Kubuda Kwekuita Kuyerera uye Kuongorora Kuyerera

Tine vashandi vanopfuura 9000 vane hunyanzvi hwepamusoro uye mitsara yekugadzira 293 yepamusoro yakapararira mumafekitori gumi nematatu, takagadzira 20 miriyoni matani mapaipi esimbi muna 2022, uye mutengo wekutengesa unodarika 160 miriyoni US Dollars muna 2018. Kwemakore gumi nemanomwe akateedzana, Youfa yakanzi pakati peTOP 500 Enterprises muChina Manufacturing Indasitiri kubvira 2006.

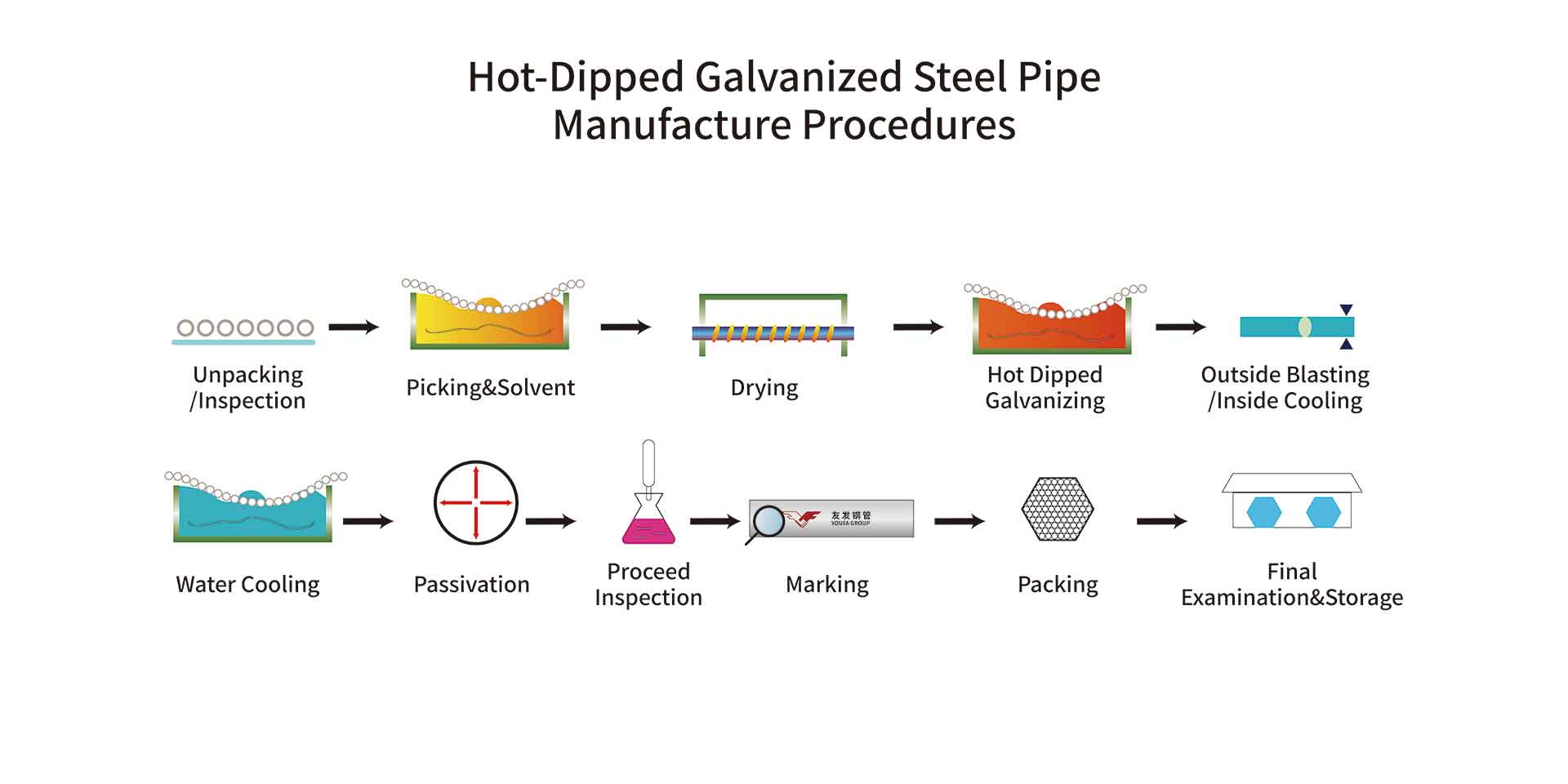

Pipe yeSimbi Inopisa Yakanyura

Maitiro ekugadzira

01.Kuburutsa/Kuongorora→02.Kunhonga&Solvent→03.Kuomesa→04.Bhoti rakanyudzwa rinopfuta→05.Kuputika kwekunze/kutonhora mukati→06.Kutonhodza kwemvura→07.Kufambisa→08.Ramba uchiongorora→09.Kumaka→10.Kurongedza→ 11.Kuongorora kwekupedzisira&Kuchengeta

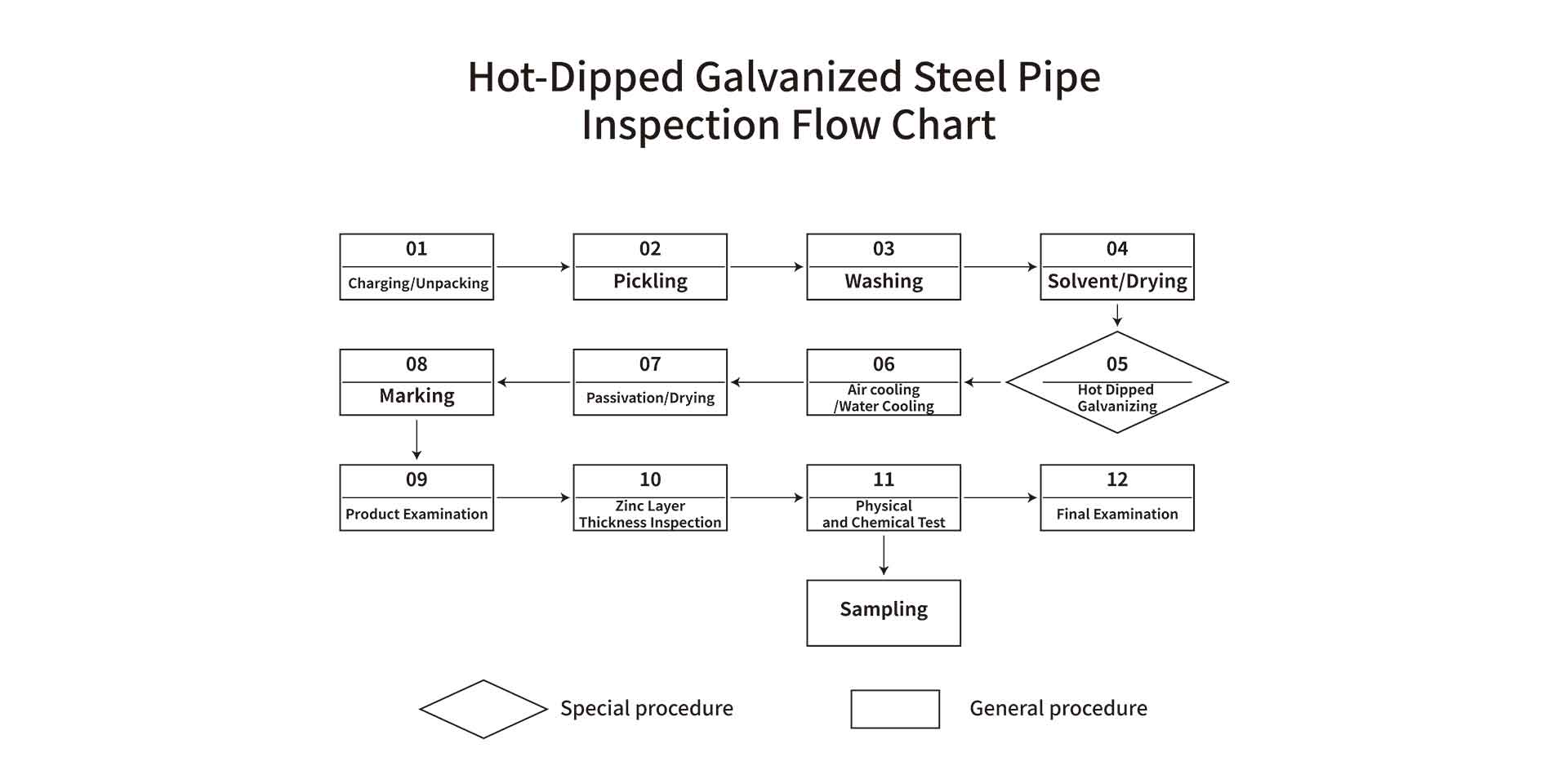

Pipe yeSimbi Inopisa Yakanyura

Inspection Flow chati

01.Kuchaja/Kuburutsa →02.Pickling→03.Kuwacha→04.Solvent/Drying→05.Kupisa kunyudzwa kwemarara→06.Kutonhodza mhepo/Kutonhodza nemvura→07.Passivation/Kuomesa→08.Kumaka→09.Kuongorora kwechigadzirwa→10 .Zinc layer yekuongorora ukobvu→11.Physical and chemical test→12.Final examination

