Cov txheej txheem ntau lawm ntws thiab soj ntsuam Flow

Nrog rau ntau tshaj 9000 tus neeg ua haujlwm txawj ntse thiab 293 cov kab ntau lawm tau nthuav dav thoob plaws 13 lub chaw tsim khoom, peb tau tsim 20 lab tons steel kav xyoo 2022, thiab cov nyiaj muag khoom tau tshaj 160 lab US las hauv 2018. Rau 17 xyoo sib law liag, Youfa yog lub npe ntawm TOP 500 Enterprises nyob rau hauv Tuam Tshoj Manufacturing Industry txij thaum 2006.

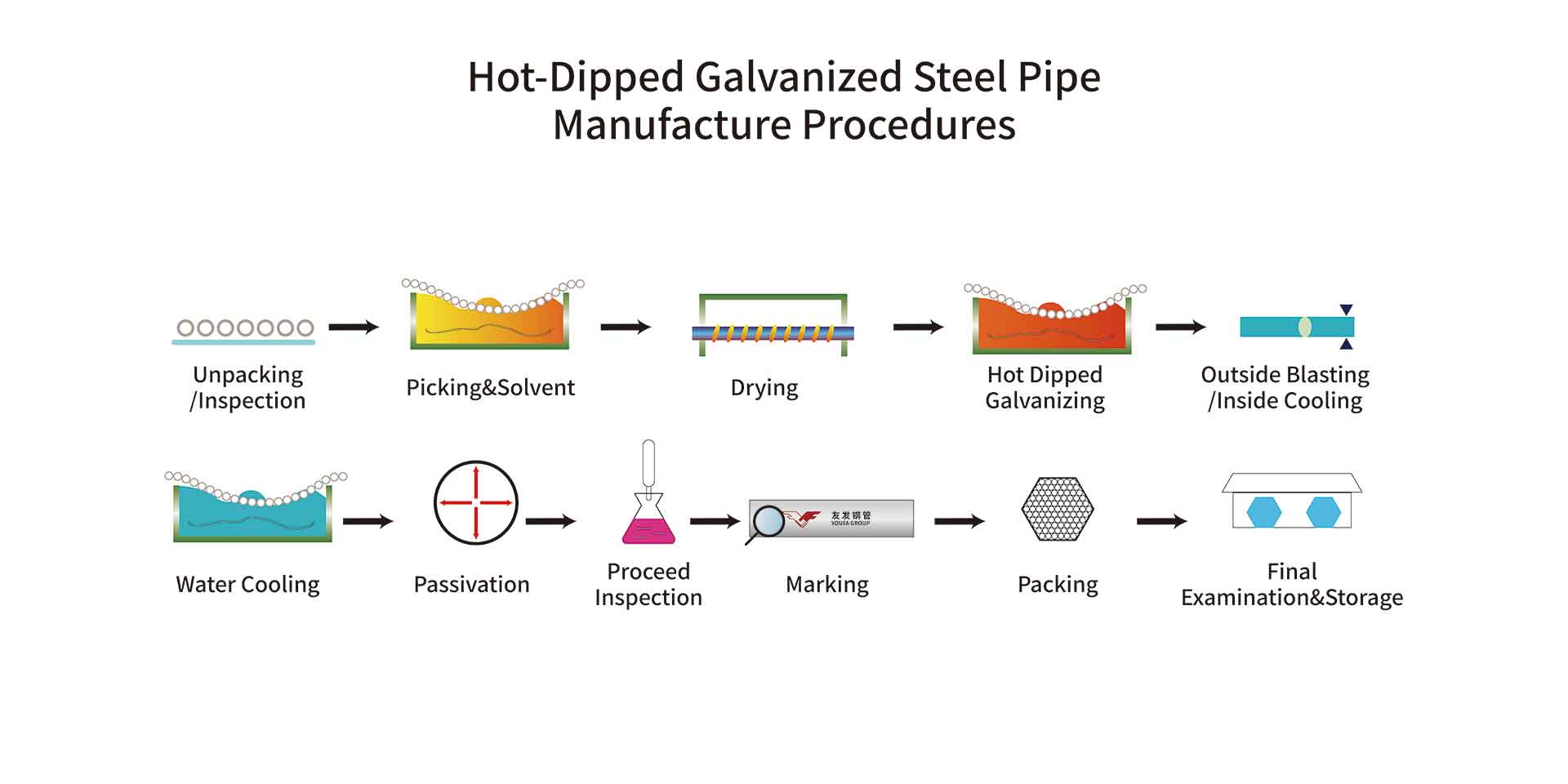

Kub-dipped galvanized steel yeeb nkab

Cov txheej txheem tsim khoom

01.Unpacking/Inspection → 02.Picking & Solvent → 03.Drying → 04.Shot dipped galvanizing → 05.Outside blasting/Inside cooling → 06.Water cooling → 07.Passivation → 08.Proceed inspection → 09.Marking → 10.Packing → 11.Final kuaj & Cia

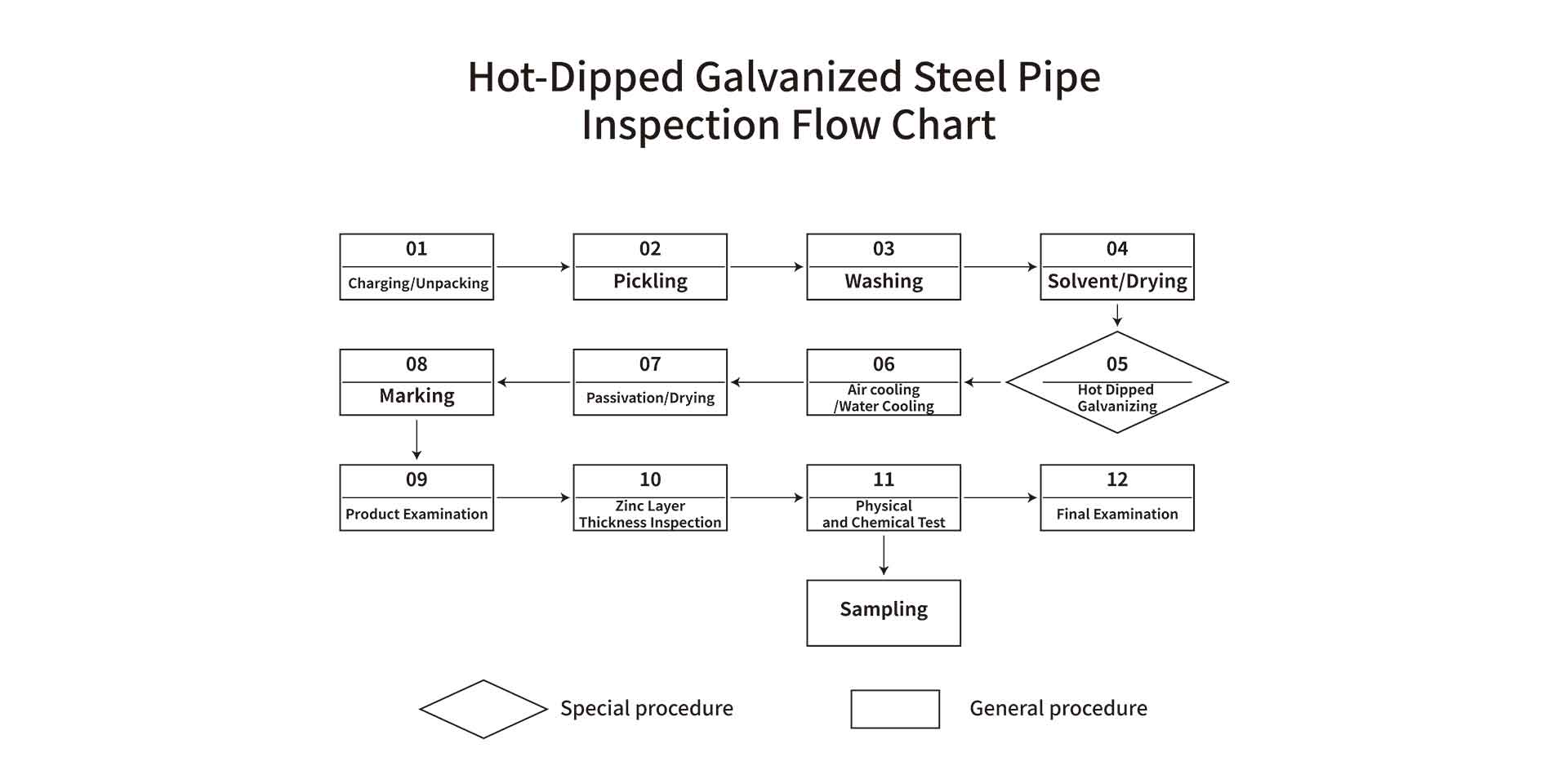

Kub-dipped galvanized steel yeeb nkab

Inspection Flow chart

01.Charging/Unpacking → 02.Pickling → 03.Washing → 04.Solvent/Drying → 05.Hot dipped galvanizing → 06.Air cooling/dej cooling → 07.Passivation/Drying → 08.Marking → 09.Product exam → 10 .Zinc txheej thickness tshuaj xyuas → 11.Lub cev thiab tshuaj ntsuam xyuas → 12.Final kev tshuaj xyuas

