Produktioun Prozess Flow an Inspektioun Flow

Mat iwwer 9000 héichqualifizéierten Mataarbechter an 293 fortgeschratt Produktiounslinnen iwwer 13 Fabriken verdeelt, hu mir 2022 20 Milliounen Tonnen Stolleitungen produzéiert, an de Verkafsbetrag huet iwwer 160 Milliounen US Dollar am Joer 2018. Fir 17 Joer hannereneen ass Youfa ënner TOP 500 Entreprisen an der China Fabrikatioun Industrie zënter 2006.

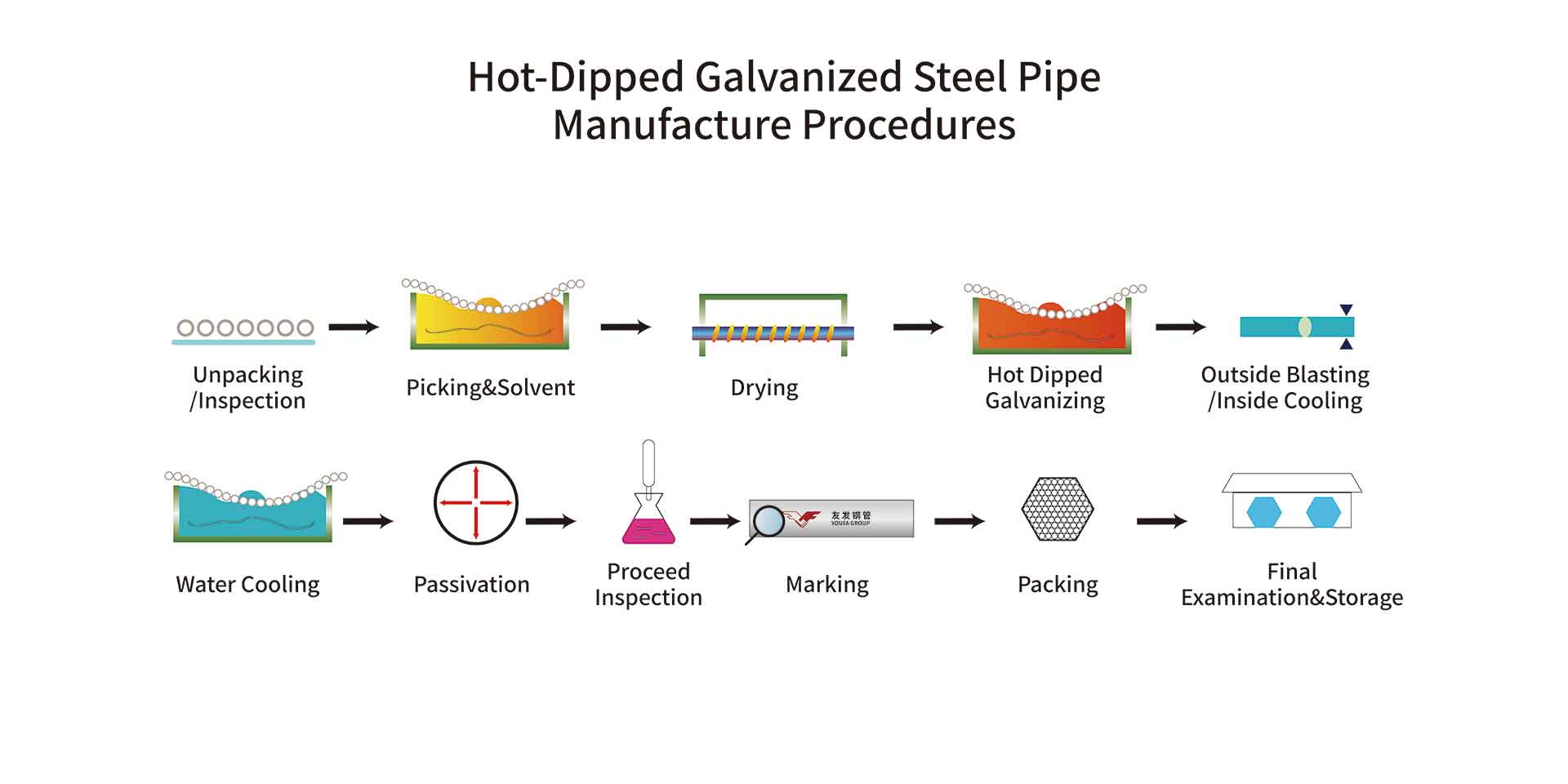

Hot-Dipped galvanized Stol Pipe

Fabrikatioun Prozeduren

01.Unpacking/Inspection→02.Picking&Solvent→03.Drying→04.Shot-dipped galvanizing→05.Aussen Sprengung/Bannen ofkillen→06.Waasserkühlen→07.Passivatioun→08.Virufueren Inspektioun→09.Markéierung→10.Packing→ 11.Finale Ënnersichung & Stockage

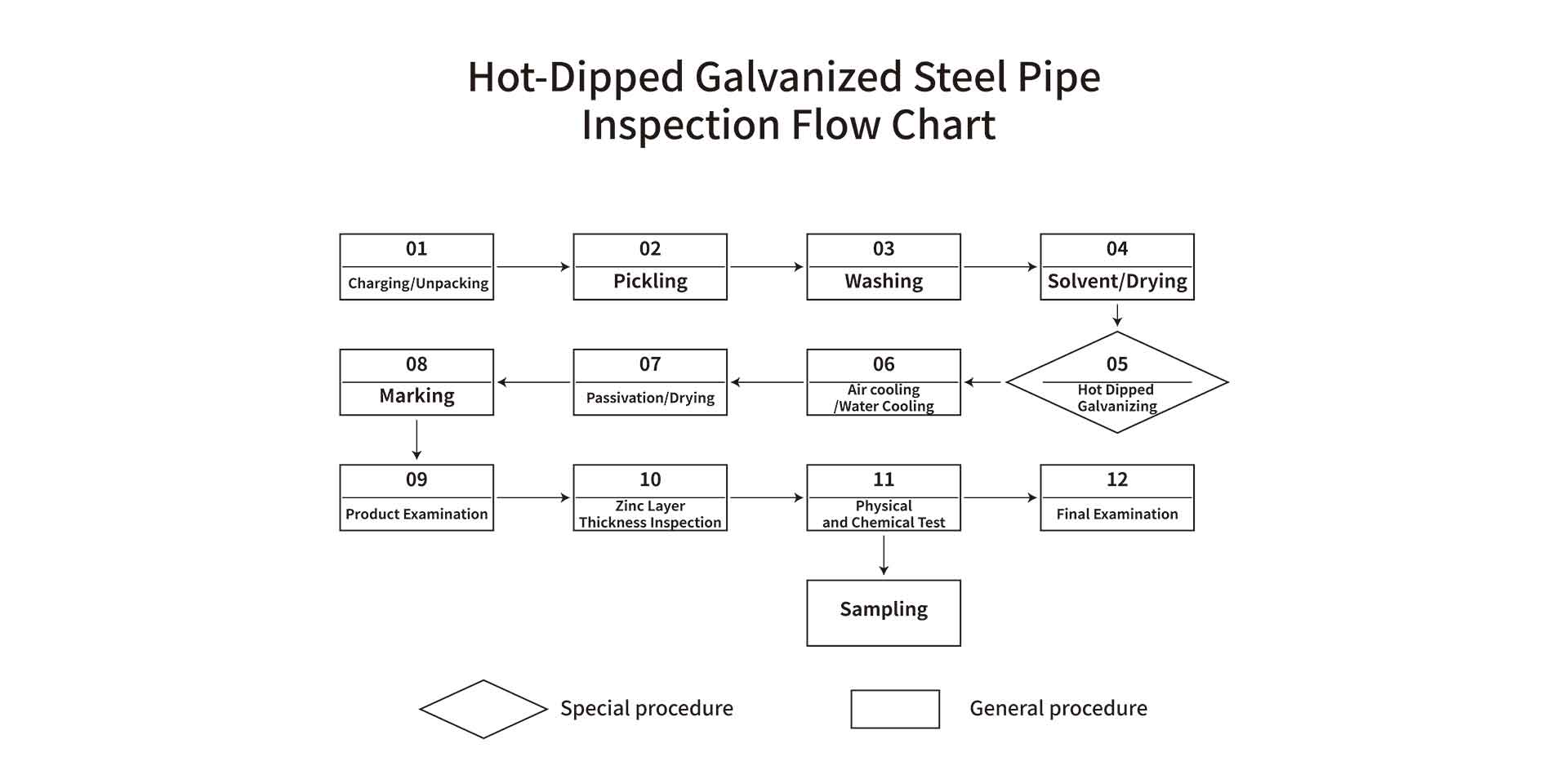

Hot-Dipped galvanized Stol Pipe

Inspektioun Flow Chart

01.Charging/Upacking→02.Pickling→03.Washing→04.Solvent/Drying→05.Warm-Tipped Galvanizing→06.Air cooling/Water Cooling→07.Passivation/Drying→08.Marking→09.Product Examen→10 .Zink Schichtdicke Inspektioun→11.Physikalesch a chemesch Test→12.Finale Examen