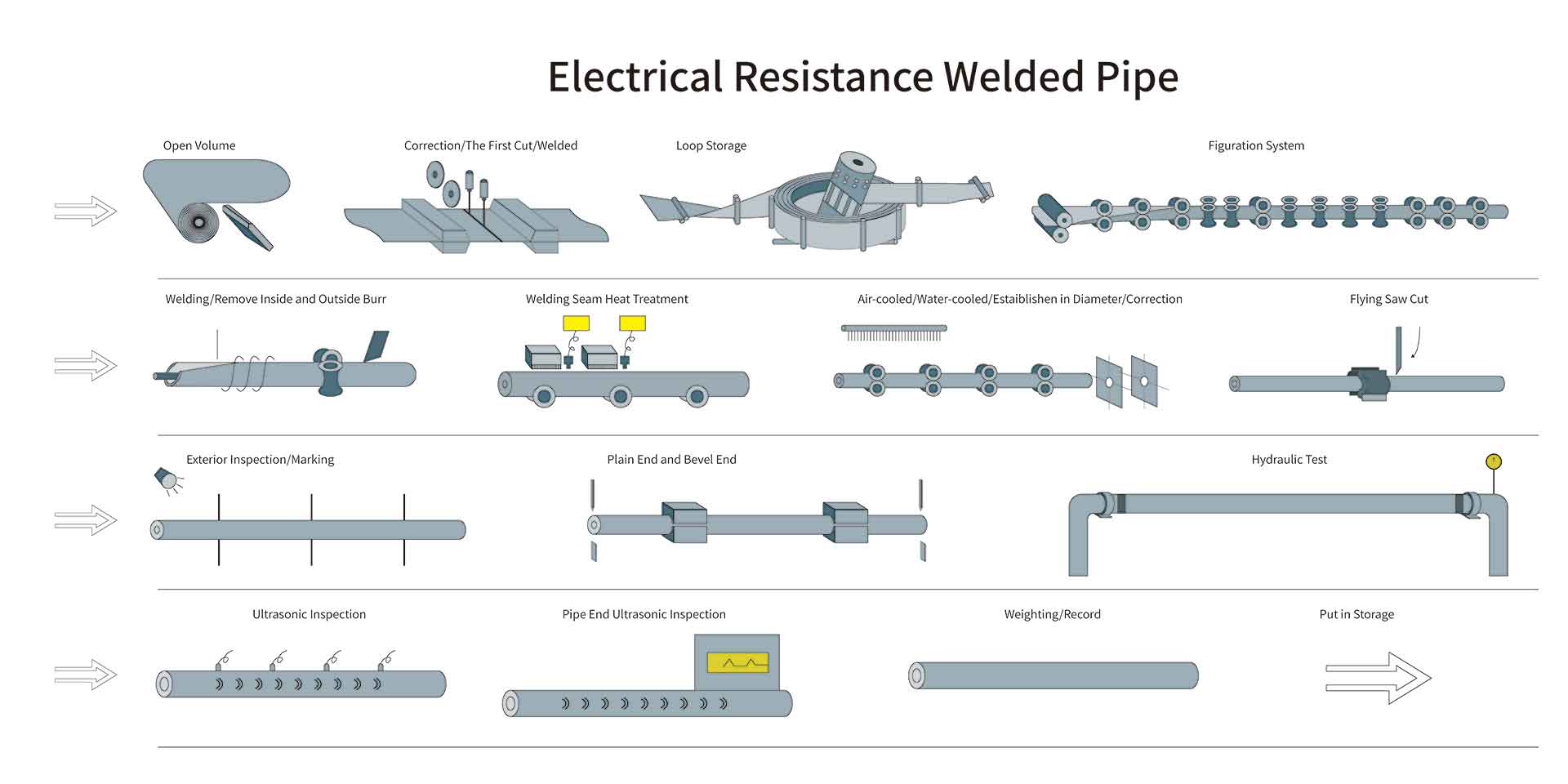

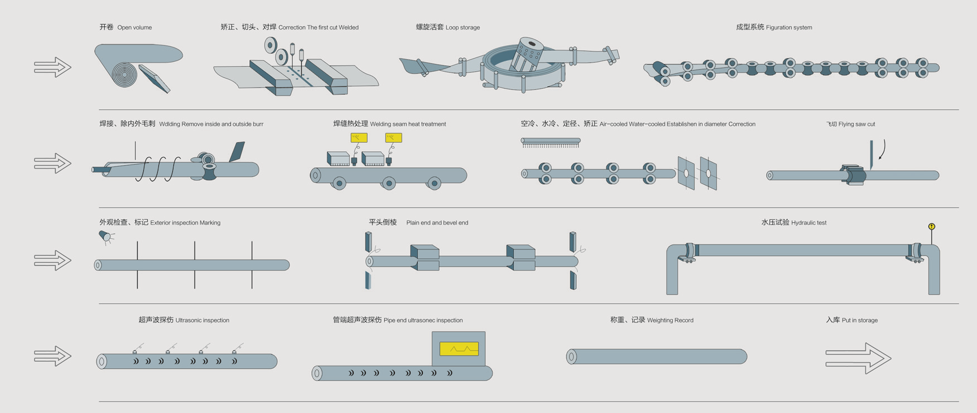

Magetsi Resistance Weld Pipe-ERW

Maitiro ekugadzira

01.Vhoriyamu yakavhurika→ 02.Kururamisa/Kuchekwa kwekutanga/Kuchimbidzika→03.Loop storage→04.Figuration system→05.Welding/Bvisa mukati nekunze burr→06.Welding seam heat treatment→07.Air-yakatonhorera/Mvura- yakatonhodzwa/Yakagadzirwa mudhayamita/Kururamisa→08.Kubhururuka saha cheka→09.Kunze kuongorora/Kuisa mucherechedzo → 10.Plain end uye bevel end→11.Hydraulic test→12.Ultrasonic inspection→13.Pipe end Ultrasonic inspection→14.Kuyera/Rekodha→15.Isai mudura