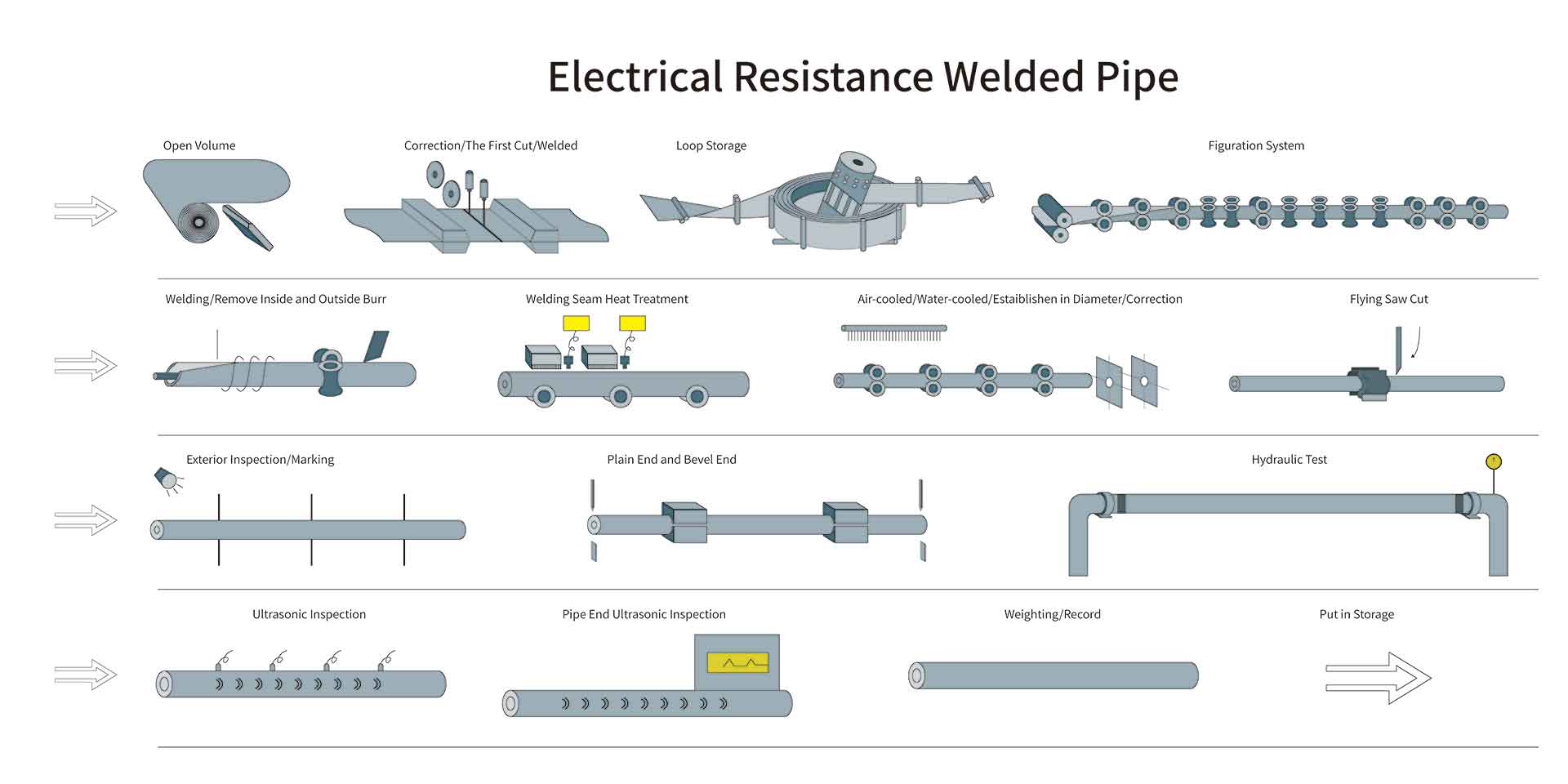

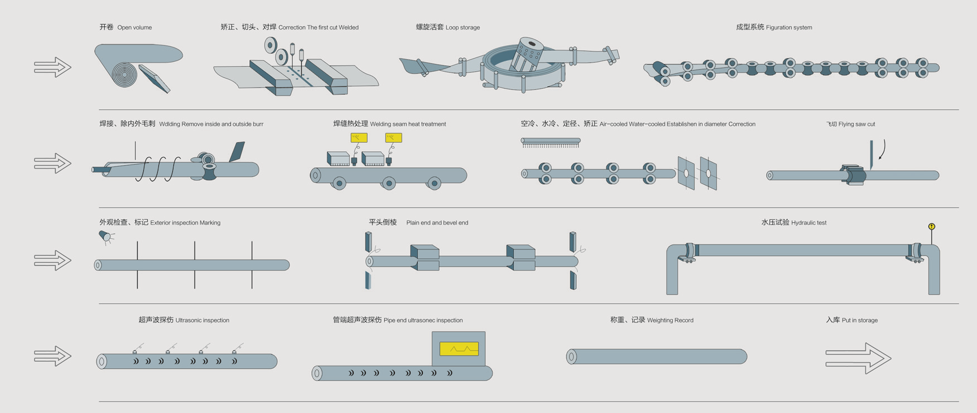

Hluav taws xob Resistance Weld Pipe-ERW

Cov txheej txheem tsim khoom

01.Open ntim → 02.Correction / Thawj txiav / Welded → 03.Loop cia → 04.Figuration system → 05.Welding / Tshem tawm sab hauv thiab sab nraud burr → 06.Welding seam kho cua sov → 07.Air-cooled / Dej- Txias / Tsim kom muaj txoj kab uas hla / Kho → 08.Flying saw txiav → 09.Exterior Kev tshuaj xyuas / kos npe → 10.Plain kawg thiab bevel kawg → 11.Hydraulic kuaj → 12.Ultrasonic tshuaj xyuas → 13.Pipe kawg Ultrasonic tshuaj ntsuam → 14.Weighting/Record → 15.Sau cia

