Usoro mmepụta usoro na-aga na nyocha nyocha

Na n'elu 9000 ukwuu nkà ọrụ na 293 elu mmepụta ahịrị gbasaa gafee 13 ụlọ mmepụta ihe, anyị emepụtala 20 nde tọn ígwè ọkpọkọ na 2022, na ahịa ego karịrị 160 nde US Dollar na 2018. N'ihi na 17 consecutive afọ, Youfa na-tinyere aha n'etiti TOP. Ụlọ ọrụ 500 dị na ụlọ ọrụ mmepụta ihe China kemgbe 2006.

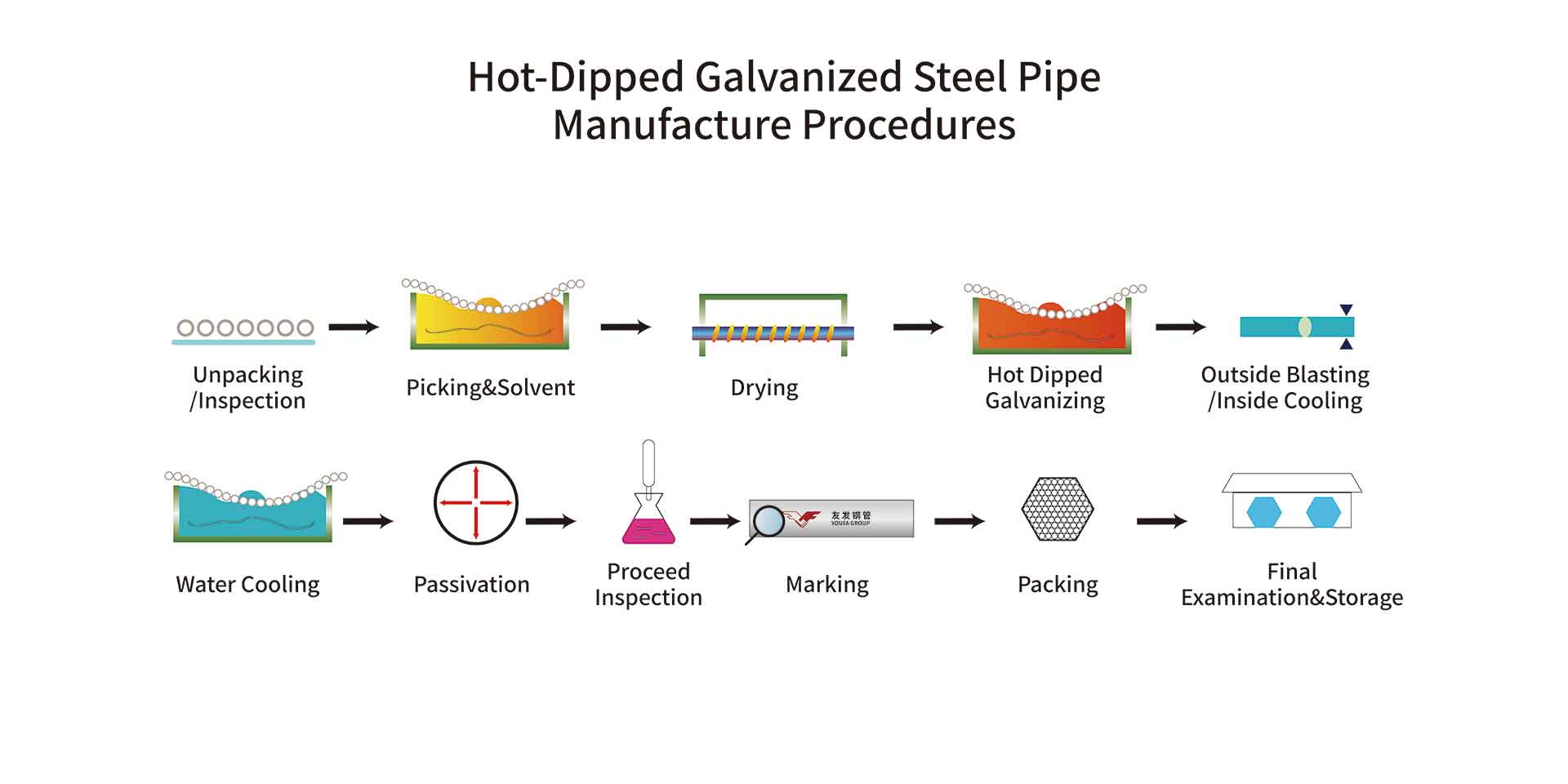

Ọkụ ígwè galvanized na-ekpo ọkụ

Usoro nrụpụta

01.Unpacking/Inspection→02.Picking&Research→03.Drying→04.SHot tinye galvanizing→05.Mpụ gbawara agbawa/N'ime jụrụ oyi→06.Mmiri jụrụ oyi→07.Passivation→08.Ga n'ihu nyocha→09.Marking→10.Packing→ 11.Nnwale ikpeazụ & Nchekwa

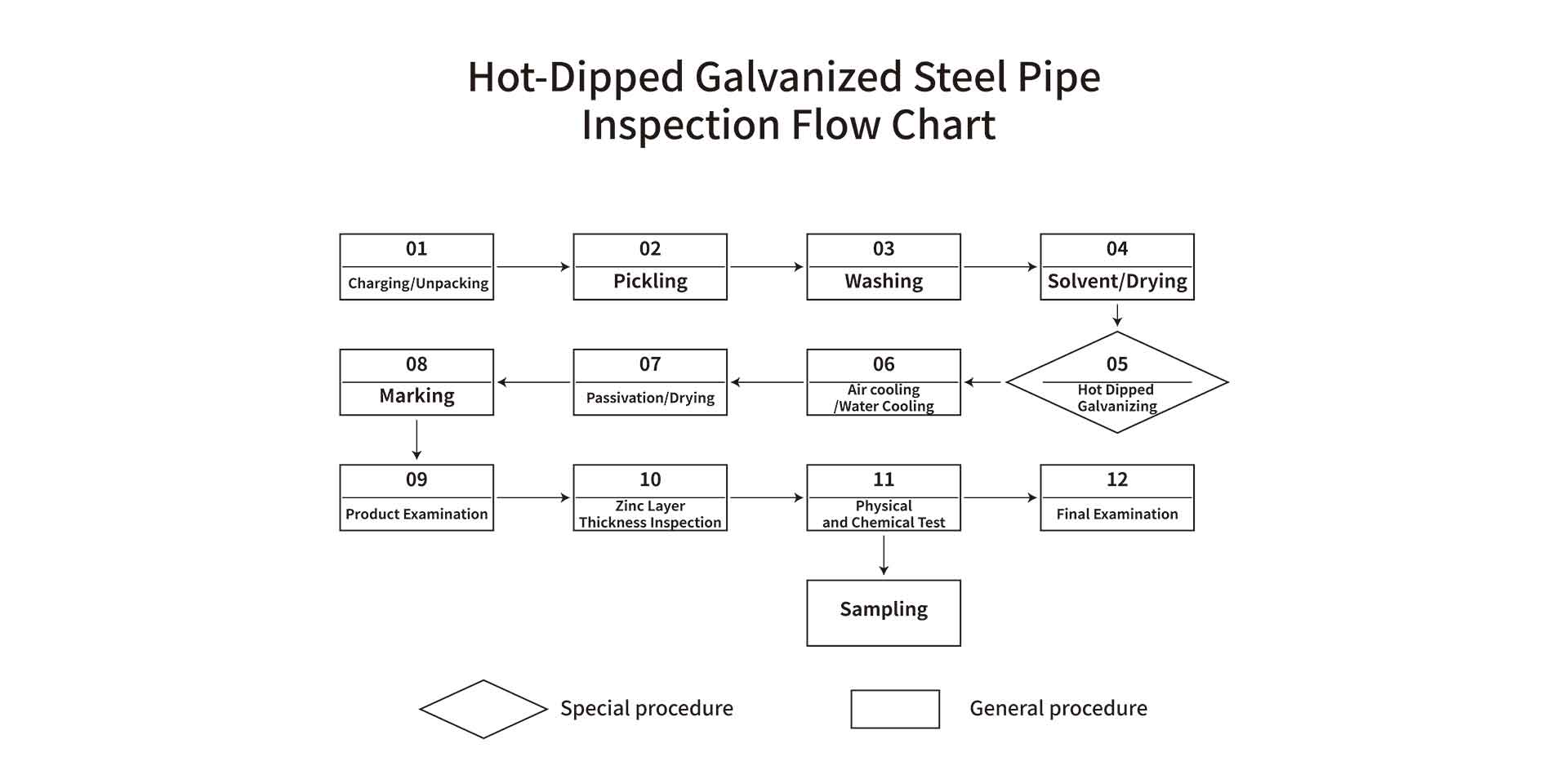

Ọkụ ígwè galvanized na-ekpo ọkụ

Chaatị usoro nyocha

01.Charging/Unpacking→02.Pickling→03.Washing→04.Solvent/Drying→05.Hot dipped galvanizing→06.Ikuku jụrụ oyi/mmiri jụrụ oyi→07.Passivation/Ihicha →08.Marking→09.Nyocha ngwaahịa→10 .Zinc oyi akwa nnyocha →11.Nnwale anụ ahụ na kemikal →12.Nnwale ikpeazụ