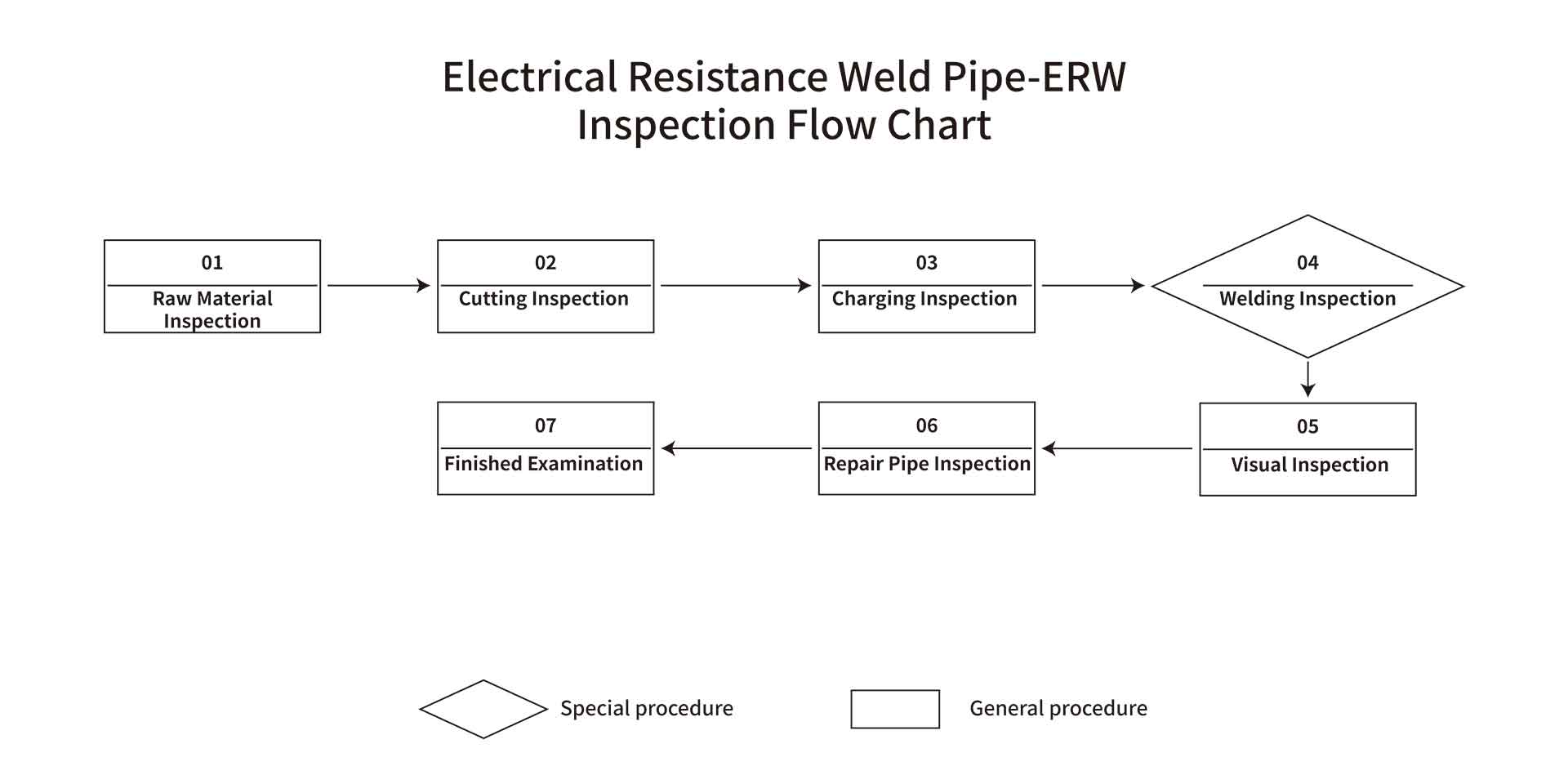

Magetsi Resistance Weld Pipe-ERW

Inspection Flow chati

01. Kuongorora kwezvinhu →02.Kuchekwa kwekucheka →03.Kuongorora kuchaja →04.Kuongorora kwewelding→05.Ongororo yekuona→06.Kuongorora pombi →07.Kuongorora kwapera

Isu tichayedza zvigadzirwa uye maitiro ekugadzira zvinoenderana neakasiyana mazinga kuti tive nechokwadi chekuti zvigadzirwa zvinosangana nemazinga kana chibvumirano zvinodiwa.

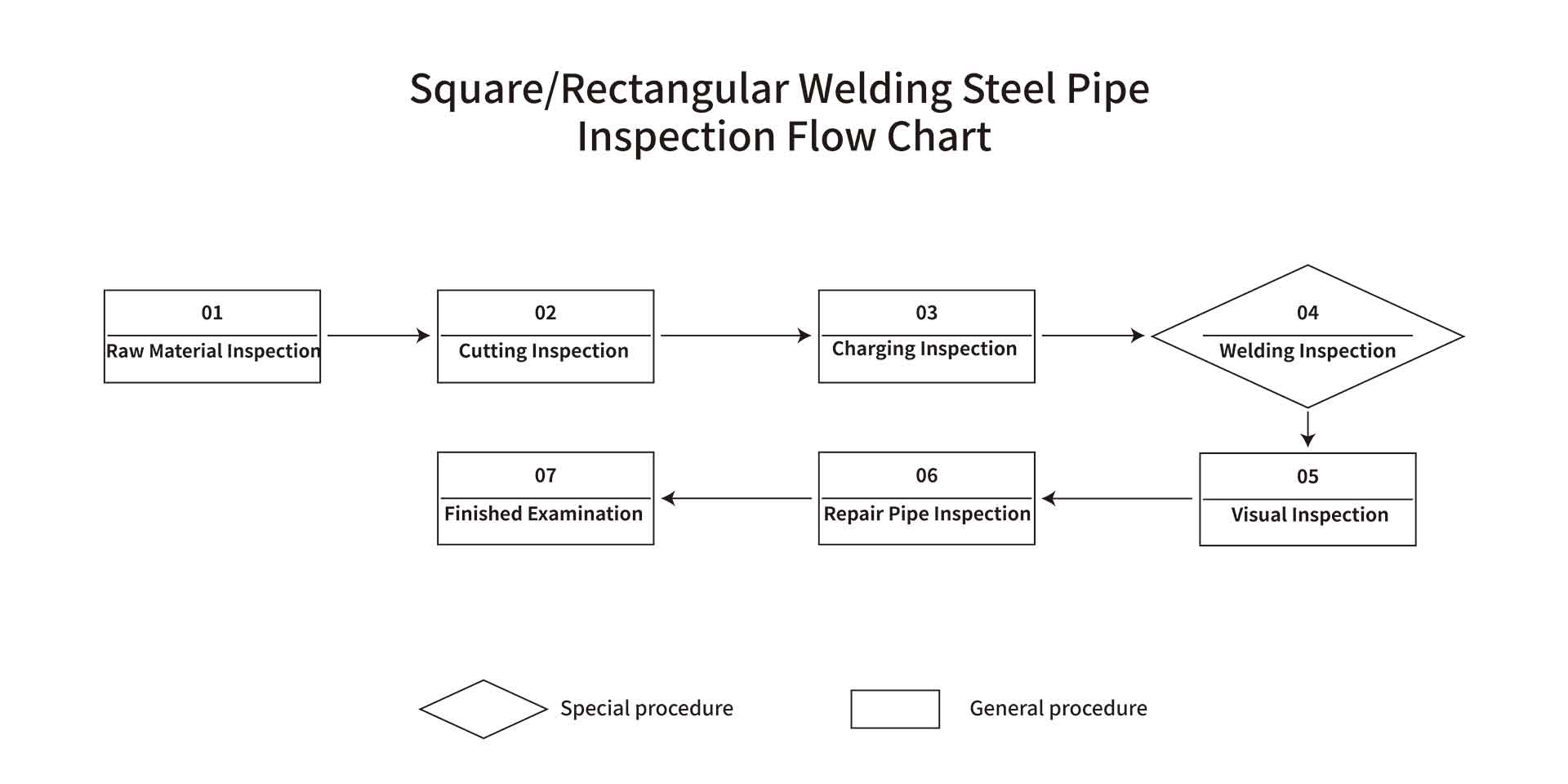

Square / Rectangular Welding Steel Pipe

Inspection Flow chati

01. Kuongorora kwezvinhu →02.Kuchekwa kwekucheka →03.Kuongorora kuchaja →04.Kuongorora kwewelding→05.Ongororo yekuona→06.Kuongorora pombi →07.Kuongorora kwapera

