Spiral Welded Steel Pipes Specifications and Standards

Specifications: Outside diameter 219mm to 3000mm; Thickness sch40, sch80, sch160; Length 5.8m, 6m, 12m or customized

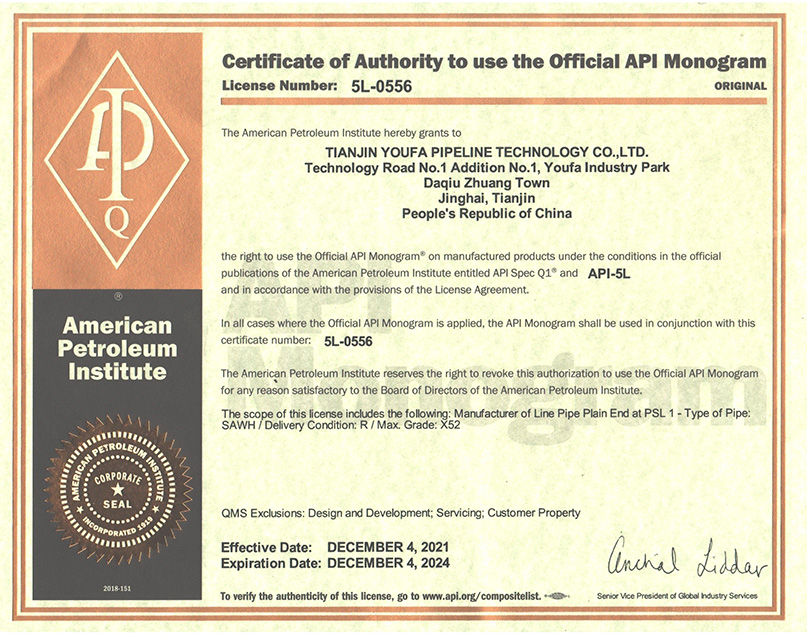

Grades: SSAW pipes can be produced in various grades, including API 5L specifications like Grade B, X42, X52, X60, X65, X70, and X80.

Standards: Typically manufactured according to standards like API 5L, ASTM A252, or other relevant specifications depending on the application.

API 5L: This standard is issued by the American Petroleum Institute and specifies the requirements for the manufacture of two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.

ASTM A252: This standard is issued by the American Society for Testing and Materials and covers nominal wall cylindrical steel pipe piles in which the steel cylinder acts as a permanent load-carrying member or as a shell to form cast-in-place concrete piles.

SSAW Spiral Welded Steel Pipe Surface Coating

3-Layer Polyethylene (3LPE) Coating: This coating consists of a fusion-bonded epoxy layer, an adhesive layer, and a polyethylene layer. It provides excellent corrosion resistance and is often used for pipelines in harsh environments.

Fusion-Bonded Epoxy (FBE) Coating: FBE coating provides good chemical resistance and is suitable for both above-ground and underground applications.

Galvanizing: The galvanizing process involves applying a protective zinc coating to the steel pipe to provide corrosion resistance. Spiral weld steel pipe is immersed in a bath of molten zinc, which forms a metallurgical bond with the steel, creating a durable and corrosion-resistant coating. Hot-dip galvanizing is suitable for both interior and exterior applications and provides excellent protection against rust and corrosion.

Spiral Welded Carbon Steel Pipes Applications

Oil and Gas Transportation: Used extensively for transporting crude oil, natural gas, and other petroleum products over long distances.

Water Distribution: Suitable for water pipelines due to their durability and resistance to corrosion.

Structural Applications: Employed in construction for structural support, such as in bridges, buildings, and other infrastructure projects.

Spiral Welded Carbon Steel Pipes Inspection and Quality Control

Dimensional Inspection: The pipes are checked for compliance with diameter, wall thickness, and length specifications.

Mechanical Testing: Pipes are tested for tensile strength, yield strength, elongation, and toughness to ensure they meet required standards.

Non-Destructive Testing:

Ultrasonic Testing (UT): Used to detect internal defects in the weld seam.

Hydrostatic Testing: Each pipe is subjected to hydrostatic pressure testing to ensure it can handle the operating pressures without leaking.

Spiral Welded Carbon Steel Pipes Packing and Delivery

Packing Details : in hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles.

Delivery Details : Depending on the QTY, normally one month.