Tuubooyinka API 5L ayaa si caadi ah loo isticmaalaa dhismahadhuumaha qaada shidaalka iyo gaastamasaafo dheer, iyo sidoo kale loo isticmaalo dhismaha kaabayaasha warshadaha tamarta, sida sifaynta iyo dhirta petrochemical.

API 5L Hordhac Kooban

| Alaabta | API 5L Dhuumaha Birta aan Xumaan lahayn | Tilmaamid |

| Qalab | Birta Kaarboonka | OD: 13.7-610mm Dhumucda: sch40 sch80 sch160 Dhererka: 5.8-6.0m |

| Darajo | L245, API 5L B/ASTM A106 B | |

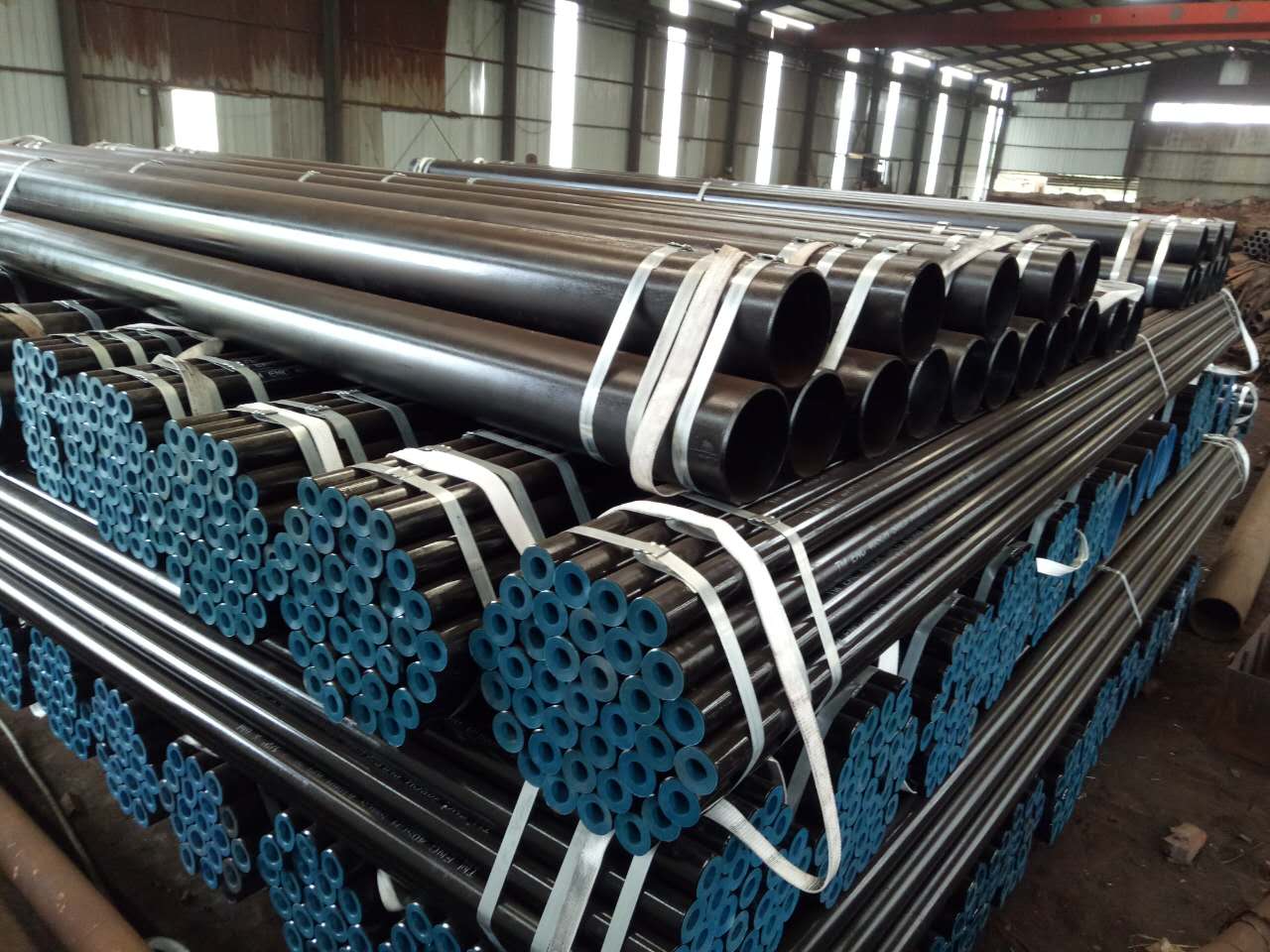

| Dusha sare | Bare ama Madow rinji | Isticmaalka |

| Dhammaad | Bannaan dhammaad | Saliida/Gaaska keenista dhuunta birta ah |

| Ama Beveled dhamaado |

Baakaynta iyo keenista:

Faahfaahinta Xirmooyinka: xirmooyin laba geesood ah oo badeed mudan oo ay ka buuxaan xariijimo bir ah, oo leh laba dharbaaxo naylon ah xidhmo kasta

Faahfaahinta Bixinta: Waxay kuxirantahay QTYda, sida caadiga ah hal bil.

API 5L Fasalka Birta Beebka Kaarboon-Kaarboon ee aan Xumaan lahayn

| Heerka Birta Tuubbada aan Xumaan lahayn | Halabuurka Kiimikada loogu talagalay PSL 1 tuubo leh WT ≤25mm (0.984 inc) | ||||

| C (ugu badnaan)% | Mn (ugu badnaan)% | P (ugu badnaan)% | S (ugu badnaan)% | V + Nb + Ti | |

| L245 ama Darajada B | 0.28 | 1.2 | 0.03 | 0.03 | Haddii aan si kale lagu heshiin, wadarta niobium iyo vanadium waxa ku jira waa u 0,06 %. Isu geynta niobium, vanadium iyo titanium-ku waa inay noqdaan 0,15 %. |

| Heerka Birta Tuubbada aan Xumaan lahayn | Tijaabooyinka Xasilloonidaee PSL 1 jirka tuubada | |||