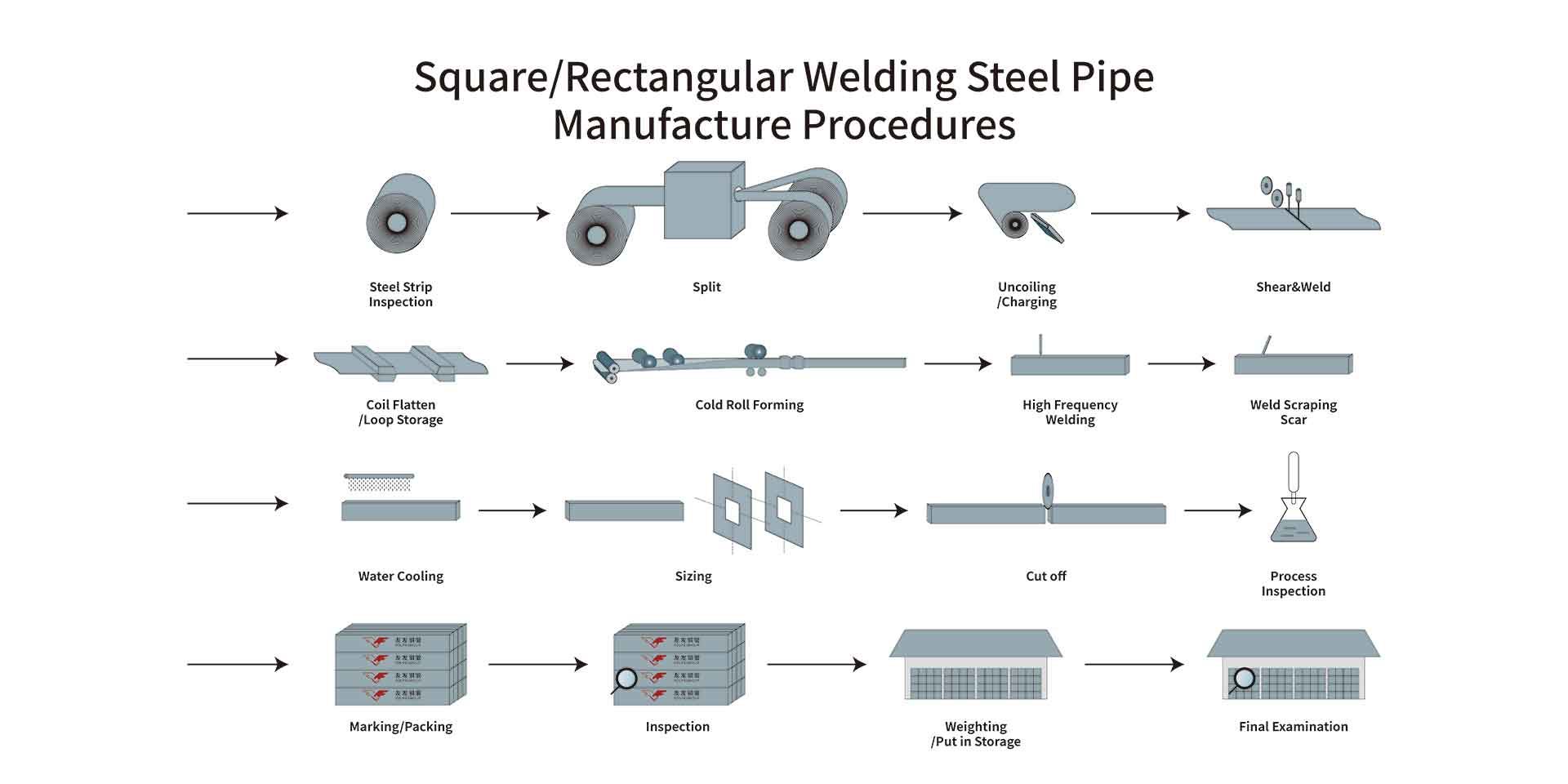

Square / Rectangular Welding Steel Pipe

Maitiro ekugadzira

01. Kuongorora tambo →10.Kukura→11.Cheka→12.Gadzirisa kuongorora→ 13.Kumaka/Kurongedza→14.Kuongorora→15.Kuyeresa/Kuisa mudura→16.Kuongorora kwekupedzisira

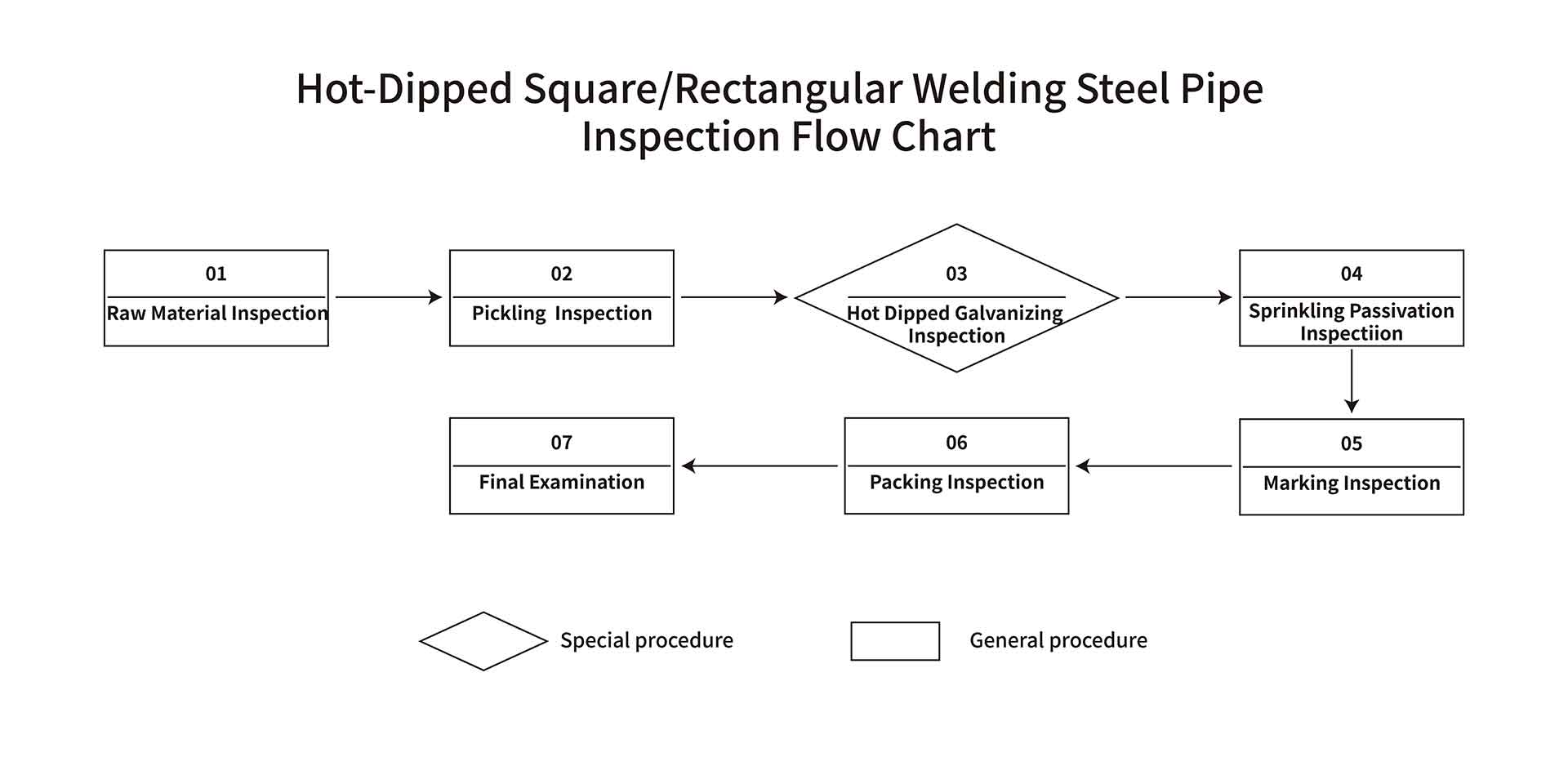

Hot-Dipped Square / Rectangular Welding Steel Pipe

Inspection Flow chati

01. Raq kuongorora zvinhu→02.Pickling inspection→03.Hot Dipped Galvanizing inspection

Isu tichayedza zvigadzirwa uye maitiro ekugadzira zvinoenderana neakasiyana mazinga kuti tive nechokwadi chekuti zvigadzirwa zvinosangana nemazinga kana chibvumirano zvinodiwa.

