Alur Proses Produksi lan Alur Inspeksi

Kanthi luwih saka 9000 karyawan sing trampil lan 293 jalur produksi maju sing nyebar ing 13 pabrik, kita wis ngasilake 20 yuta ton pipa baja ing 2022, lan jumlah dodolan ngluwihi 160 yuta Dolar AS ing 2018. Kanggo 17 taun berturut-turut, Youfa dijuluki TOP 500 Perusahaan ing Industri Manufaktur China wiwit 2006.

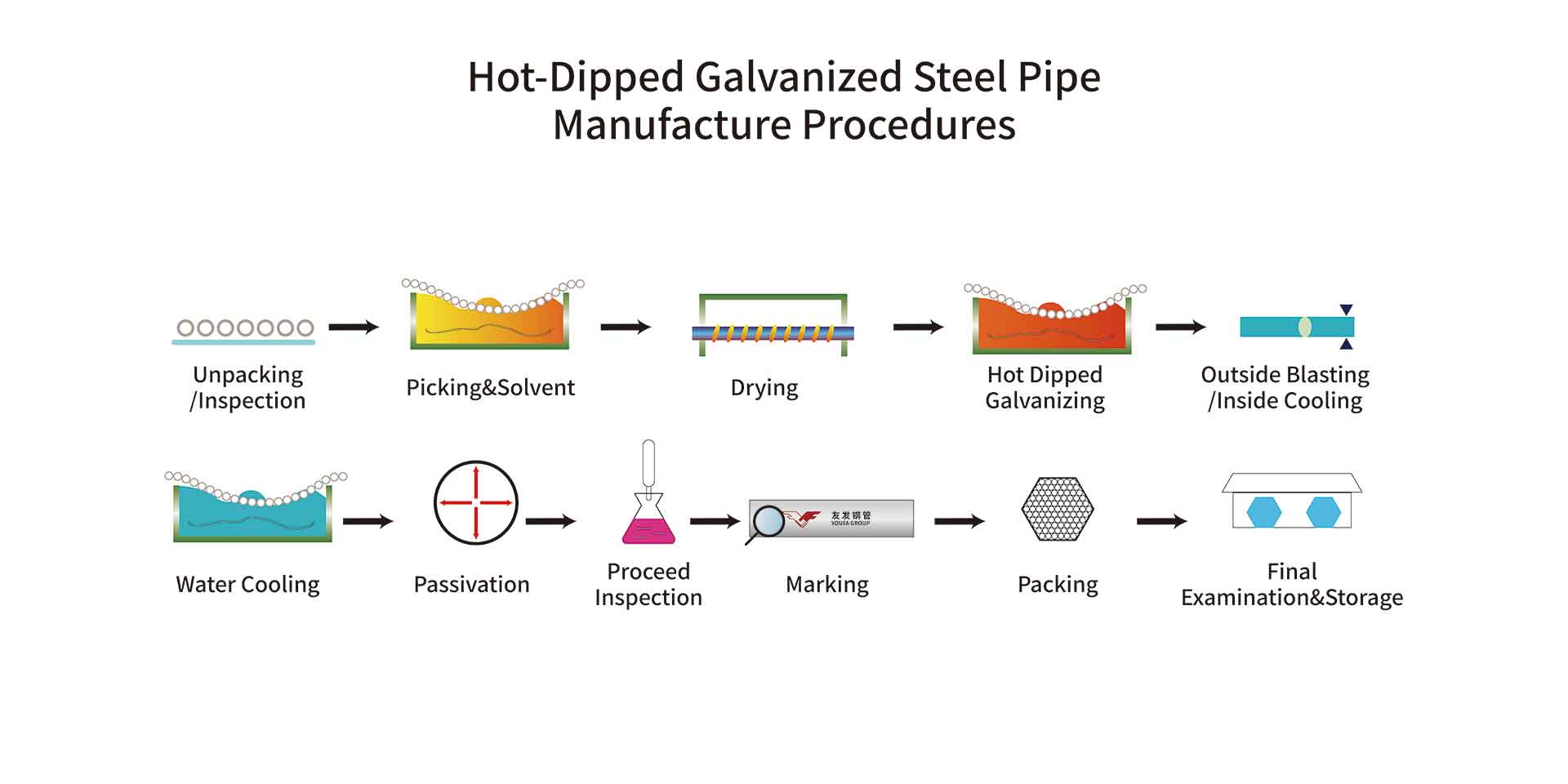

Hot-Dipped Pipa Baja Galvanis

Prosedur Produksi

01. Unpacking / Inspection → 02. Picking & Solvent → 03. Drying → 04. SHot dipped galvanizing → 05. Outside blasting / Inside cooling → 06. Water cooling → 07. Passivation → 08. Nerusake inspeksi → 09. Marking → 10. Packing → 11. Ujian Akhir & Panyimpenan

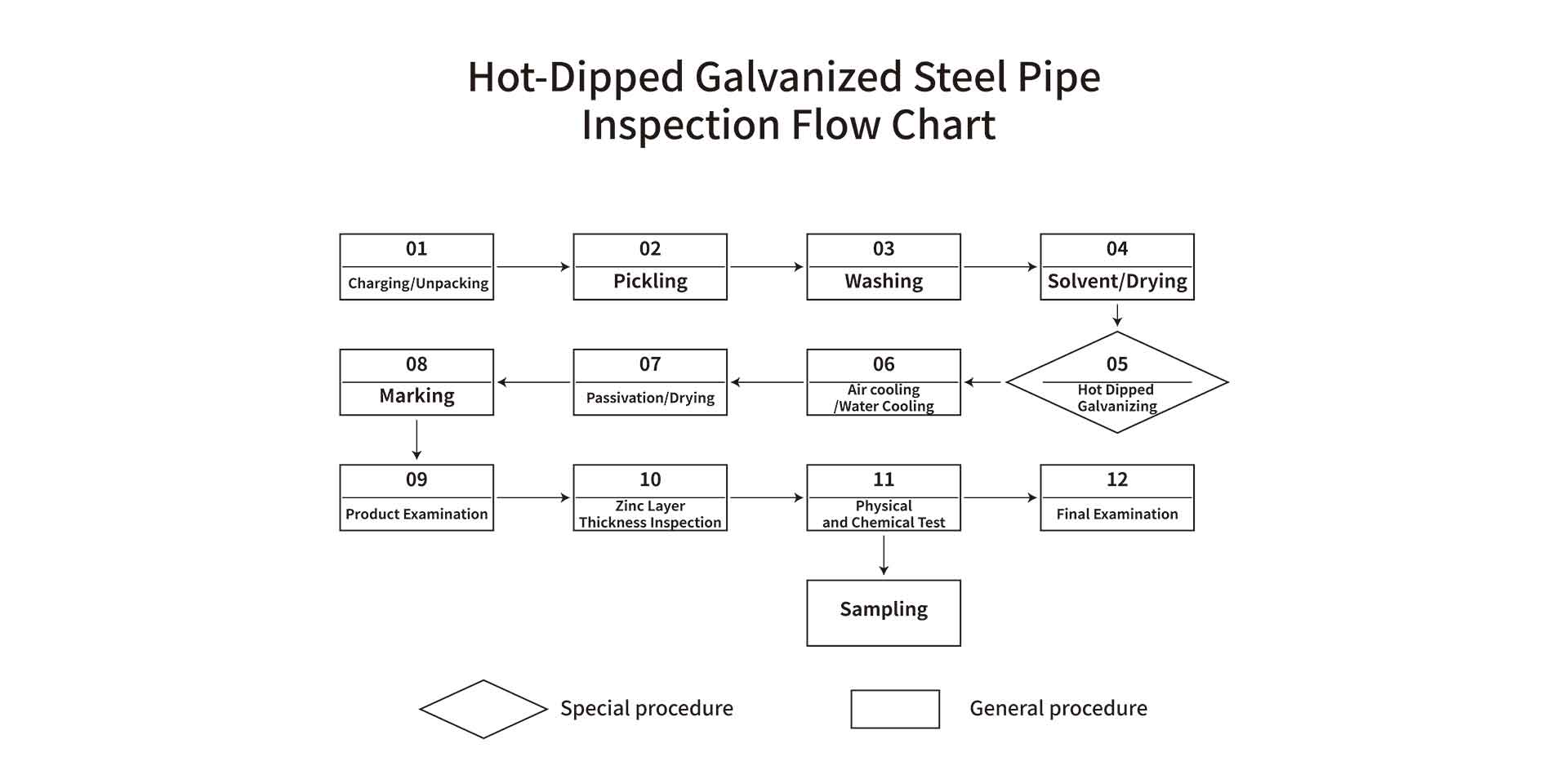

Hot-Dipped Pipa Baja Galvanis

Bagan Alur Inspeksi

01. Ngisi daya / Mbukak kemasan → 02. Acar → 03. Cuci → 04. Pelarut / Pengeringan → 05. Galvanizing dicelup panas → 06. Pendinginan Udara / Pendinginan Air → 07. Pasifasi / Pengeringan → 08. Penandaan → 09. Pemeriksaan produk → 10 .Pemeriksaan ketebalan lapisan seng → 11. Tes fisik lan kimia → 12. Pemeriksaan pungkasan