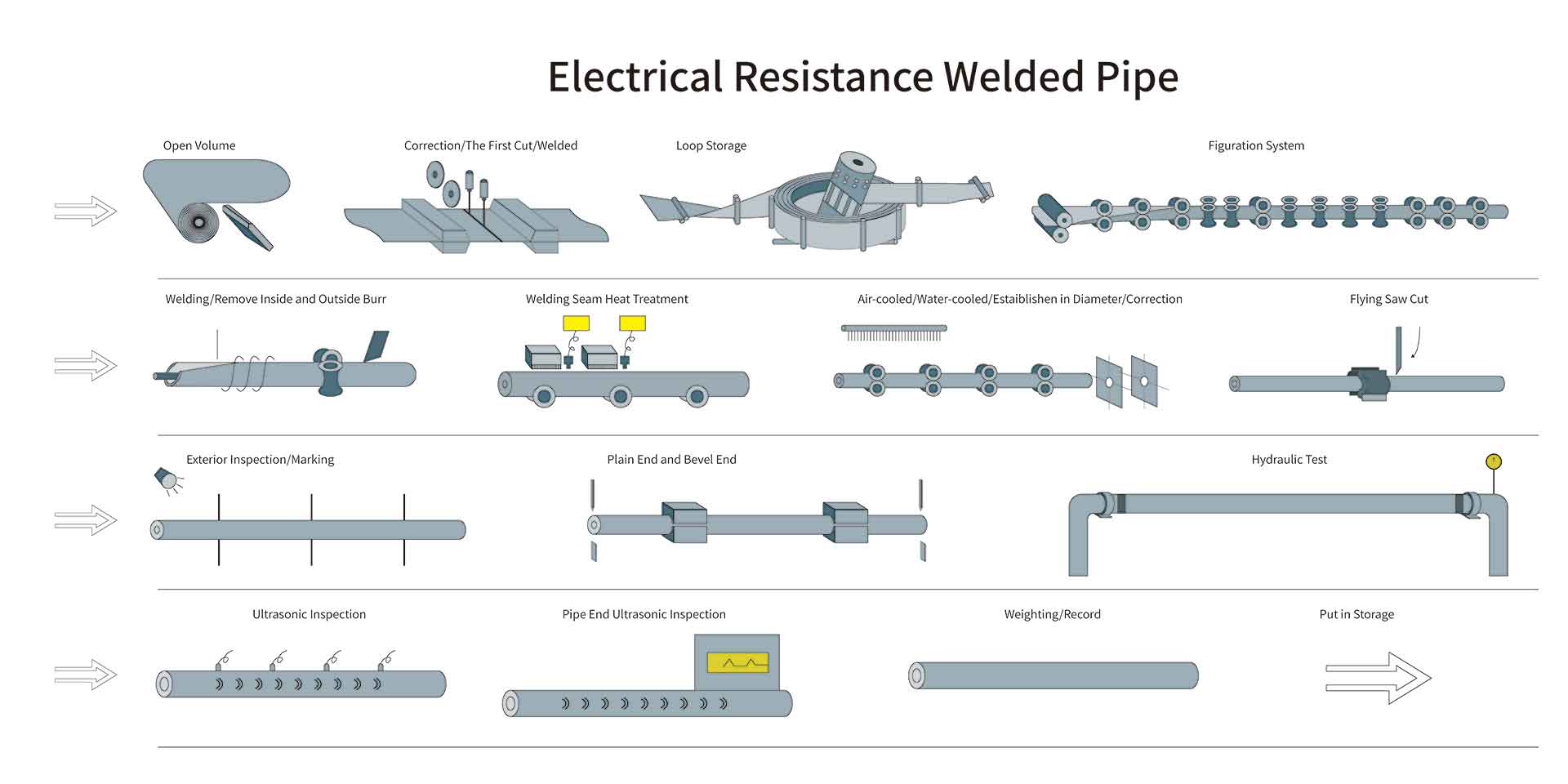

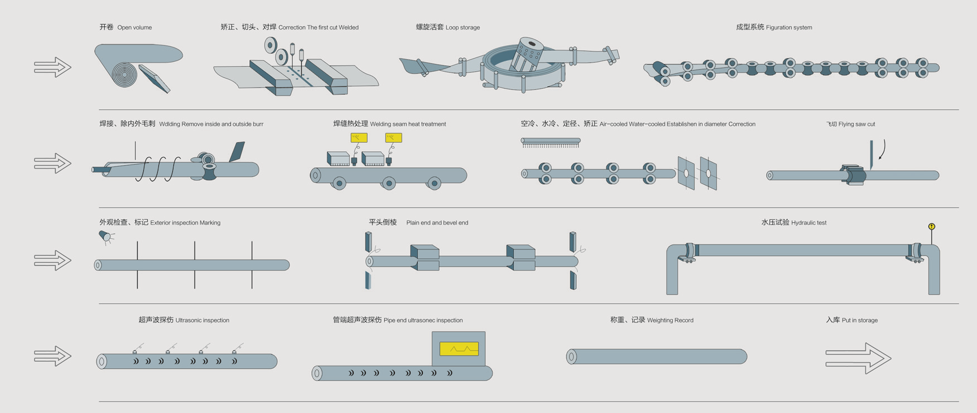

Elektresch Resistenz Weld Pipe-ERW

Fabrikatioun Prozeduren

01.Open Volume→02.Correction/The first cut/Welded→03.Loop storage→04.Figuration system→05.Welding/Remove inside and outside burr→06.Welding seam heat treatment→07.Air-cooled/Water- gekillt/Duerchmiesser festleeën/Korrektur→08.Fléiensäge geschnidden→09.Exterieur Inspection/Marking→10.Plain end and bevel end→11.Hydraulic test→12.Ultrasonic Inspection→13.Pipe end Ultrasonic Inspection→14.Weighting/Record→15.Put in storage