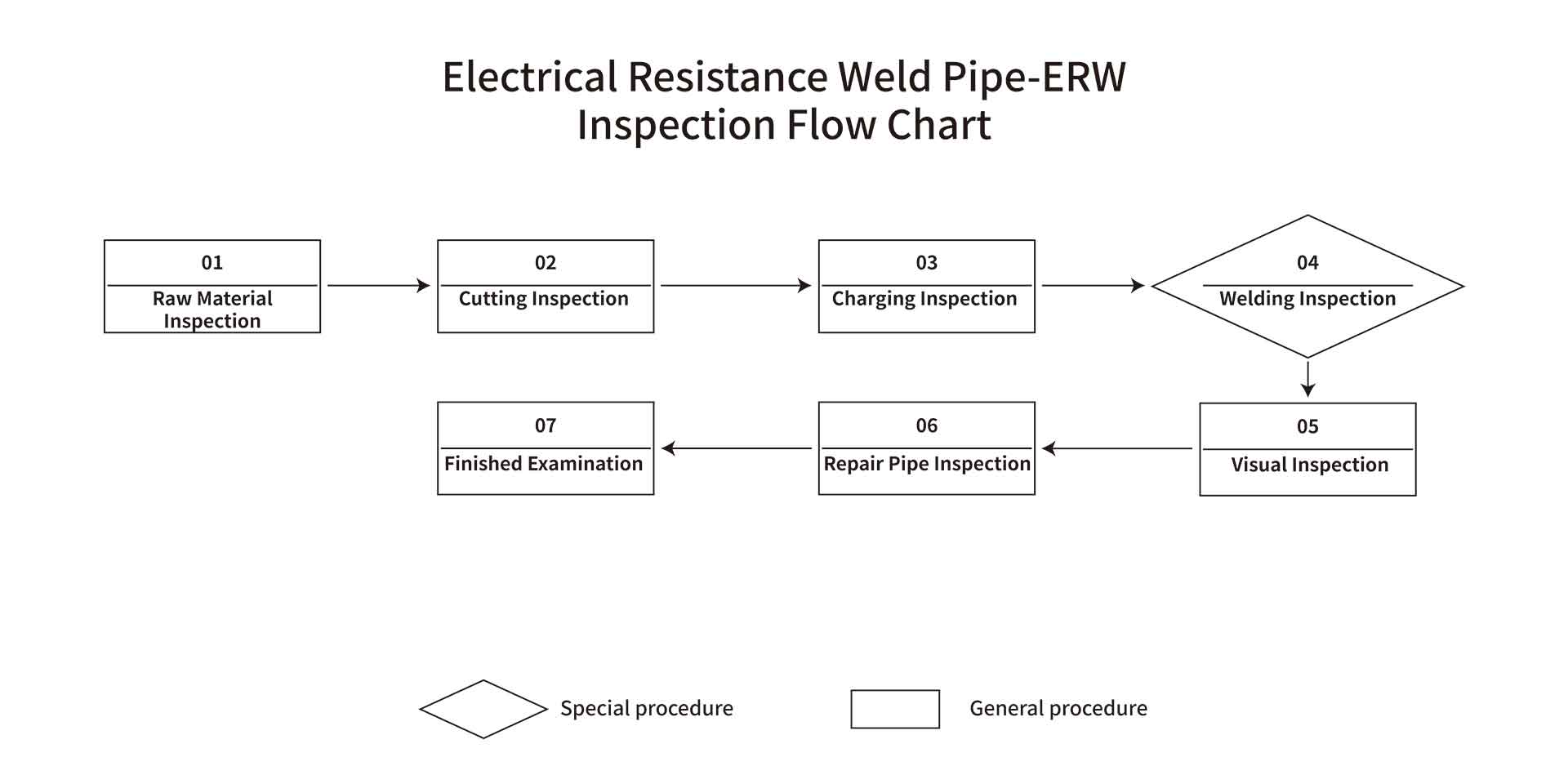

Hluav taws xob Resistance Weld Pipe-ERW

Inspection Flow chart

01. Raw khoom tshuaj xyuas → 02.Cutting inspection → 03.Charging inspection →04.Welding inspection → 05.Visual inspection → 06.Repair pipe inspection → 07.Finished exam

Peb yuav sim cov khoom siv raw thiab cov txheej txheem tsim khoom raws li cov qauv sib txawv kom ntseeg tau tias cov khoom ua tau raws li cov qauv lossis cov ntawv cog lus.

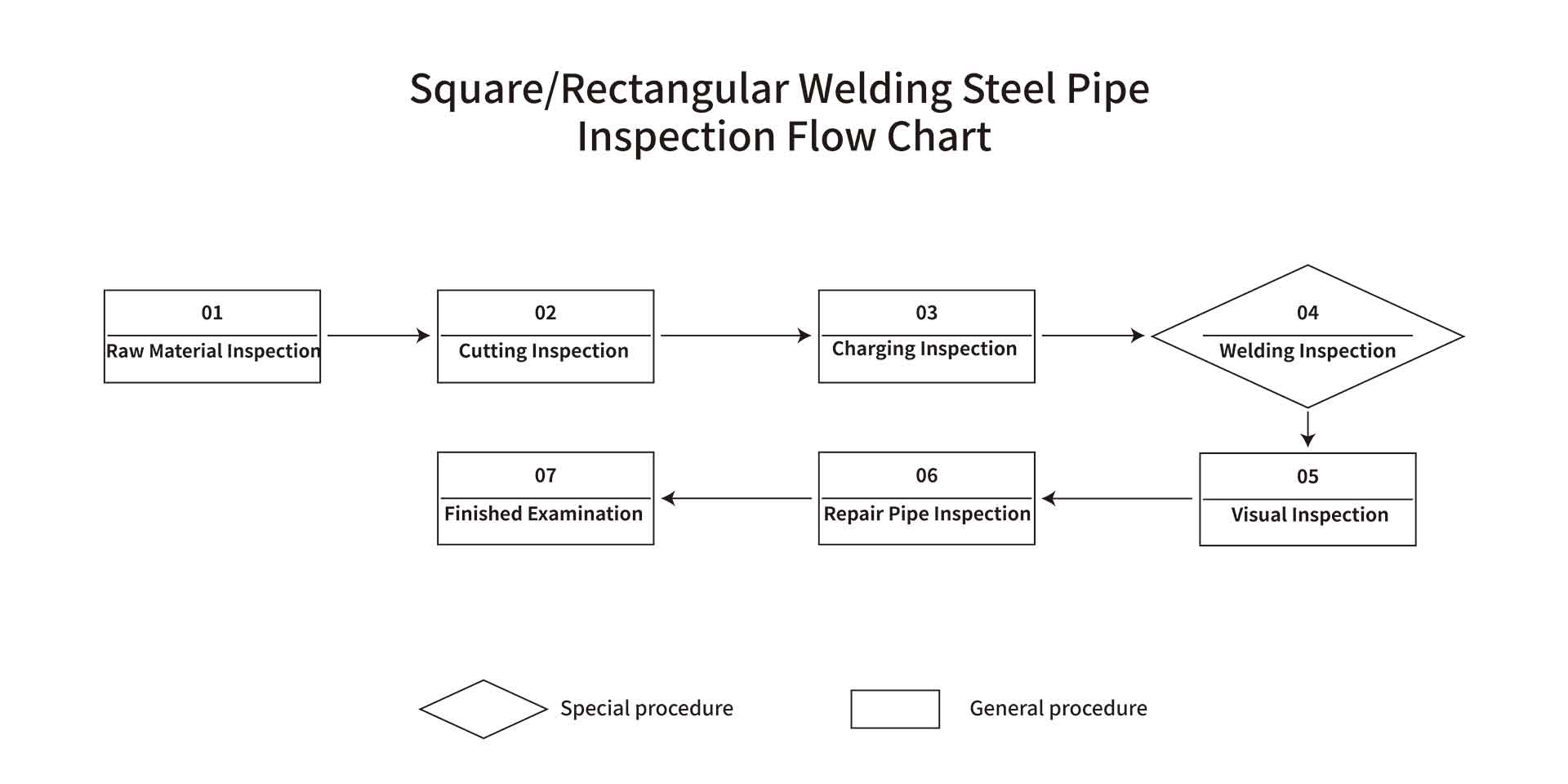

Square / Rectangular Vuam Hlau Yeeb

Inspection Flow chart

01. Raw khoom tshuaj xyuas → 02.Cutting inspection → 03.Charging inspection →04.Welding inspection → 05.Visual inspection → 06.Repair pipe inspection → 07.Finished exam

