Ke Kaʻina Hana Hana a me ke Kaʻina Nānā

Me ka 9000 o nā limahana akamai loa a me 293 mau laina hana kiʻekiʻe i hoʻolaha ʻia ma waena o nā hale hana 13, ua hana mākou i 20 miliona tons paipu kila ma 2022, a ʻoi aku ka nui o ke kūʻai aku ma mua o 160 miliona US Dollars i 2018. ʻO 500 mau ʻoihana ma Kina Manufacturing Industry mai 2006.

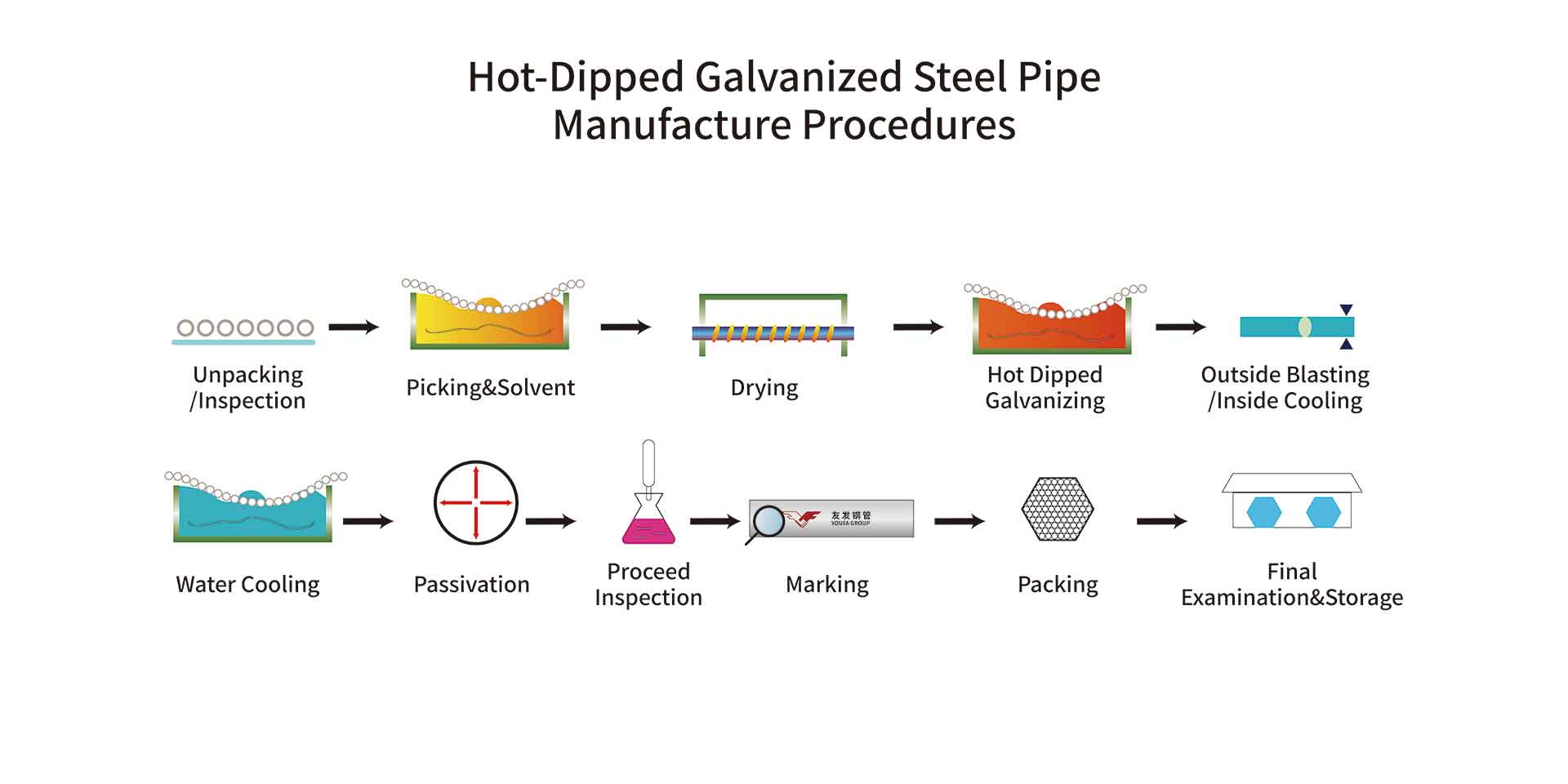

Paipu kila umehana wela

Nā Kaʻina Hana Hana

01. Unpacking/Inspection→02.Picking&Solvent→03.Drying→04.SHot dipped galvanizing→05.Outside blasting/Inside cooling→06.Water cooling→07.Passivation→08.Proceed inspection→09.Marking→10.Packing→ 11. Hoʻokolokolo hope a mālama

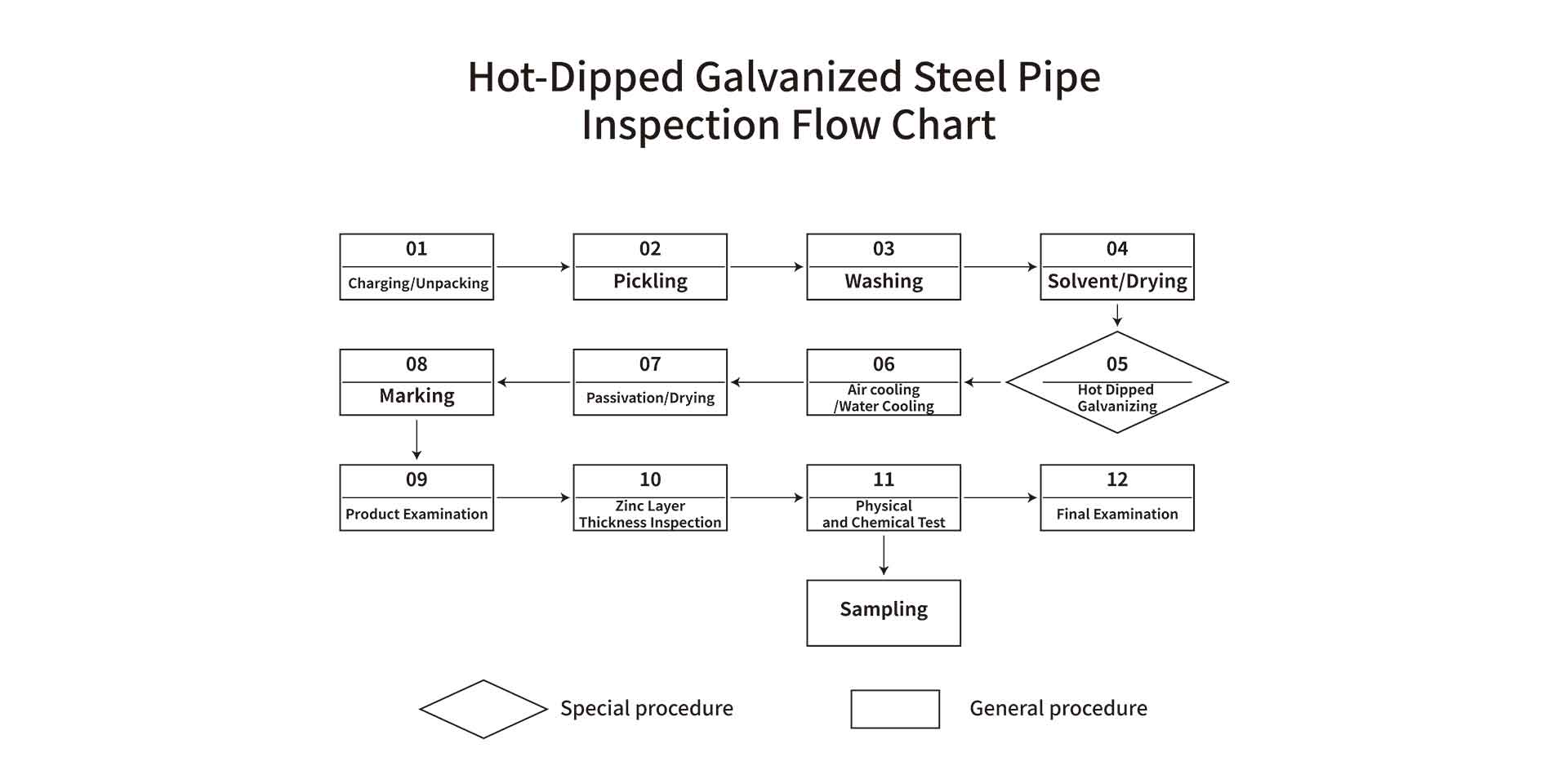

Paipu kila umehana wela

Papa Kahe Kahea

01. Hoʻouka / Wehe → 02. Pickling → 03. Holoi → 04. Solvent / Drying → 05. Hot dipped galvanizing → 06. Ea hoʻoluʻu / wai hoʻoluʻu → 07. Passivation / Drying → 08. Marking → 09. Nānā huahana → 10 .Hōʻike mānoanoa papa Zinc → 11. Hoʻāʻo kino a me kemika→ 12. Hoʻokolokolo hope