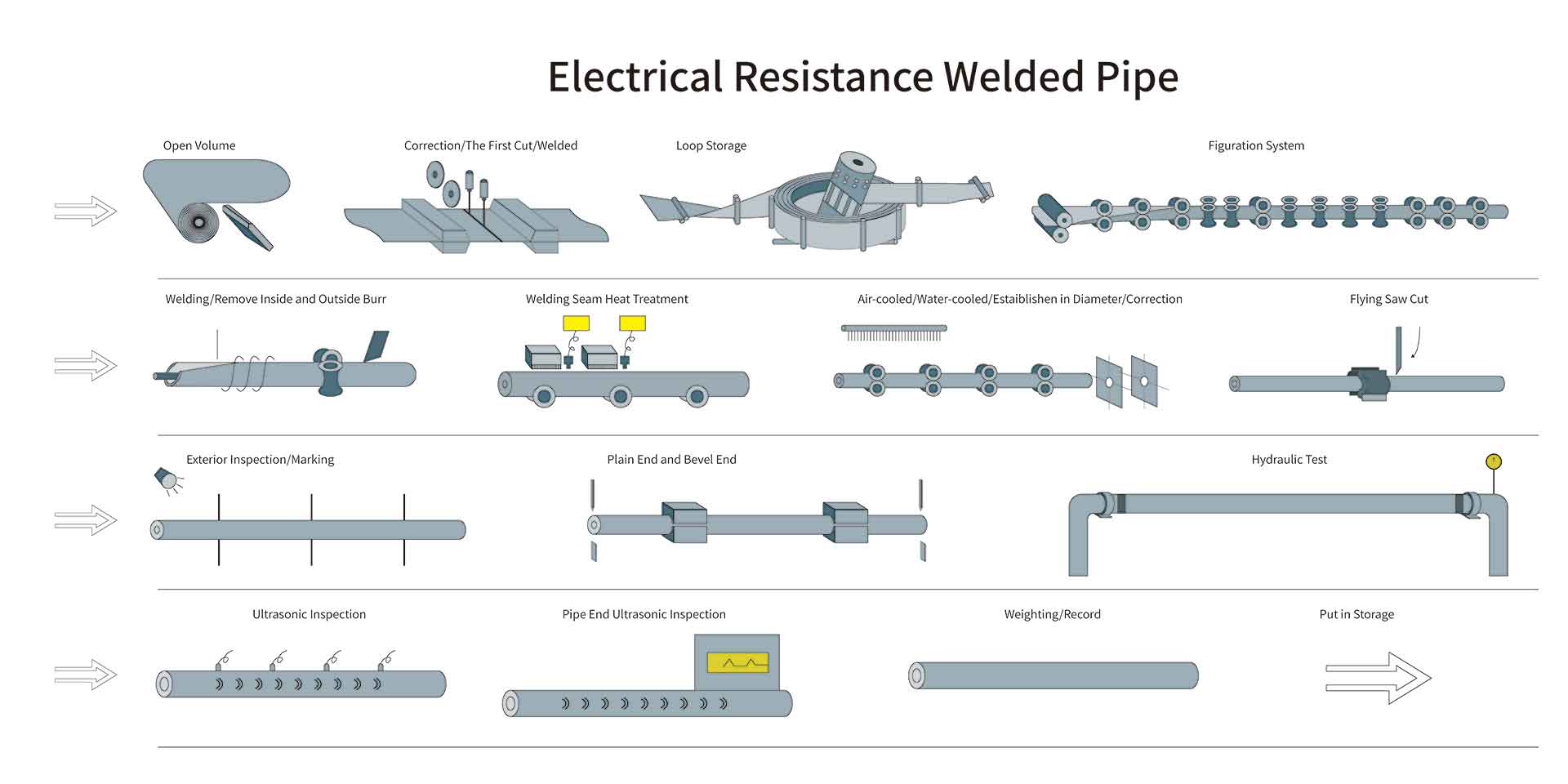

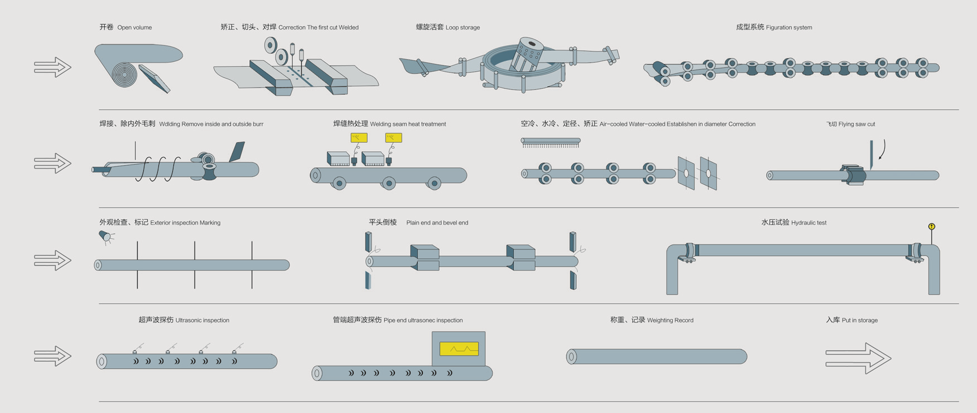

Resistansi Listrik Weld Pipe-ERW

Prosedur Produksi

01. Volume mbukak → 02. Koreksi / Potong pisanan / Welded → 03. Panyimpenan loop → 04. Sistem Figuration → 05. Welding / Copot jero lan njaba burr → 06. Welding jahitan perawatan panas → 07. Air-cooled / Water- digawe adhem / Nggawe diameter / Koreksi → 08. Potong gergaji mabur → 09. Eksterior inspeksi / Marking → 10. Plain end and bevel end → 11. Hydraulic test → 12. Ultrasonic inspection → 13. Pipe end Ultrasonic inspection → 14. Bobot / Rekam → 15. Lebokake ing panyimpenan