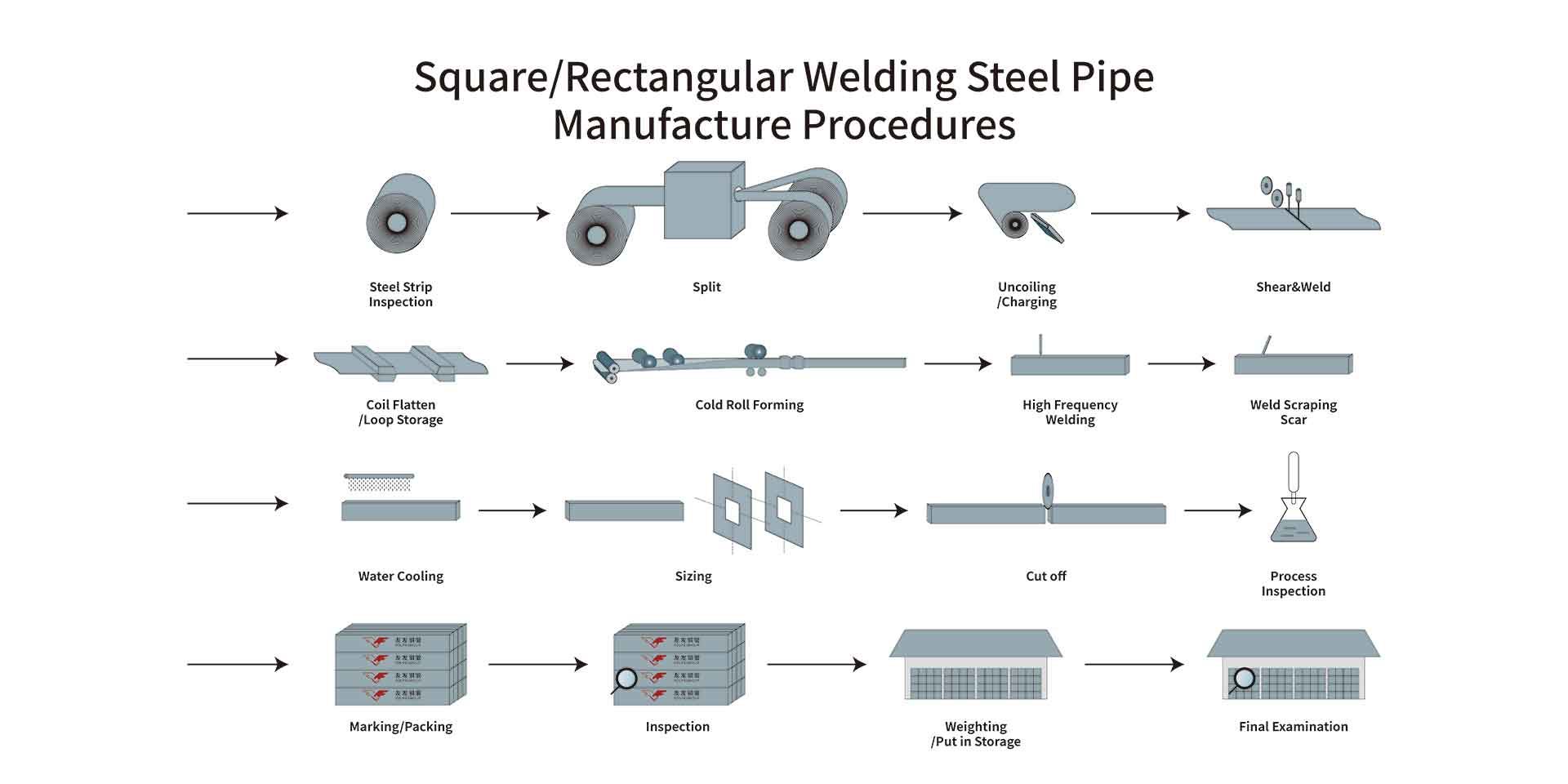

Square / Rectangular Vuam Hlau Yeeb

Cov txheej txheem tsim khoom

01. Steel strip tshuaj xyuas → 02.Split → 03.Uncoiling / Them → 04.Shear & Weld → 05.Coil Flatten / Loop cia → 06.Cold yob txoj kev → 07.High Frequency vuam → 08.Weld scraping scar → 09. Dej txias → 10.Sizing → 11. Txiav tawm → 12. txheej txheem Kev tshuaj xyuas → 13.Marking/Packing → 14.Inspection → 15.Weighting / Muab tso rau hauv cia → 16.Final kuaj