| Xoogga Wax-soo-saarka (min.) MPa | Xoog Jiidashada (min.) MPa | |||

| L245 ama Darajada B | 245 | 415 | ||

API 5L Shaxda Cabbirrada Tubooyinka Birta ee aan Xunaanshaha lahayn

| INCH | OD | API 5L ASTM A106 Dhumucda Darbiga Strandard | |||||||

| (MM) | SCH 10 | SCH 20 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 160 | XXS | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8" | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Habka Soo saarista Dhuumaha ee SMLS aan Xumaan lahayn

Xulashada Qalabka Ceyriinka:Birta kaarboonka ee tayada sare leh ayaa loo doortaa sida alaabta ceeriin ee tuubooyinka birta kaarboonka ee aan waxba tarayn. Kaarboonka ku jira birta ayaa ah arrin muhiim u ah go'aaminta sifooyinkeeda iyo ku habboonaanta codsiyada kala duwan.

Kululaynta iyo daloolinta:Walxaha ceeriin ayaa lagu kululeeyaa heerkul sare ka dibna waa la daloolaa si ay u sameeyaan qolof bannaan. Habkani waxa uu muhiim u yahay abuurista qaabka bilowga ah ee tuubada waxaana sida caadiga ah lagu gaaraa hababka ay ka midka yihiin daloolinta wareegtada, extrusion, ama farsamooyin kale oo khaas ah.

Wareegid iyo Cabbir:Qolfoofka daloolku waxa uu maraa habab rogrogis iyo cabbirid si loo dhimo dhexroorka iyo dhumucda gidaarka ilaa cabbirka loo baahan yahay. Tan waxaa caadi ahaan lagu gaaraa iyada oo la isticmaalayo taxane ah mishiinnada duubista iyo miraha cabbirka si loo gaaro qaabka iyo cabbirka la doonayo.