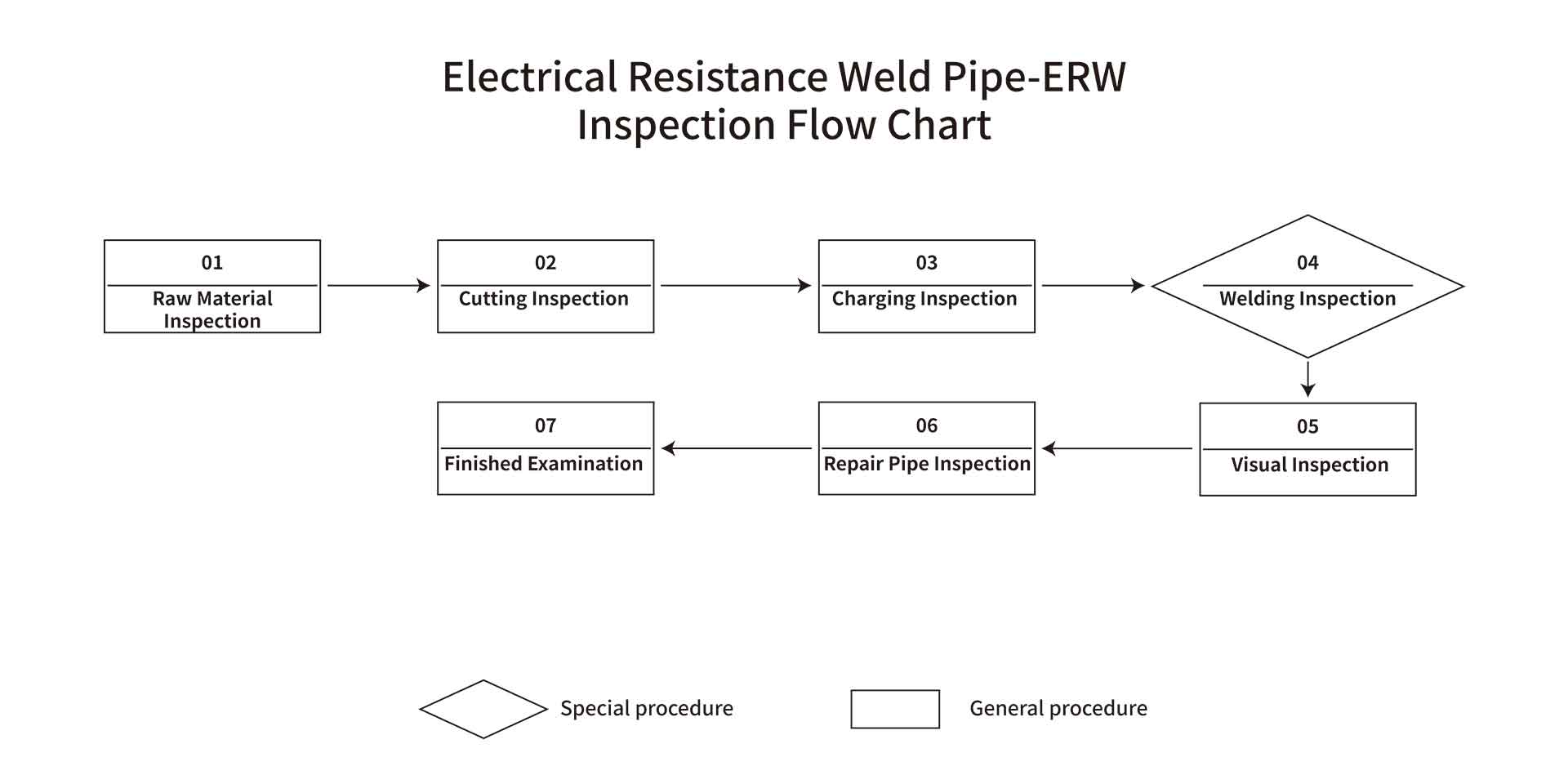

Resistansi Listrik Weld Pipe-ERW

Bagan Alur Inspeksi

01. Inspeksi bahan baku → 02. Inspeksi pemotongan → 03. Inspeksi pengisian → 04. Inspeksi pengelasan → 05. Inspeksi visual → 06. Inspeksi pipa → 07. Pemeriksaan rampung

Kita bakal nguji bahan mentah lan proses produksi miturut standar sing beda-beda kanggo mesthekake yen produk kasebut cocog karo standar utawa syarat kontrak.

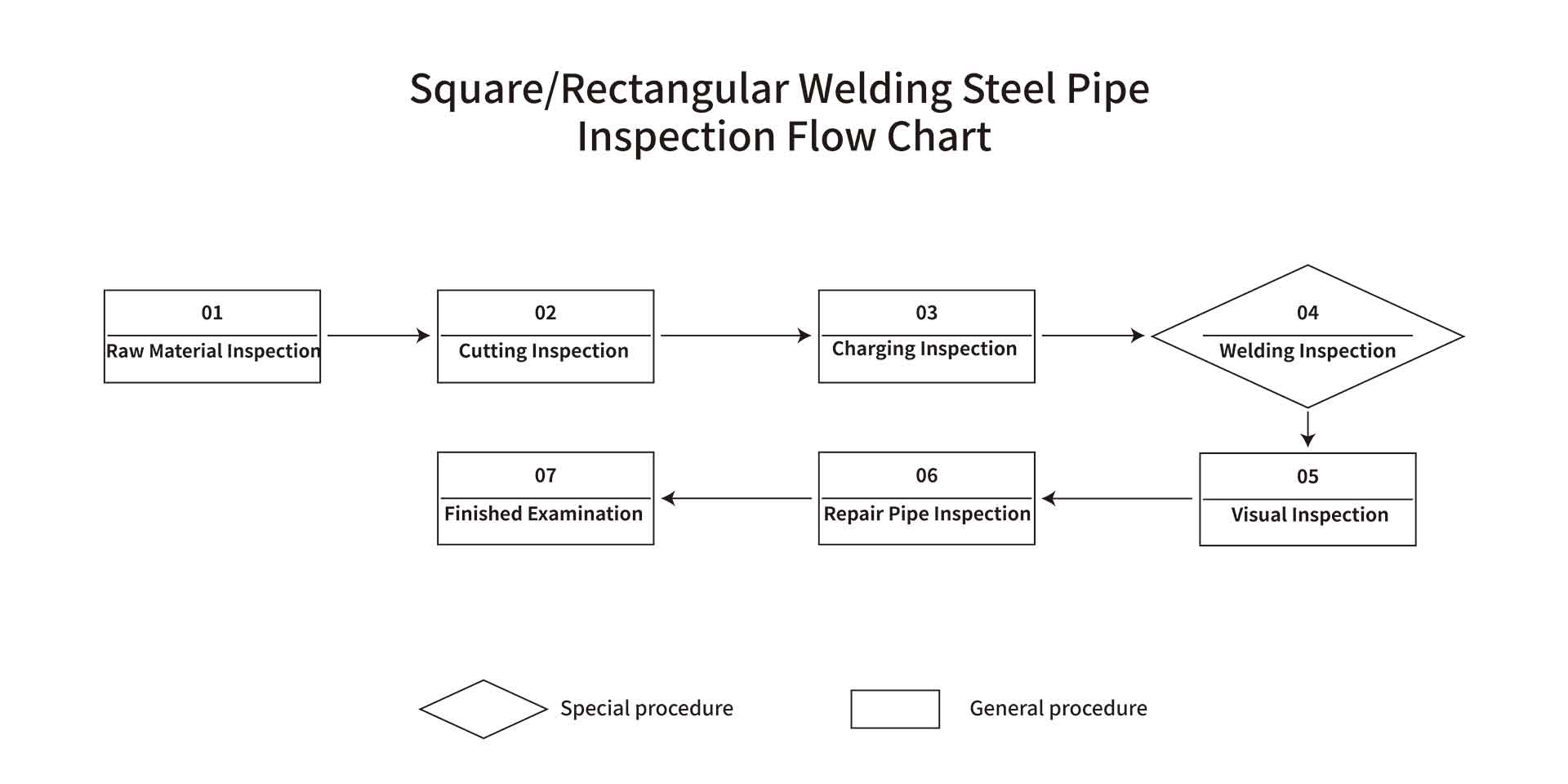

Pipa Baja Welding Square/Rectangular

Bagan Alur Inspeksi

01. Inspeksi bahan baku → 02. Inspeksi pemotongan → 03. Inspeksi pengisian → 04. Inspeksi pengelasan → 05. Inspeksi visual → 06. Inspeksi pipa → 07. Pemeriksaan rampung