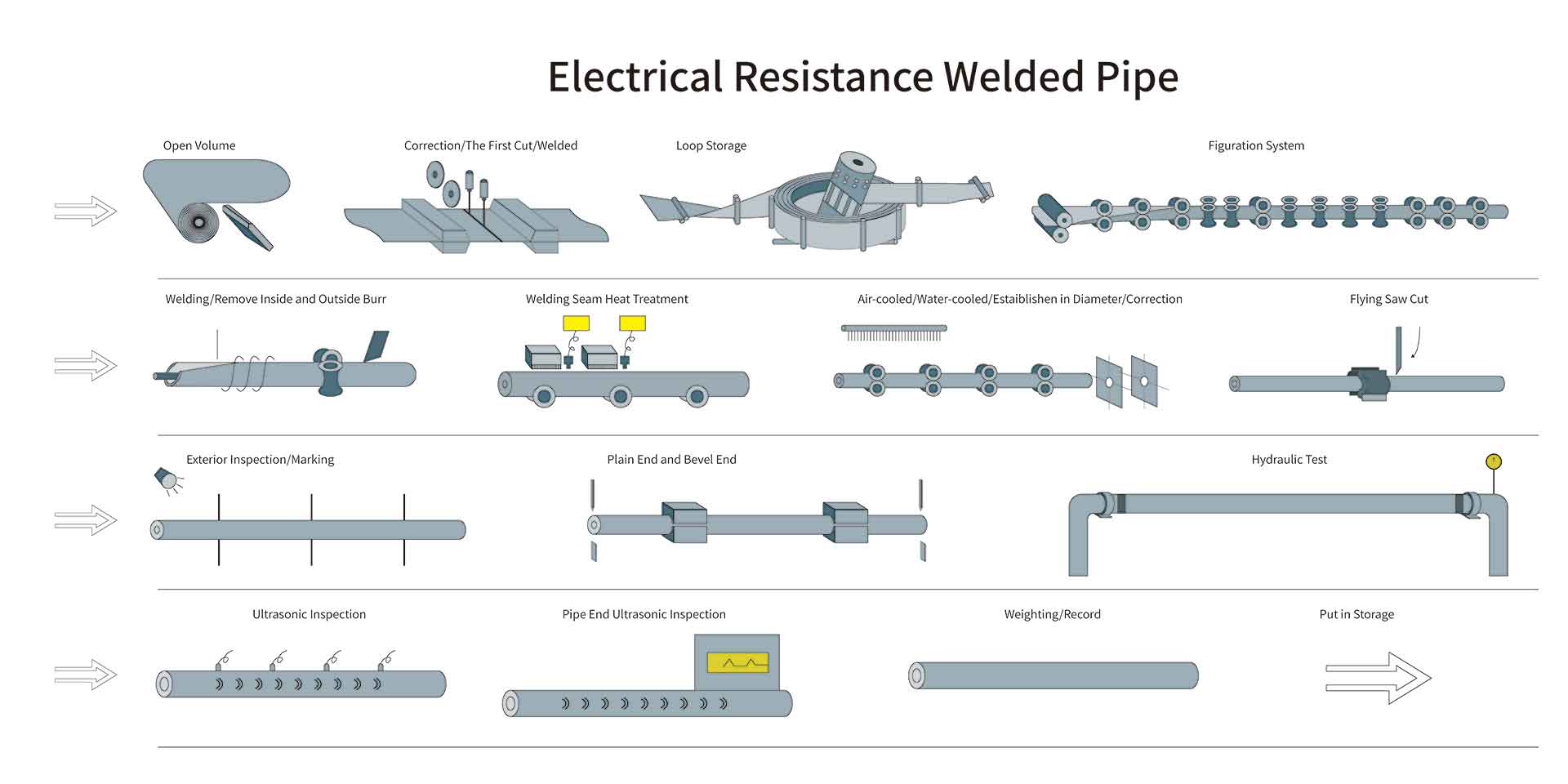

Pipa Weld Kū'ē Uila-ERW

Nā Kaʻina Hana Hana

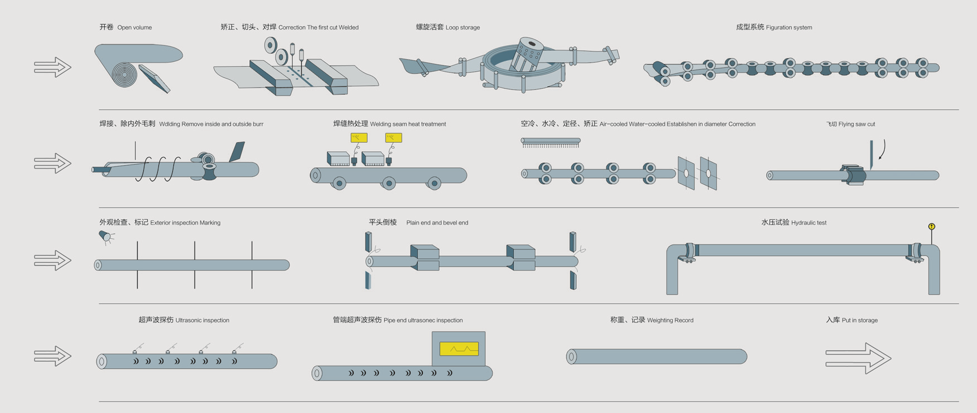

01.Open volume → 02. Hoʻoponopono / ʻO ka ʻoki mua / Welded → 03. Loop waihona → 04. Pūnaehana Figuration → 05. Welding / Wehe i loko a waho burr → 06. Welding seam wela wela → 07. Air-cooled / Wai- ʻoluʻolu/E hoʻopaʻa i ke anawaena/Hoʻoponopono → 08. ʻoki ʻoki lele → 09. Ma waho ka nānā ʻana/marking→10.Plain end and bevel end→11.Hydraulic test→12.Ultrasonic inspection→13.Pipe end Ultrasonic inspection→14.Weighting/Record→15.Put in storage