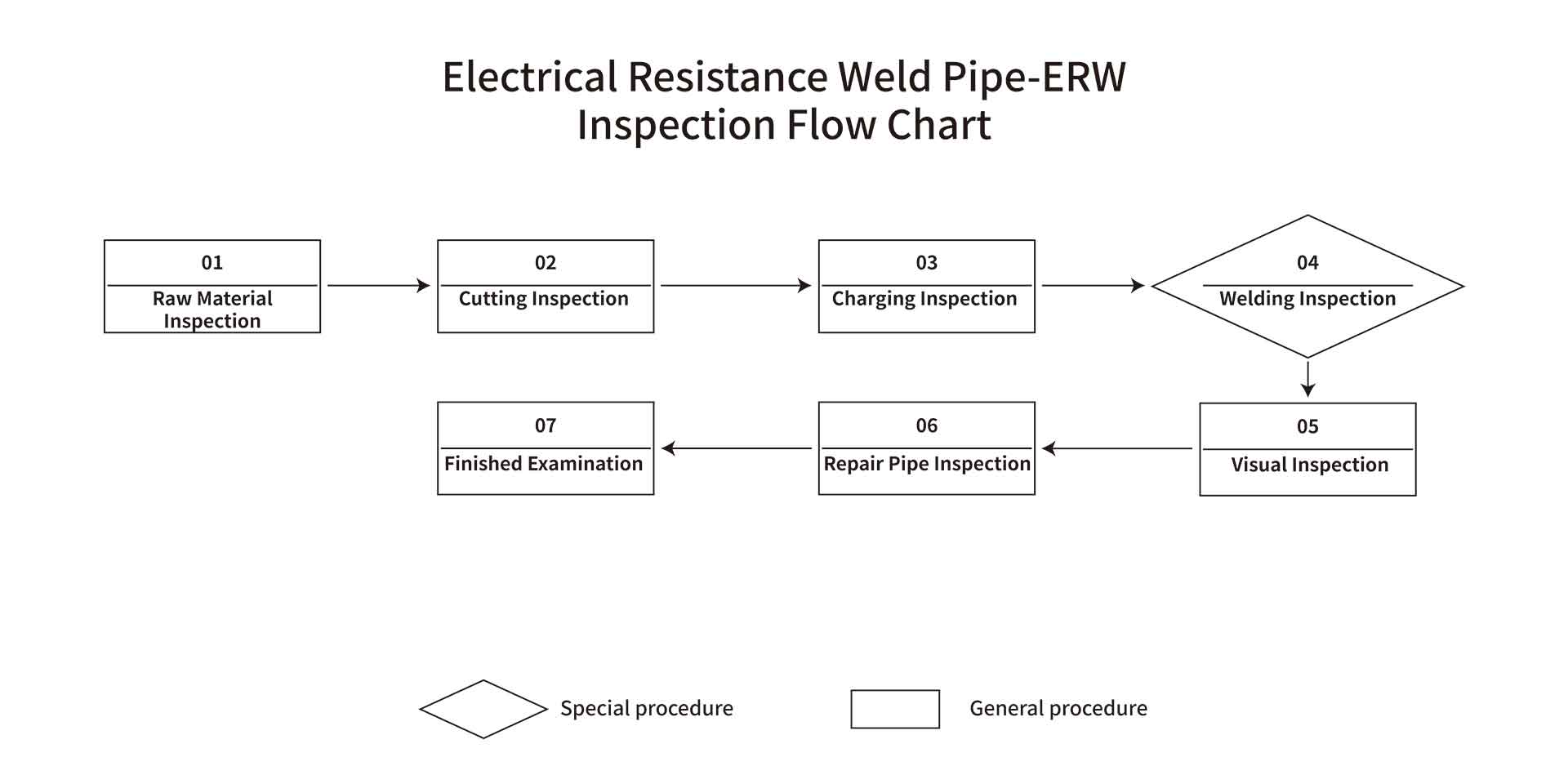

Elektresch Resistenz Weld Pipe-ERW

Inspektioun Flow Chart

01. Raw Material Inspection →02.Cutting Inspection →03.Charging Inspection →04.Welding Inspection→05.Visual Inspection→06.Repair Pipe Inspection →07.Finished Examen

Mir testen Matière première a Produktiounsprozesser no verschiddene Standarden fir sécherzestellen datt d'Produkter d'Standarden oder Kontraktfuerderunge entspriechen.

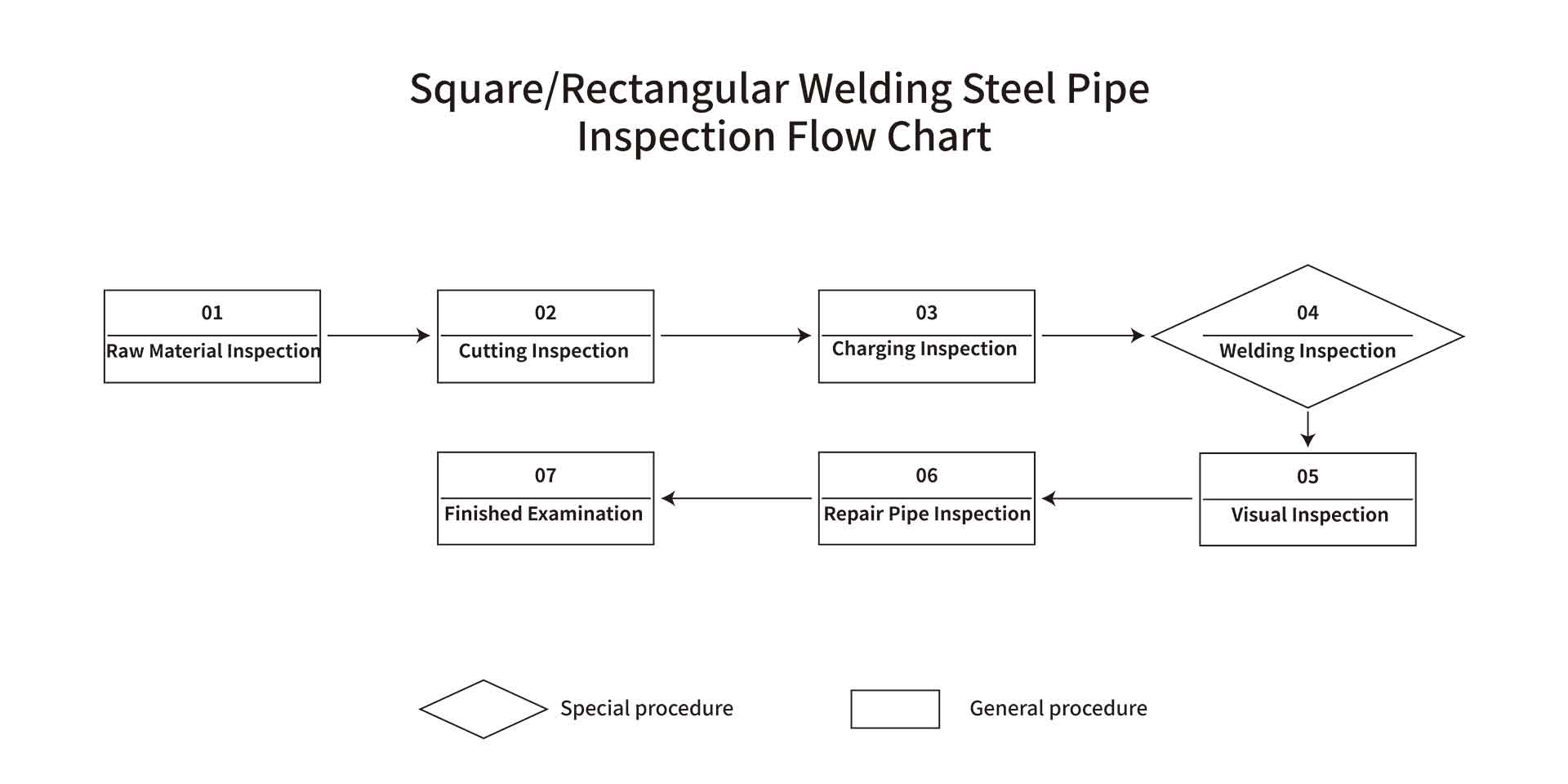

Square / véiereckege Schweess Steel Pipe

Inspektioun Flow Chart

01. Raw Material Inspection →02.Cutting Inspection →03.Charging Inspection →04.Welding Inspection→05.Visual Inspection→06.Repair Pipe Inspection →07.Finished Examen