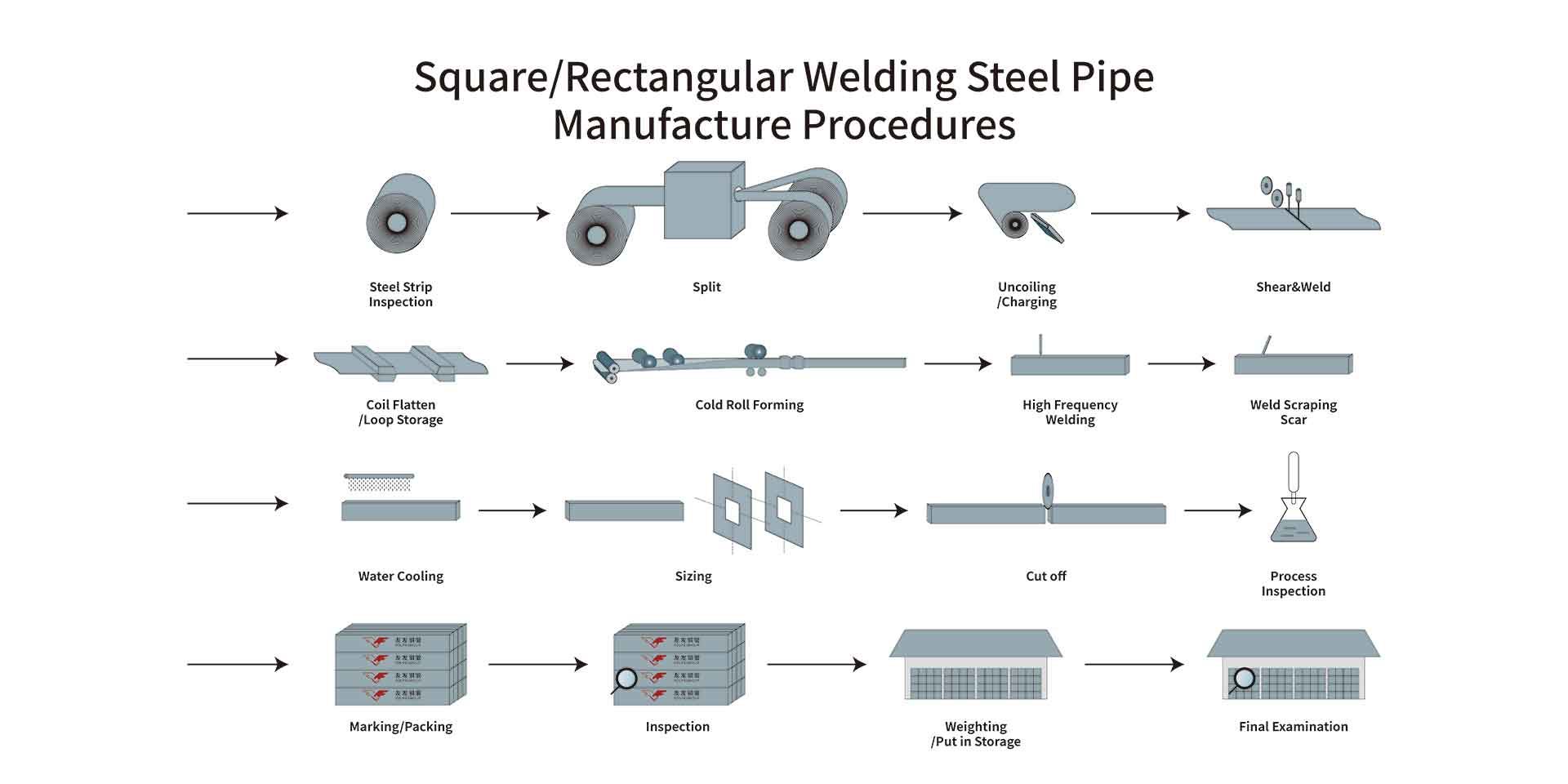

Pipa Baja Welding Square/Rectangular

Prosedur Produksi

01. Inspeksi Strip baja → 02. Split → 03. Uncoiling / Pengisian → 04. Shear & Weld → 05. Coil Flatten / Loop storage → 06. Cold roll forming → 07. High Frequency welding → 08. Weld scraping scar → 09. Water cooling →10.Sizing→11.Cut off→12.Proses inspeksi → 13. Marking / Packing → 14. Inspection → 15. Bobot / Lebokake ing panyimpenan → 16. Ujian pungkasan