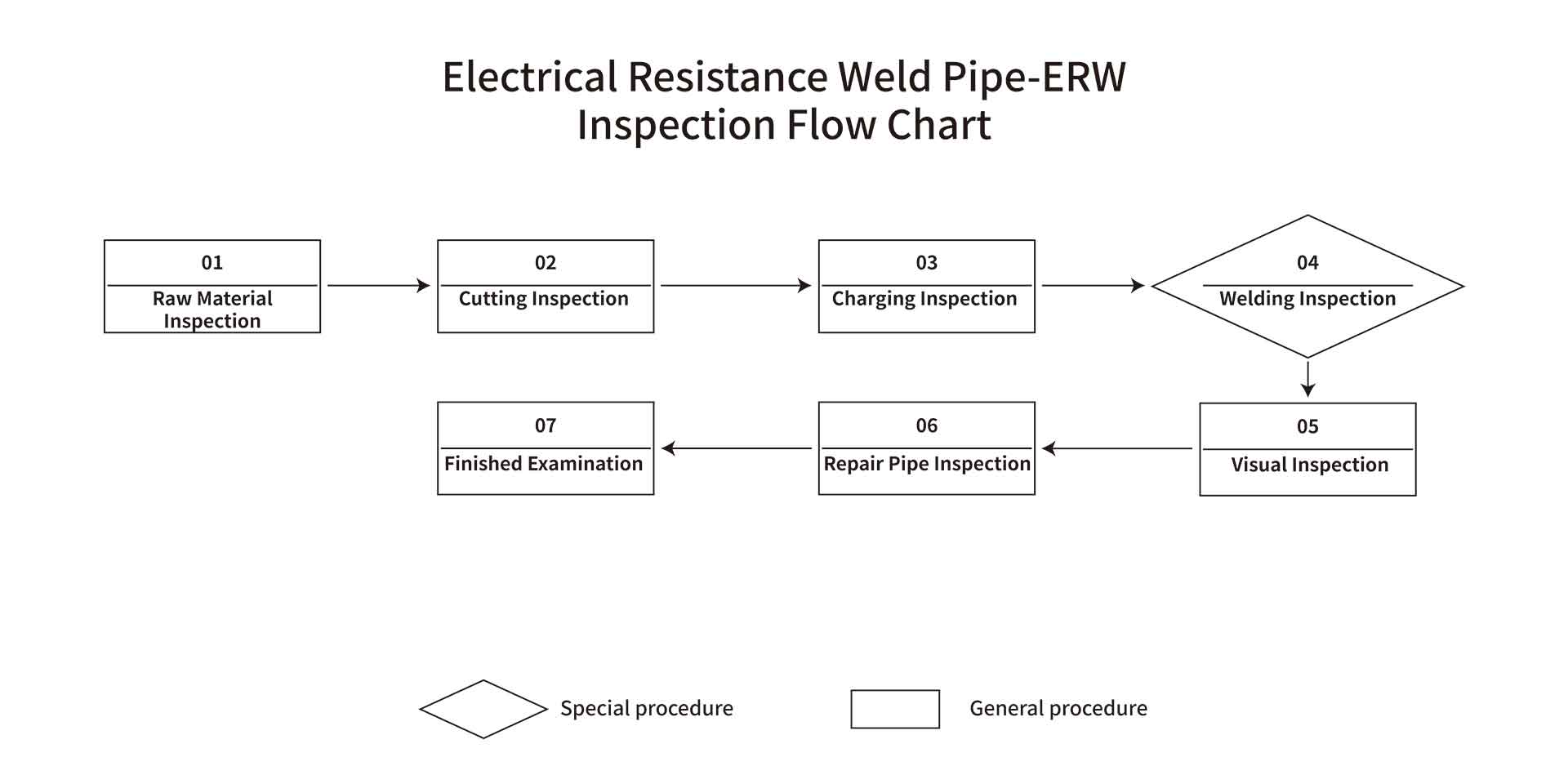

Pipa Weld Kū'ē Uila-ERW

Papa Kahe Kahea

01. Nānā mea maka → 02. ʻOki ʻoki → 03. Hoʻopiʻi i ka nānā ʻana → 04. Ka nānā ʻana i ka welding → 05. Nānā ʻike → 06. Hoʻoponopono i ka paipu → 07. Hoʻopau ʻia

E hoʻāʻo mākou i nā mea maka a me nā kaʻina hana e like me nā kūlana like ʻole e hōʻoia i ka hoʻokō ʻana o nā huahana i nā kūlana a i ʻole nā koi ʻaelike.

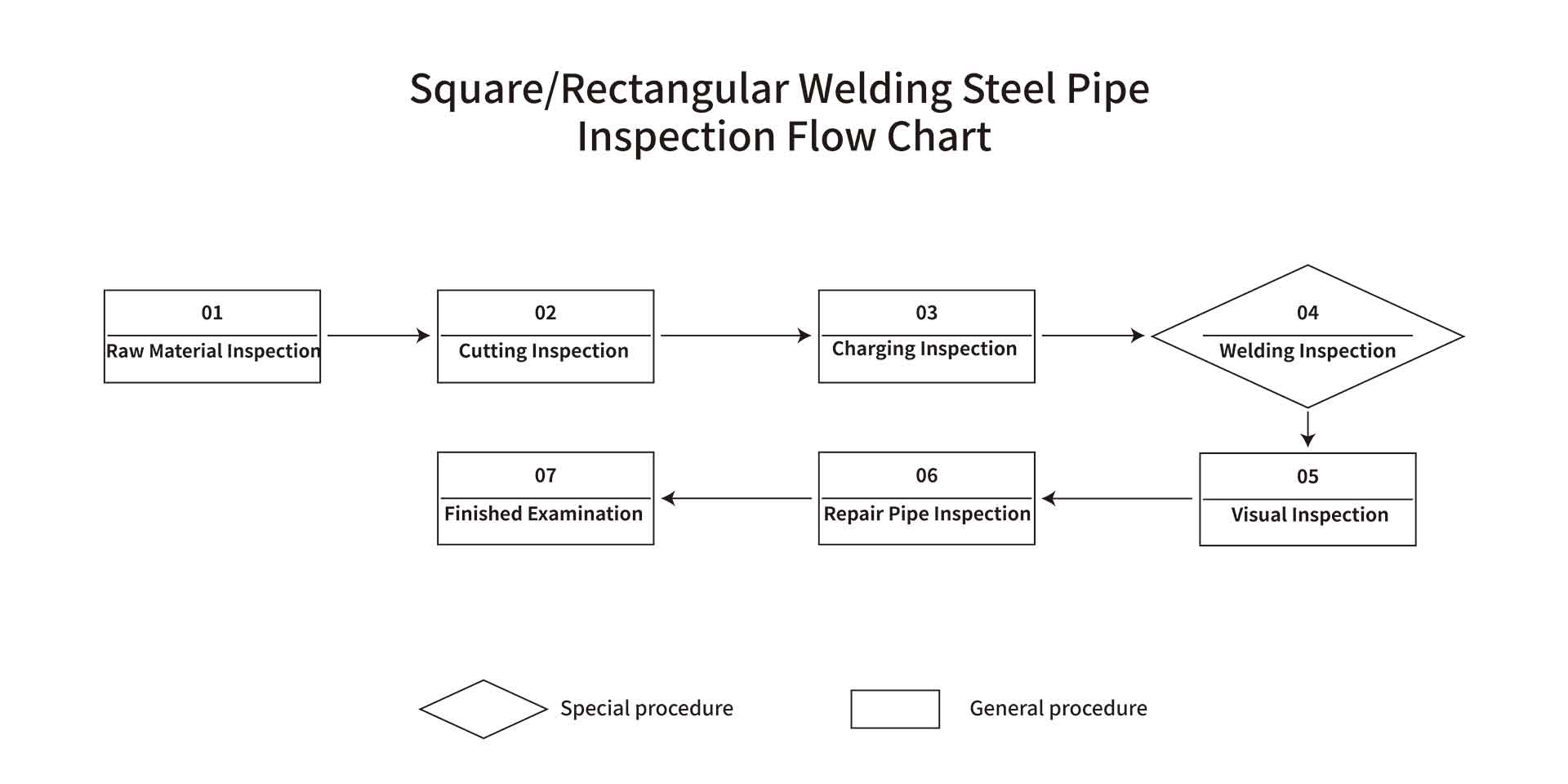

Pāha/Rectangular Welding Steel Pipe

Papa Kahe Kahea

01. Nānā mea maka → 02. ʻOki ʻoki → 03. Hoʻopiʻi i ka nānā ʻana → 04. Ka nānā ʻana i ka welding → 05. Nānā ʻike → 06. Hoʻoponopono i ka paipu → 07. Hoʻopau ʻia