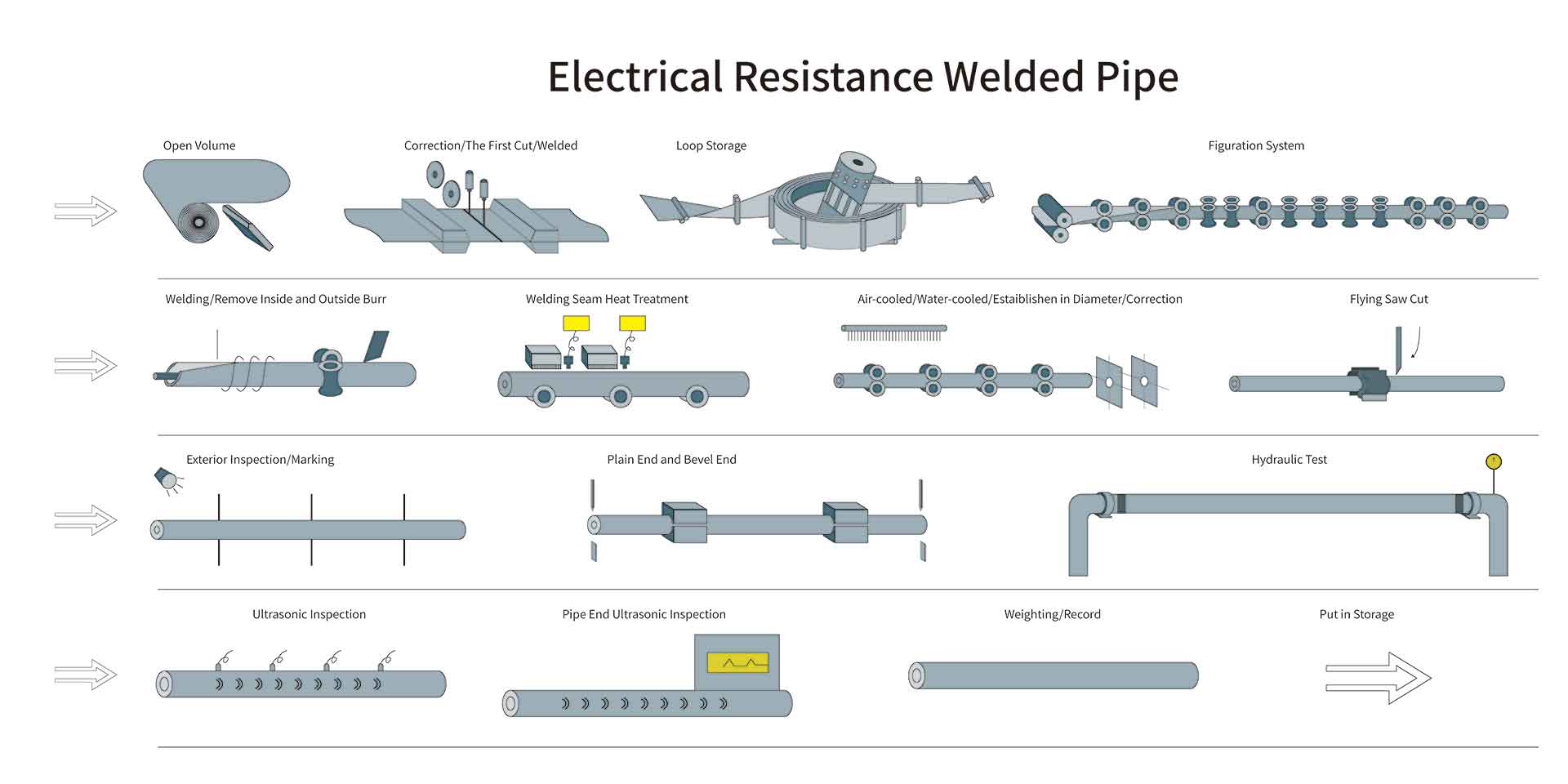

Eletriki Resistance Weld Pipe-ERW

Usoro nrụpụta

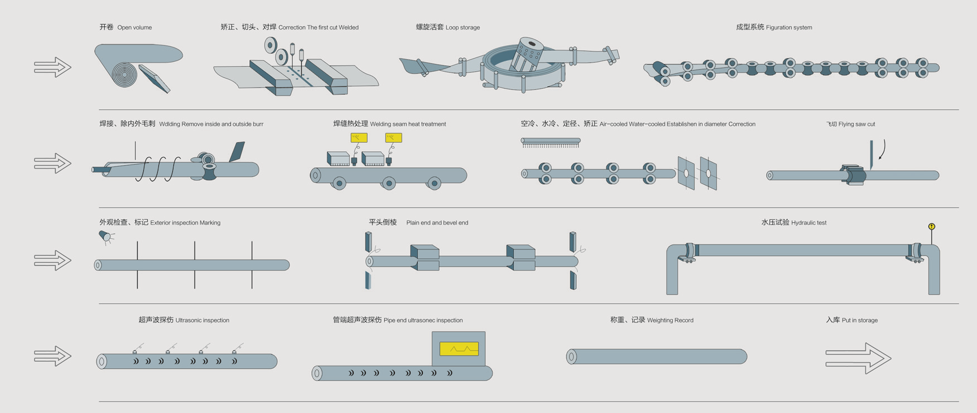

01.Open olu → 02.Corection / Mbụ ịkpụ / Welded → 03. Loop nchekwa → 04.Figuration usoro → 05. Welding / Welding n'ime na n'èzí burr → 06. Welding seams okpomọkụ ọgwụgwọ →07.Air-cooled / Water- mma/Estaiblishen na dayameta/Ndozi →08.Flying hụrụ ịkpụ →09.Mpụga nleba anya / akara → 10. Nkwụsị larịị na njedebe bevel → 11. Nnwale hydraulic → 12. Nyocha Ultrasonic → 13. Ọgwụgwụ nyocha Ultrasonic → 14. Ibu ibu / ndekọ → 15. Tinye na nchekwa

