API 5L seamless pipes are commonly used in the construction of pipelines for transporting oil and gas over long distances, and also used in the construction of infrastructure for the energy industry, such as refineries and petrochemical plants.

API 5L Seamless Steel Pipes Brief Introductions

| Product | API 5L Seamless Steel Pipe | Specification |

| Material | Carbon Steel | OD: 13.7-610mm

Thickness: sch40 sch80 sch160 Length: 5.8-6.0m |

| Grade | L245,API 5L B /ASTM A106 B | |

| Surface | Bare or Black Painted | Usage |

| Ends | Plain ends | Oil /Gas delivery steel pipe |

| Or Beveled ends |

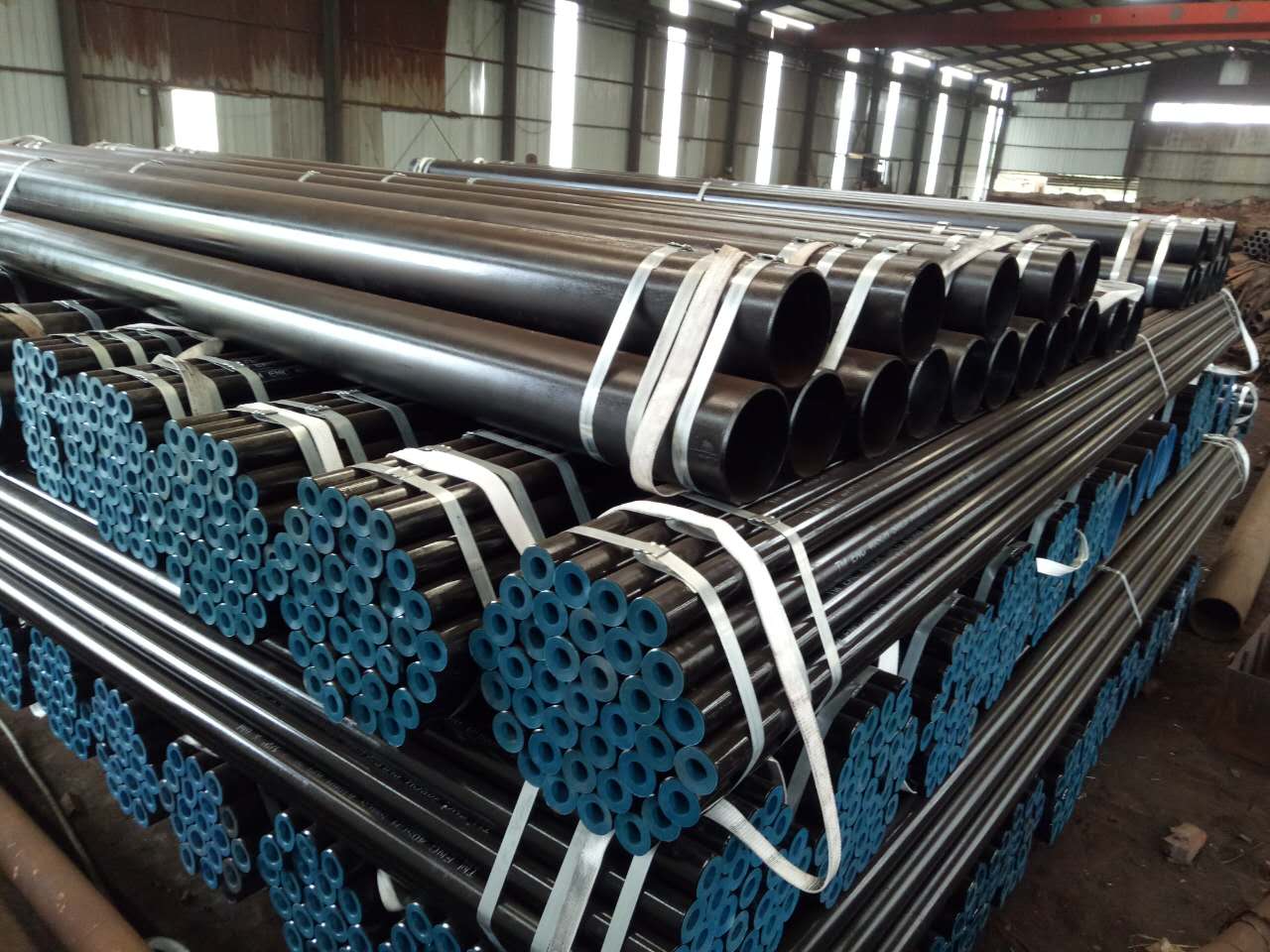

Packing and Delivery:

Packing Details : in hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles.