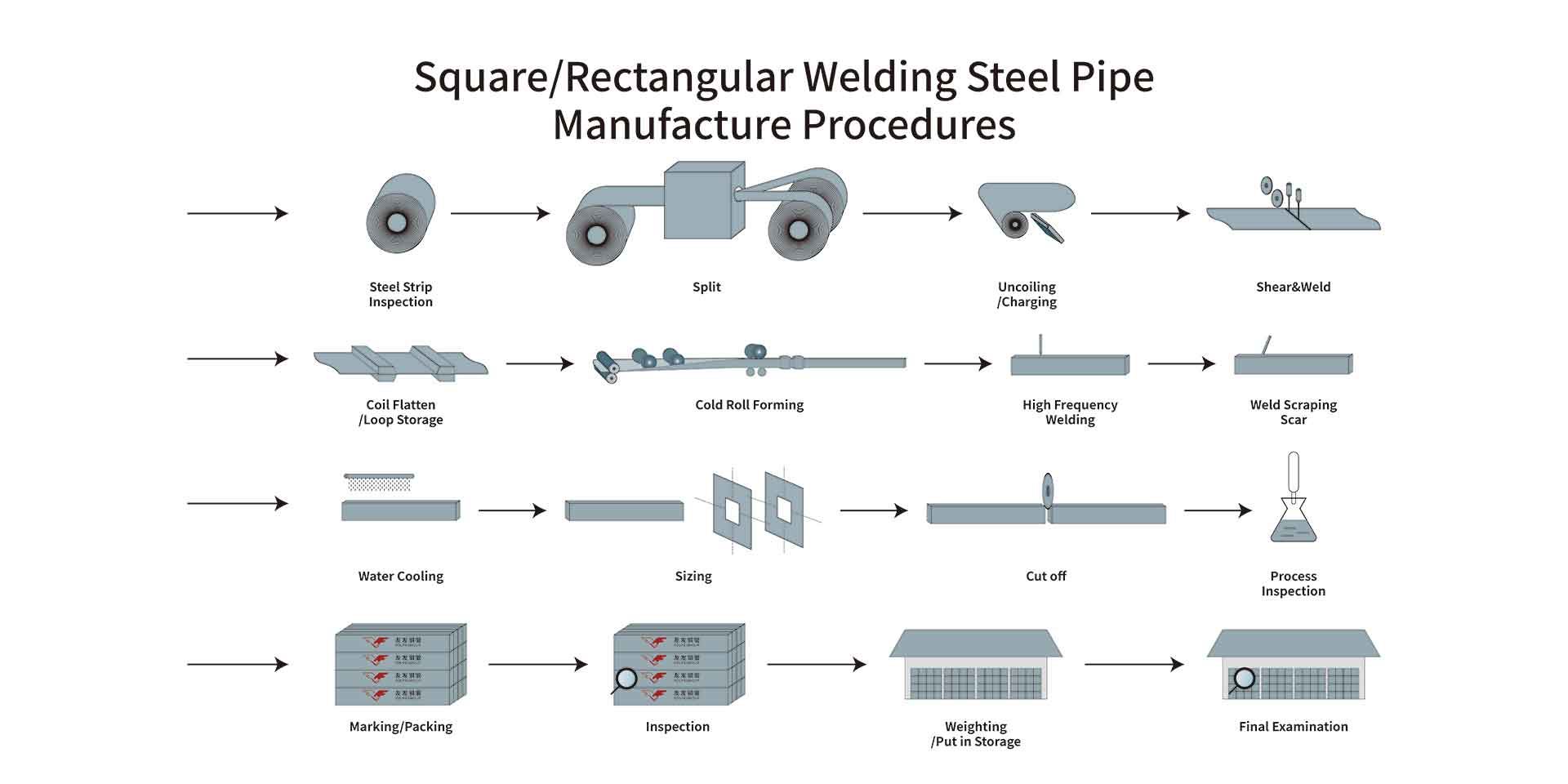

Pāha/Rectangular Welding Steel Pipe

Nā Kaʻina Hana Hana

01. Nānā hao hao → 02. Māhele → 03. Uncoiling / Charging → 04. Shear & Weld → 05. Coil Flatten / Loop storage→06. Cold roll forming →07. High Frequency welding →08. Weld scraping scar→09.Water cooling. →10.Sizing→11.Oki ʻoki→12.Kaʻina nānā → 13. Hoʻopaʻa ʻia / Hoʻopili → 14. Nānā → 15. Kaumaha / Hoʻokomo i kahi waihona → 16. Hoʻokolokolo hope

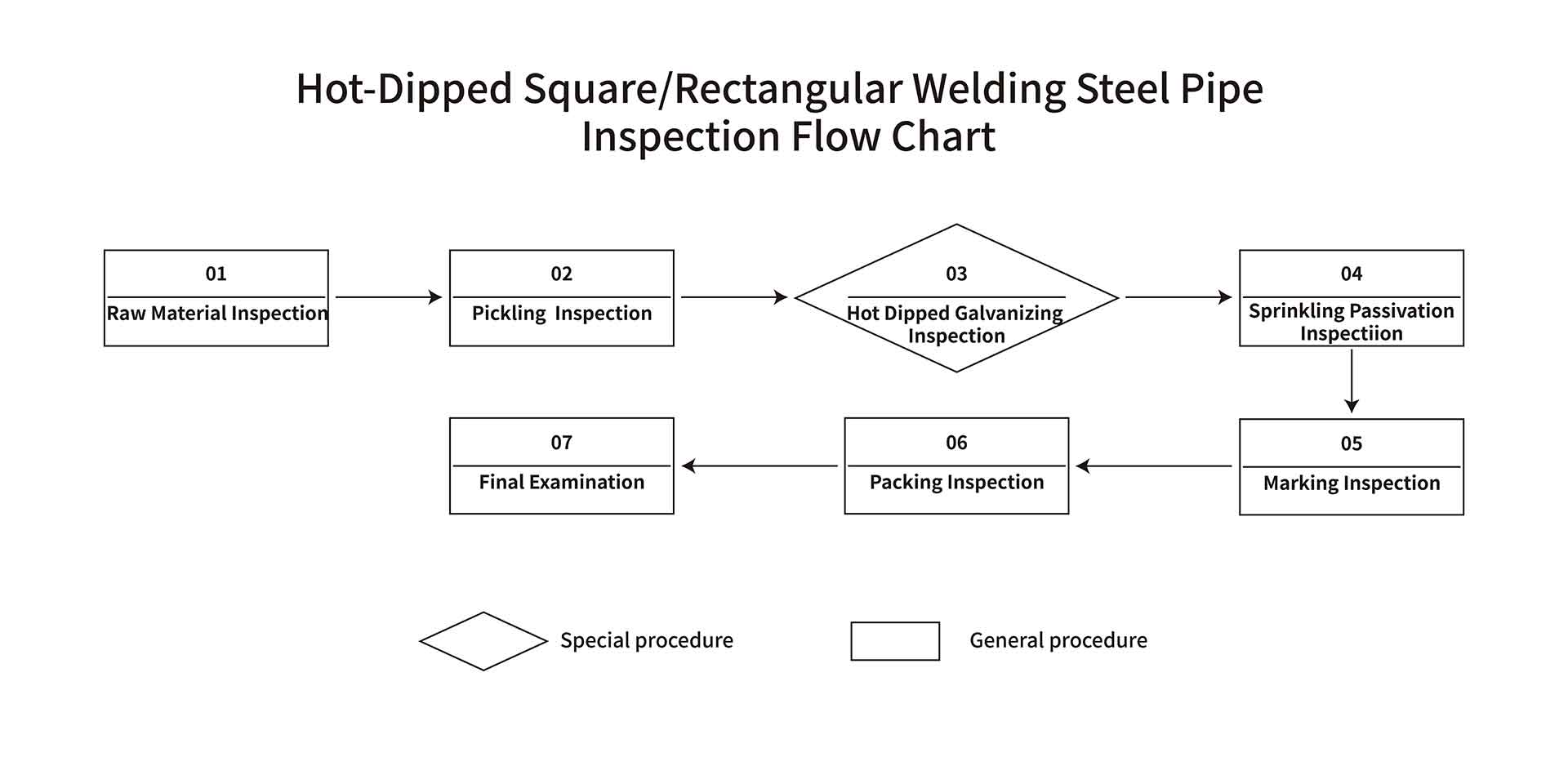

Pipe hao wiliwili wela wela/rectangular

Papa Kahe Kahea

01. Raq material inspection→02.Pickling inspection→03.Hot Dipped Galvanizing inspection→04.Sprinkling Passivation inspectiion→05.Marking inspection→06.Packing inspection→07.Final examination

E hoʻāʻo mākou i nā mea maka a me nā kaʻina hana e like me nā kūlana like ʻole e hōʻoia i ka hoʻokō ʻana o nā huahana i nā kūlana a i ʻole nā koi ʻaelike.