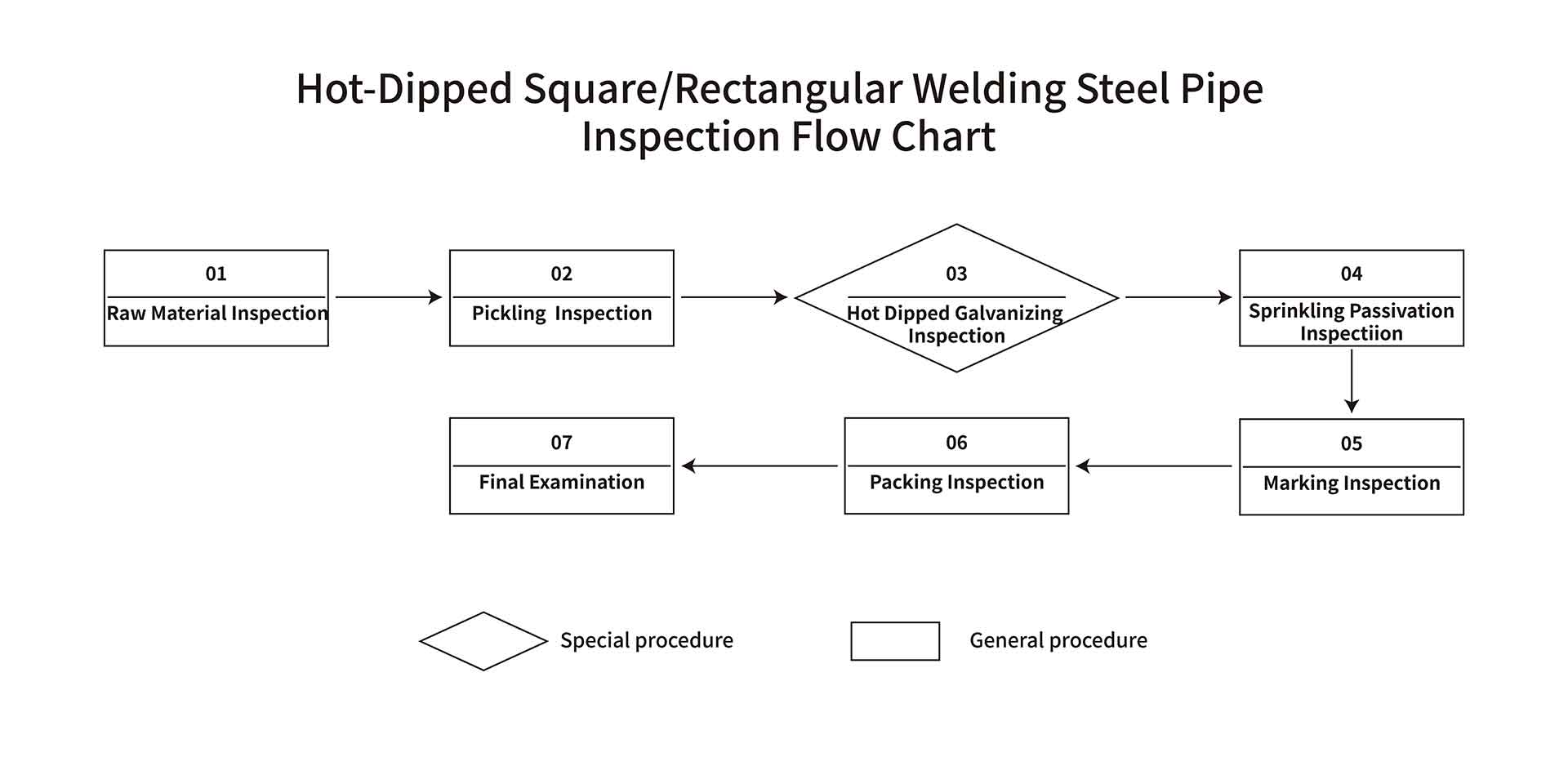

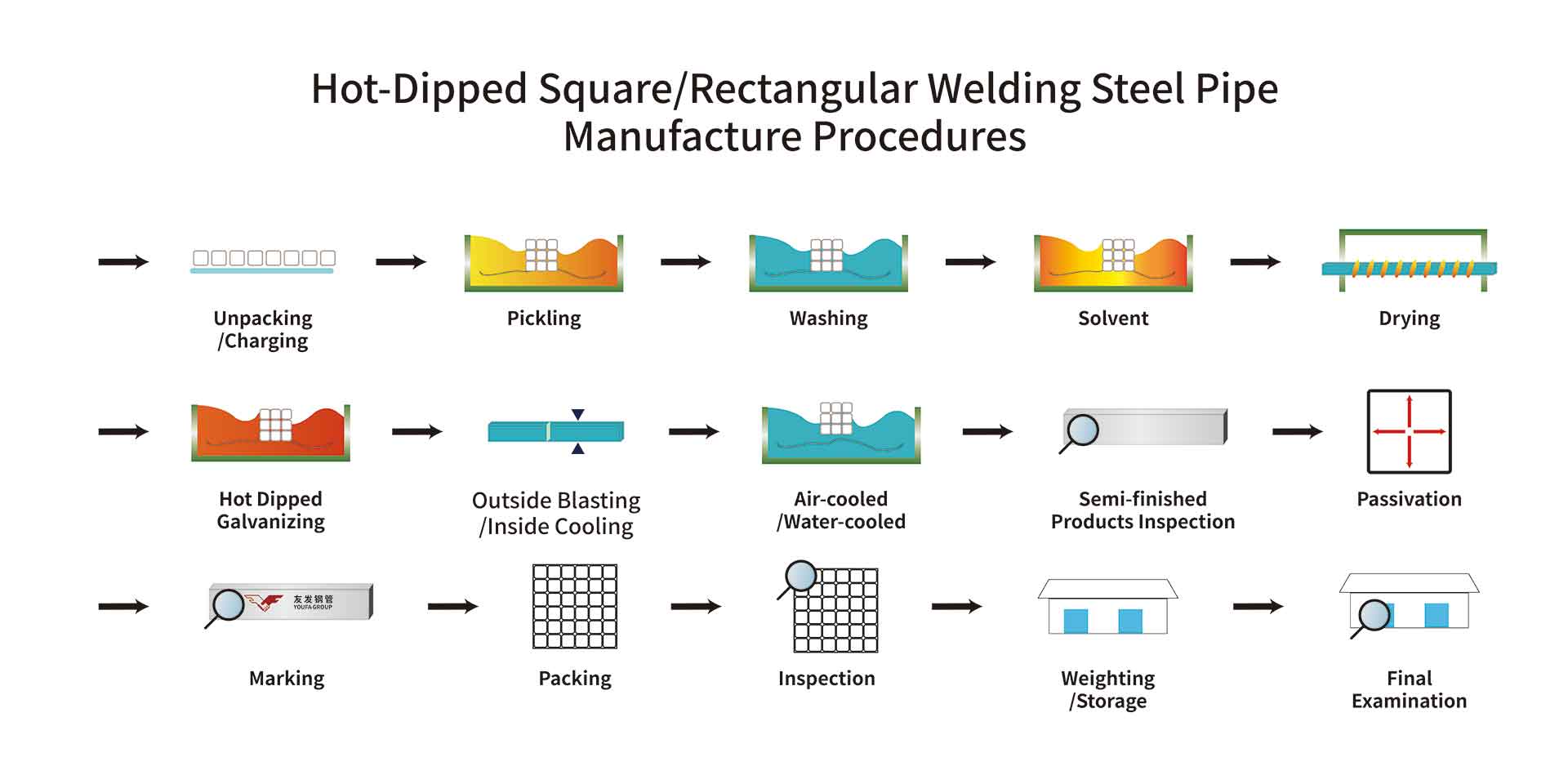

Kub-Dipped Square / Rectangular Vuam Hlau Yeeb Nkab

Inspection Flow chart

01. Raq khoom tshuaj xyuas → 02.Pickling tshuaj xyuas → 03.Hot Dipped Galvanizing tshuaj xyuas → 04.Sprinkling Passivation tshuaj ntsuam → 05.Marking tshuaj ntsuam → 06.Packing tshuaj ntsuam → 07.Kuaj xyuas kawg

Peb yuav sim cov khoom siv raw thiab cov txheej txheem tsim khoom raws li cov qauv sib txawv kom ntseeg tau tias cov khoom ua tau raws li cov qauv lossis cov ntawv cog lus.

Kub-Dipped Square / Rectangular Vuam Hlau Yeeb Nkab

Cov txheej txheem tsim khoom

01.Welding steel yeeb nkab → 02.Unpacking/Charging → 03.Pickling → 04.Washing → 05.Solvent → 06.Drying → 07.Hot Dipped Galvanizing → 08.Outside Blasting → 09.Inside Cooling → 10.Air-cooled/ Dej-txias → 11.Semi-tiav khoom Kev tshuaj xyuas → 12.Passivation → 13.Marking → 14.Packing → 15.Inspection → 16.Weighting/Storage → 17.Final Examination

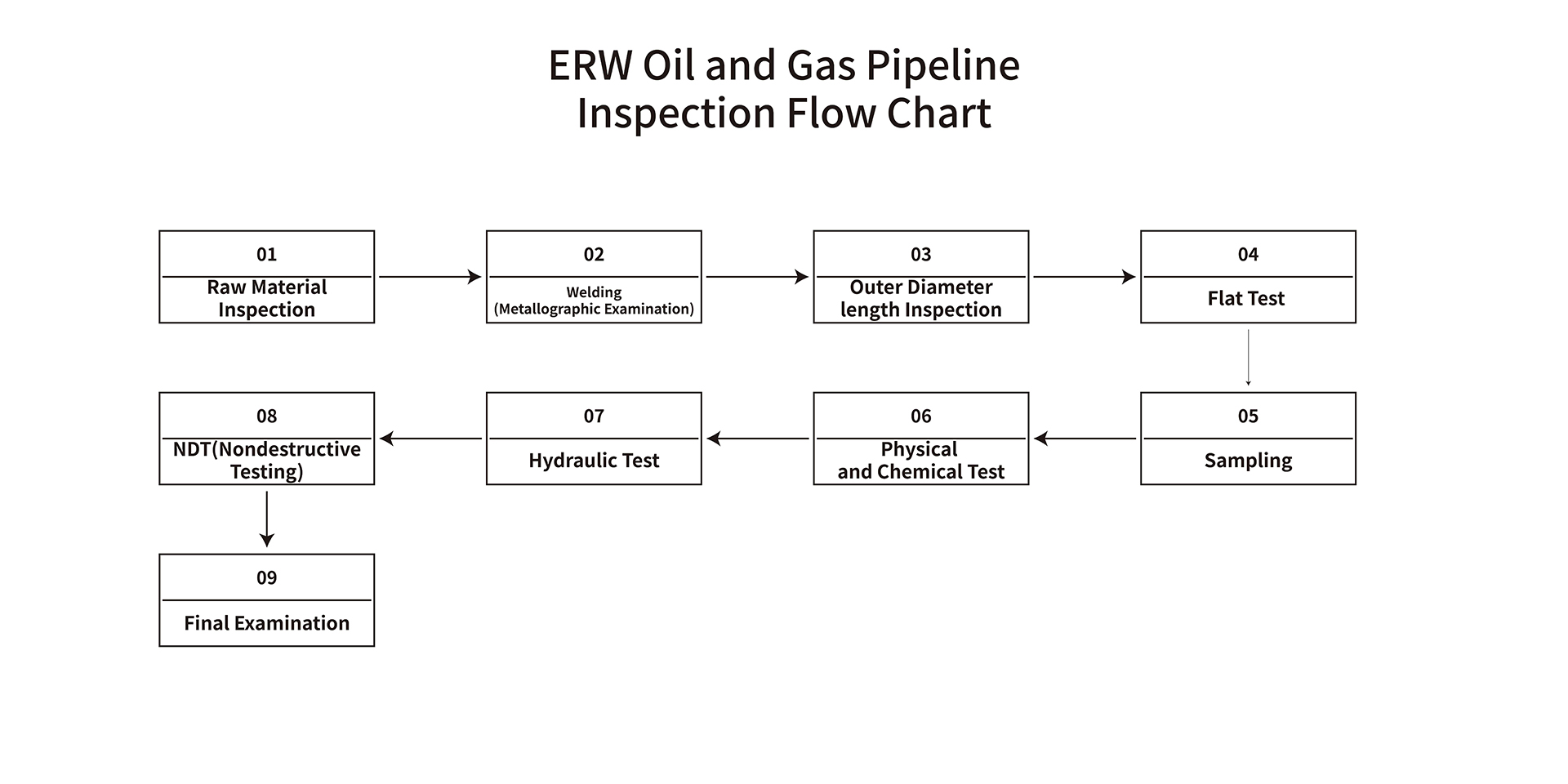

ERW roj thiab roj pipeline

Inspection Flow chart

01. Raw khoom tshuaj xyuas → 02.Welding (Metallographic kuaj) → 03.Outer txoj kab uas hla ntev soj ntsuam → 04.Flat test → 05.Sampling → 06.Physical and chemical test → 07.Hydraulic test → 08.NDT(nondestructive testing) → 09. Kev Xeem Kawg

Peb yuav sim cov khoom siv raw thiab cov txheej txheem tsim khoom raws li cov qauv sib txawv kom ntseeg tau tias cov khoom ua tau raws li cov qauv lossis cov ntawv cog lus.