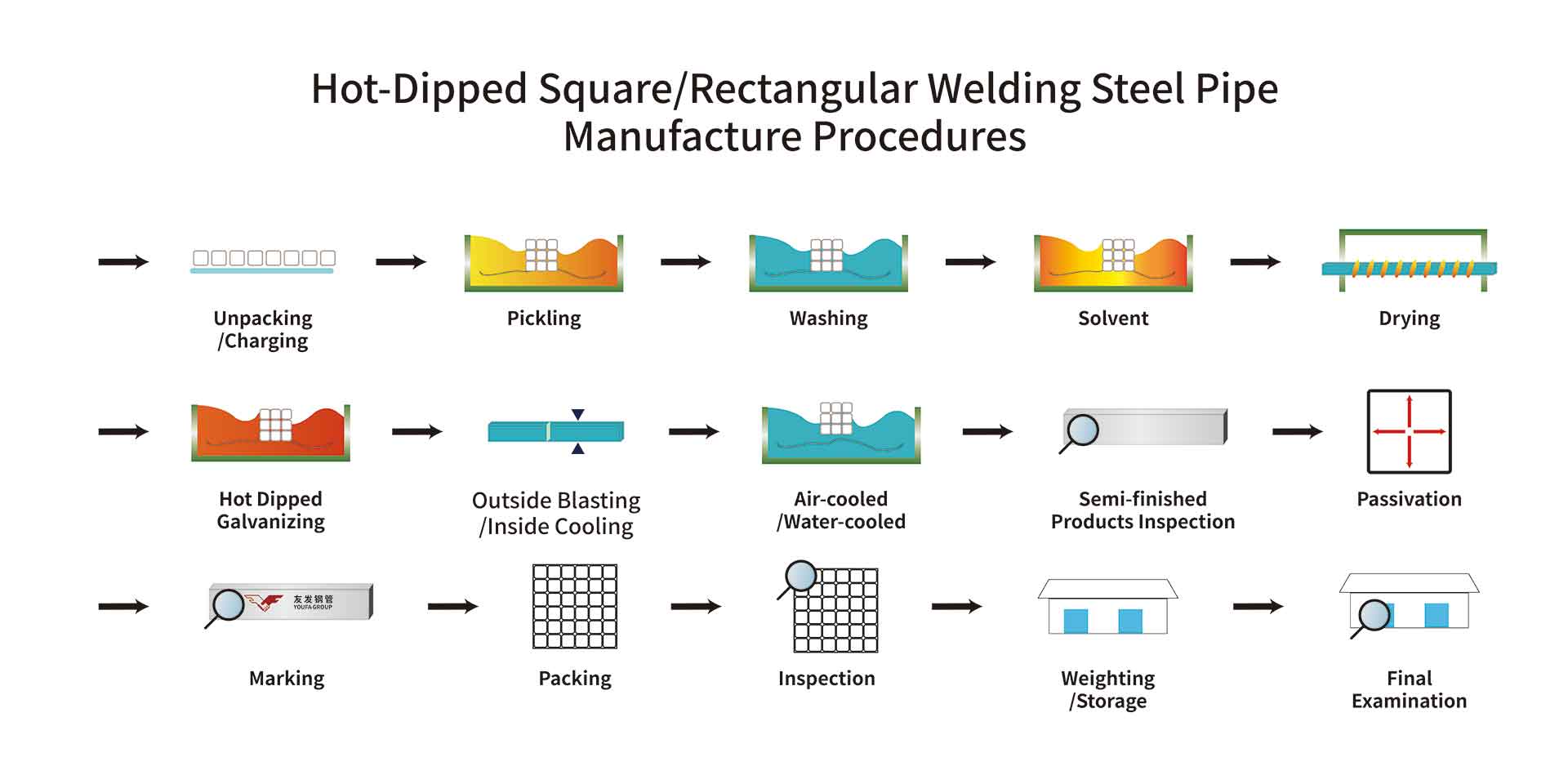

Hot-Dipped Square / Rectangular Welding Steel Pipe

Maitiro ekugadzira

01.Pombi yesimbi yemagetsi→02.Kuburutsa/Kuchaja→03.Pickling→04.Kugeza→05.Solvent→06.Kuomesa→07.Kupisa Kunopfuta Kunopfuta→08.Kuputika Kwekunze→09.Kutonhodza Mukati→10.Kutonhodzwa nemhepo/ Mvura-yakatonhorera→ 11.Semi-yakapera zvigadzirwa kuongorora→12.Pasivation→13.Kumaka→14.Kurongedza→15.Kuongorora→16.Kuyera/Kuchengeta→17.Kuongorora Kwekupedzisira

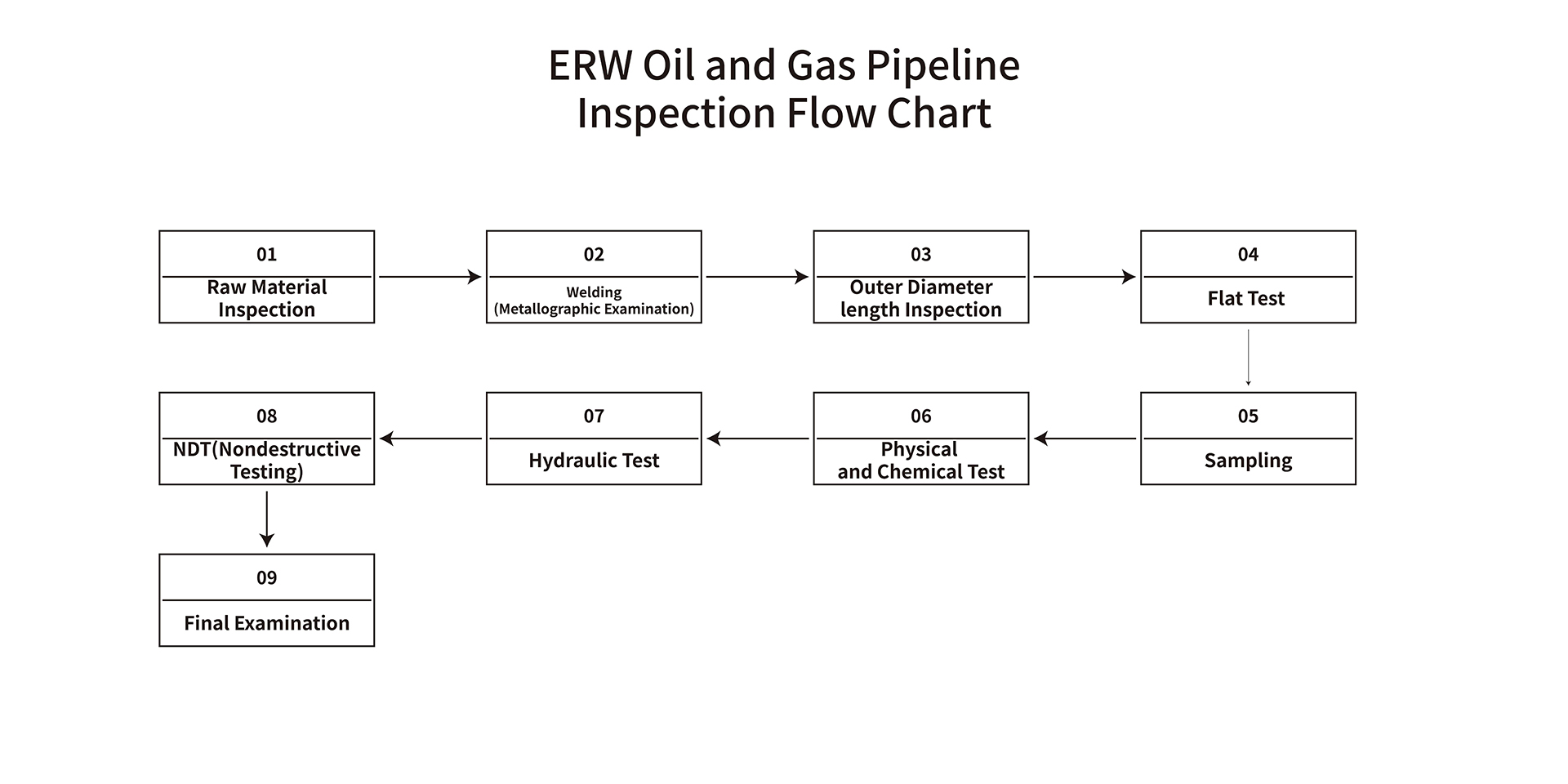

ERW pombi yemafuta uye gasi

Inspection Flow chati

01. Raw material inspection→02.Welding(Metallographic examination)→03.Outer dhayamita yekuongorora kureba→04.Flat test→05.Sampling→06.Physical and chemical test→07.Hydraulic test→08.NDT(nondestructive test)→ 09.Final Examination

Isu tichayedza zvigadzirwa uye maitiro ekugadzira zvinoenderana neakasiyana mazinga kuti tive nechokwadi chekuti zvigadzirwa zvinosangana nemazinga kana chibvumirano zvinodiwa.