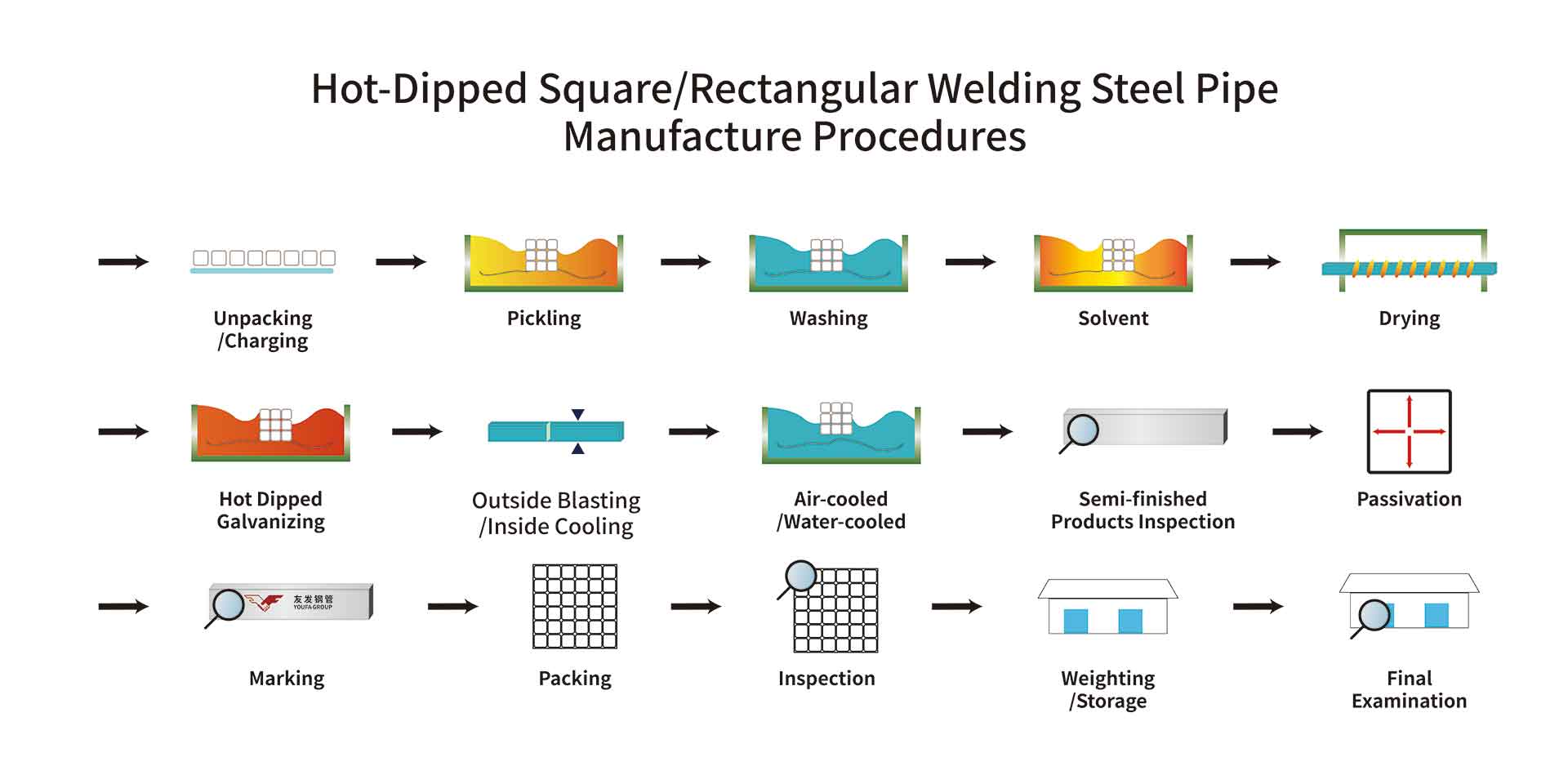

Pipe hao wiliwili wela wela/rectangular

Nā Kaʻina Hana Hana

01. Welding steel pipe→02. Unpacking/Charging→03.Pickling→04.Washing→05.Solvent→06.Drying→07.Hot Dipped Galvanizing→08.Outside Blasting→09.Inside Cooling→10.Air-cooled/ Hoʻomaʻalili wai → 11. Nā huahana semi-hoʻopau nānā →12.Passivation→13.Marking→14.Packing→15.Inspection→16.Weighting/Storage→17.Final Examination

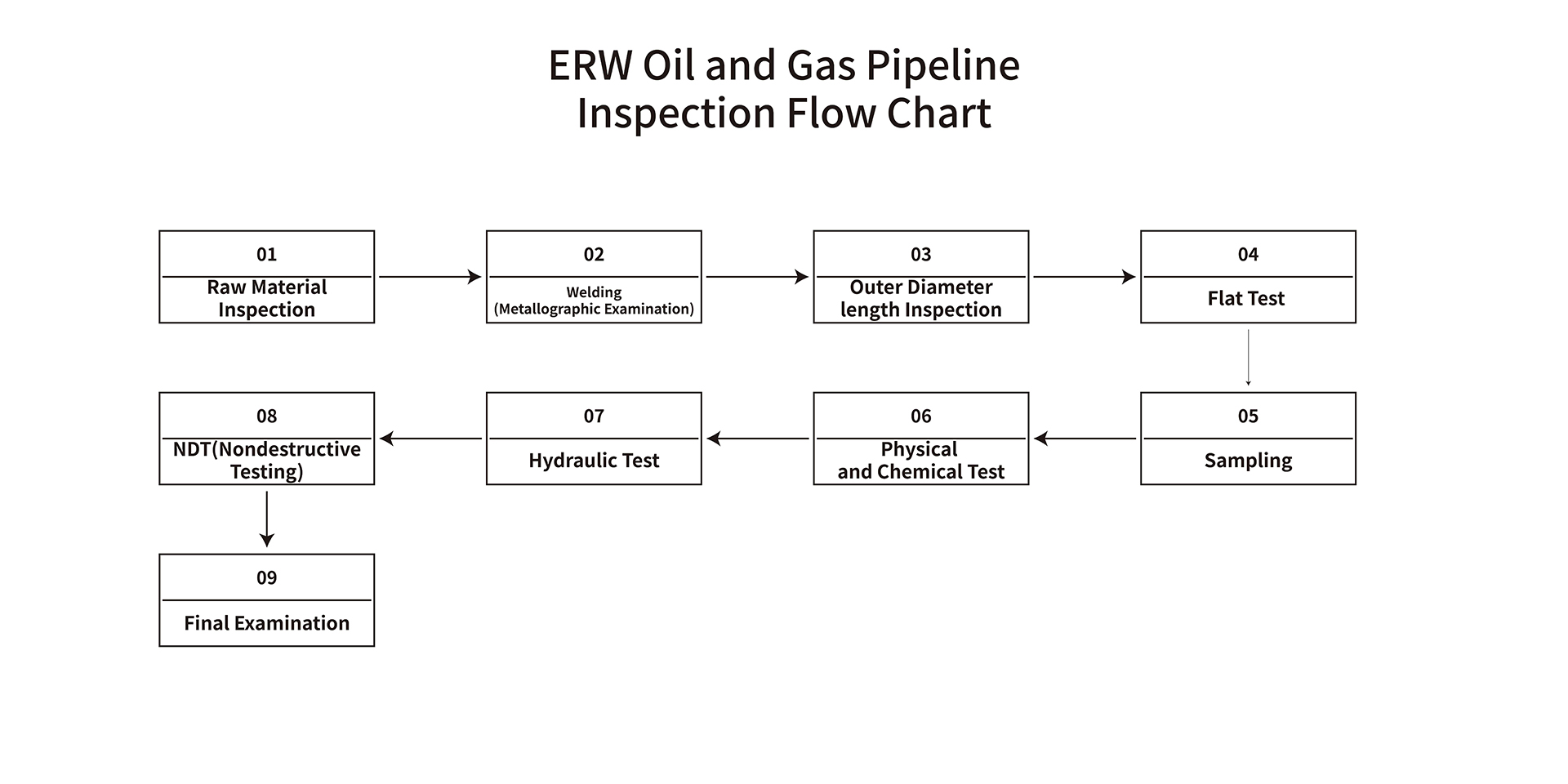

ERW aila a me ka paipu kinoea

Papa Kahe Kahea

01. Nānā mea maka → 02. Welding (Metallographic exam) → 03. Outer diameter lōʻihi inspection → 04. Flat test → 05. Sampling → 06. Physical and chemical test → 07. Hydraulic test → 08.NDT (nondestructive testing)→ 09. Hookolokolo Hope

E hoʻāʻo mākou i nā mea maka a me nā kaʻina hana e like me nā kūlana like ʻole e hōʻoia i ka hoʻokō ʻana o nā huahana i nā kūlana a i ʻole nā koi ʻaelike.