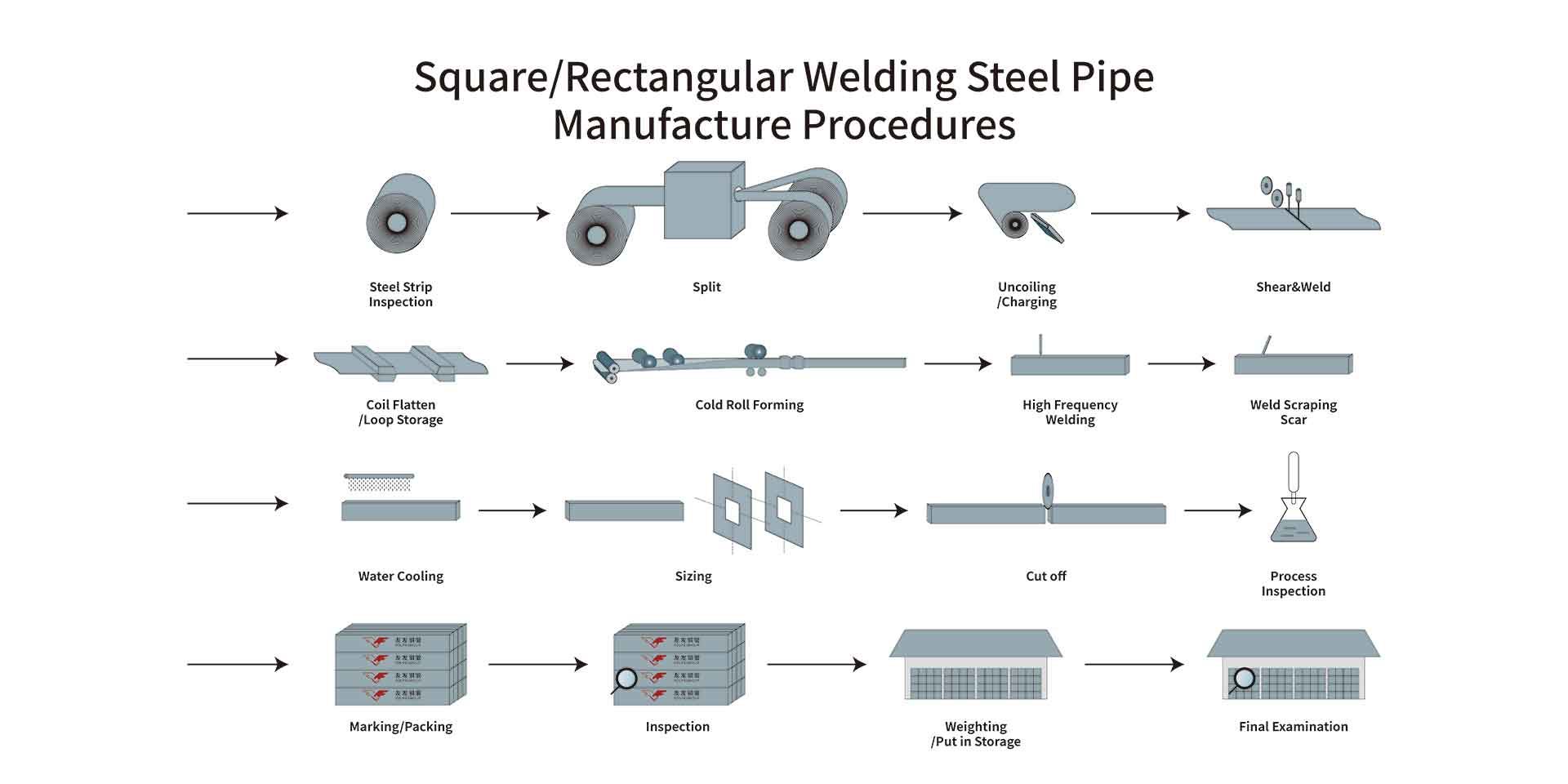

Square / véiereckege Schweess Steel Pipe

Fabrikatioun Prozeduren

01. Stol Sträif Inspektioun → 02. Split → 03. Uncoiling / Charging → 04. Schéier & Schweess → 05. Coil Flatten / Loop Stockage → 06. Kale Rouleau Formatioun → 07. Héich Frequenz Schweess → 08. Weld scraping Narben → 09. Waasser Ofkillung →10.Gréisst→11.Ausschneiden→12.Prozess Inspection→13.Marking/Packing→14.Inspection→15.Weighting/Set in storage→16.Final Examen