01.Vhoriyamu yakavhurika→ 02.Kururamisa/Kuchekwa kwekutanga/Kuchimbidzika→03.Loop storage→04.Figuration system→05.Welding/Bvisa mukati nekunze burr→06.Welding seam heat treatment→07.Air-yakatonhorera/Mvura- yakatonhodzwa/Yakagadzirwa mudhayamita/Kururamisa→08.Kubhururuka saha cheka→09.Kunze kuongorora/Kuisa mucherechedzo → 10.Plain end uye bevel end→11.Hydraulic test→12.Ultrasonic inspection→13.Pipe end Ultrasonic inspection→14.Kuyera/Rekodha→15.Isa mudura

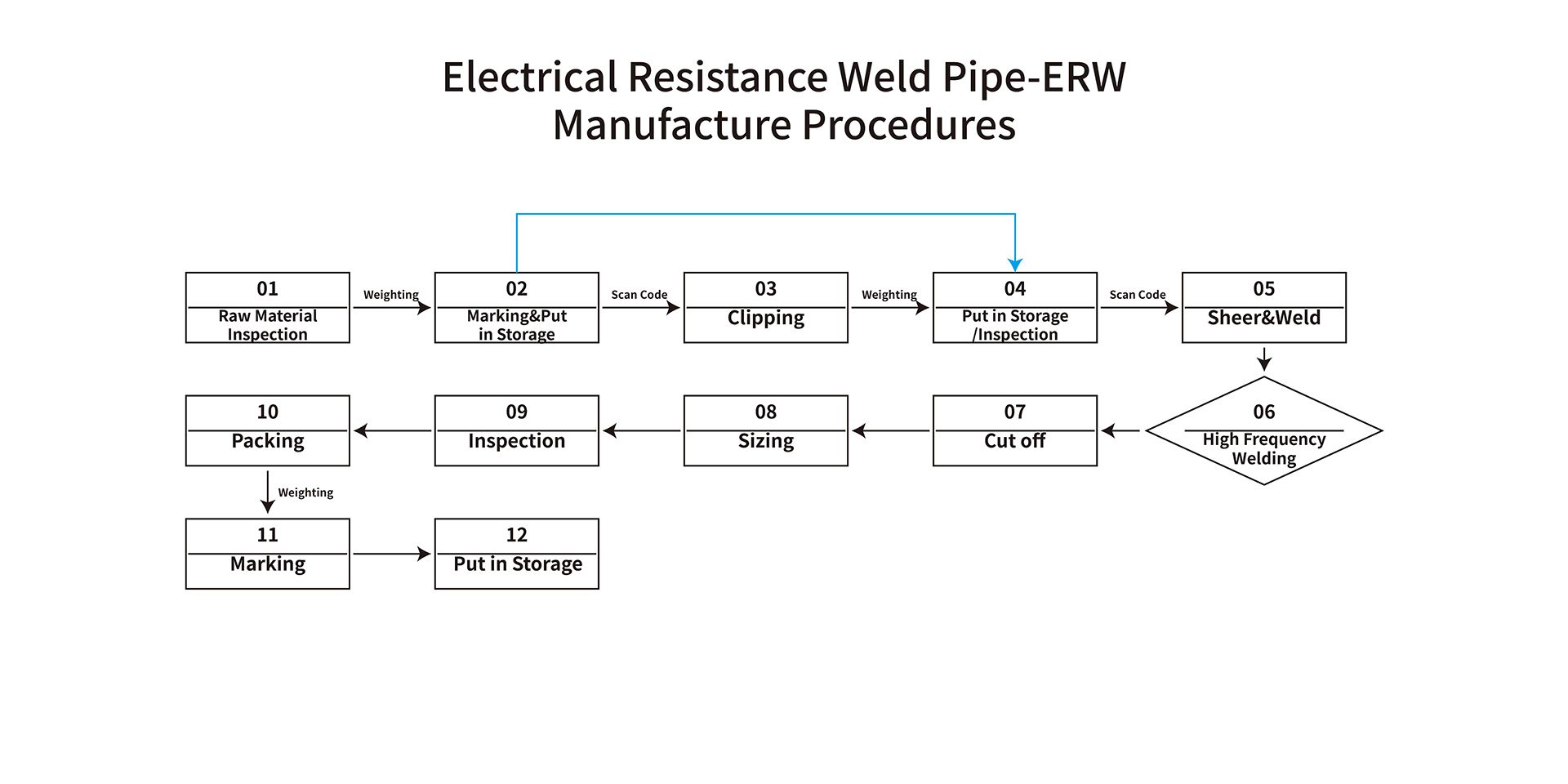

Magetsi Resistance Weld Pipe-ERW

Maitiro ekugadzira

01. Kuongorora kwezvinhu zvakasvibirira→02.Kumaka&Kuisa muchichengetedzo→03.kuchekerera→04.Isa muchichengetedzo/Ongororo→05.Sheer&Weld→06.Muedzo wemuviri nekemikari→07.Dimbura→08.Kukura→09.Kuongorora→10. Kurongedza→ 11.Kuyera → 12.Scan codes

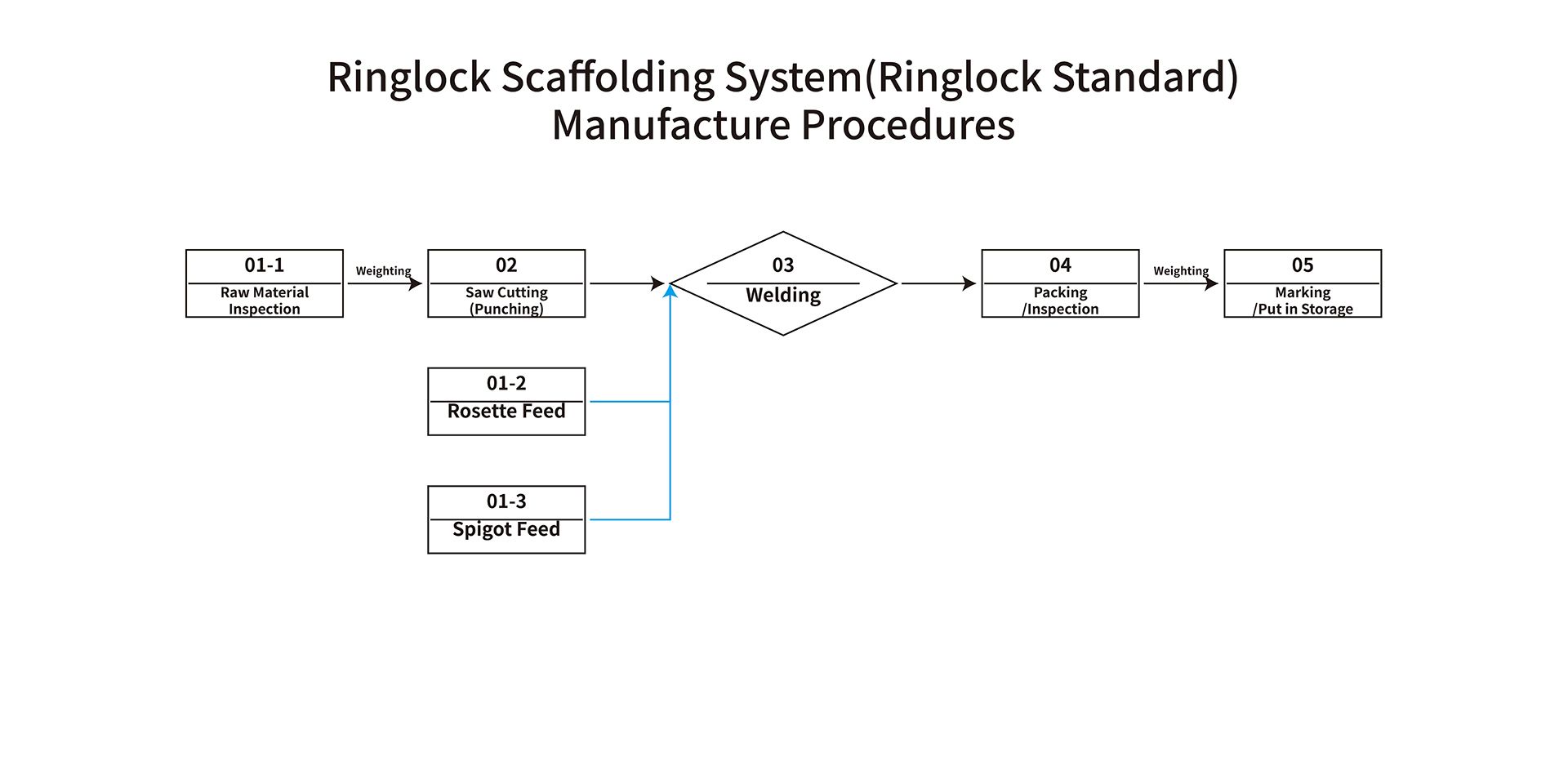

Ringlock Scaffolding System (Ringlock Standard)