Daawaynta Kulaylka:Tuubbada birta kaarboonka ee aan waxba tarayn waxa la mariyaa hababka daawaynta kulaylka sida nuugista, caadi ka dhigista, ama deminta iyo xanaaqa si kor loogu qaado sifooyinkeeda makaanikada loogana saaro wixii walbahaar ee hadhay. Daawaynta kulaylku waxa kale oo ay caawisaa in la gaadho qaab-dhismeed yar oo la doonayo iyo sifooyinka birta kaarboonka.

Baaritaanka iyo Kormeerka:Inta lagu jiro habka wax soo saarka, tuubada kaarboonka ee aan cillad lahayn waxay martaa habab tijaabo ah oo kala duwan oo aan burburin iyo burburin si loo hubiyo inay buuxiso heerarka tayada ee loo baahan yahay. Tan waxaa ku jiri kara baaritaanka ultrasonic, baaritaanka hydrostatic, baaritaanka hadda jira, iyo kormeer muuqaal ah.

Dhamaystirka iyo Dahaarka:Marka dhuumaha aan kala go'a lahayn ay buuxiyaan shuruudaha loo baahan yahay, waxay maraysaa hababka dhamaystirka sida toosinta, goynta, iyo dhamaystirka dhamaystirka. Intaa waxaa dheer, tuubada waxaa lagu dahaadhay waxyaabo ka hortag ah sida varnish, rinji, ama galvanizing si kor loogu qaado iska caabbinta daxalka, gaar ahaan kiiska birta kaarboonka.

Kormeerka Ugu Dambeeya iyo Baakaynta:Tuubada birta ah ee dhammaatay waxay maraysaa kormeerka ugu dambeeya si loo hubiyo inay buuxisay dhammaan heerarka tayada iyo shuruudaha macaamiisha. Kadibna si taxadar leh ayaa loo baakadeeyay oo loo diyaariyey in loo raro macaamiisha.

API 5L Hubinta Tayada Tubta Kaarboonka iyo Tijaabada

Baaritaanka Hydrostatic

Dhuumaha aan xuduud lahayn ayaa u adkeysan doona tijaabada hydrostatic iyada oo aan la dareerin tolleynta alxanka ama jirka tuubada.

U dulqaadashada dhexroorka, dhumucda gidaarka, dhererka iyo toosnaanta

| Lagu cayimay dhexroor ka baxsan | Tuubooyinka SMLS Dulqaadyada dhexroorka | Dulqaadyada ka baxsan wareega | ||

| Dhuumaha marka laga reebo dhamaadka | dhamaadka tuubada | Dhuumaha marka laga reebo dhamaadka | dhamaadka tuubada | |

| <60.3mm | - 0.8mm ilaa +0.4mm | - 0.4mm ilaa +1.6mm | ||

| ≥60.3mm ilaa ≤168.3mm | ± 0.0075 D | 0.020 D | 0.015 D | |

| > 168.3mm ilaa ≤610mm | ± 0.0075 D | ± 0.005 D, laakiin ugu badnaan ± 1.6mm | ||

| > 610mm ilaa ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, laakiin ugu badnaan 15mm, ee D/T≤75 | 0.01 D, laakiin ugu badnaan 13mm, ee D/T≤75 |

| heshiis ee D/T>75 | heshiis ee D/T>75 | |||

D: OD dhexroor ka baxsan T: WT dhumucda derbiga

Waxyaabaha kale ee la xidhiidha API 5L Tubooyinka Birta Kaarboon

-

Q355 S355 labajibbaaran iyo tuubo bir ah oo afargees ah Pri...

-

Halbeegga EN74 rinji iyo galvanized steel Safka...

-

Pre Gi Steel Pipe Wareegga Wareegga Godan Qaybta 60mm

-

Qalabka issaffolding ee ringlock

-

Jaranjarada Qaab-dhismeedka Scaffol ee Dhismaha...

-

Dhuumaha birta Galvanized ee googo'ay wuu dhamaanayaa