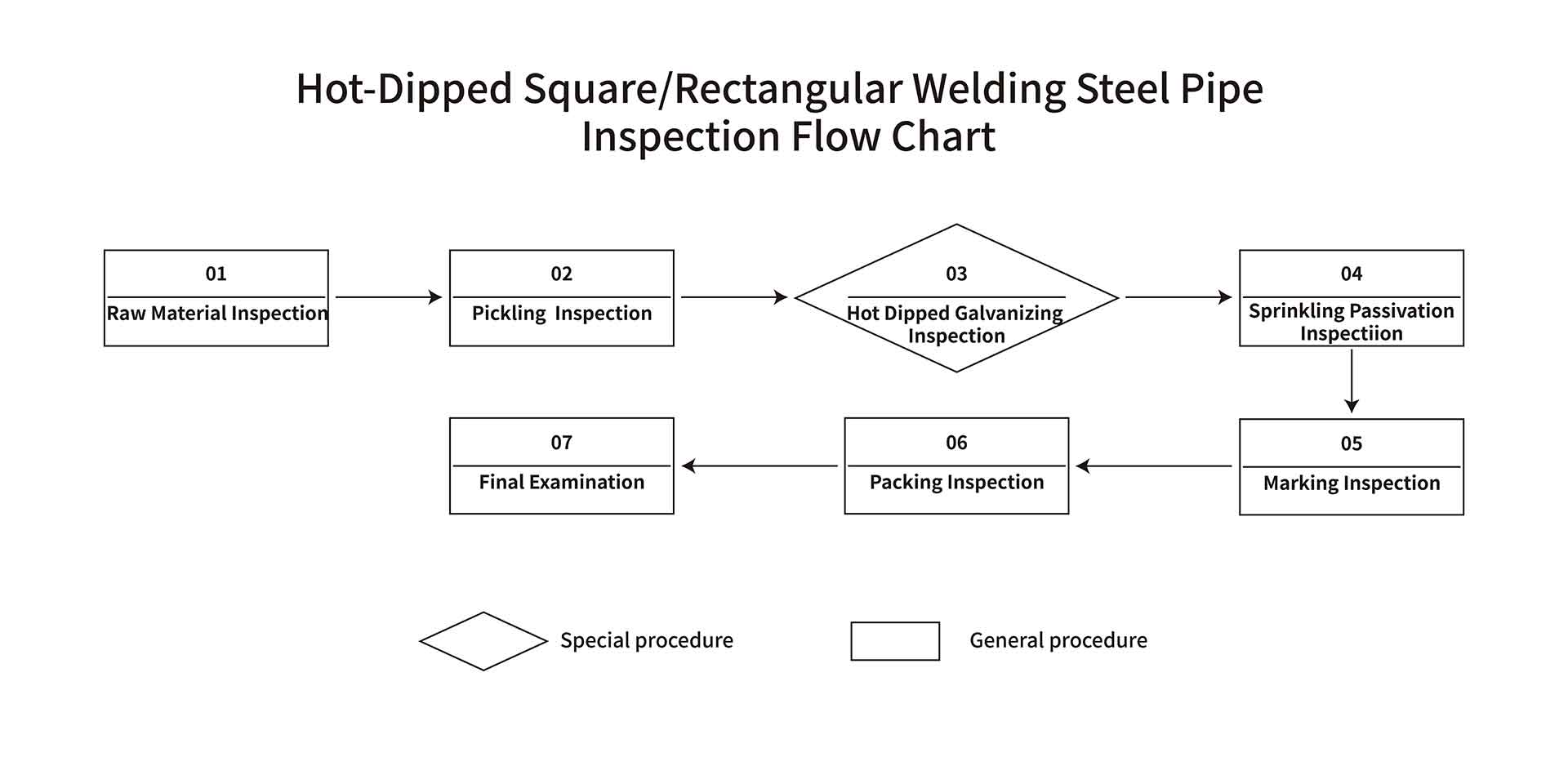

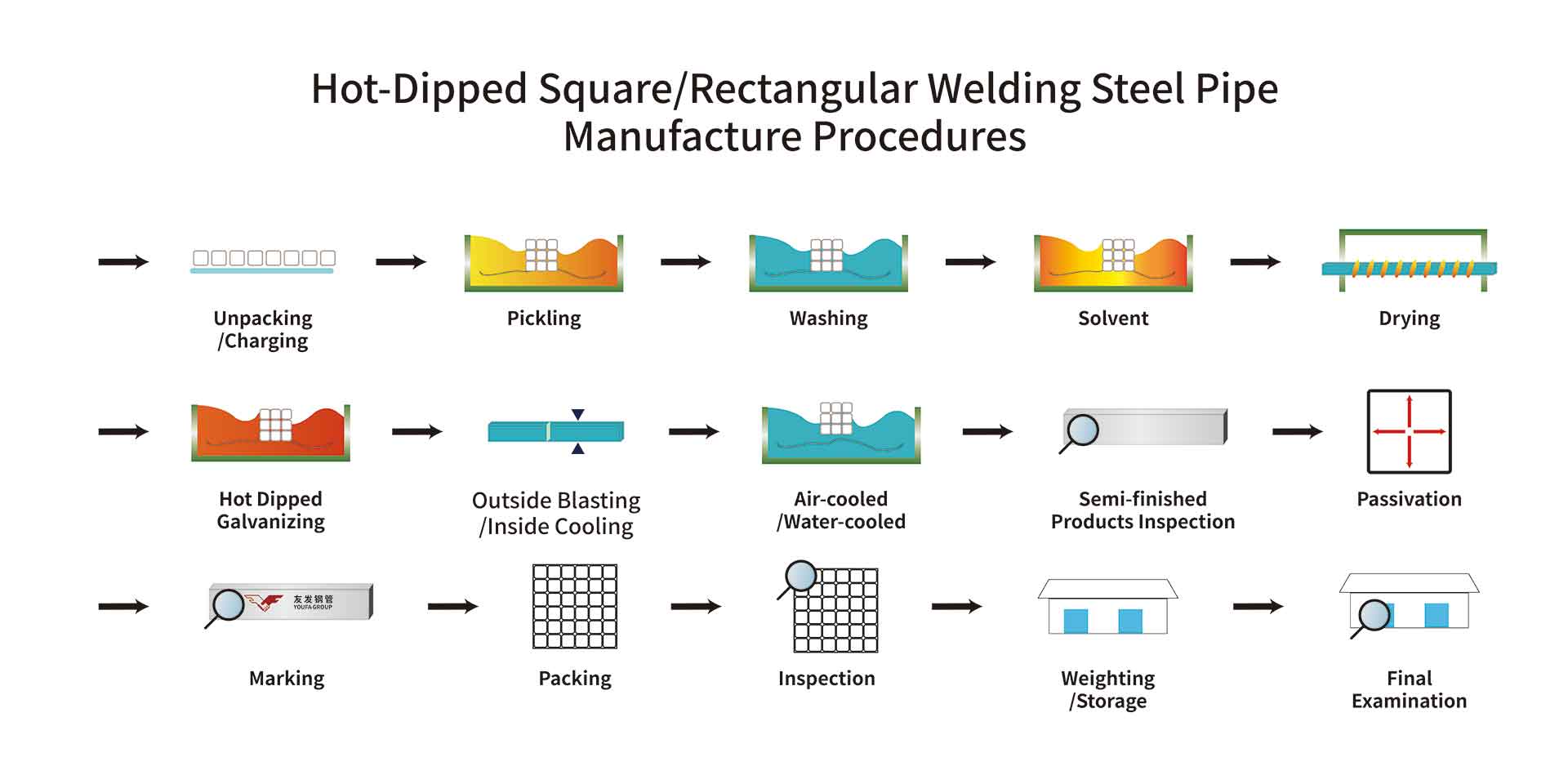

Hot-Dipped Square / véiereckege Schweess Steel Pipe

Inspektioun Flow Chart

01. Raq Material Inspection→02.Pickling Inspection→03.Hot Dipped Galvanizing Inspection→04.Sprinkling Passivation Inspectiion→05.Marking Inspection→06.Packing Inspection→07.Final Examen

Mir testen Matière première a Produktiounsprozesser no verschiddene Standarden fir sécherzestellen datt d'Produkter d'Standarden oder Kontraktfuerderunge entspriechen.

Hot-Dipped Square / véiereckege Schweess Steel Pipe

Fabrikatioun Prozeduren

01.Schweißstahlpipe→02.Unpacken/Laden→03.Pickling→04.Washing→05.Solvent→06.Drying→07.Hot-Dipped Galvanizing→08.Aussen Sprengung→09.Bannenkühlen→10.Loftgekillt/ Waassergekillt→11.Halleffäerdeg Produkter Inspektioun→12.Passivatioun→13.Markéierung→14.Verpackung→15.Inspektioun→16.Gewiicht/Lagerung→17.Finale Examen

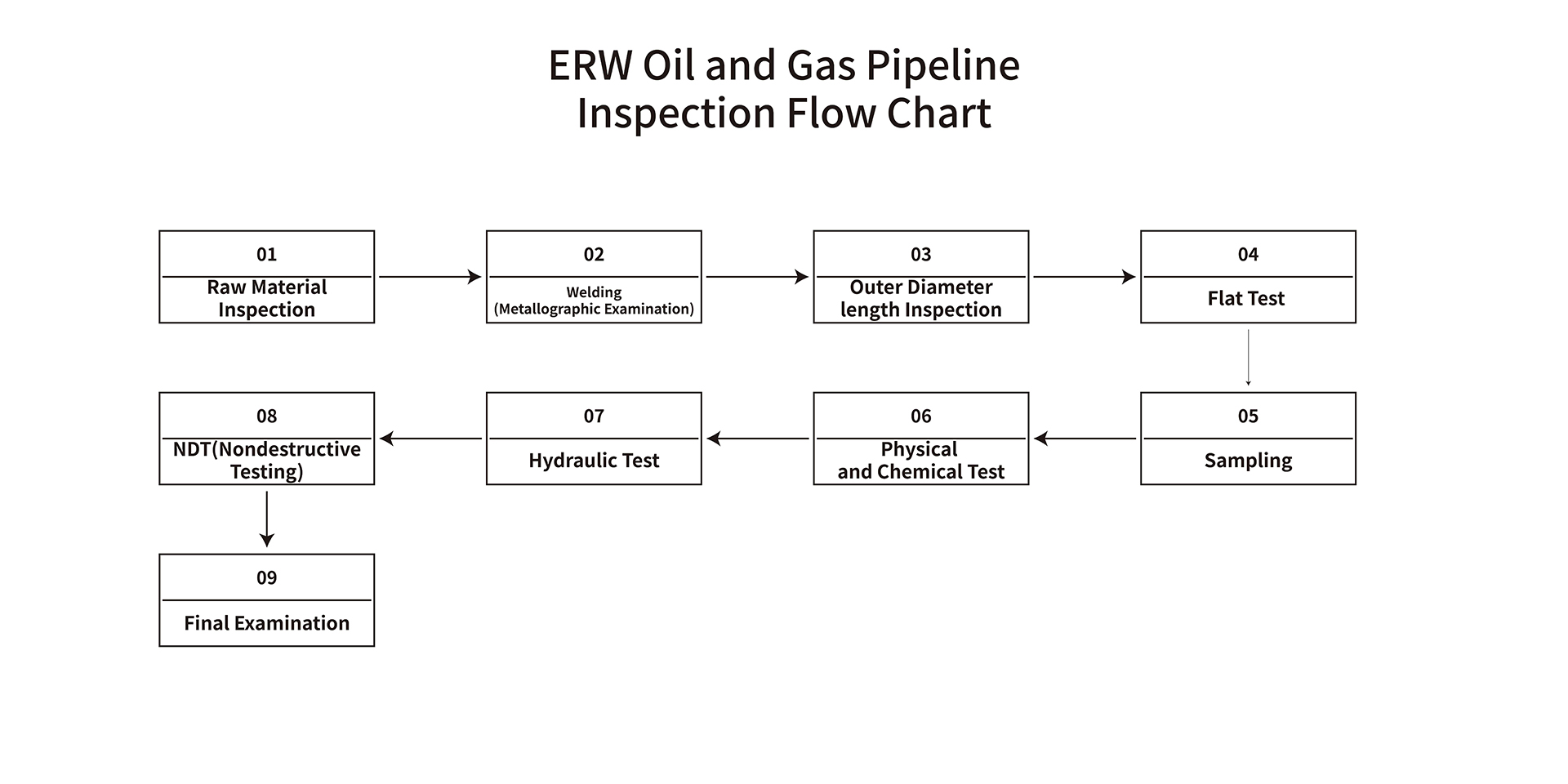

ERW Ueleg a Gas Pipeline

Inspektioun Flow Chart

01. Matière première Inspektioun→02.Schweißen(Metallographesch Untersuchung)→03.Outer Duerchmiesser Längt Inspektioun→04.Flat Test→05.Sampling→06.Physical and Chemical Test→07.Hydraulic test→08.NDT(nondestructive testing)→ 09.Finale Examen

Mir testen Matière première a Produktiounsprozesser no verschiddene Standarden fir sécherzestellen datt d'Produkter d'Standarden oder Kontraktfuerderunge entspriechen.