Maitiro ekugadzira

01.Kuongorora zvinhu zvakasara→02.Kucheka masaha (kubaya)/Rosette feed/Spigot feed→03.Welding→04.Kurongedza/kuongorora→05.Kumaka/Kuisa mudura

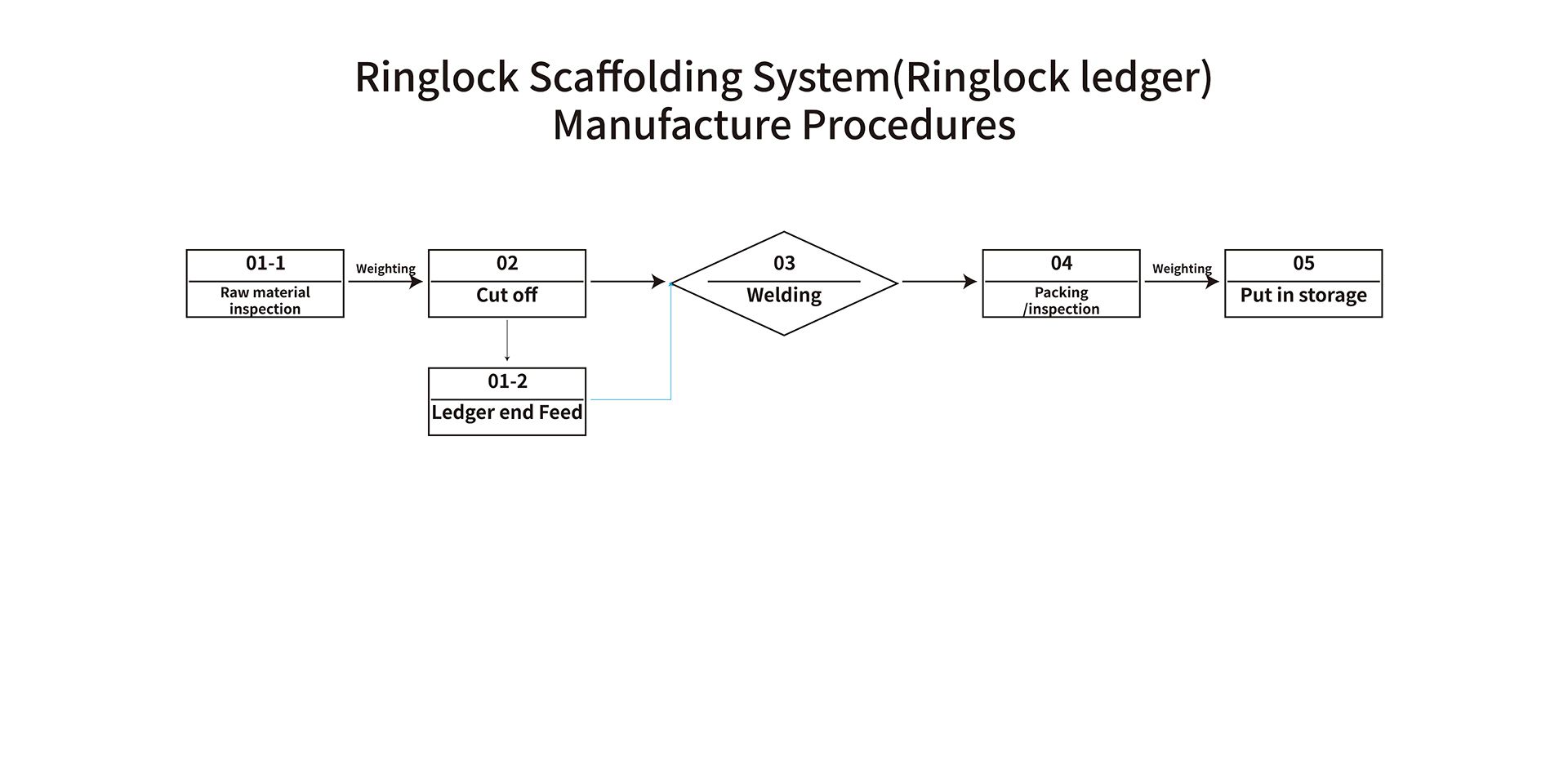

Ringlock Scaffolding System (Ringlock ledger)

Maitiro ekugadzira

01.Kuongorora zvinhu zvisina kugadzirwa →02.Dimbura/Ledger kupera Kudyisa→03.Welding→04.Kurongedza/kuongorora→05.Kumaka/Kuisa mudura

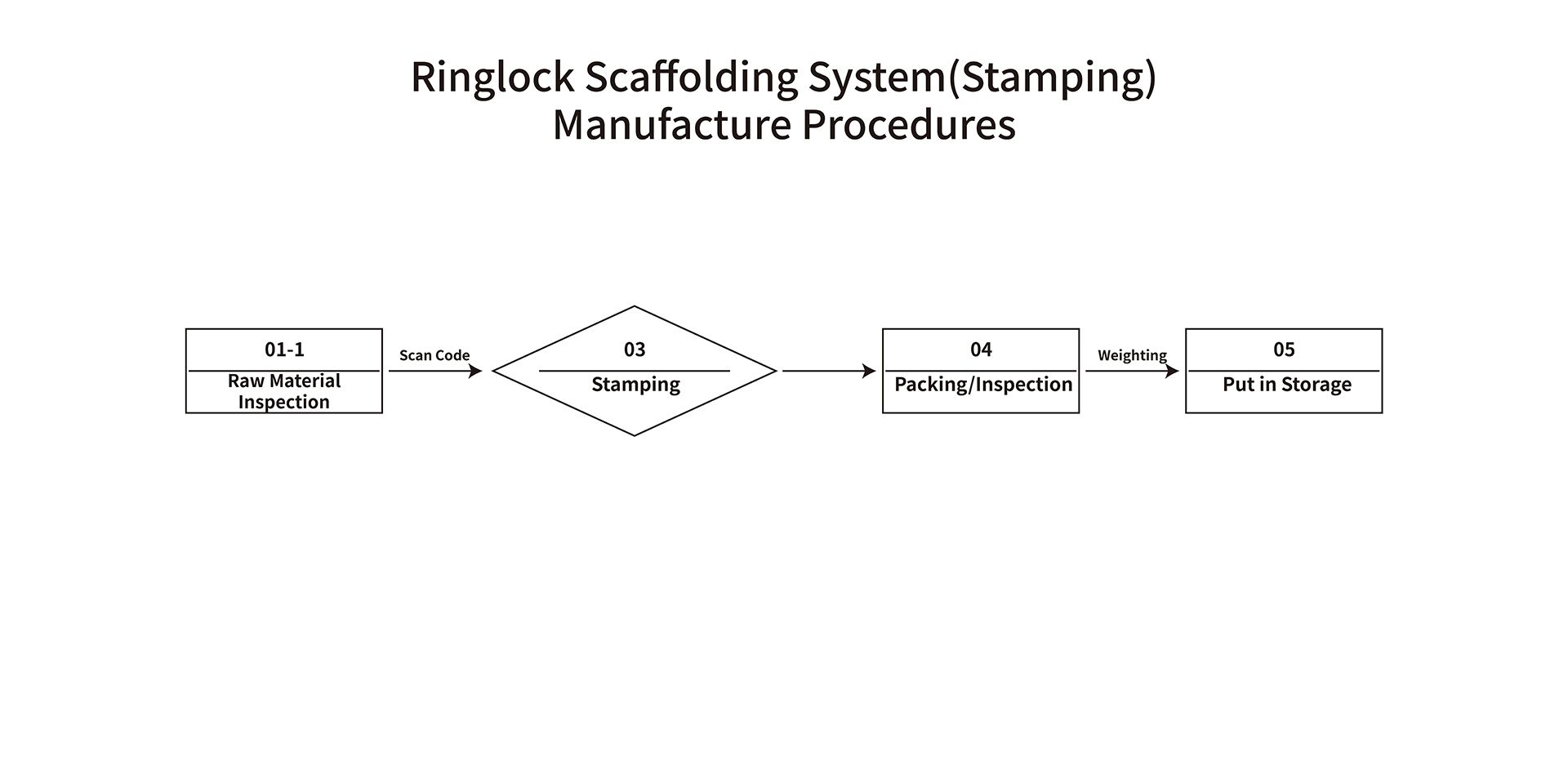

Ringlock Scaffolding System (Stamping)