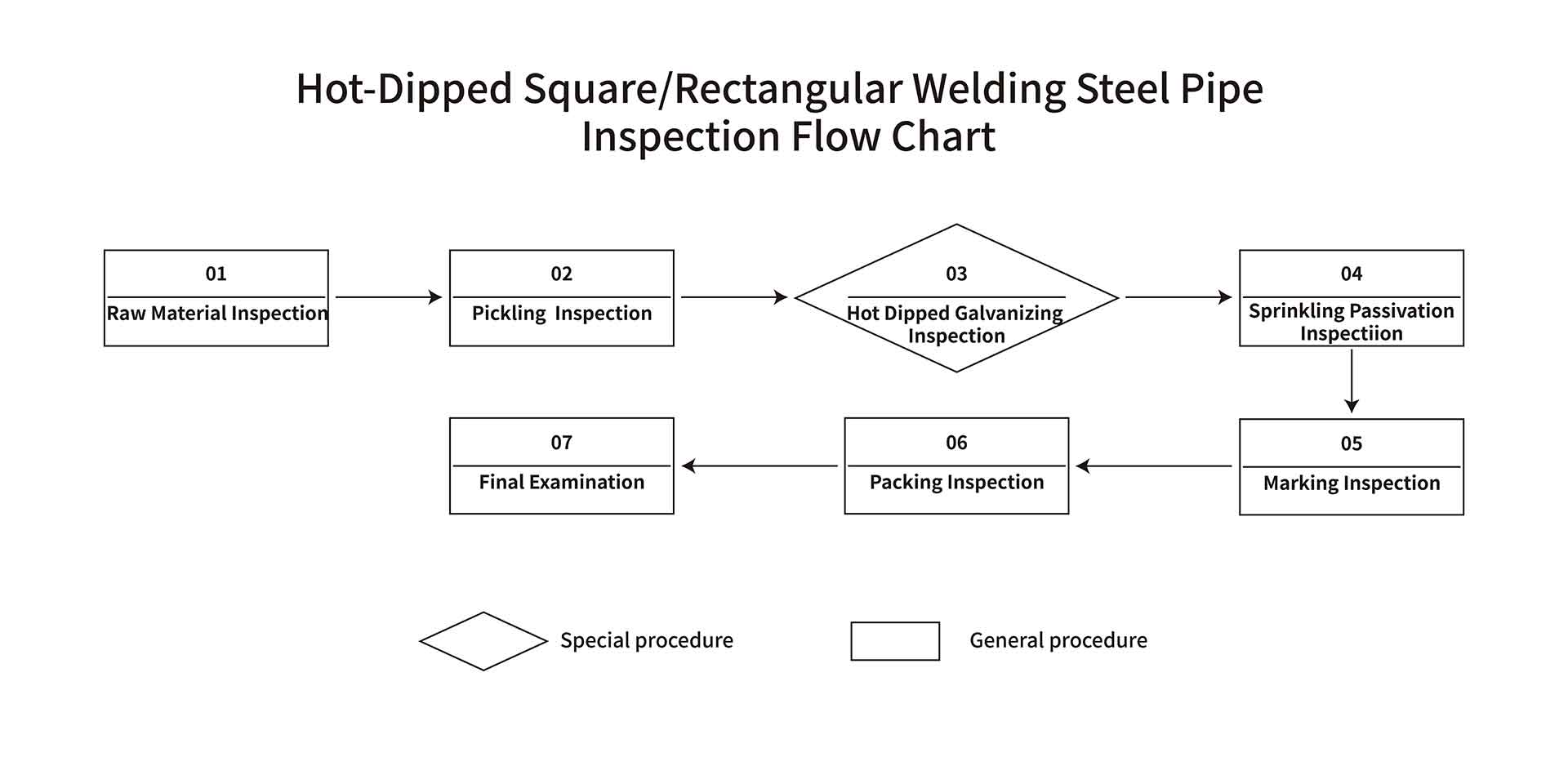

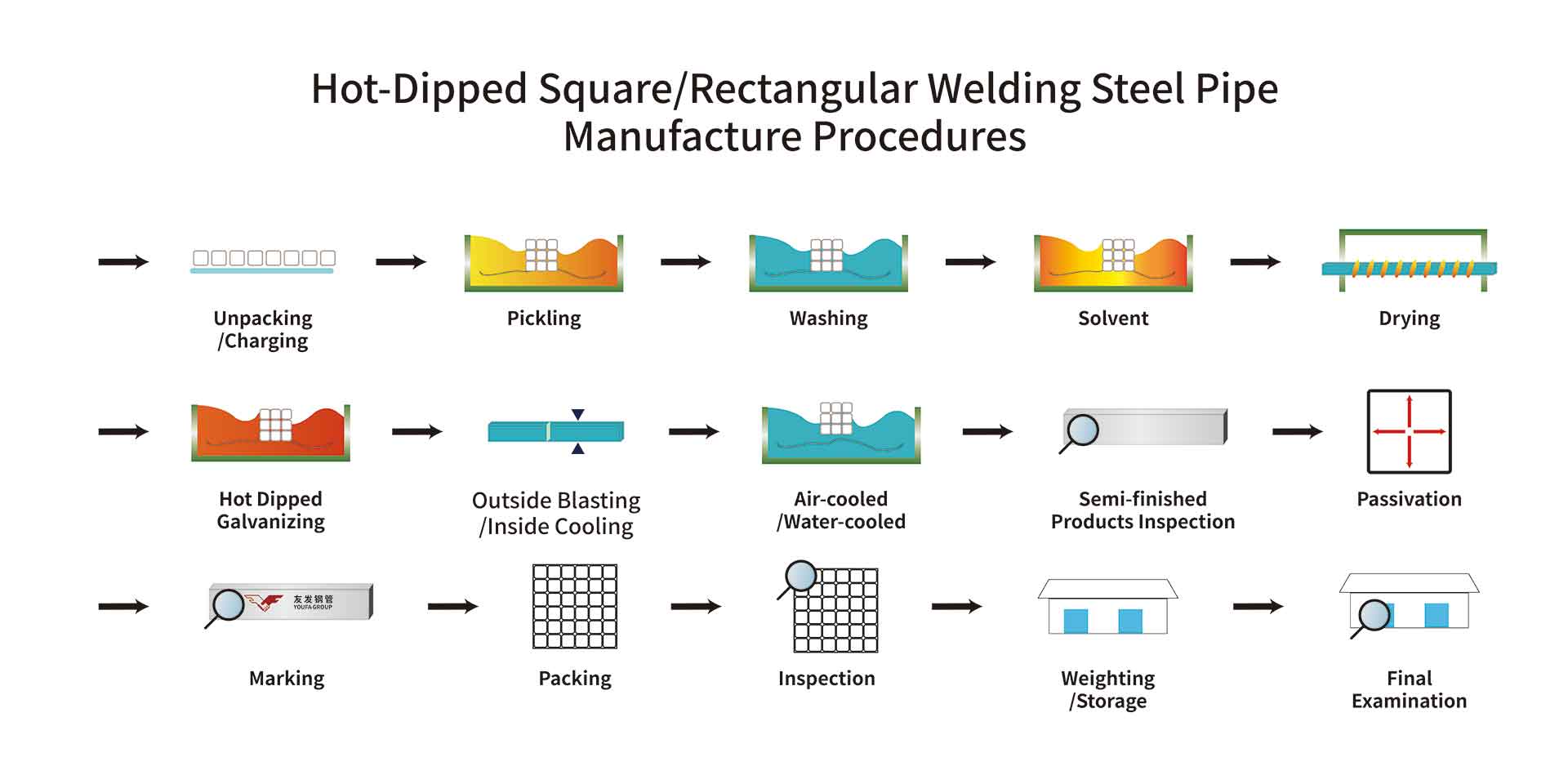

Hot-Dipped Square / Rectangular Welding Steel Pipe

Bagan Alur Inspeksi

01. Raq material inspection→02.Pickling inspection→03.Hot Dipped Galvanizing inspection→04.Sprinkling Passivation inspectiion→05.Marking inspection→06.Packing inspection→07.Final examination

Kita bakal nguji bahan mentah lan proses produksi miturut standar sing beda-beda kanggo mesthekake yen produk kasebut cocog karo standar utawa syarat kontrak.

Hot-Dipped Square / Rectangular Welding Steel Pipe

Prosedur Produksi

01. Welding steel pipe→ 02. Unpacking / Charging → 03. Pickling → 04. Cuci → 05. Solvent → 06. Drying → 07. Hot Dipped Galvanizing → 08. Outside Blasting → 09. Inside Cooling → 10. Air-cooled/ Water-cooled→ 11.Produk setengah rampung inspeksi → 12. Pasivation → 13. Marking → 14. Packing → 15. Inspection → 16. Bobot / Panyimpenan → 17. Ujian Akhir

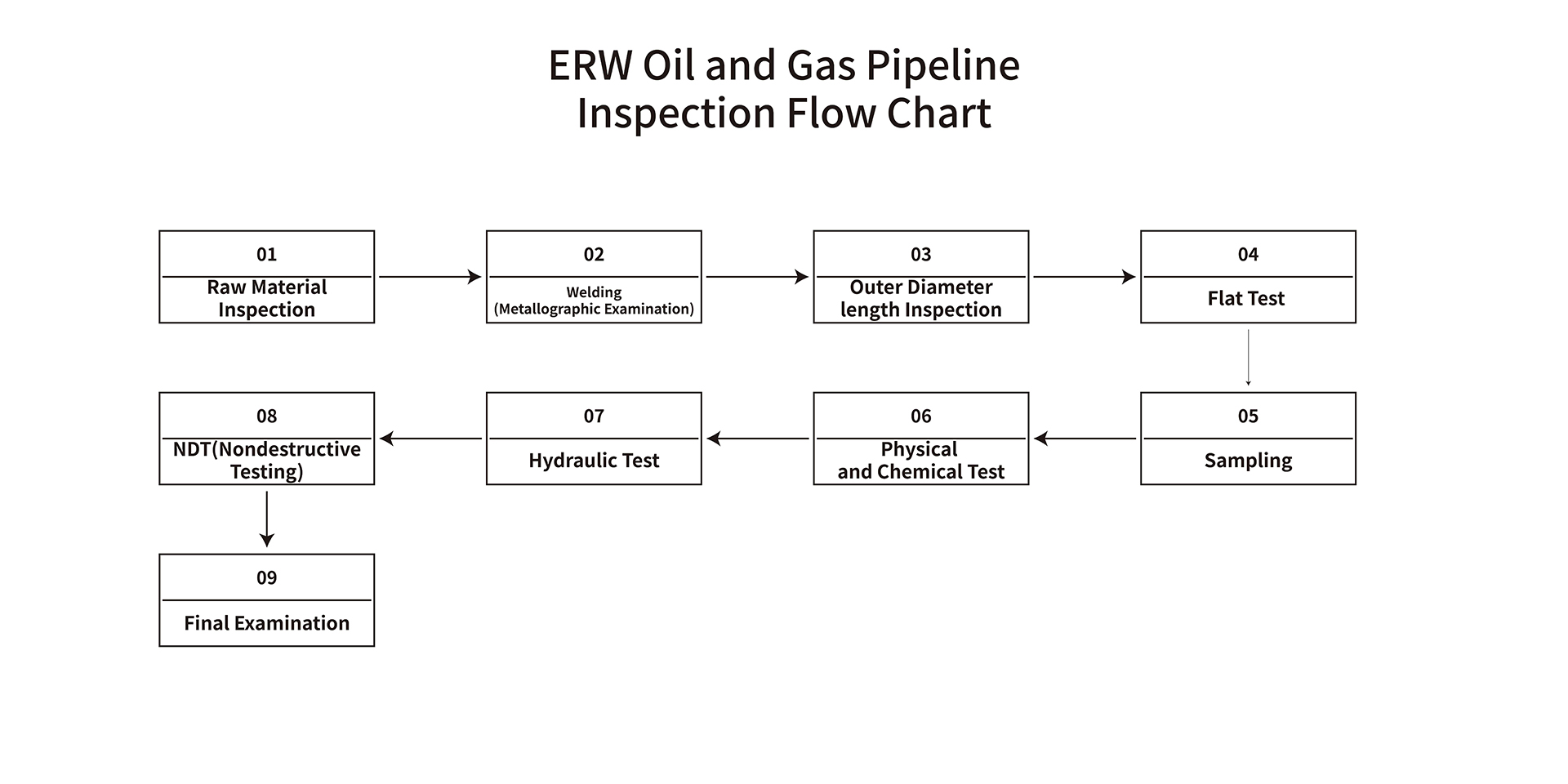

Pipa minyak lan gas ERW

Bagan Alur Inspeksi

01. Inspeksi bahan baku → 02. Welding (pemeriksaan Metalografi) → 03. Inspeksi dawa diameter njaba → 04. Tes datar → 05. Sampling → 06. Uji fisik lan kimia → 07. Uji hidrolik → 08. NDT (uji nondestruktif)→ 09. Ujian Akhir

Kita bakal nguji bahan mentah lan proses produksi miturut standar sing beda-beda kanggo mesthekake yen produk kasebut cocog karo standar utawa syarat kontrak.