01.Open volume → 02. Hoʻoponopono / ʻO ka ʻoki mua / Welded → 03. Loop waihona → 04. Pūnaehana Figuration → 05. Welding / Wehe i loko a waho burr → 06. Welding seam wela wela → 07. Air-cooled / Wai- ʻoluʻolu/E hoʻopaʻa i ke anawaena/Hoʻoponopono → 08. ʻoki ʻoki lele → 09. Ma waho ka nānā/marking→10.APlain hope a me ka bevel end→11.Hydraulic test→12.Ultrasonic inspection→13.Pipe end Ultrasonic inspection→14.Weighting/Record→15.Put in storage

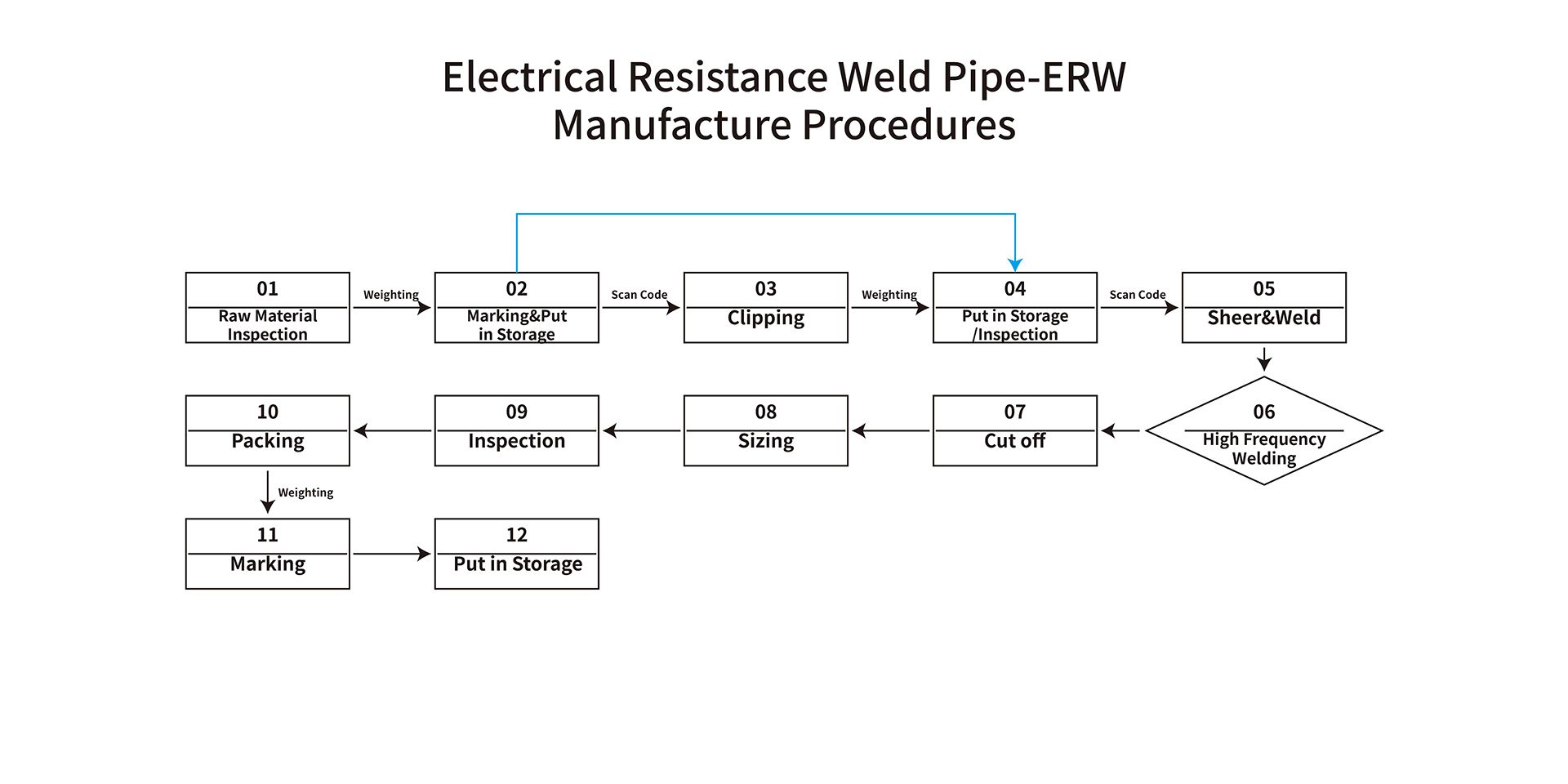

Pipa Weld Kū'ē Uila-ERW

Nā Kaʻina Hana Hana

01. Nānā mea maka → 02. Marking & Hoʻokomo i loko o kahi waihona → 03. ʻokiʻoki → 04. Hoʻokomo i loko o kahi waihona / Inspection → 05. Sheer & Weld → 06. Hoʻāʻo kino a me kemika → 07. ʻoki → 08. Sizing → 09. Nānā → 10. Hoʻopili → 11. Weighting → 12. Scan code

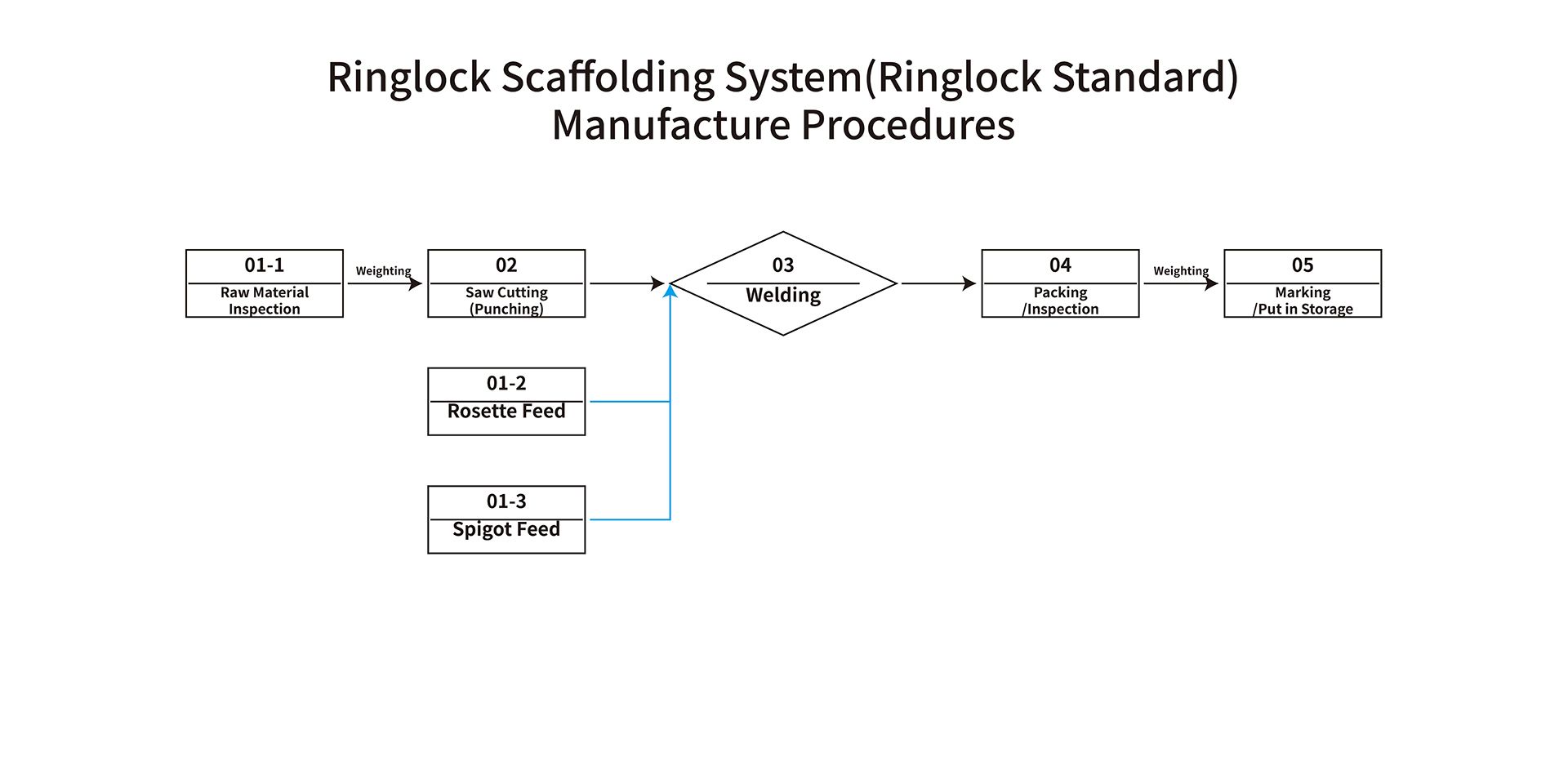

Pūnaehana Scaffolding Ringlock (Ringlock Standard)