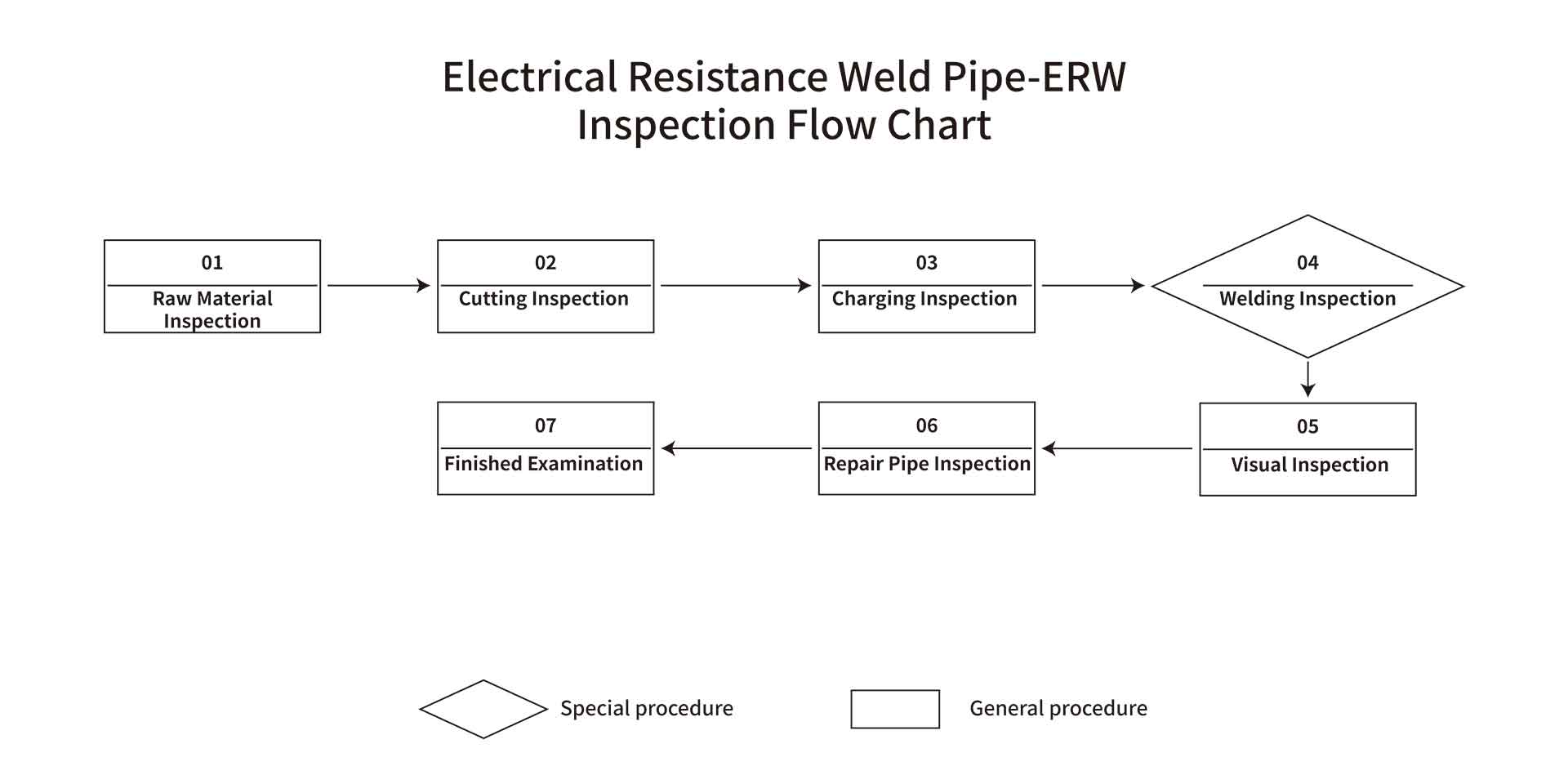

Eletriki Resistance Weld Pipe-ERW

Chaatị usoro nyocha

01. Nnyocha ihe eji eme ihe →02.Nyocha nchacha →03.Nleba nyocha →04.Nyocha welding →05.Nleba anya →06.Nleba anya nyocha nke ọkpọkọ →07.Emechachara nyocha.

Anyị ga-anwale akụrụngwa na mmepụta usoro dịka ụkpụrụ dị iche iche si dị iji hụ na ngwaahịa ndị ahụ kwekọrọ ụkpụrụ ma ọ bụ nkwekọrịta nkwekọrịta.

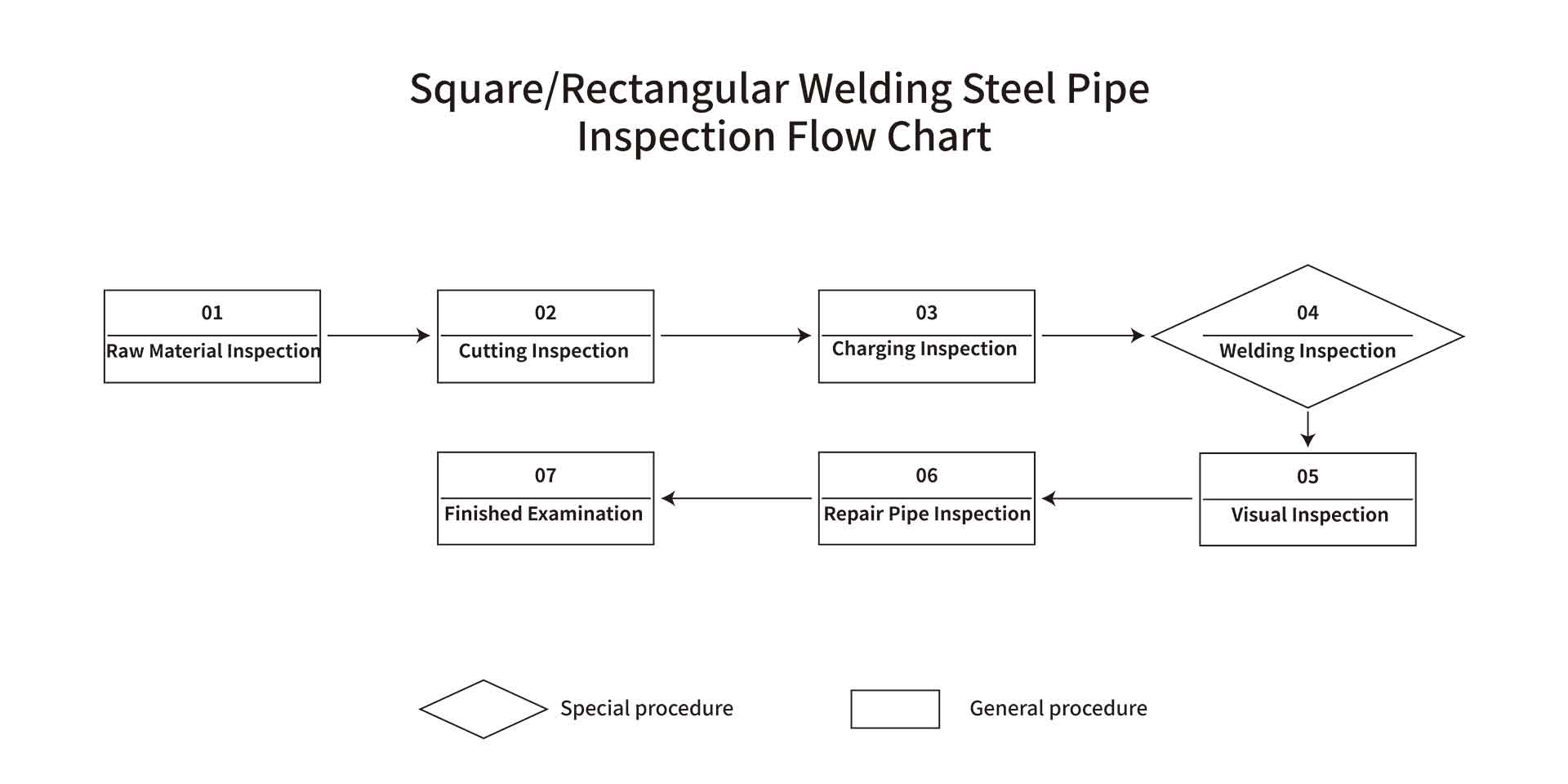

Ọkụ ígwè ịgbado ọkụ Square/Rectangular

Chaatị usoro nyocha

01. Nnyocha ihe eji eme ihe →02.Nyocha nchacha →03.Nleba nyocha →04.Nyocha welding →05.Nleba anya →06.Nleba anya nyocha nke ọkpọkọ →07.Emechachara nyocha.