01.Open ntim → 02.Correction / Thawj txiav / Welded → 03.Loop cia → 04.Figuration system → 05.Welding / Tshem tawm sab hauv thiab sab nraud burr → 06.Welding seam kho cua sov → 07.Air-cooled / Dej- Txias / Tsim kom muaj txoj kab uas hla / Kho → 08.Flying saw txiav → 09.Exterior Kev tshuaj xyuas / Marking → 10.APlain kawg thiab bevel kawg → 11.Hydraulic test → 12. Ultrasonic tshuaj xyuas → 13.Pipe kawg Ultrasonic tshuaj xyuas → 14.Weighting / Record → 15. Muab tso rau hauv cia

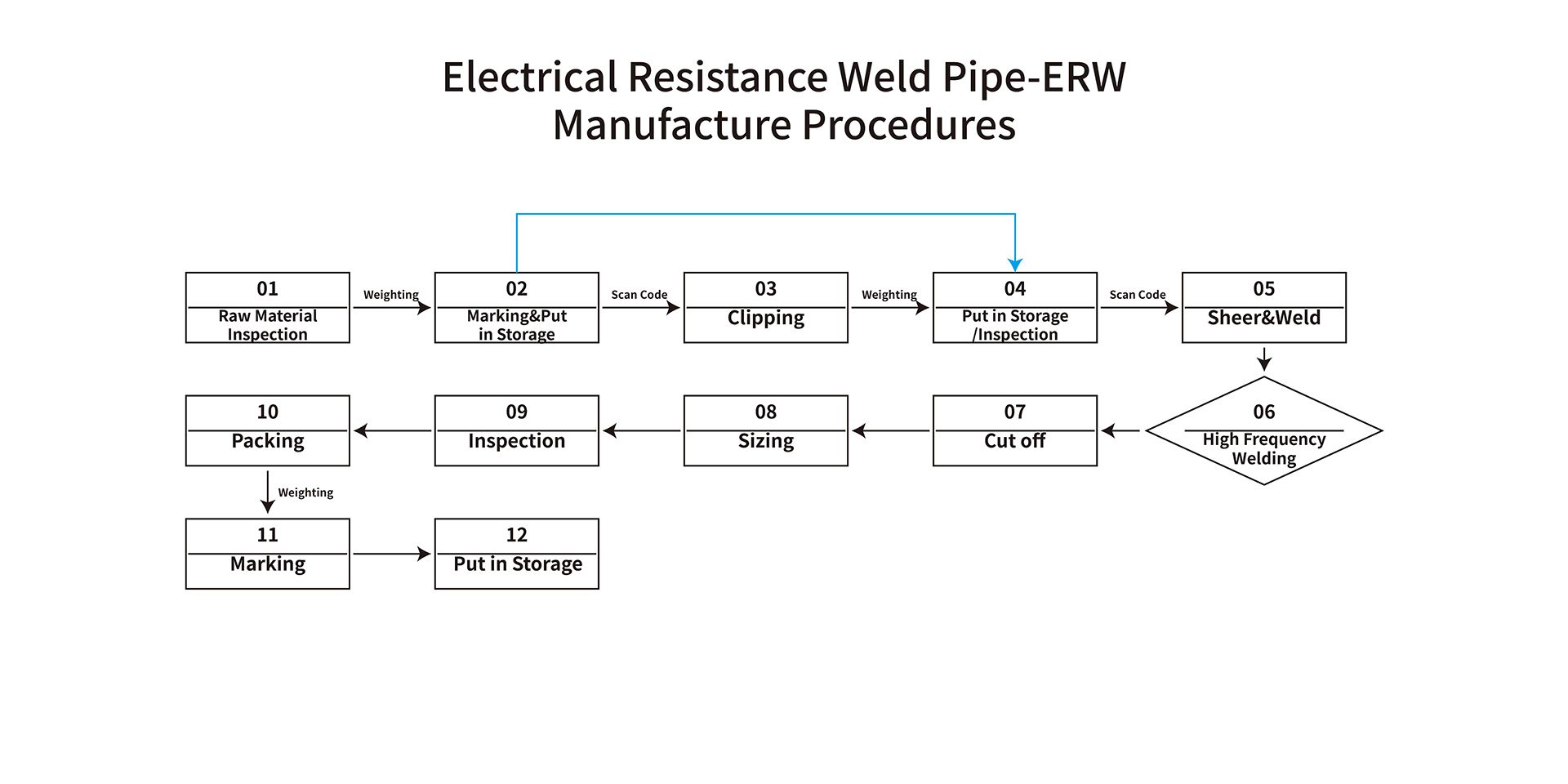

Hluav taws xob Resistance Weld Pipe-ERW

Cov txheej txheem tsim khoom

01. Raw khoom soj ntsuam → 02.Marking & Muab tso rau hauv cia → 03.clipping → 04.Put nyob rau hauv cia / Tshuaj ntsuam xyuas → 05.Sheer & Weld → 06.Physical thiab tshuaj ntsuam xyuas → 07.Cut off → 08.Sizing → 09.Inspection → 10. Packing → 11.Weighting → 12.Scan codes

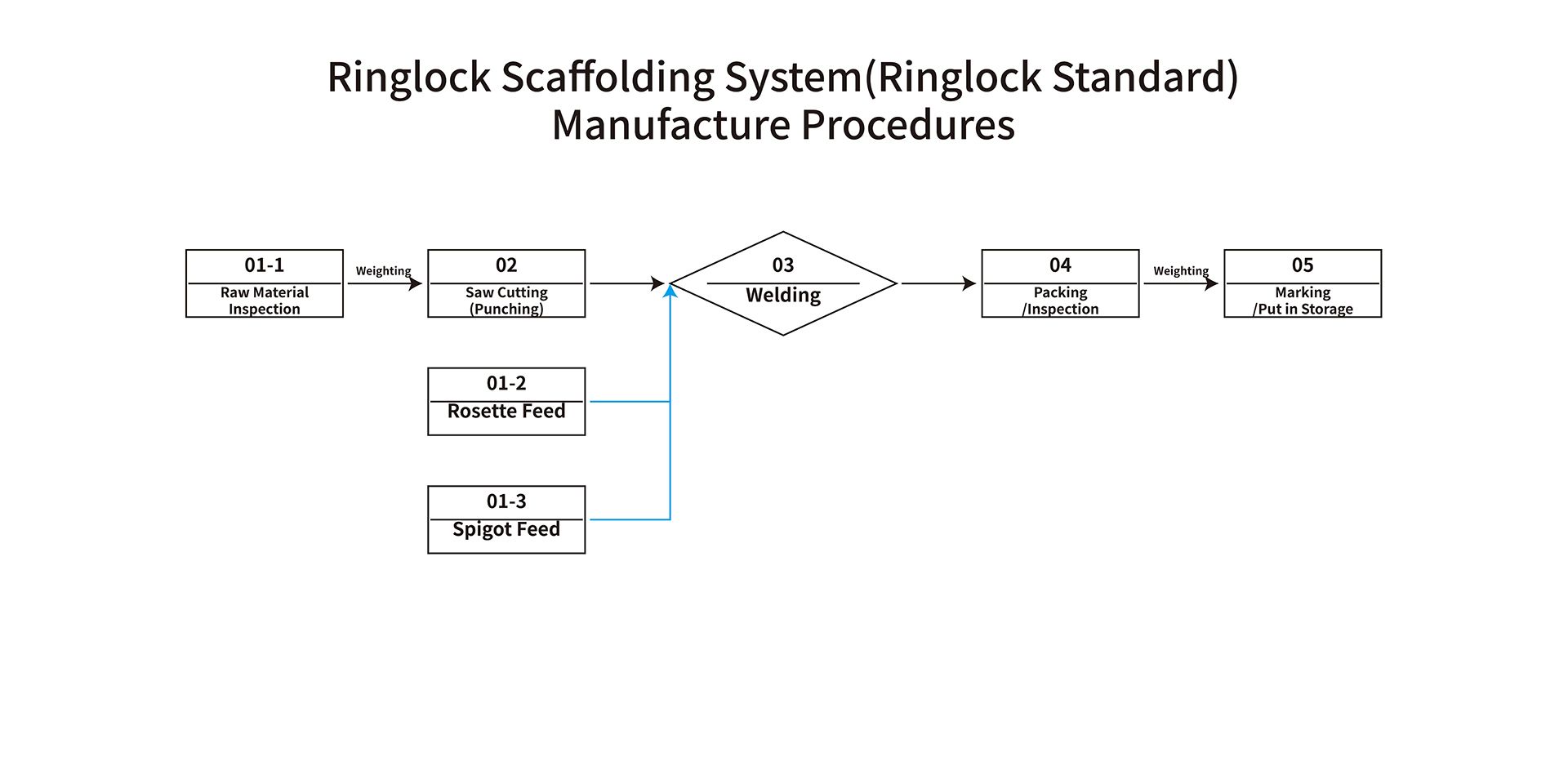

Ringlock Scaffolding System (Ringlock Standard)