01.Open Volume→02.Correction/The first cut/Welded→03.Loop storage→04.Figuration system→05.Welding/Remove inside and outside burr→06.Welding seam heat treatment→07.Air-cooled/Water- gekillt/Duerchmiesser festleeën/Korrektur→08.Fléiensäge geschnidden→09.Exterieur Inspection/Marking→10.APlain end and bevel end→11.Hydraulic test→12.Ultrasonic Inspection→13.Pipe end Ultrasonic Inspection→14.Weighting/Record→15.Put in storage

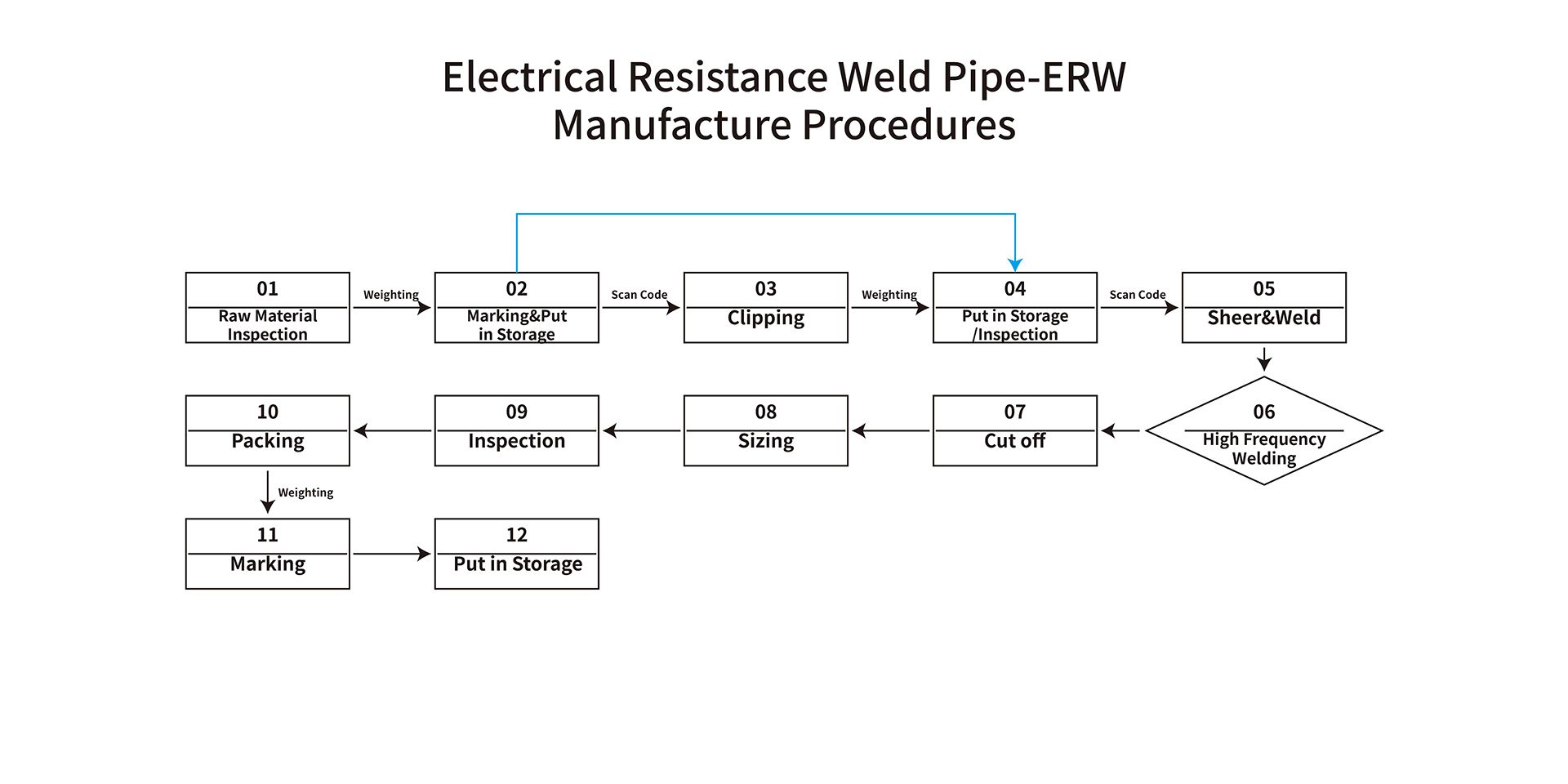

Elektresch Resistenz Weld Pipe-ERW

Fabrikatioun Prozeduren

01. Raw Material Inspection→02.Marking & Put in storage→03.clipping→04.Put in storage/Inspection→05.Sheer&Weld→06.Physical and Chemical Test→07.Cut off→08.Sizing→09.Inspection→10. Verpakung→11.Gewicht→12.Scan Coden

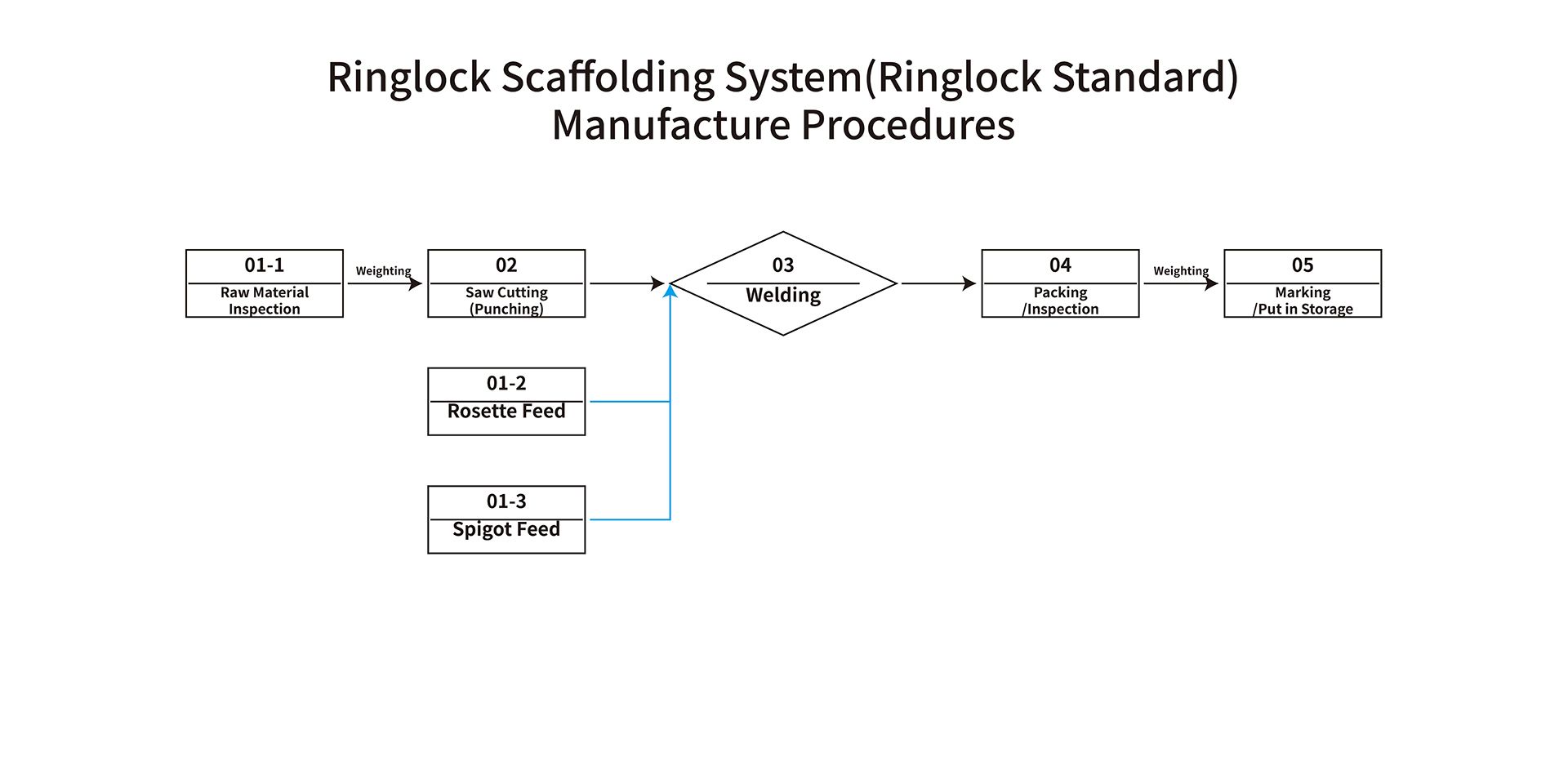

Ringlock Scaffolding System (Ringlock Standard)