Nā Kaʻina Hana Hana

01. Ka nānā 'ana i nā mea maka → 02. Ka 'oki 'ana (punching)/Ka hānai Rosette/Spigot feed → 03. Welding → 04. Packing/inspection → 05. Marking/Put in storage

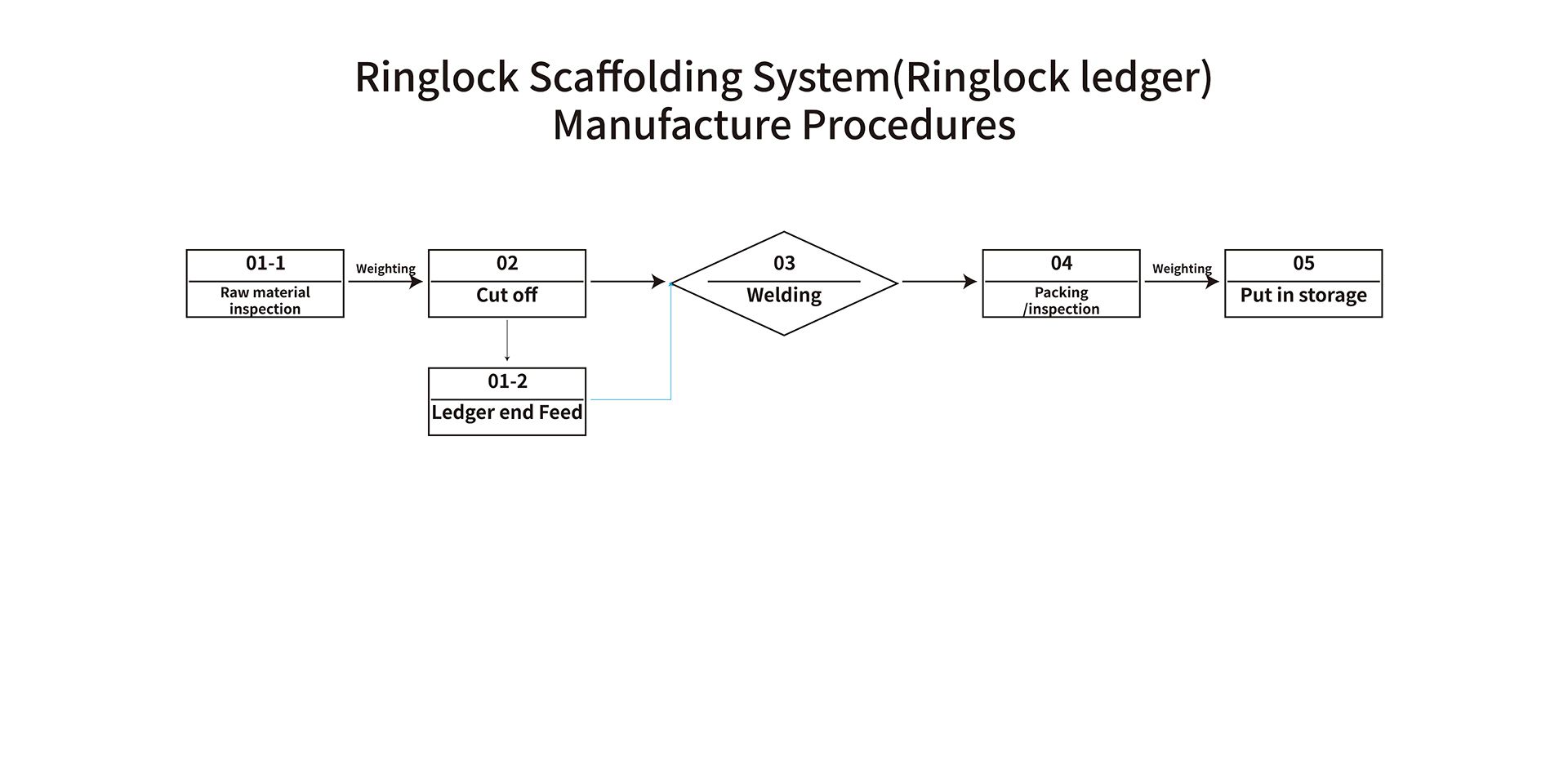

Pūnaehana Scaffolding Ringlock (Linglock Ledger)

Nā Kaʻina Hana Hana

01. Ka nānā 'ana i nā mea maka → 02. 'Oki aku / Ledger hope Feed → 03. Welding → 04. Packing/inspection → 05. Marking / Ho'okomo i ka waihona.

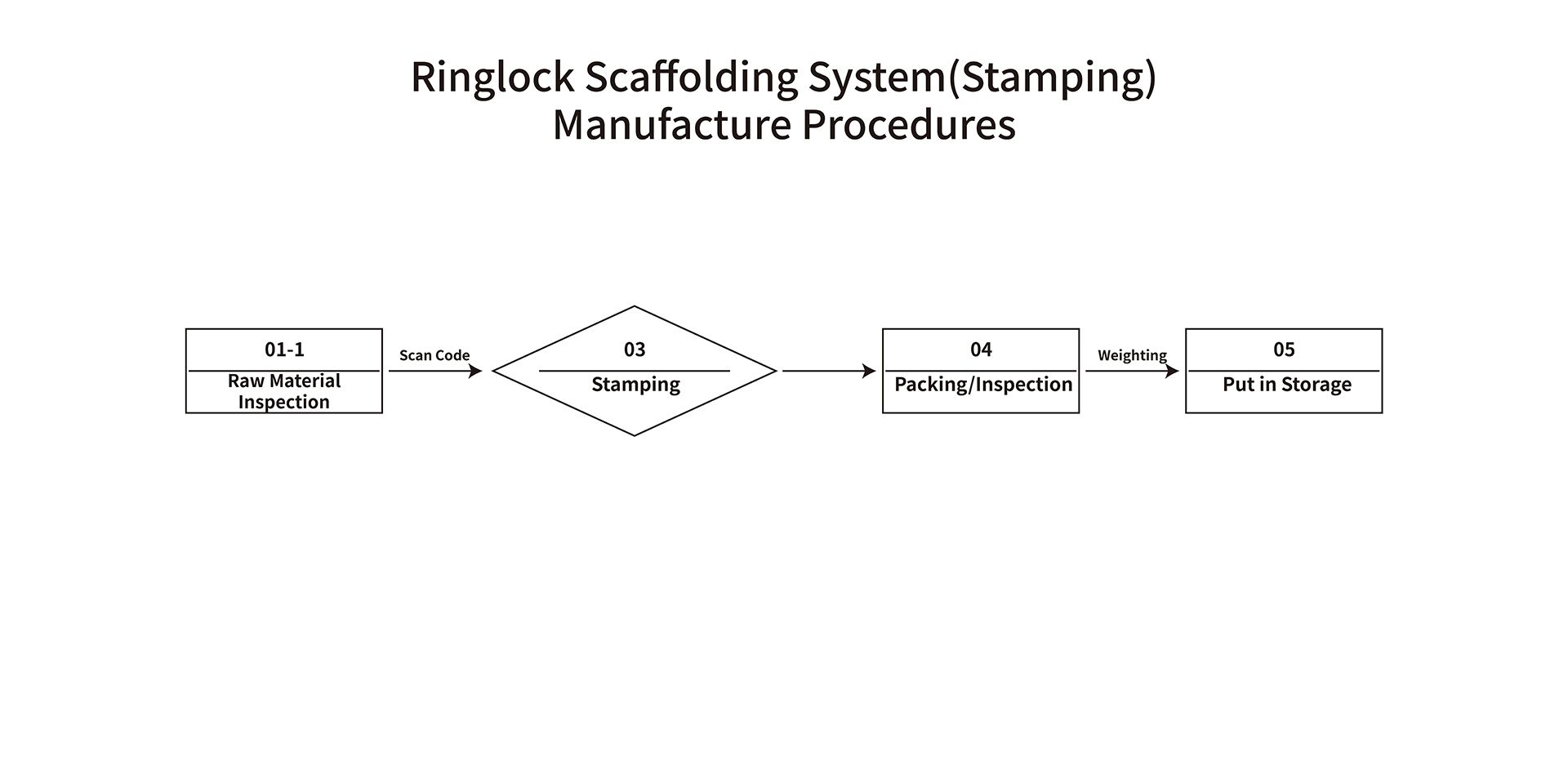

Pūnaehana Scaffolding Ringlock (Stamping)