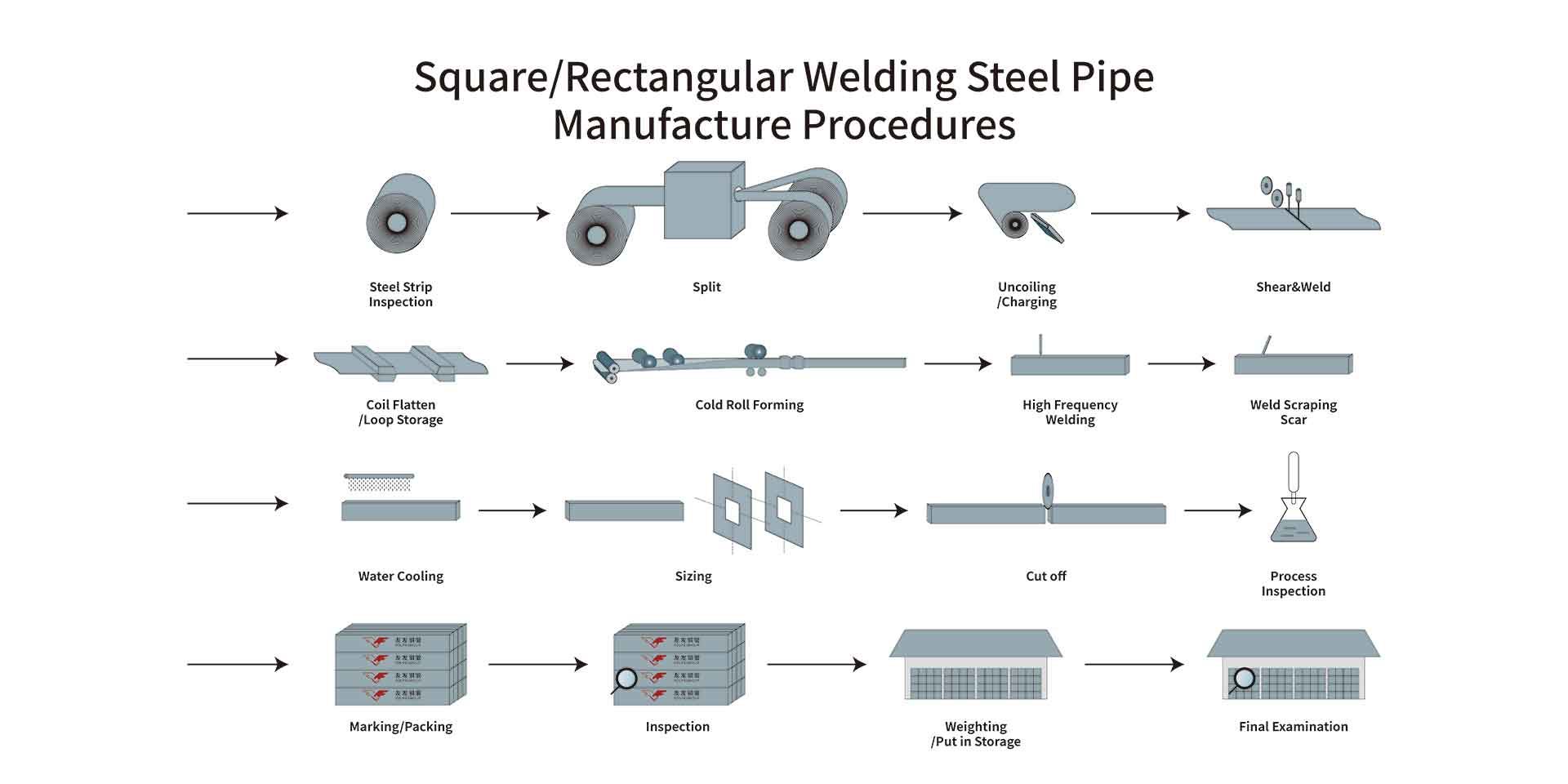

Ọkụ ígwè ịgbado ọkụ Square/Rectangular

Usoro nrụpụta

01. Steel strip inspection→02.Split→03.Uncoiling/Charging→04.Shear&Weld→05.Coil Flatten/Loop storage→06.Cold Roll forming→07.High Frequency welding→08.Weld scraping scraping scarging →09.Mmiri jụrụ oyi →10.Sizing→11.Ebipụ→12.Usoro nyocha→13.Marking/Packing→14.Nnyocha→15.Ịdị arọ/Tinye na nchekwa →16.Nnwale ikpeazụ

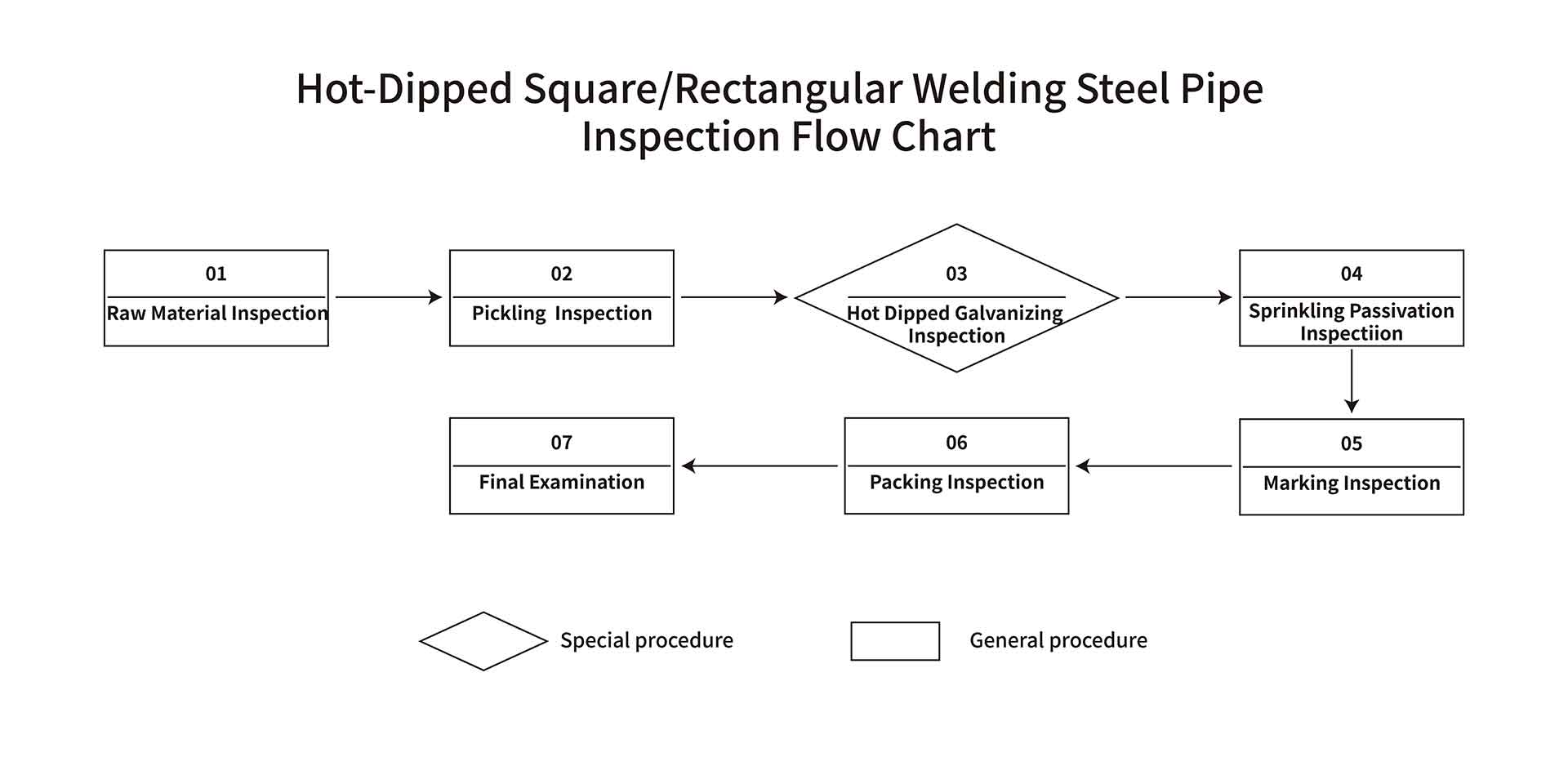

Ọkụ nchara na-ekpo ọkụ na-agbado ọkụ / akụkụ anọ

Chaatị usoro nyocha

01. Nyocha ihe Raq →02.Nyocha ihe nlele →03.Nleba anya na-ekpo ọkụ na-ekpo ọkụ →04.Nleba anya na-efesa Passivation →05.Nyocha akara → 06.Nyocha nkwakọ ngwaahịa →07.Nnwale ikpeazụ

Anyị ga-anwale akụrụngwa na mmepụta usoro dịka ụkpụrụ dị iche iche si dị iji hụ na ngwaahịa ndị ahụ kwekọrọ ụkpụrụ ma ọ bụ nkwekọrịta nkwekọrịta.

