Black iron pipes and galvanized pipes are two of the most common pipes used to transport liquids and gases. So, what is the difference between black pipe and galvanized pipe.

Corrosion Resistance

The main difference between black iron pipes and galvanized pipes is corrosion resistance.

Black iron pipe is manufactured using mild steel. It has a low-grade carbon content. The corrosion resistance of mild steel can be further strengthened through the addition of carbon.

On the other hand, galvanized pipes are covered with a protective layer of zinc. The process of adding a layer of zinc is called galvanization, which makes the pipes possess an ideal property of higher corrosion resistance.

Manufacturing Process

Another significant difference between black iron pipes and galvanized pipes is associated with their manufacturing processes. Black iron pipes are manufactured by stretching the steel out into a seamless tube or forcing the edges together and sealing them with a weld.

Hot-dip galvanized pipes are manufactured by black steel pipe and with zinc coating. The process involves acid washing the steel pipe to remove any rust or oxidation, cleaning it with a solution of ammonium chloride, zinc chloride, or a combination of both before immersion in a hot-dip galvanizing bath.

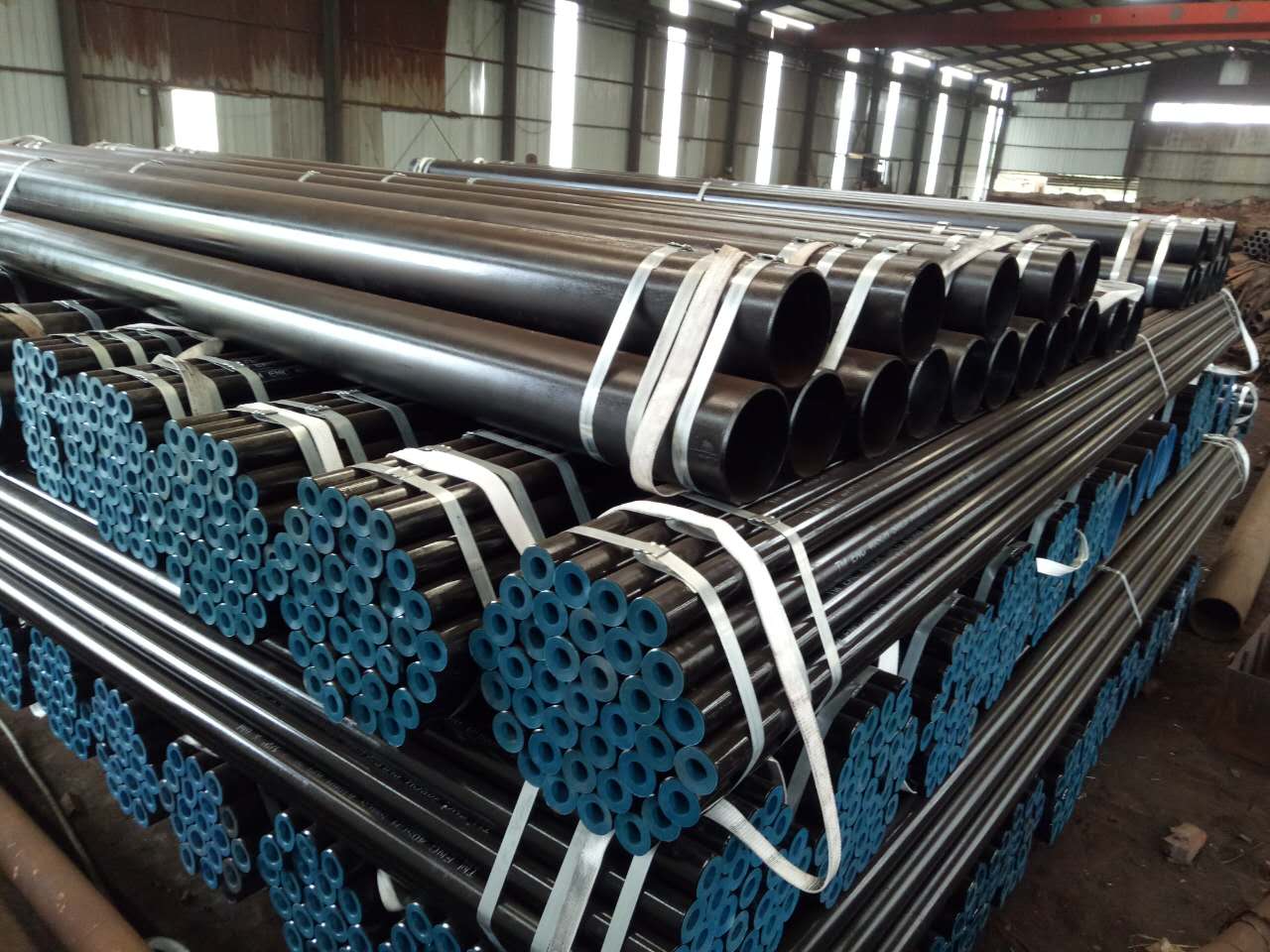

Appearance

Black iron pipes are darker compared to galvanized pipes. The iron oxide formed during manufacturing is what resulted in its gray appearance. Galvanized pipes appear silvery-white in color due to the galvanization. The zinc coating results in a smoother and higher quality finish.

Applications

Both types of pipes have distinct properties that are ideal for certain applications. The seamless feature of black iron pipes makes it the best and safe option for transporting natural and propane gas. The black welded steel pipe is not only cheaper, but also good choice for delivery natural gas and also used for fire sprinkler systems.

Black iron pipes are known to corrode from water easily. This is why mainly use galvanized pipe for carrying water. Due to its ability to resist corrosion, it can also be utilized for countless outdoor and industrial applications. Its applications can include outdoor railings, scaffolding frames, fences, sewage plumbing, road signage, and farm irrigation.

Durability

While it’s true that steel is already a relatively durable material, galvanized pipes have better strength due to the protective zinc coating.

Zinc coating increases galvanized pipes life expectancy for up to 40 or 50 years.

On the other hand, black iron pipes are uncoated and therefore less durable. In addition, water does corrode this type of pipe fairly easily.

Cost

Black iron pipes are less costly than galvanized pipes. This is due to the absence of zinc coating. Instead, black iron pipes are covered in iron oxide during the manufacturing process. Consider choosing black iron pipes over galvanized pipes if you have a budget in mind and if durability is not your primary consideration.

The final decision should depend on what the project requires.

Post time: Dec-27-2024