Cov txheej txheem tsim khoom

01.Raw khoom tshuaj xyuas → 02.Saw txiav (punching) / Rosette pub / Spigot pub → 03.Welding → 04.Packing / tshuaj xyuas → 05.Marking / Muab tso rau hauv cia

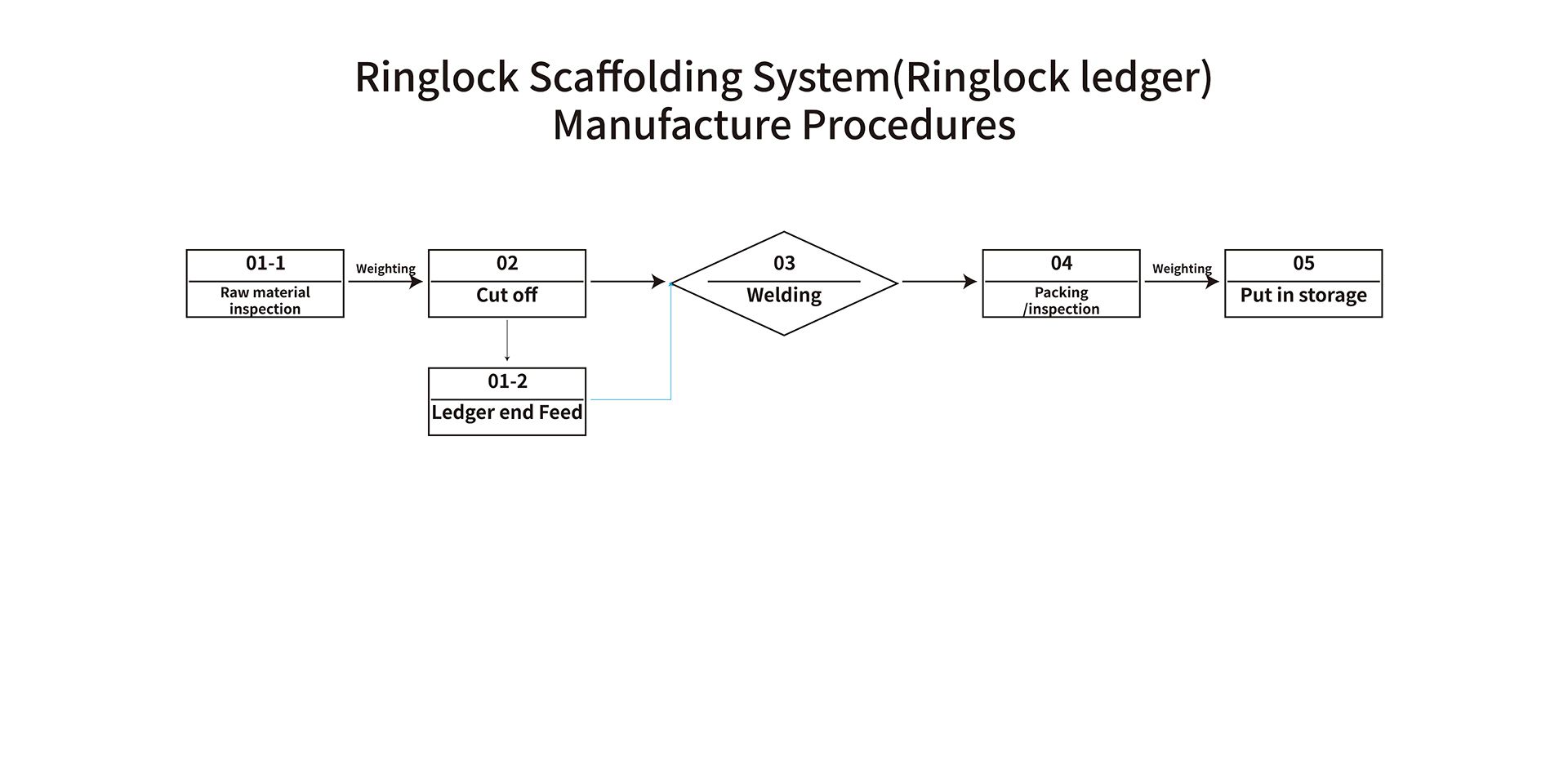

Ringlock Scaffolding System (Ringlock ledger)

Cov txheej txheem tsim khoom

01.Raw khoom tshuaj xyuas → 02.Cut off/Ledger kawg pub → 03.Vuam → 04.Packing/inspection → 05.Marking/Muab tso rau hauv cia

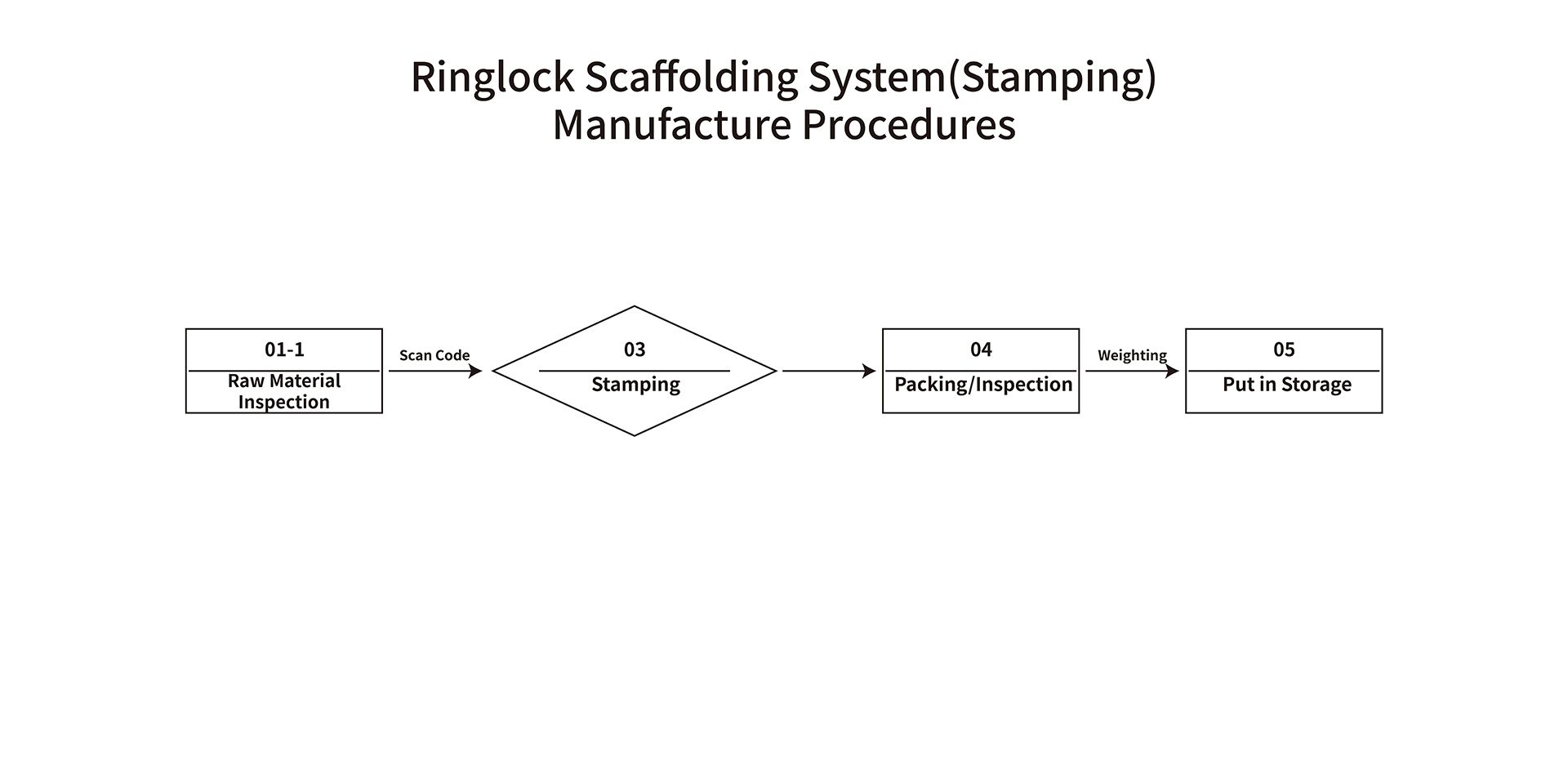

Ringlock Scaffolding System (Stamping)