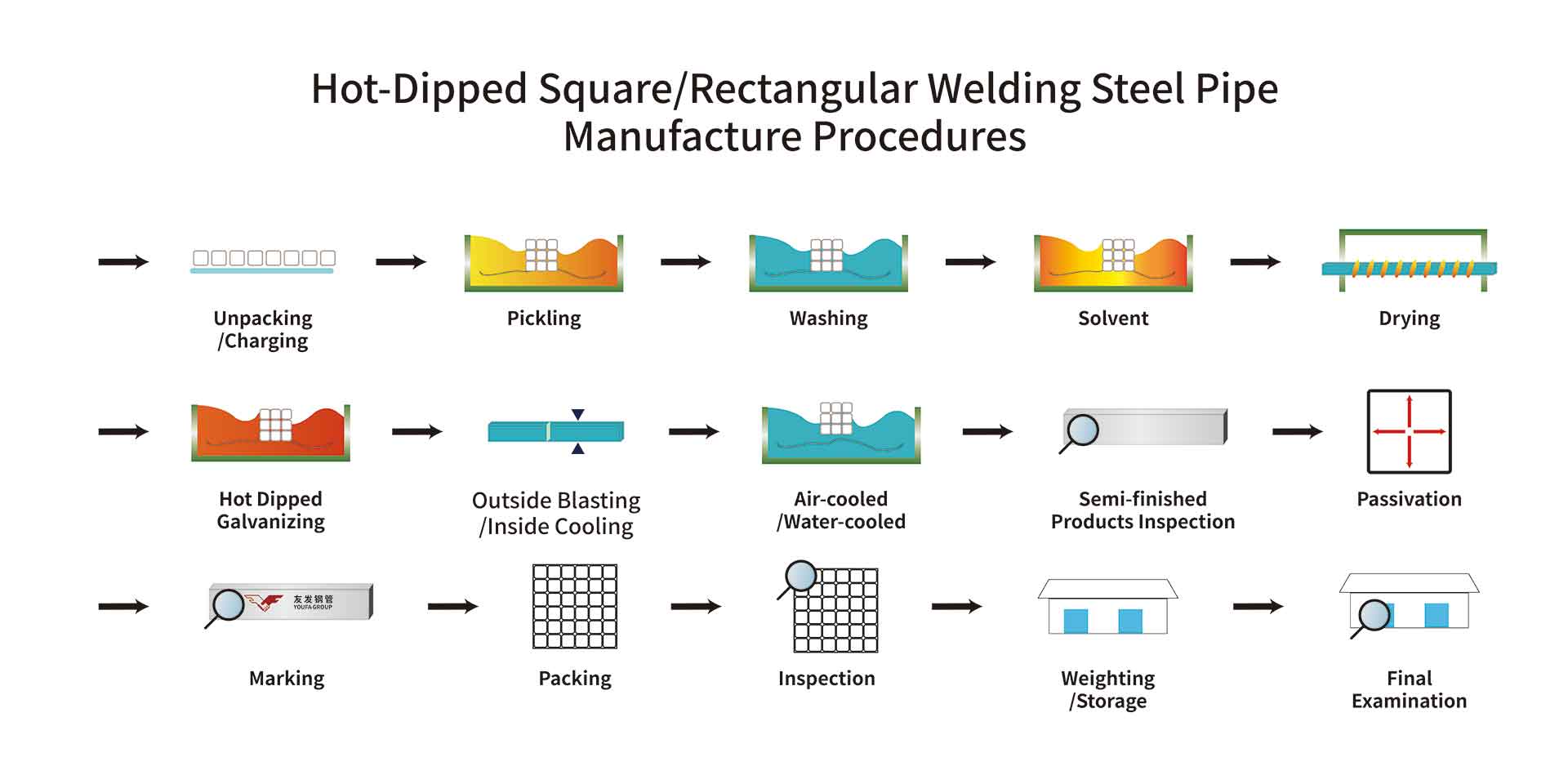

Ọkụ nchara na-ekpo ọkụ na-agbado ọkụ / akụkụ anọ

Usoro nrụpụta

01.Welding steel pipe →02.Unpacking/Charging→03.Pickling→04.Washing→05.Solvent→06.Drying→07.Hot Dipped Galvanizing→08.Outside Blasting→09.Inside Cooling→10.Ikuku jụrụ oyi/ Mmiri jụrụ oyi→11.Ọkara ngwaahịa emechara nyocha →12.Ngafe →13.Marking→14.Packing→15.Nnyocha→16.Ịdị arọ/Nchekwa →17.Nlele ikpeazụ

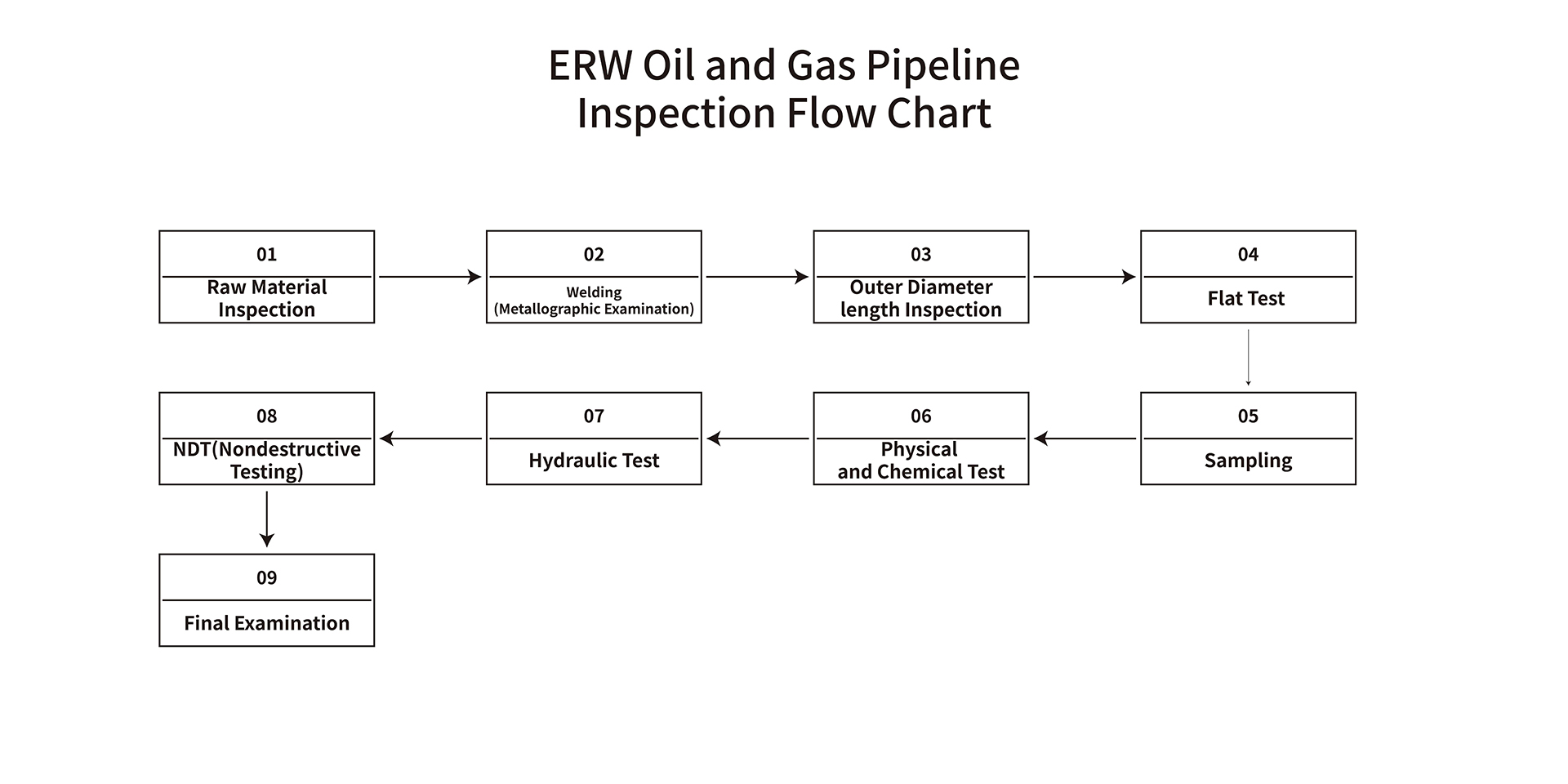

ERW mmanụ na gas pipeline

Chaatị usoro nyocha

01. Raw material inspection→02.Welding(Metallographic exam)→03.Nleba anya dayameta nke mpụga →04.Flat test→05.Sampling→06.Nnwale anụ ahụ na kemịkal 09.Nnwale ikpeazụ

Anyị ga-anwale akụrụngwa na mmepụta usoro dịka ụkpụrụ dị iche iche si dị iji hụ na ngwaahịa ndị ahụ kwekọrọ ụkpụrụ ma ọ bụ nkwekọrịta nkwekọrịta.