01. Volume mbukak → 02. Koreksi / Potong pisanan / Welded → 03. Panyimpenan loop → 04. Sistem Figuration → 05. Welding / Copot jero lan njaba burr → 06. Welding jahitan perawatan panas → 07. Air-cooled / Water- digawe adhem / Nggawe diameter / Koreksi → 08. Potong gergaji mabur → 09. Eksterior inspeksi / Marking → 10. APlain end and bevel end → 11. Hydraulic test → 12. Ultrasonic inspection → 13. Pipe end Ultrasonic inspection → 14. Bobot / Rekam → 15. Lebokake ing panyimpenan

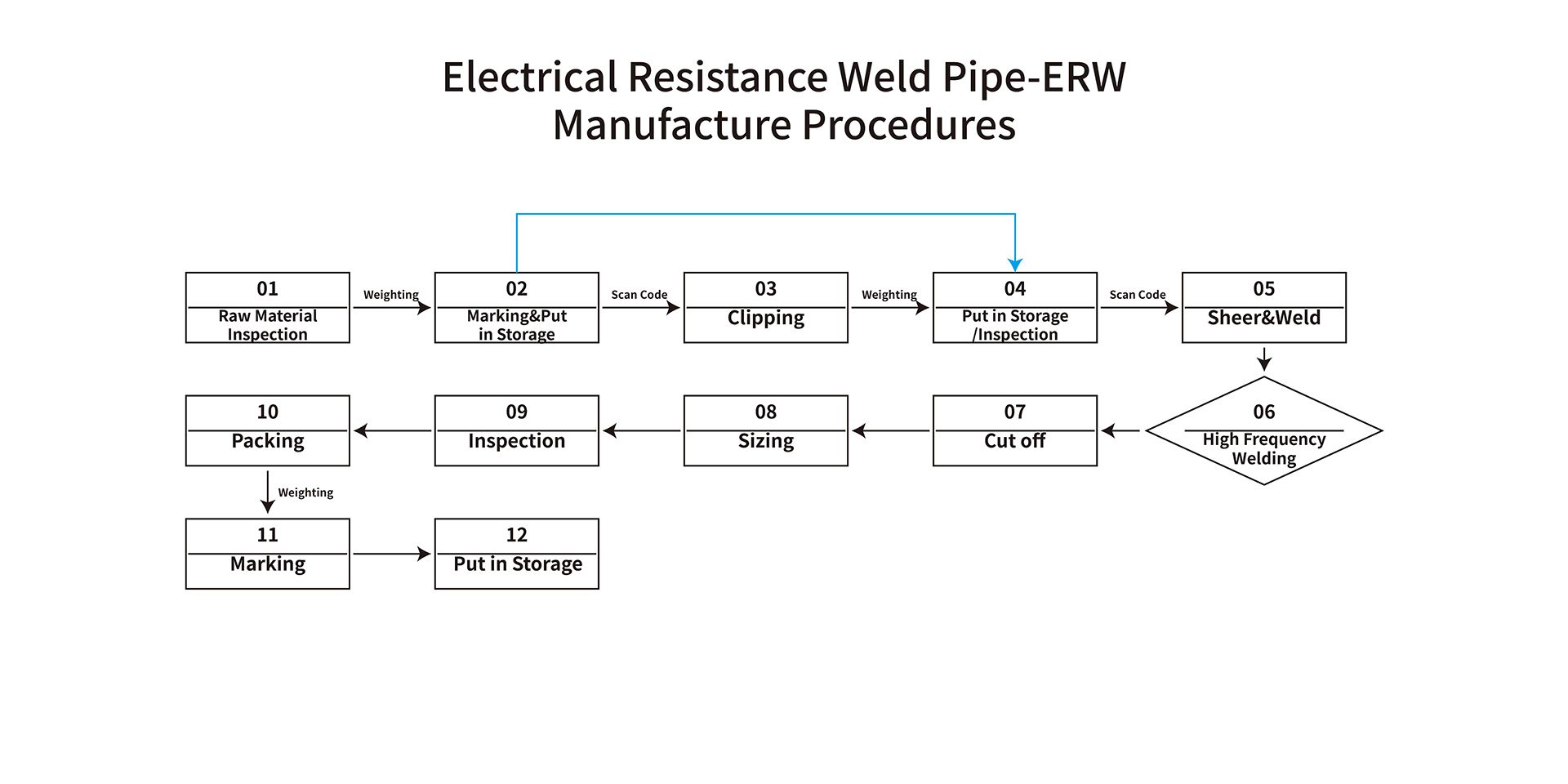

Resistansi Listrik Weld Pipe-ERW

Prosedur Produksi

01. Inspeksi bahan mentah→ 02. Marking & Lebokake ing panyimpenan → 03. clipping → 04. Lebokake ing panyimpenan / Inspection → 05. Sheer & Weld → 06. Tes fisik lan kimia → 07. Cut off → 08. Sizing → 09. Inspection → 10. Packing → 11. Bobot → 12. Scan kode

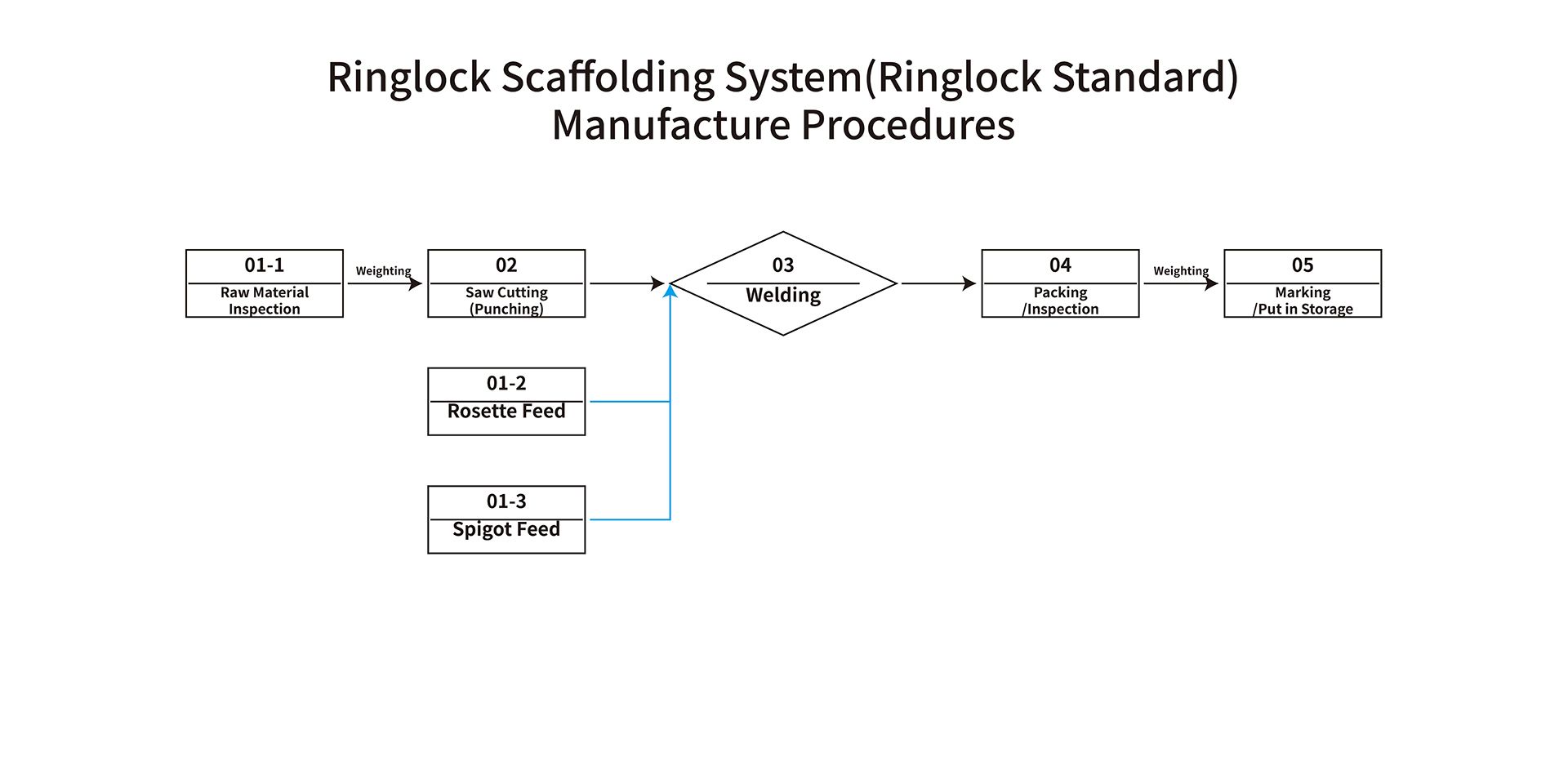

Sistem Perancah Ringlock (Standar Ringlock)