Fabrikatioun Prozeduren

01.Raw Material Inspection→02.Saw cutting (punching)/Rosette feed/Spigot feed→03.Welding→04.Packing/Inspection→05.Marking/Put in storage

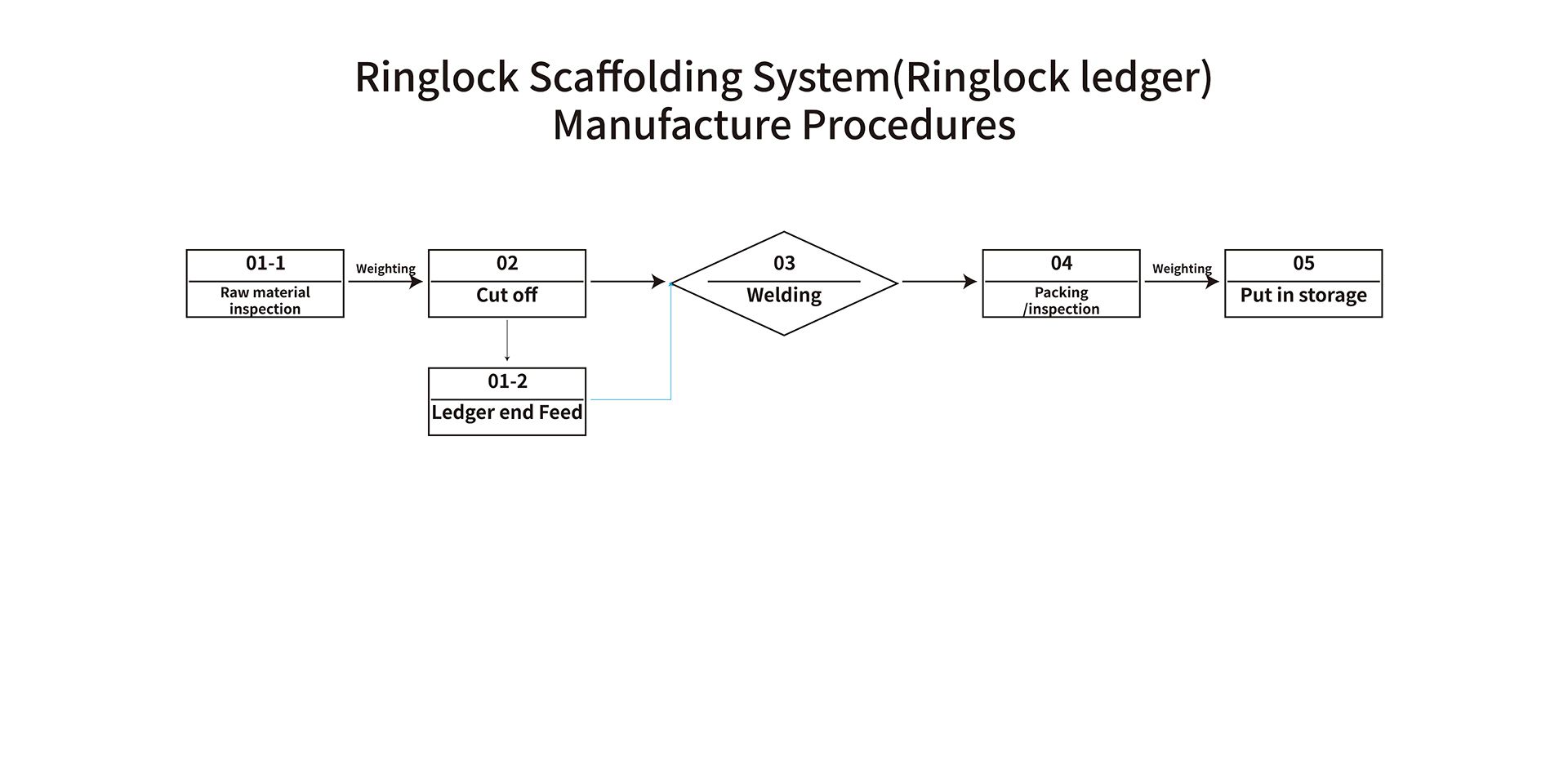

Ringlock Scaffolding System (Ringlock Ledger)

Fabrikatioun Prozeduren

01.Rohmaterialinspektioun→02.Ofschneiden/Ledger End Feed→03.Welding→04.Packing/Inspection→05.Marking/Put in storage

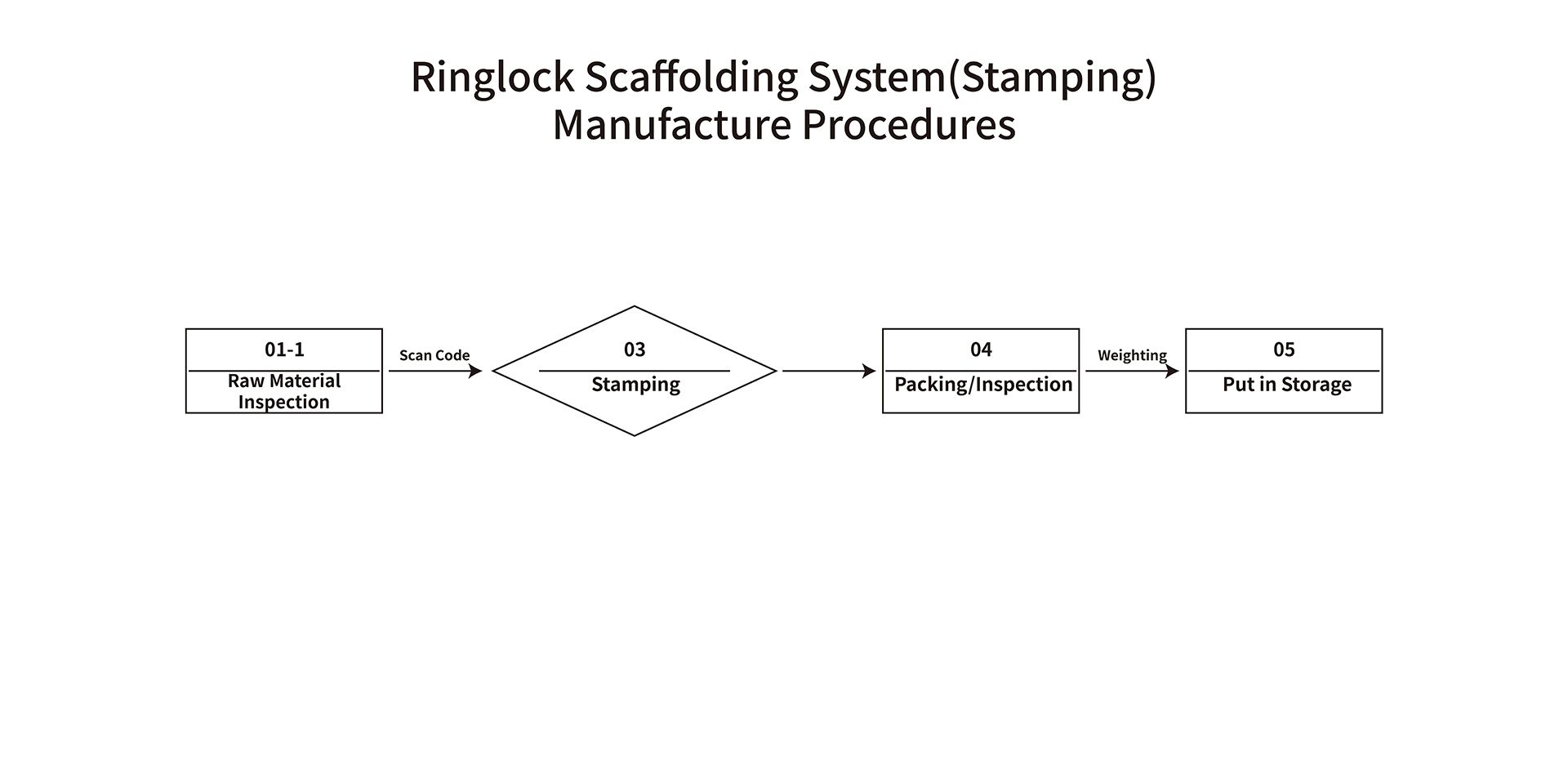

Ringlock Scaffolding System (Stamping)