01.Open olu → 02.Corection / Mbụ ịkpụ / Welded → 03. Loop nchekwa → 04.Figuration usoro → 05. Welding / Welding n'ime na n'èzí burr → 06. Welding seams okpomọkụ ọgwụgwọ →07.Air-cooled / Water- mma/Estaiblishen na dayameta/Ndozi →08.Flying hụrụ ịkpụ →09.Mpụga nyocha / Marking → 10.Alain njedebe na njedebe bevel → 11. Nnwale hydraulic → 12. Nnyocha nyocha Ultrasonic → 13. Ọgwụgwụ nyocha Ultrasonic → 14. Ibu ibu / ndekọ → 15. Tinye na nchekwa

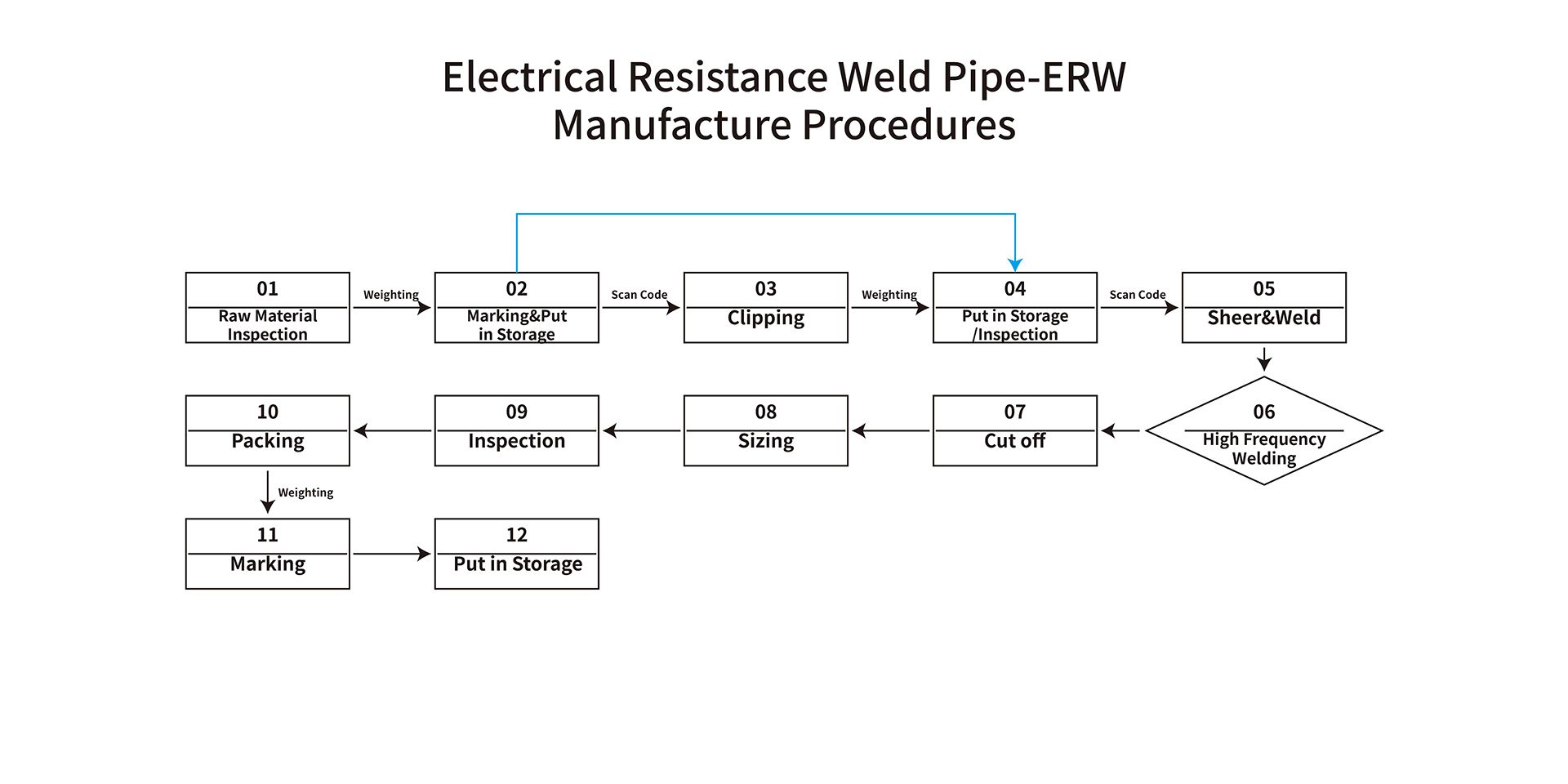

Eletriki Resistance Weld Pipe-ERW

Usoro nrụpụta

01. Nyocha ihe onwunwe →02.Akara&Tinye na nchekwa →03.clipping→04.Tinye na nchekwa/Nyocha 05.Sheer&Weld→06.Nnwale anụ ahụ na kemịkalụ →07.Egbupụ 08.Sizing→09.Nyocha →10. Mbukota →11.Arọ →12.Nyocha koodu

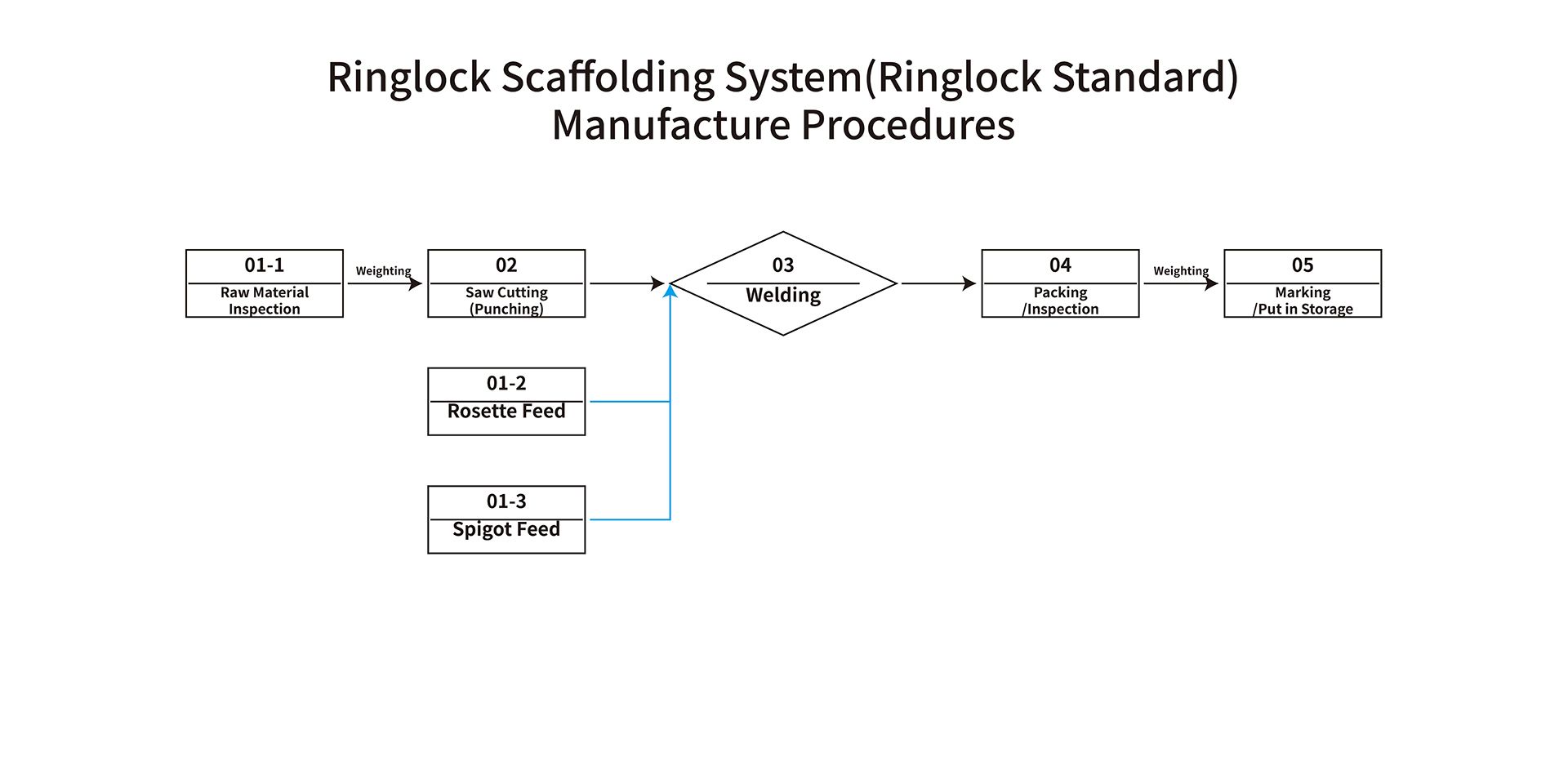

Sistemụ mkpọchi mgbanaka (Ọkọlọtọ mkpọchi)