Cov txheej txheem tsim khoom

01.Raw khoom tshuaj xyuas → 02.Stamping → 03.Packing/Inspection → 04.Pov cia

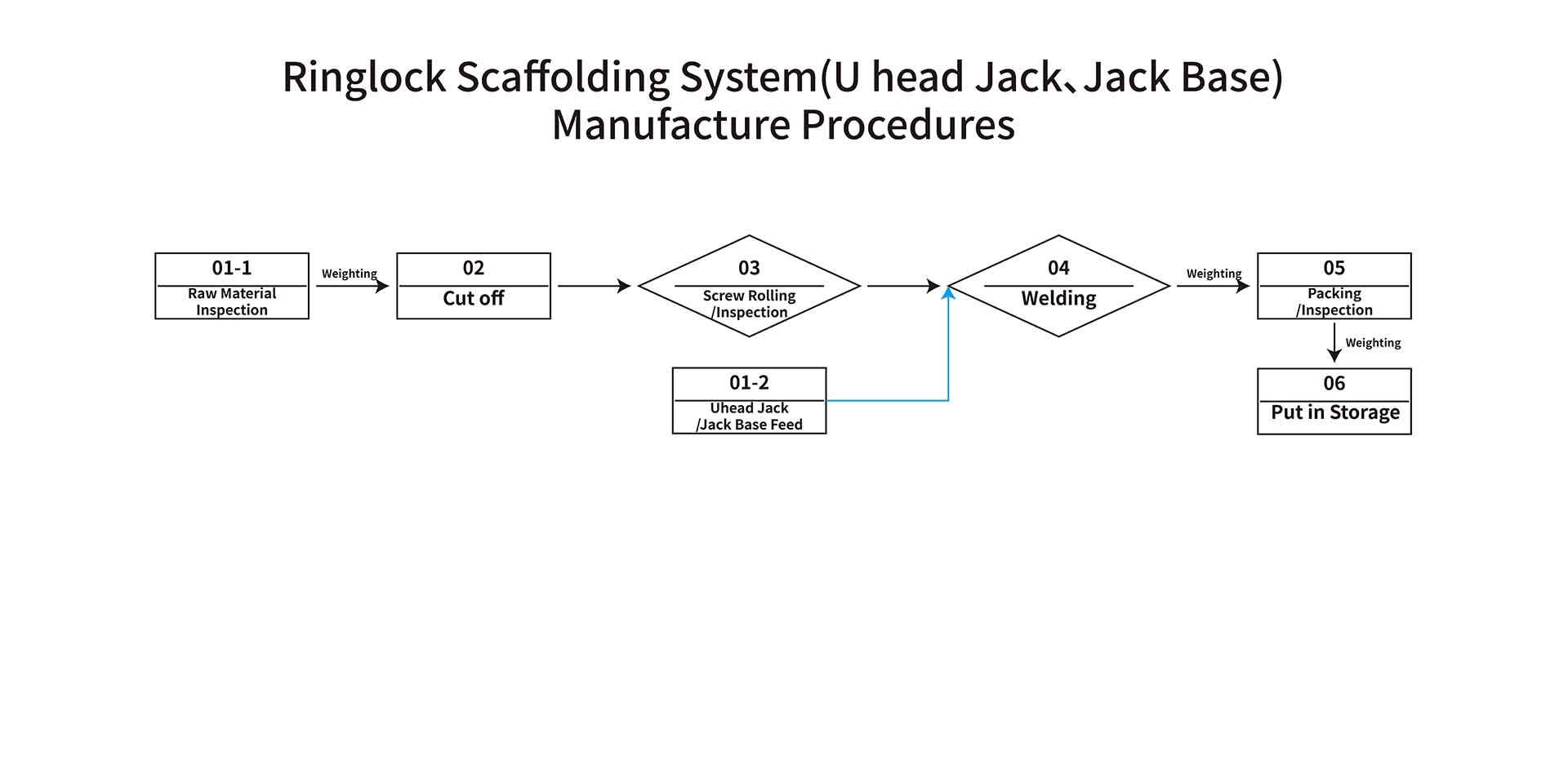

Ringlock Scaffolding System (U lub taub hau jack, Jack puag)

Cov txheej txheem tsim khoom

01.Raw khoom tshuaj ntsuam xyuas → 02.Txiav tawm → 03.Screw dov/Inspection/Uhead jack/jack base feed → 04.Welding → 05.Packing/inspection → 06.Tau cia

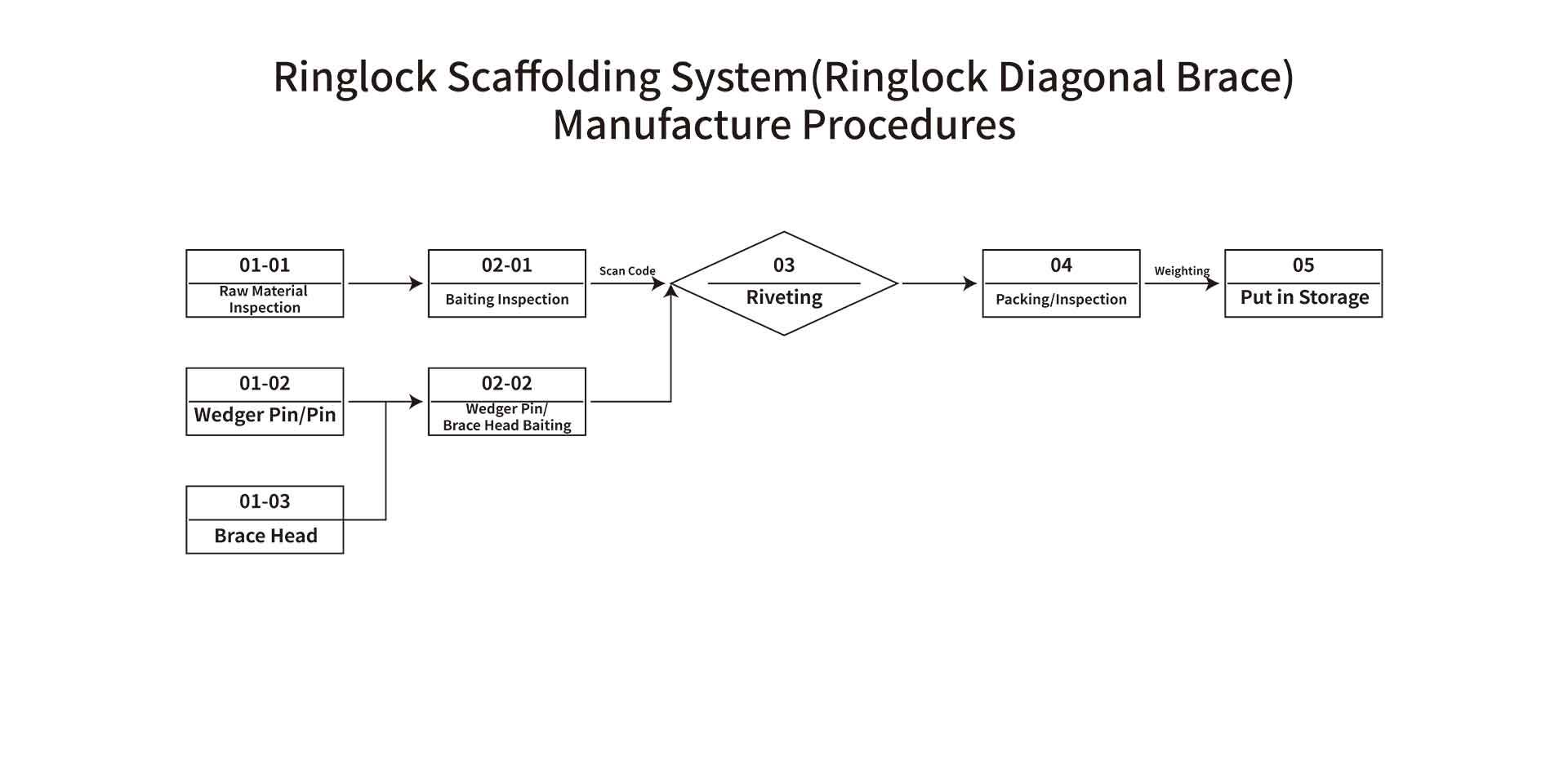

Ringlock Scaffolding System (Ringlock kab pheeb ces kaum brace)

Cov txheej txheem tsim khoom

01.Raw khoom tshuaj xyuas/Wedger tus pin/Pin/Brace taub hau → 02.Baiting tshuaj xyuas/edger tus pin/Brace taub hau baiting → 03.Welding → 04.Packing/inspection → 05.Tau rau hauv cia