Fabrikatioun Prozeduren

01.Raw Material Inspection→02.Stamping→03.Packing/Inspection→04.Put in storage

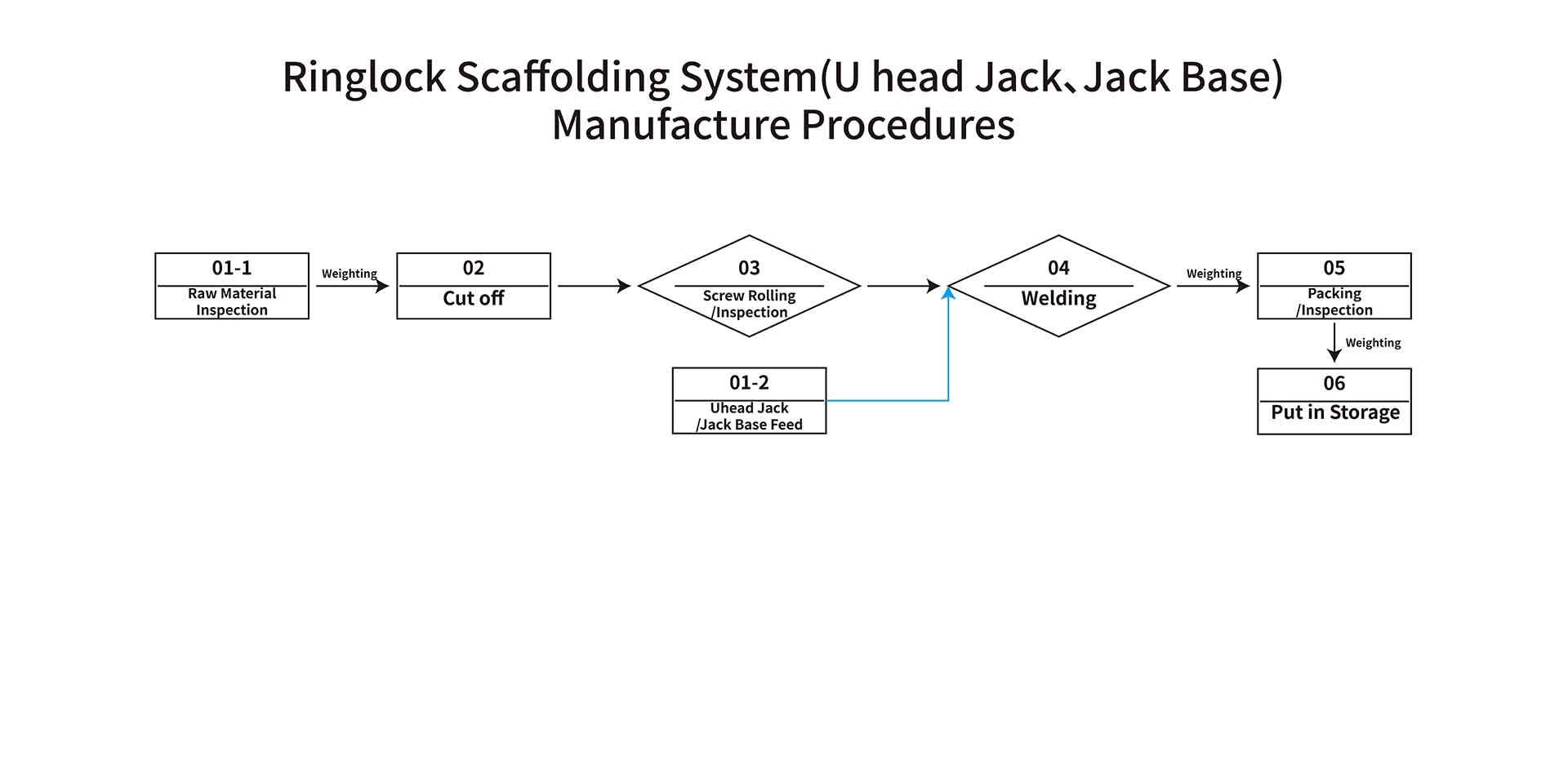

Ringlock Scaffolding System (U Kapp Jack, Jack Base)

Fabrikatioun Prozeduren

01.Raw Material Inspection→02.Cut off→03.Screw Rolling/Inspection/Uhead Jack/Jack base feed→04.Welding→05.Packing/Inspection→06.Put in storage

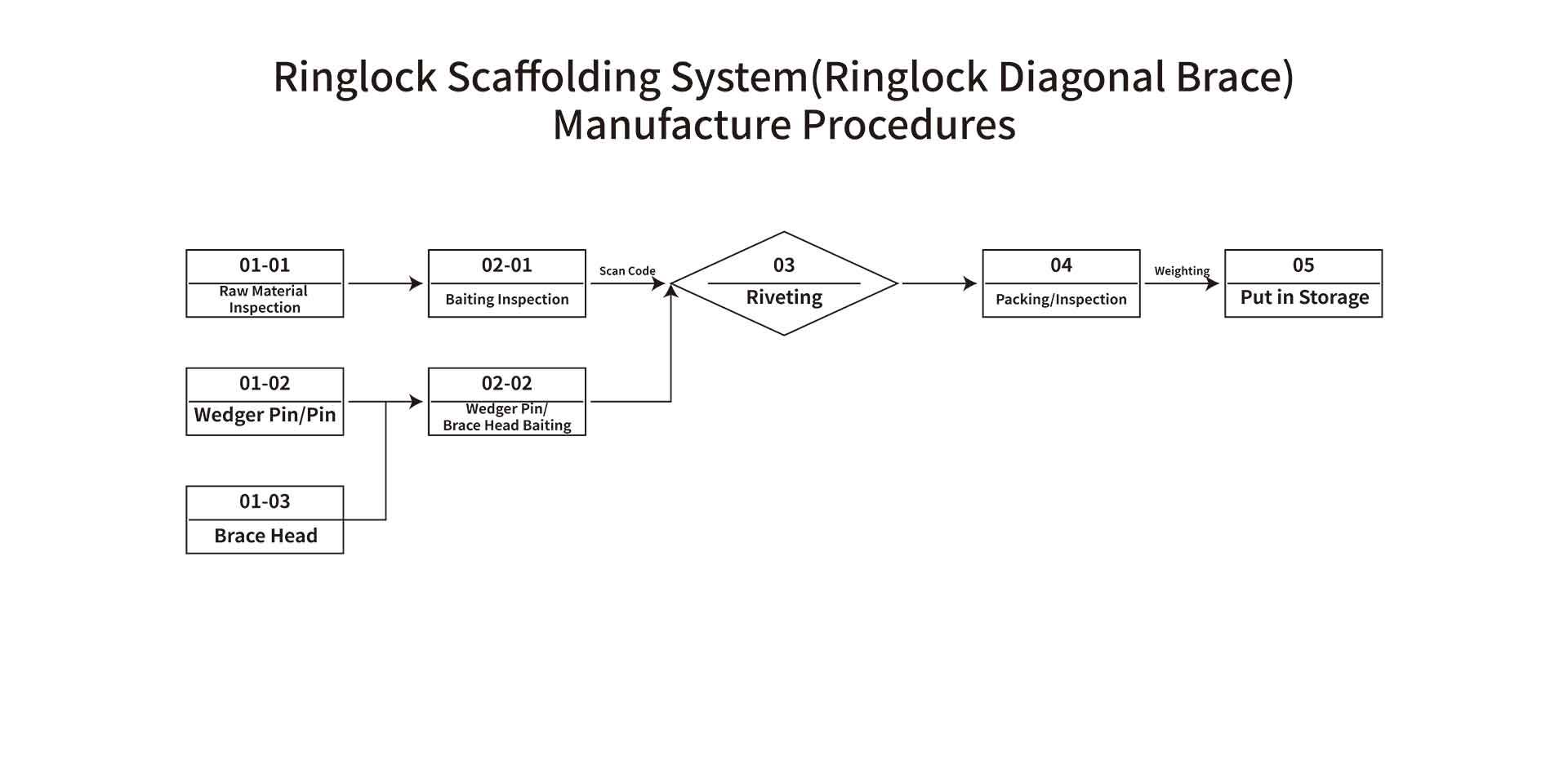

Ringlock Scaffolding System (Ringlock diagonal Brace)

Fabrikatioun Prozeduren

01.Rohmaterialinspektioun/Wedger Pin/Pin/Brace head→02.Baiting Inspection/edger pin/Brace head baiting→03.Welding→04.Packing/Inspection→05.Put in storage