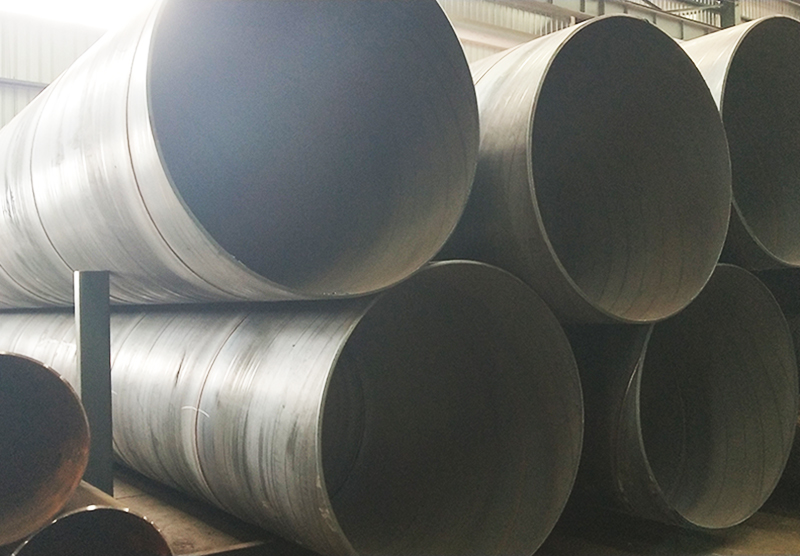

Spiral Welded Steel Pipes Manufacturing Process

Material Selection:

Steel Coils: High-quality steel coils are selected, typically made from low-carbon or medium-carbon steel, to meet required mechanical properties and chemical composition.

Uncoiling and Slitting:

Uncoiling: The steel coils are uncoiled and flattened into a sheet form.

Slitting: The flattened steel is slit into strips of the required width. The width of the strip determines the diameter of the final pipe.

Forming:

Spiral Formation: The steel strip is fed through a series of rollers that gradually form it into a spiral shape. The edges of the strip are brought together in a helical pattern to form a pipe.

Welding:

Submerged Arc Welding (SAW): The spiral seam of the pipe is welded using the submerged arc welding process. This involves the use of an electric arc and a granular flux, which provides a strong, high-quality weld with minimal spatter.

Weld Seam Inspection: The weld seam is inspected for quality using non-destructive testing methods such as ultrasonic or radiographic testing.

Sizing and Shaping:

Sizing Mills: The welded pipe passes through sizing mills to achieve the precise diameter and roundness required.

Expansion: Hydraulic or mechanical expansion may be used to ensure uniform pipe dimensions and to enhance material properties.

Non-Destructive Testing:

Ultrasonic Testing (UT): Used to detect internal defects in the weld seam.

Hydrostatic Testing: Each pipe is subjected to hydrostatic pressure testing to ensure it can handle the operating pressures without leaking.

Finishing:

Beveling: The ends of the pipes are beveled to prepare for welding at the installation site.

Surface Treatment: Pipes may receive surface treatments such as cleaning, coating, or galvanizing to enhance corrosion resistance.

Inspection and Quality Control:

Dimensional Inspection: The pipes are checked for compliance with diameter, wall thickness, and length specifications.

Mechanical Testing: Pipes are tested for tensile strength, yield strength, elongation, and toughness to ensure they meet required standards.

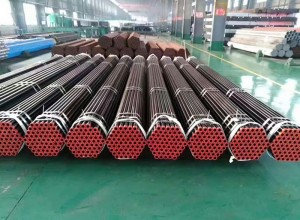

Marking and Packaging:

Marking: Pipes are marked with important information such as the manufacturer’s name, pipe specifications, grade, size, and heat number for traceability.

Packaging: Pipes are bundled and packaged according to customer requirements, ready for transportation and installation.

| Product | ASTM A252 Spiral Welded Steel Pipe | Specification |

| Material | Carbon Steel | OD 219-2020mm

Thickness: 7.0-20.0mm Length: 6-12m |

| Grade | Q235 = A53 Grade B / A500 Grade A

Q345 = A500 Grade B Grade C |

|

| Standard | GB/T9711-2011API 5L, ASTM A53, A36, ASTM A252 | Application: |

| Surface | 3PE or FBE | Oil, line pipe

Water delivery pipe Pipe Pile |

| Ends | Plain ends or Beveled ends | |

| with or without caps |

Strict Quality Control:

1) During and after production, 4 QC staffs with more than 5 years experience inspect products in random.

2) National accredited laboratory with CNAS certificates

3) Acceptable inspection from third party appointed/paid by buyer, such as SGS, BV.

4) Approved by Malaysia, Indonesia, Singapore, Philippines, Australia, Peru and UK. We own UL /FM, ISO9001/18001, FPC certificates

About us:

Tianjin Youfa Steel Pipe Group Co., Ltd was founded on July 1st, 2000. There are totally about 8000 employees, 9 factories, 179 steel pipe production lines, 3 national accredited laboratory, and 1 Tianjin government accredited business technology center.

9 SSAW steel pipe production lines

Factories: Tianjin Youfa Pipeline Technology Co.,Ltd

Handan Youfa Steel Pipe Co.,Ltd;

Monthly Output: about 20000Tons