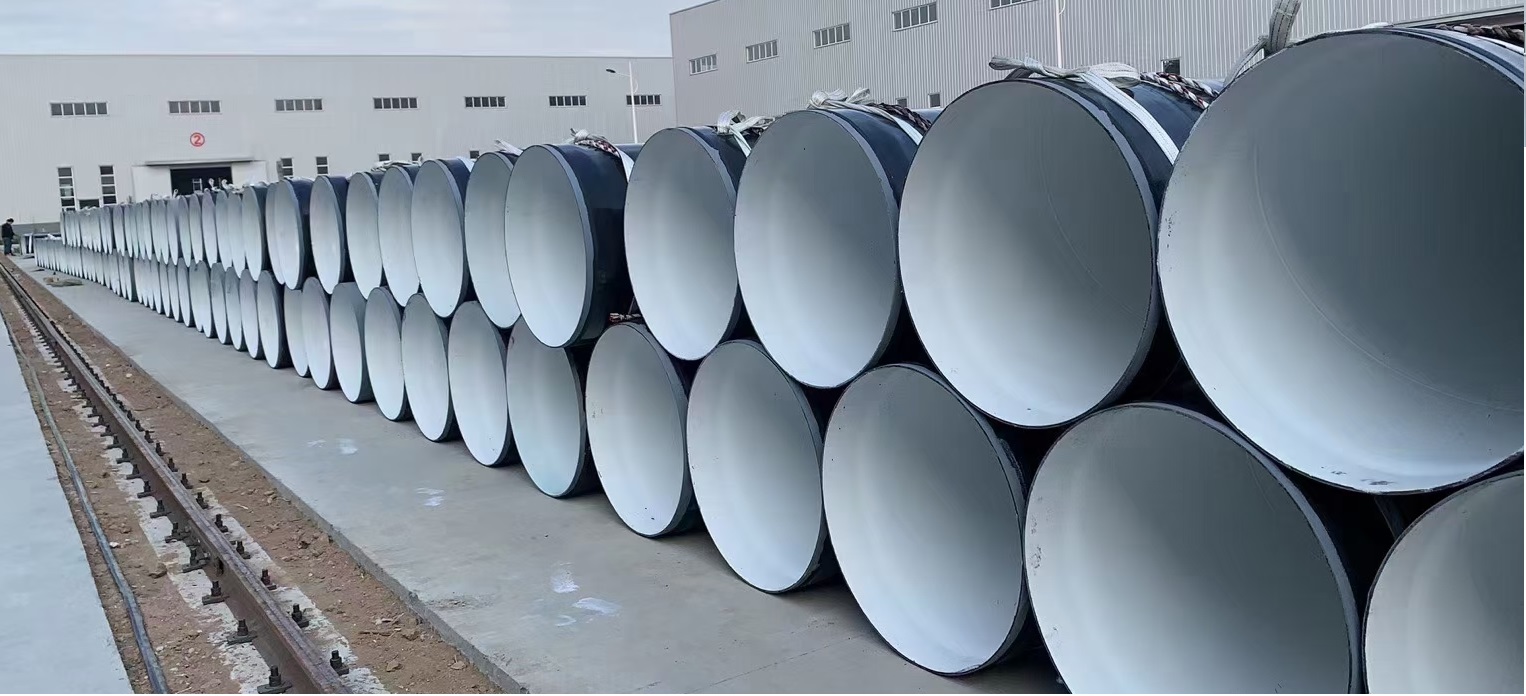

3PE Coated SSAW Steel Pipes Brief Introduction:

3PE coating is commonly used for steel pipes to provide excellent corrosion resistance and durability. The three layers of the 3PE coating work together to protect the steel pipe from environmental factors and extend its service life.

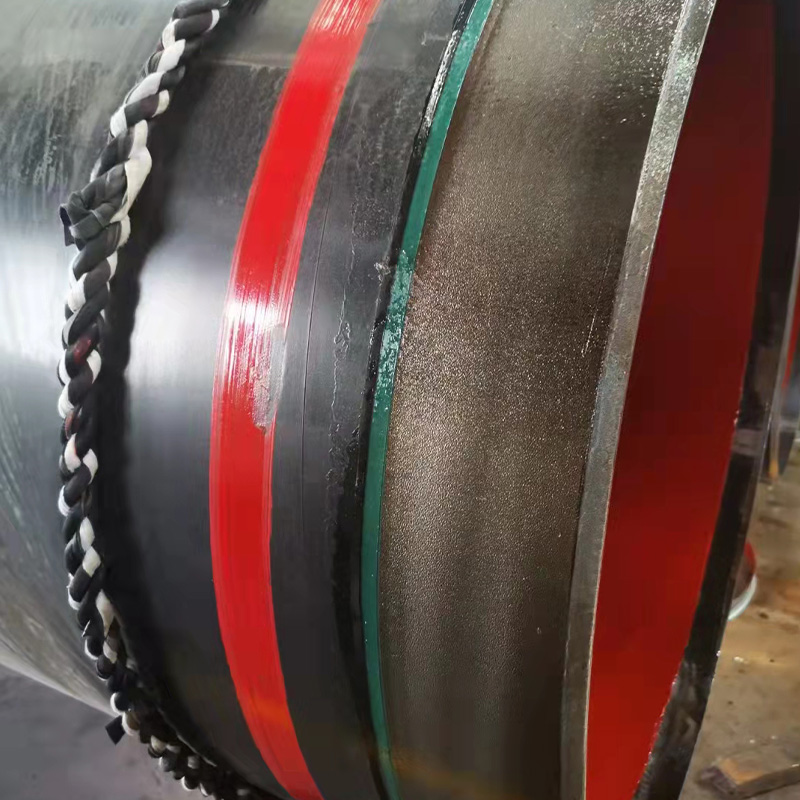

The first layer, which is the epoxy powder (FBE) with a thickness of over 100um, serves as a primer that provides excellent adhesion to the steel surface and acts as a corrosion barrier.

The second layer, the adhesive (AD) with a thickness of 170 - 250um, helps to bond the epoxy layer to the polyethylene layer and provides additional protection against corrosion.

The third layer, the polyethylene (PE) with a thickness of 2.5 ~ 3.7mm, acts as the outer layer and provides resistance to abrasion, impact, and chemical corrosion.

This 3-layer structure makes the 3PE coated pipe suitable for various applications, including transporting oil, gas, and water, as well as in structural and industrial settings where corrosion resistance is essential.

| Product | 3PE Spiral Welded Steel Pipe | Specification |

| Material | Carbon Steel | OD 219-2020mmThickness: 7.0-20.0mmLength: 6-12m |

| Grade | Q195 = A53 Grade A Q235 = A53 Grade B / A500 Grade AQ345 = A500 Grade B Grade C |

|

| Standard | GB/T9711-2011API 5L, ASTM A53, A36, ASTM A252 | Application: |

| Surface | Black Painted OR 3PE | Oil, line pipe Pipe Pile |

| Ends | Plain ends or Beveled ends | |

| with or without caps |