Usoro nrụpụta

01.Nnyocha ihe eji eme ihe → 02.Sụ ịkpụ (ịkụkụ)/Nri Rosette/Spigot feed→03.Welding→04.Packing/inspection→05.Marking/Tinye na nchekwa

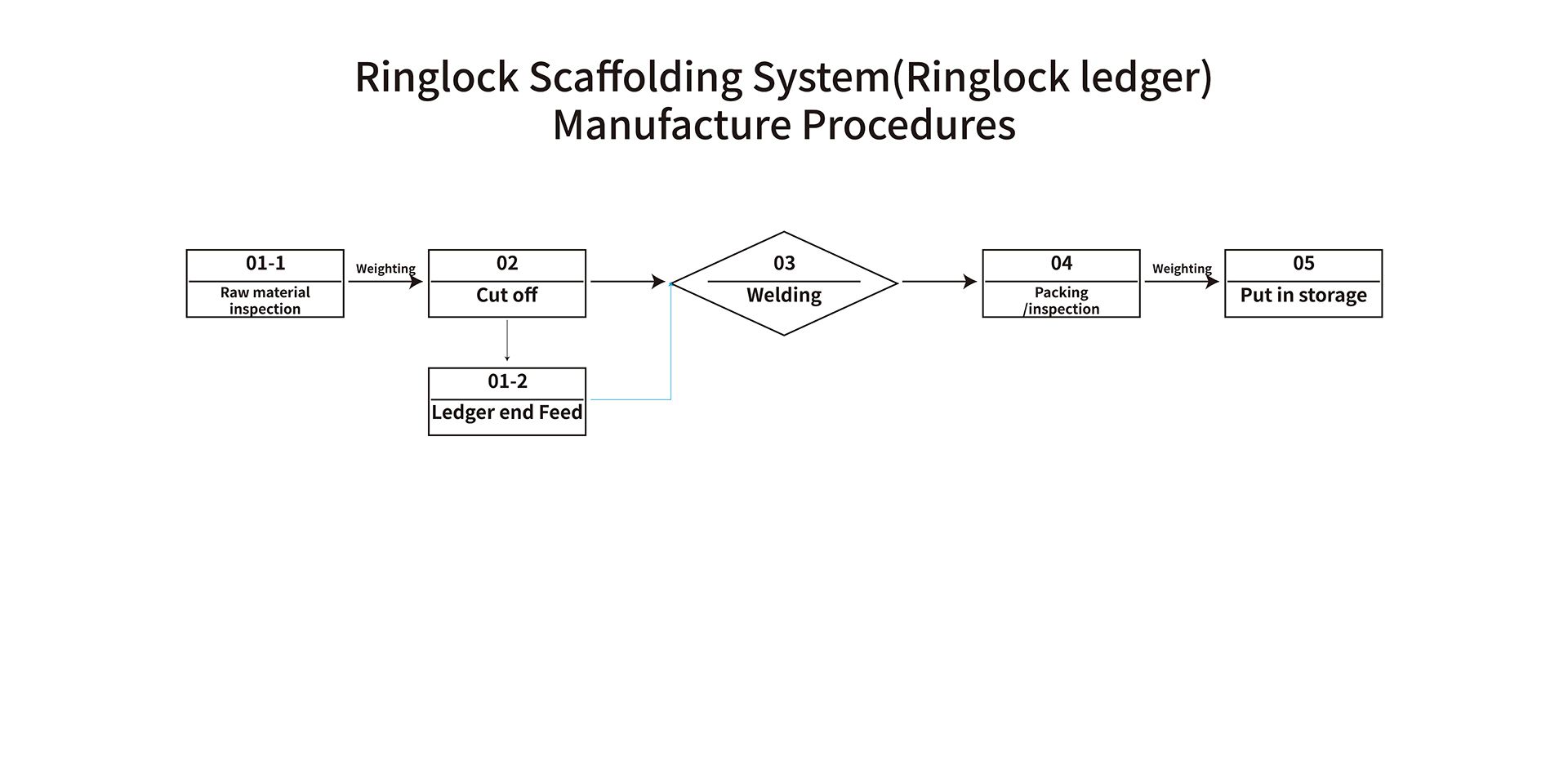

Sistemụ mkpọchi mgbanaka (akwụkwọ ndekọ mkpọchi)

Usoro nrụpụta

01.Nnyocha ihe onwunwe →02.Ebipụ / nkwụsị akwụkwọ nri →03. Welding→04.Packing/inspection→05.Marking/Tinye na nchekwa

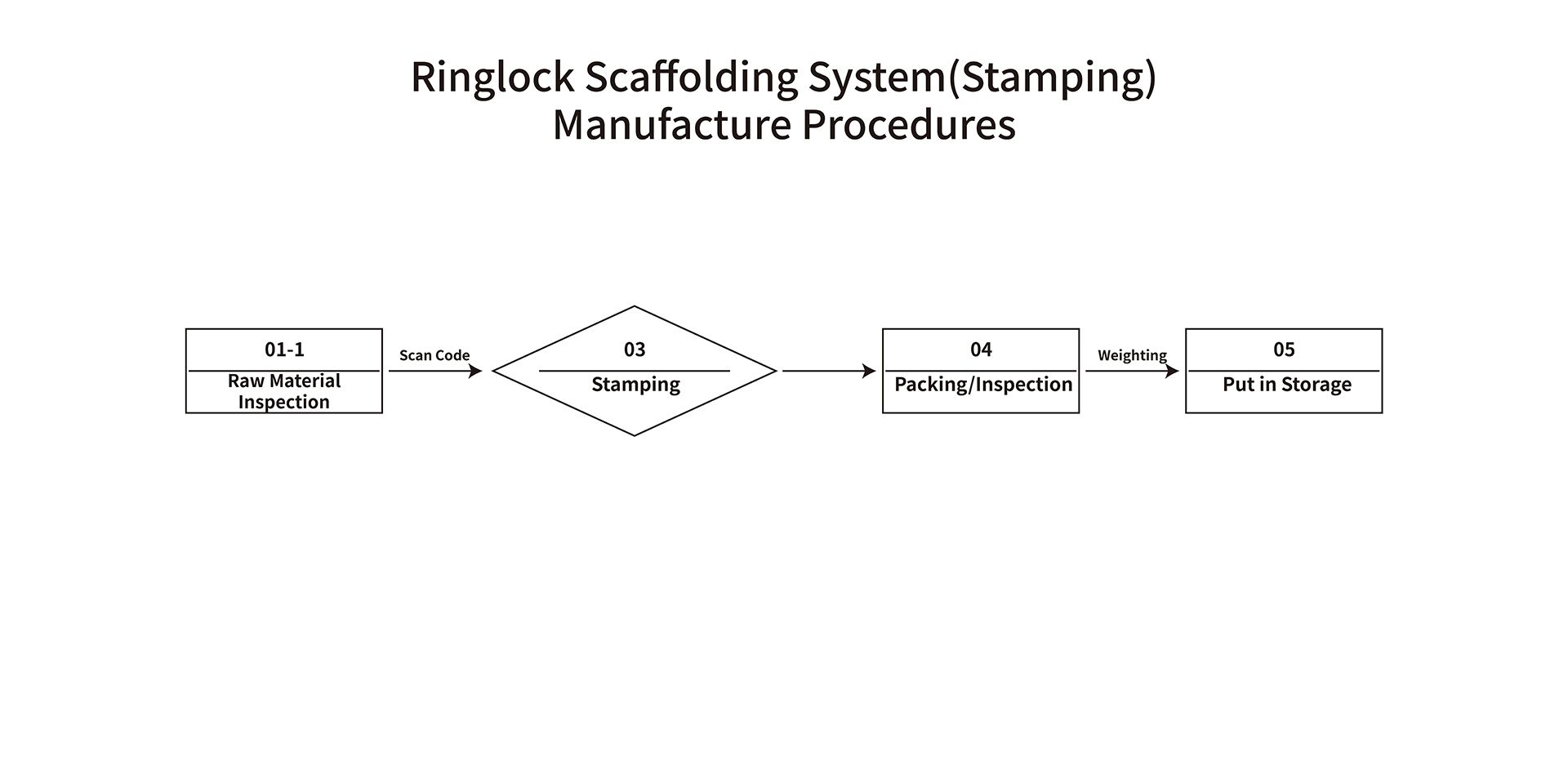

Sistemụ mkpọchi mgbanaka(stamping)

Usoro nrụpụta

01.Nnyocha ihe eji eme ihe →02.Stamping→03.Packing/Inspection→04.Tinye na nchekwa