Maitiro ekugadzira

01.Kuongorora zvinhu →02.Kutsikirira→03.Kurongedza/Kuongorora→04.Isa mudura

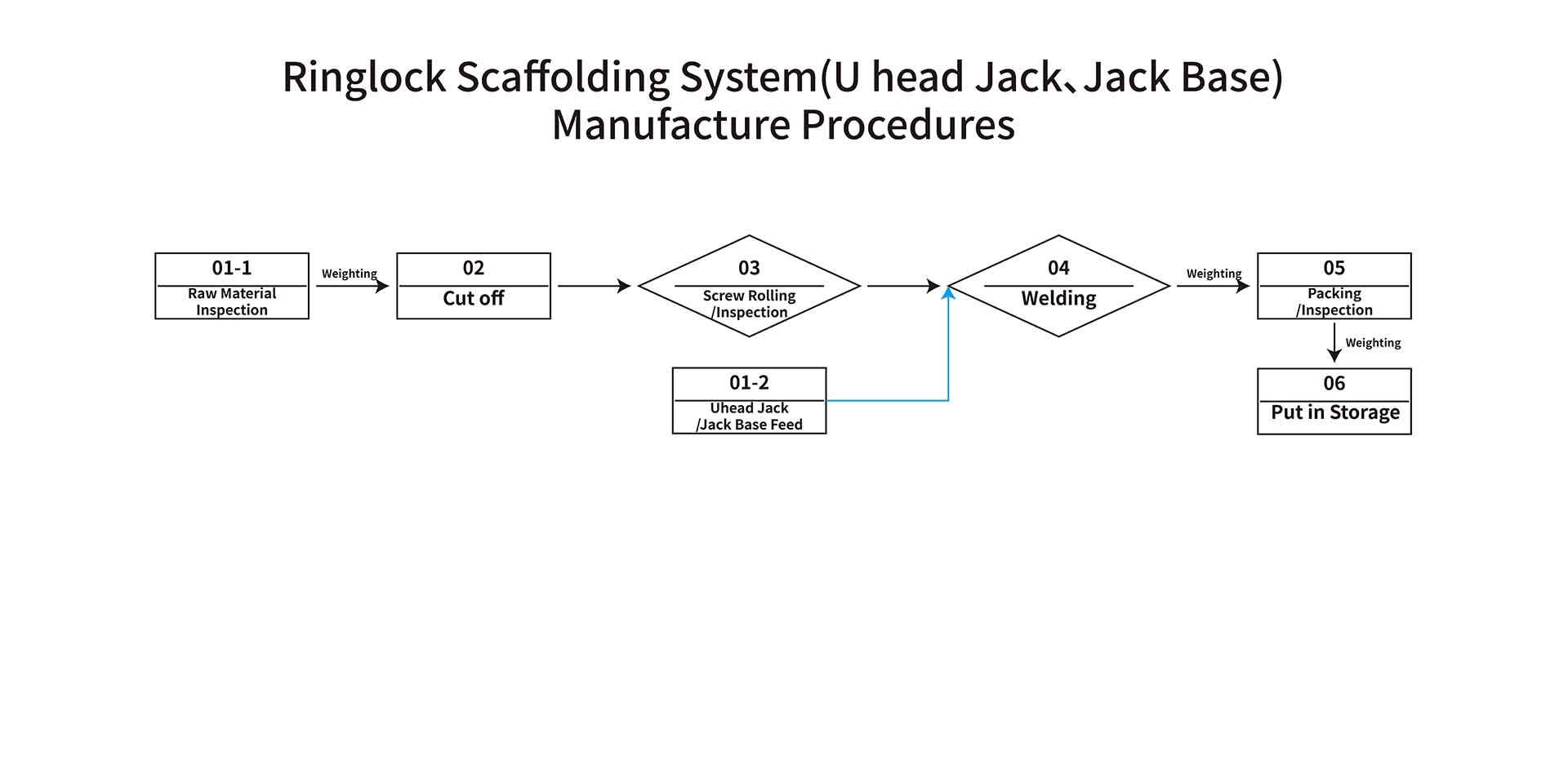

Ringlock Scaffolding System (U musoro jack, Jack base)

Maitiro ekugadzira

01.Kuongorora zvinhu zvakakura → 02. Cheka → 03.Kupeta/Kuongorora/Jeki yemusoro/jack base feed→04.Welding→05.Kurongedza/kuongorora→06.Isai mudura

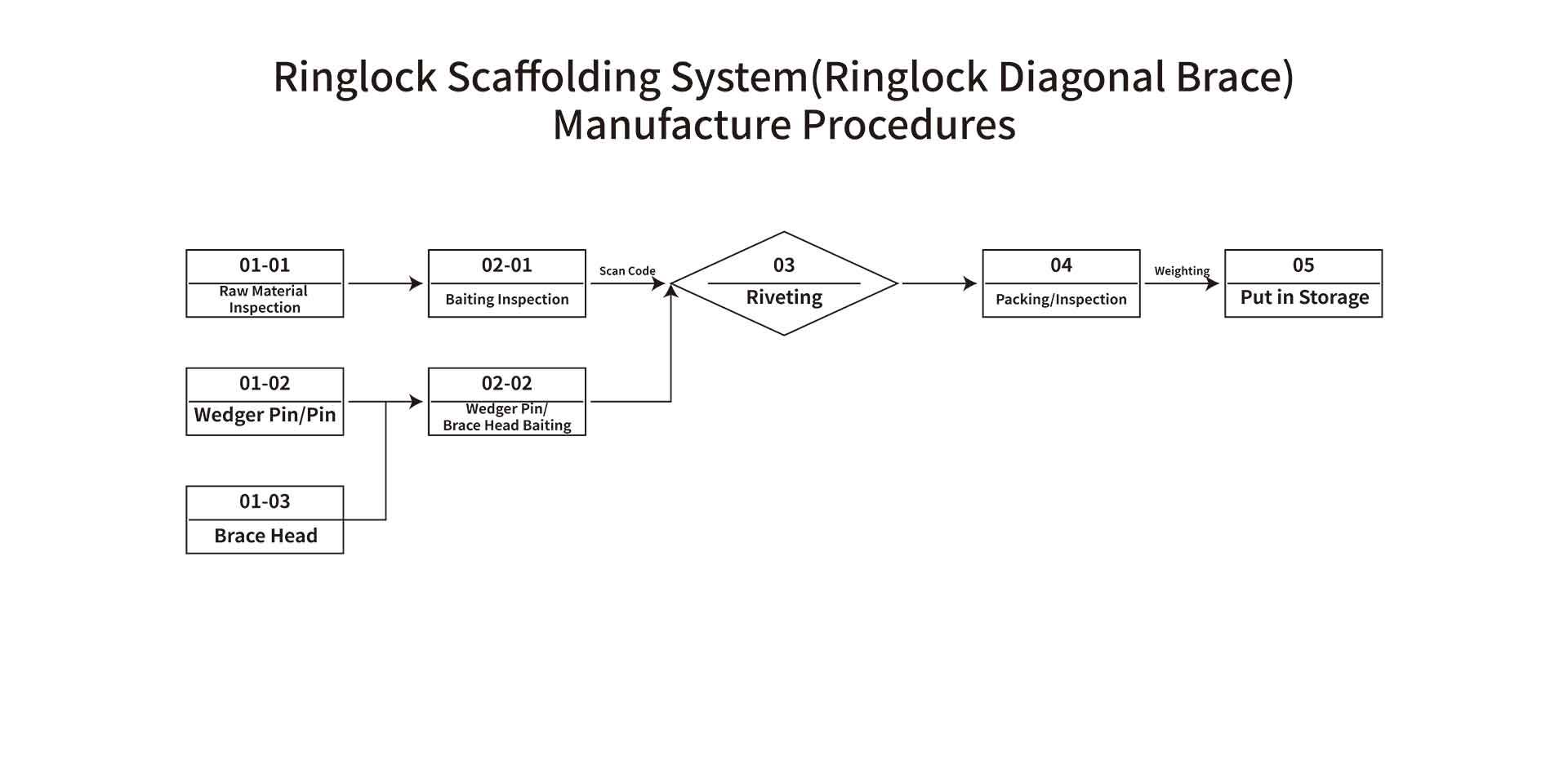

Ringlock Scaffolding System (Ringlock diagonal brace)

Maitiro ekugadzira

01.Raw material inspection/Wedger pin/Pini/Brace head →02.Baiting inspection/edger pin/Brace head baiting→03.Welding→04.Kurongedza/kuongorora→05.Isa mudura