Delivery Details : Depending on the QTY, normally one month.

API 5L Seamless Carbon Steel Pipe Steel Grade

| Seamless Pipe Steel Grade | Chemical Composition for PSL 1 pipe with WT ≤25mm (0.984 inc) |

||||

| C (max.)% | Mn (max.)% | P (max.)% | S (max.)% | V + Nb + Ti | |

| L245 or Grade B | 0.28 | 1.2 | 0.03 | 0.03 | Unless otherwise agreed, the sum of the niobium and vanadium contents shall be u 0,06 %. The sum of the niobium, vanadium and titanium concentrations shall be u 0,15 %. |

| Seamless Pipe Steel Grade | Tensile Tests for PSL 1 pipe body | |||

| Yield Strength (min.) MPa | Tensile Strength (min.) MPa | |||

| L245 or Grade B | 245 | 415 | ||

API 5L Steel Seamless Pipes Sizes Chart

| INCH | OD | API 5L ASTM A106 Strandard Wall Thickness | |||||||

| (MM) | SCH 10 | SCH 20 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 160 | XXS | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Seamless SMLS Pipe Manufacturing Process

Raw Material Selection: High-quality carbon steel is chosen as the raw material for seamless carbon steel pipes. The carbon content in the steel is a key factor in determining its properties and suitability for various applications.

Heating and Piercing: The raw material is heated to a high temperature and then pierced to form a hollow shell. This process is crucial for creating the initial shape of the pipe and is typically achieved through methods such as rotary piercing, extrusion, or other specialized techniques.

Rolling and Sizing: The pierced shell undergoes rolling and sizing processes to reduce its diameter and wall thickness to the required dimensions. This is typically achieved using a series of rolling mills and sizing mills to achieve the desired shape and dimensions.

Heat Treatment: The seamless carbon steel pipe is subjected to heat treatment processes such as annealing, normalizing, or quenching and tempering to enhance its mechanical properties and remove any residual stresses. The heat treatment also helps in achieving the desired microstructure and properties of the carbon steel.

Testing and Inspection: Throughout the manufacturing process, the seamless carbon pipe undergoes various non-destructive and destructive testing methods to ensure it meets the required quality standards. This may include ultrasonic testing, hydrostatic testing, eddy current testing, and visual inspection.

Finishing and Coating: Once seamless pipe meets the required specifications, it undergoes finishing processes such as straightening, cutting, and end finishing. Additionally, the pipe may be coated with protective materials such as varnish, paint, or galvanizing to enhance its corrosion resistance, especially in the case of carbon steel.

Final Inspection and Packaging: The finished seamless steel pipe undergoes a final inspection to ensure it meets all quality standards and customer requirements. It is then carefully packaged and prepared for shipping to the customer.

API 5L Carbon Steel Seamless Pipe Quality Assurance and Test

Hydrostatic test

seamless pipe shall withstand the hydrostatic test without leakage through the weld seam or the pipe body.

Tolerances for diameter, wall thickness, length and straightness

| Specified outside diameter |

SMLS pipe Diameter tolerances | Out-of-roundness tolerances | ||

| Pipe except the end | Pipe end | Pipe except the end | Pipe end | |

| <60.3mm | − 0.8mm to + 0.4mm | − 0.4mm to + 1.6mm | ||

| ≥60.3mm to ≤168.3mm | ± 0.0075 D | 0.020 D | 0.015 D | |

| >168.3mm to ≤610mm | ± 0.0075 D | ± 0.005 D, but maximum of ± 1.6mm |

||

| >610mm to ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, but maximum of 15mm, for D/T≤75 |

0.01 D, but maximum of 13mm, for D/T≤75 |

| by agreement for D/T>75 |

by agreement for D/T>75 |

|||

D: OD outside diameter T: WT wall thickness