Nā Kaʻina Hana Hana

01.Nānā mea maka →02.Stamping→03.Packing/Inspection→04.Hoʻokomo i ka waihona

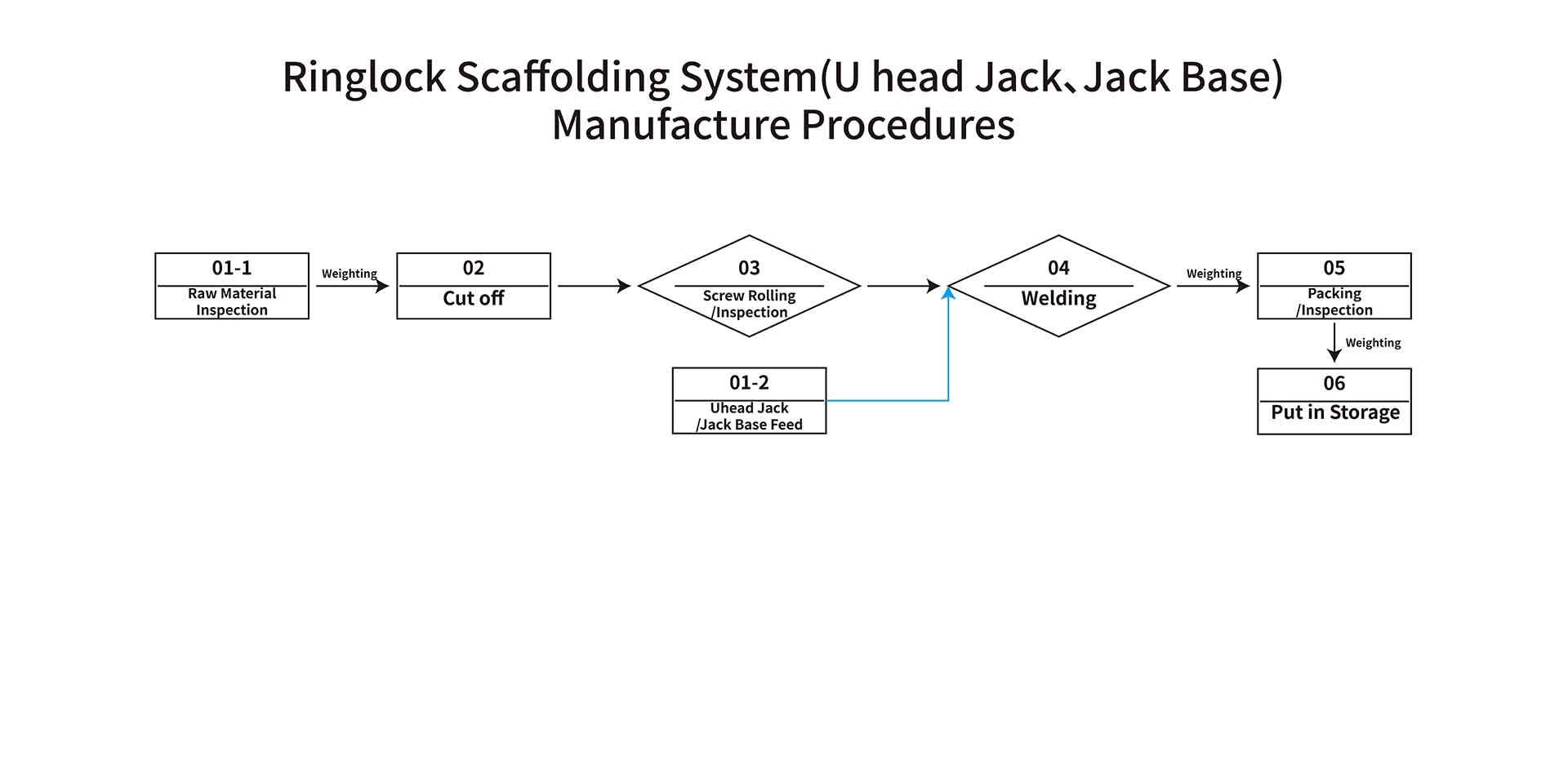

Ringlock Scaffolding System (U head jack, Jack base)

Nā Kaʻina Hana Hana

01.Nā mea maka → 02. ʻoki → 03. ʻO ka ʻōwili ʻana / Nānā / Uhead jack / jack base hānai → 04. Welding → 05. Packing / inspection → 06. Hoʻokomo i kahi waihona

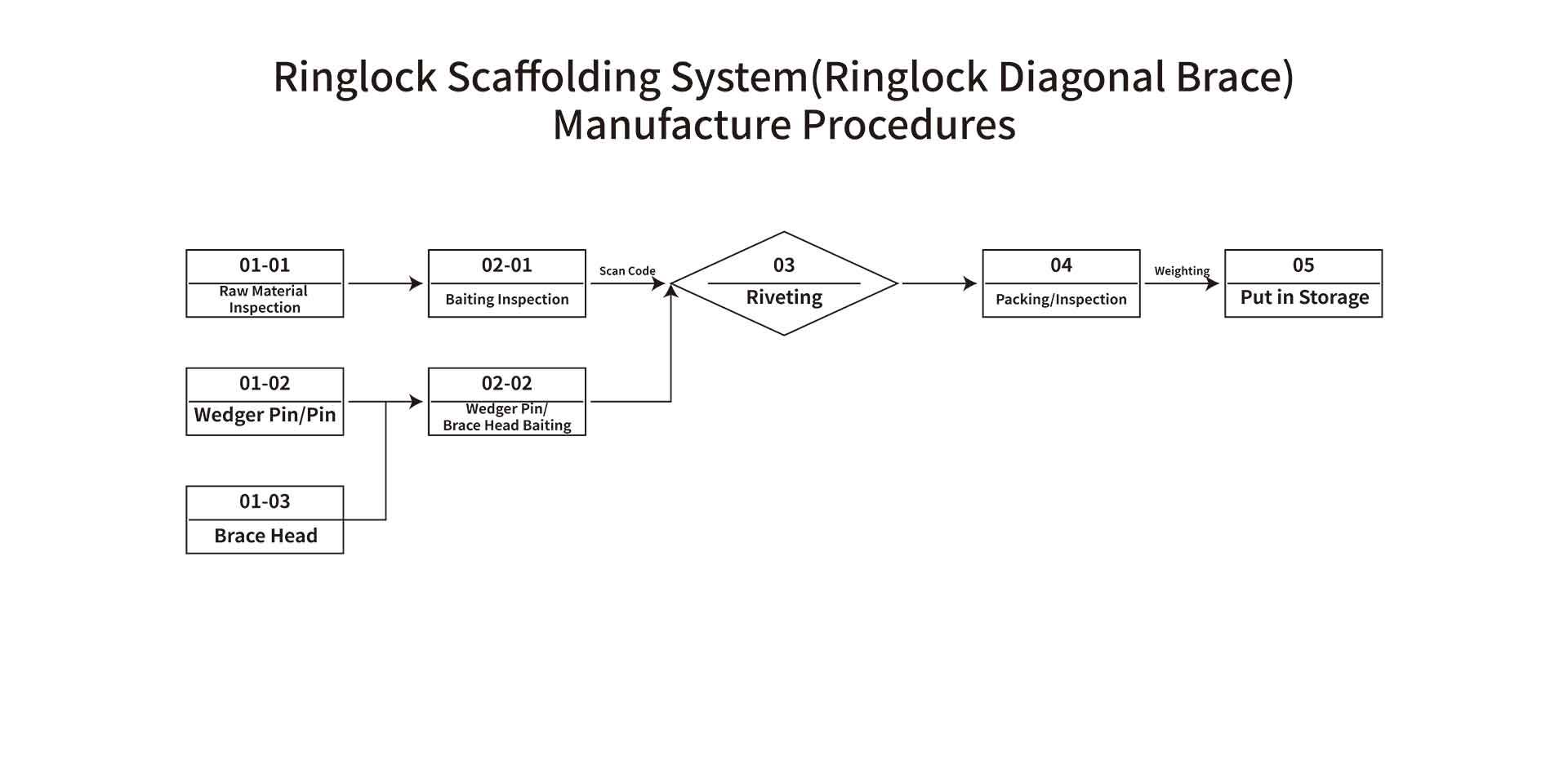

Pūnaehana Scaffolding Ringlock (Ringlock diagonal brace)

Nā Kaʻina Hana Hana

01. Ka nānā 'ana i nā mea maka/Wedger pine/Pin/Brace head→02.Baiting inspection/edger pine/Brace head baiting→03.Welding→04.Packing/inspection→05.Put in storage