API 5L and ASTM A53 Standards: These standards ensure that the steel pipe meets specific requirements for use in oil and gas industry applications, as well as for general use in mechanical and pressure applications.

Grade B: The designation "Grade B" indicates the strength and mechanical properties of the steel pipe, with specific requirements for yield strength, tensile strength, and impact properties.

| API 5L PSL1 Welded Steel Pipe Grade B |

|||||

| Chemical Composition | Mechanical Properties | ||||

| C (max.)% | Mn (max.)% | P (max.)% | S (max.)% | Yield strength min. MPa |

Tensile strength min. MPa |

| 0.26 | 1.2 | 0.03 | 0.03 | 241 | 414 |

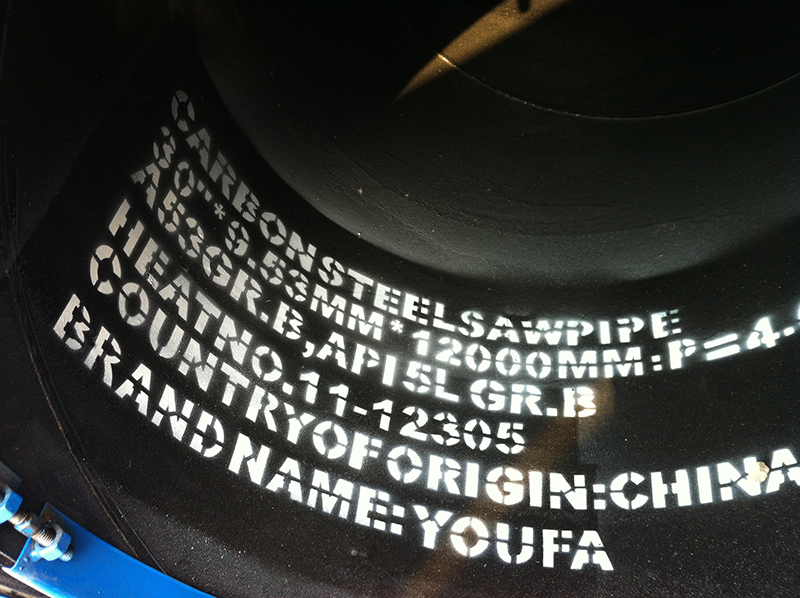

SAW Welding: The pipe is manufactured using the Submerged Arc Welding (SAW) process, which involves the formation of a welded seam using a continuous submerged arc welding process. This method is known for producing high-quality, uniform welds.

Black Painted Finish: The black painted finish provides corrosion resistance and enhances the aesthetic appearance of the steel pipe. The paint also helps protect the pipe during storage and transportation.

Applications: API 5L ASTM A53 Grade B Black Painted SAW Welded Steel Pipe is commonly used in various applications, including oil and gas transmission pipelines, structural support in construction, and other industrial and mechanical applications.

| Product | ASTM A53 API 5L Spiral Welded Steel Pipe | Specification |

| Material | Carbon Steel | OD 219-2020mm

Thickness: 7.0-20.0mm Length: 6-12m |

| Grade | Q235 = A53 Grade B / A500 Grade A

Q345 = A500 Grade B Grade C |

|

| Standard | GB/T9711-2011API 5L, ASTM A53, A36, ASTM A252 | Application: |

| Surface | Black Painted OR 3PE | Oil, line pipe Pipe Pile |

| Ends | Plain ends or Beveled ends | |

| with or without caps |

Strict Quality Control:

1) During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved by Malaysia, Indonesia, Singapore, Philippines, Australia, Peru and UK. We own UL /FM, ISO9001/18001, FPC certificates

About us:

Tianjin Youfa Steel Pipe Group Co., Ltd was founded on July 1st, 2000. There are totally about 8000 employees, 9 factories, 179 steel pipe production lines, 3 national accredited laboratory, and 1 Tianjin government accredited business technology center.

9 SSAW steel pipe production lines

Factories: Tianjin Youfa Pipeline Technology Co.,Ltd

Handan Youfa Steel Pipe Co.,Ltd;

Monthly Output: about 20000Tons