Prosedur Produksi

01. Inspeksi bahan mentah→ 02. Saw cutting (punching) / Rosette feed / Spigot feed → 03. Welding → 04. Packing / inspection → 05. Marking / Lebokake ing panyimpenan

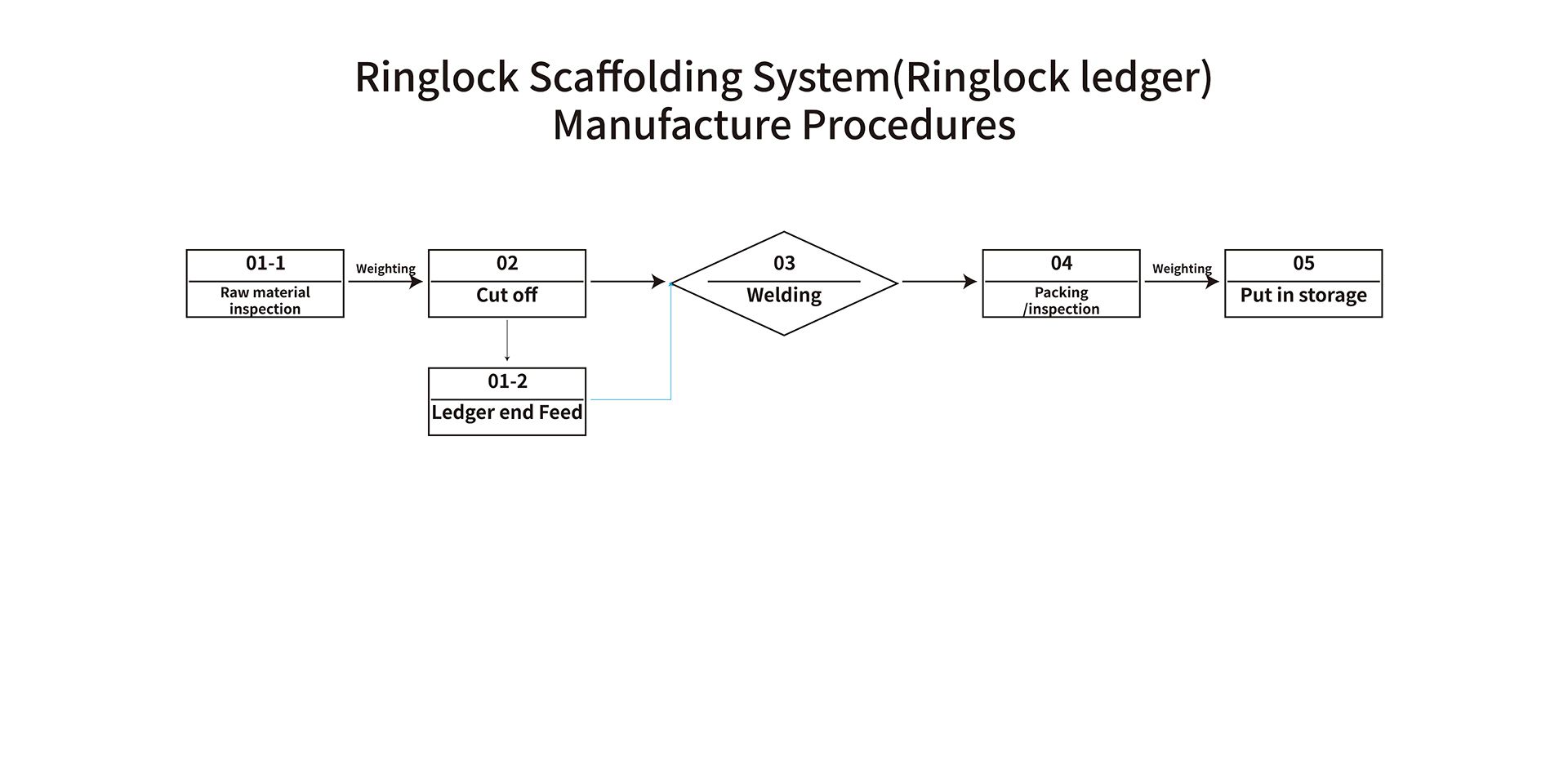

Ringlock Scaffolding System (Ringlock Ledger)

Prosedur Produksi

01. Inspeksi bahan baku → 02. Cut off / Ledger end Feed → 03. Welding → 04. Packing / inspection → 05. Marking / Lebokake ing panyimpenan

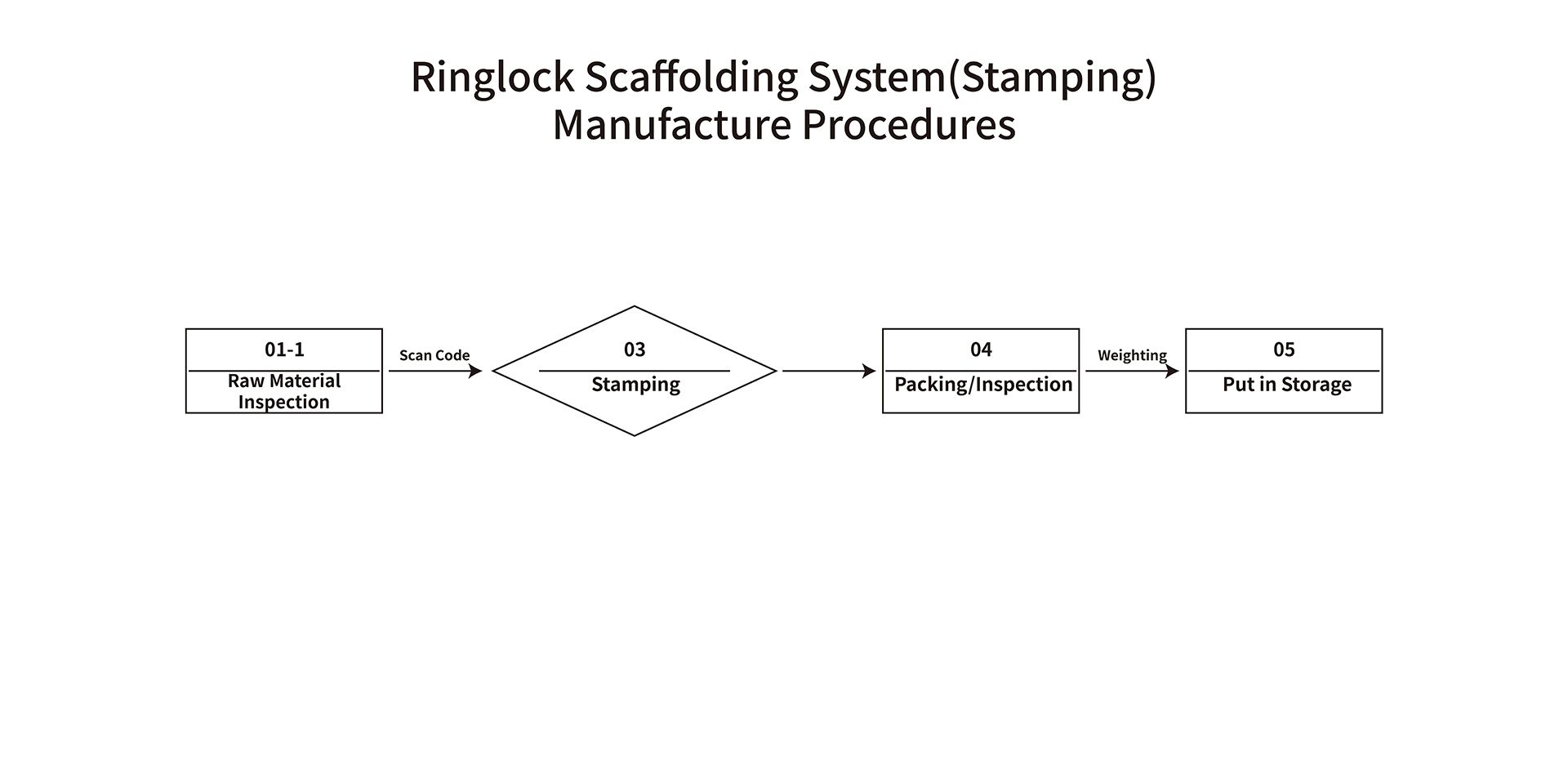

Sistem Scaffolding Ringlock (Stamping)