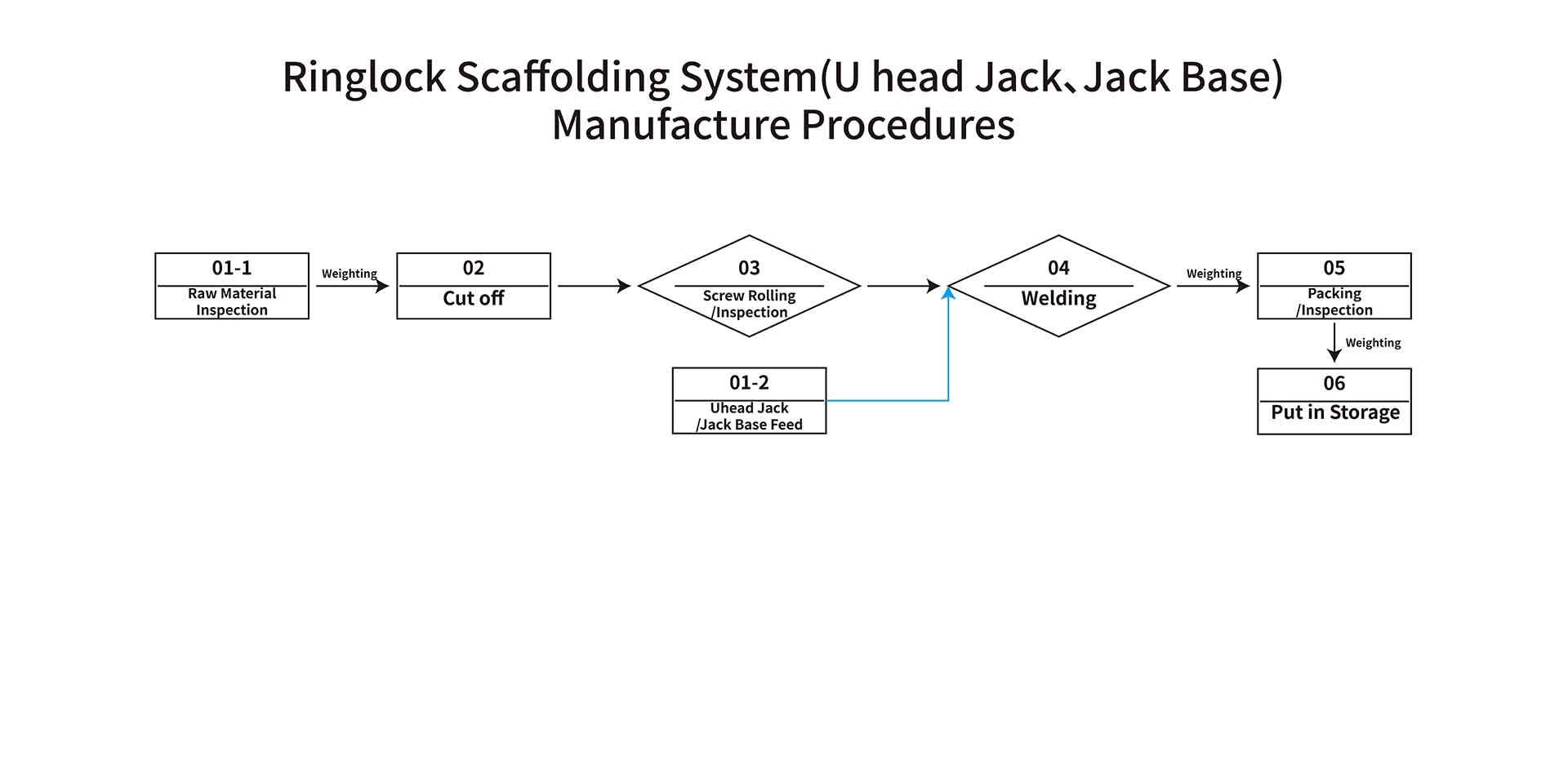

Sistemụ mkpuchi mkpuchi mgbanaka (U head jack, Jack base)

Usoro nrụpụta

01.Raw ihe nlebanya →02.Kpụ →03.Screw rolling/Inspection/Uhead Jack / Jack base feed→04.Welding→05.Packing/inspection→06.Tinye na nchekwa

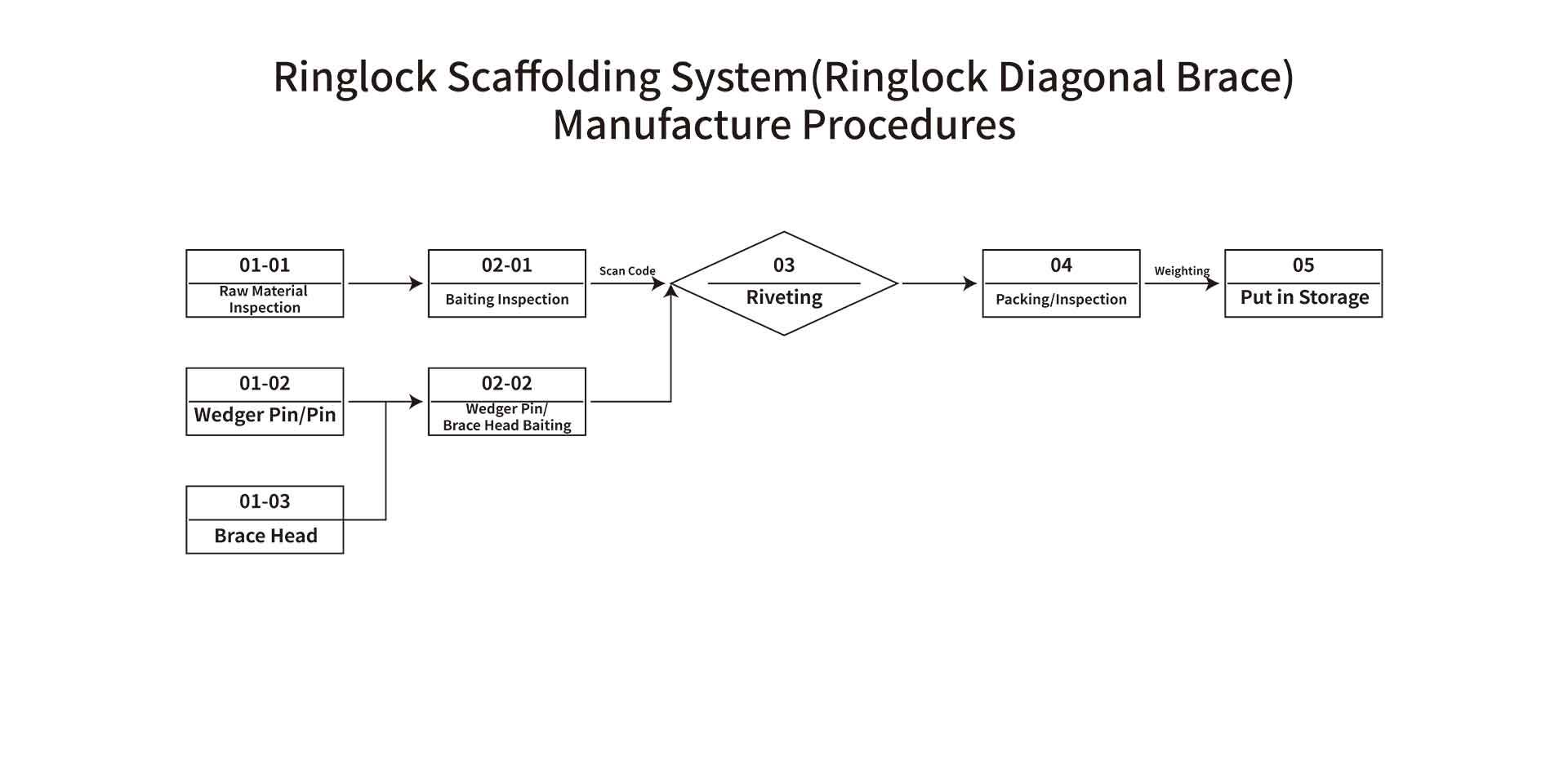

Sistemụ mkpọchi mgbanaka (ihe nkwado diagonal mgbanaka)

Usoro nrụpụta

01.Nnyocha ihe eji eme ihe/Wedger pin/Pin/ Brace head→02.Nleba anya nleba anya/edger pin/ brace head baiting→03.Welding→04.Packing/inspection→05.Tinye na nchekwa