Prosedur Produksi

01. Inspeksi bahan baku → 02. Stamping → 03. Pengemasan / Inspeksi → 04. Lebokake ing panyimpenan

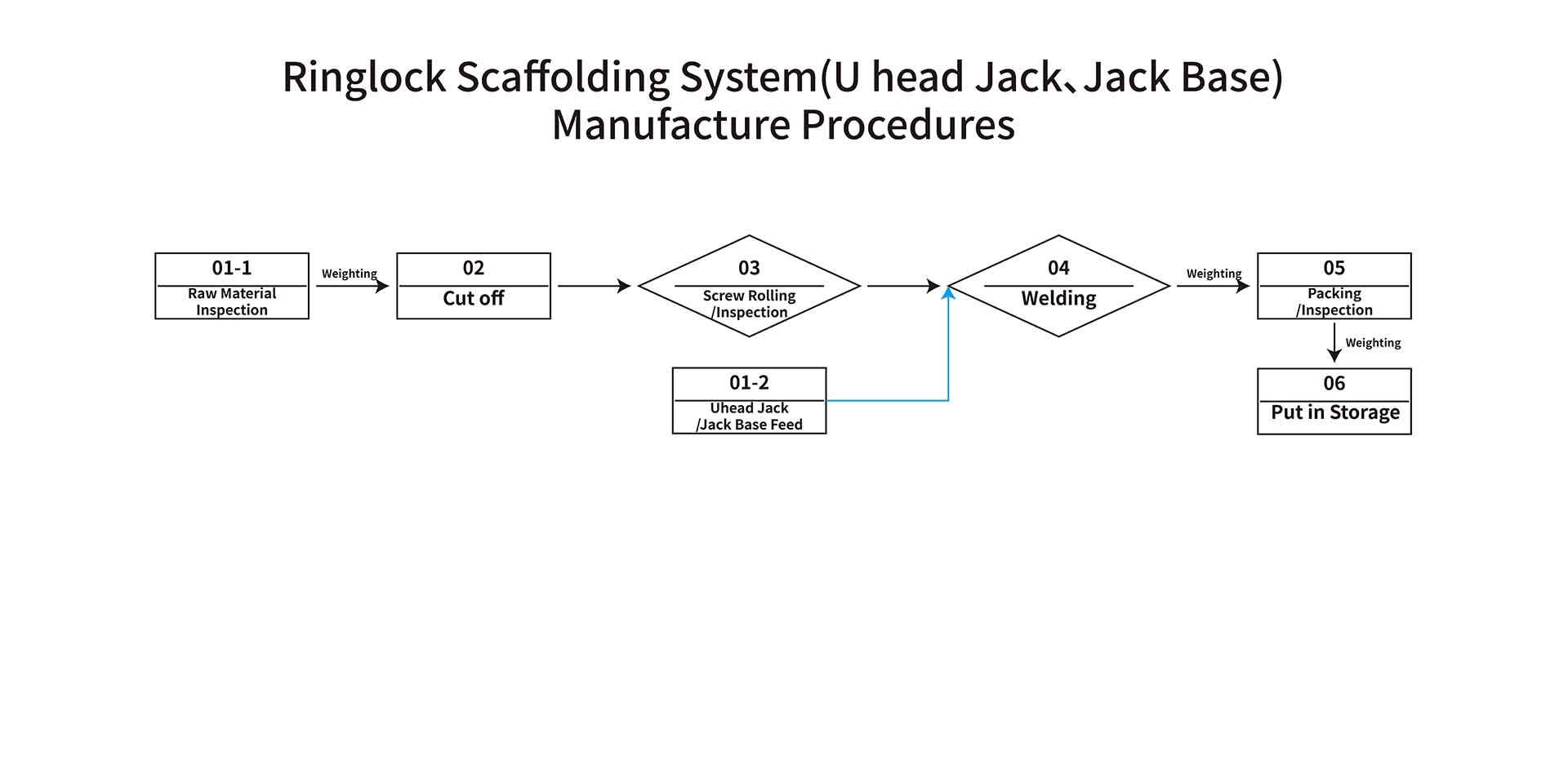

Ringlock Scaffolding System (U head jack, jack base)

Prosedur Produksi

01. Inspeksi bahan mentahan → 02. Cut off → 03. Screw rolling / Inspection / Uhead jack / jack base feed → 04. Welding → 05. Packing / inspection → 06. Lebokake ing panyimpenan

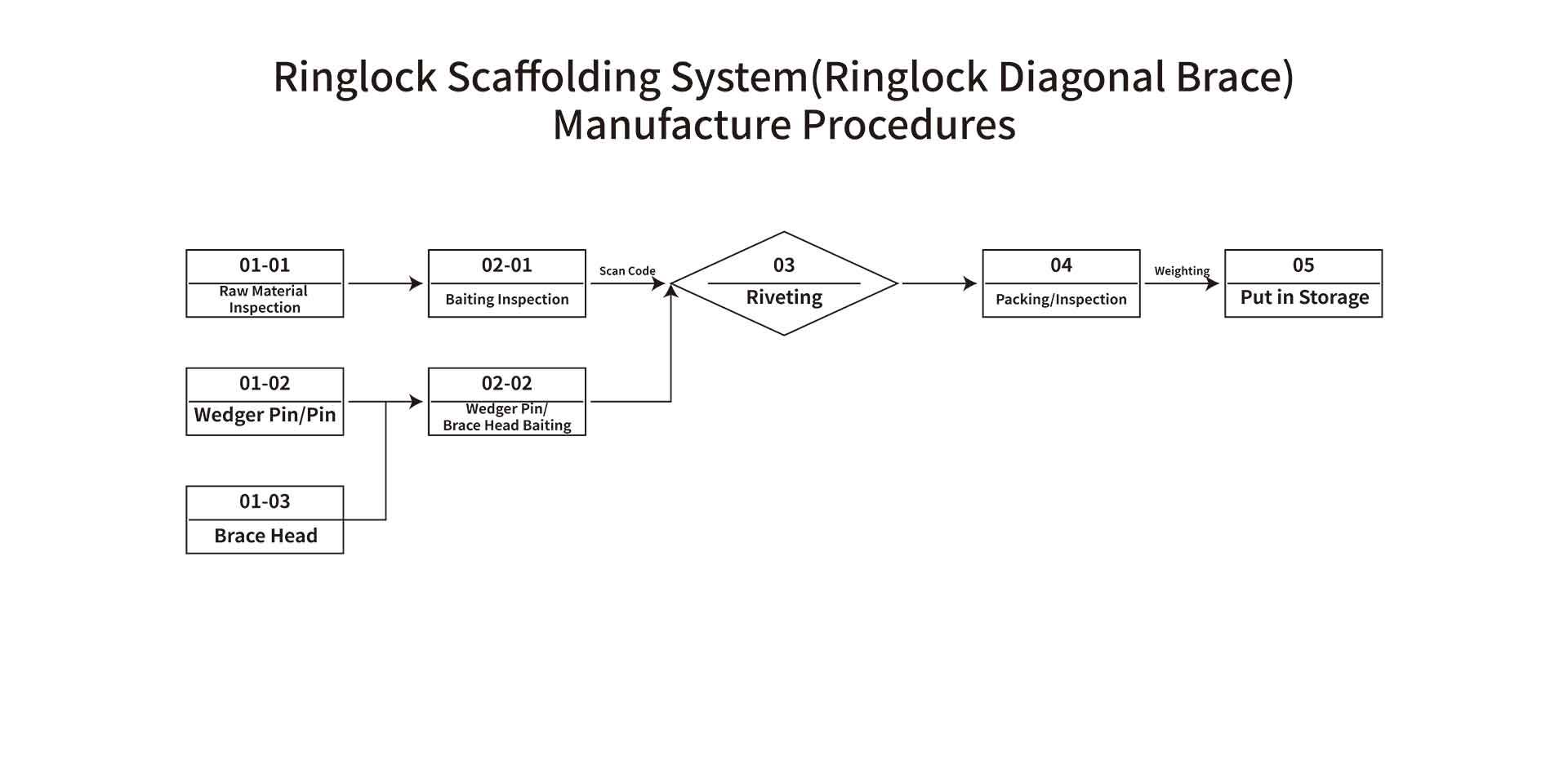

Ringlock Scaffolding System (Ringlock diagonal brace)

Prosedur Produksi

01. Inspeksi bahan baku/Wedger pin/Pin/Brace head→02.Baiting inspection/edger pin/Brace head baiting→03.Welding→04.Packing/inspection→05.Simpenan