Phallo ea Ts'ebetso ea Tlhahiso le Phallo ea Tlhahlobo

Re na le basebetsi ba fetang 9000 ba nang le litsebo tse phahameng le melapo ea tlhahiso e tsoetseng pele ea 293 e phatlalalitsoeng ho pholletsa le lifeme tse 13, re hlahisitse liphaephe tsa tšepe tse boima ba lithane tse limilione tse 20 ka 2022, 'me theko ea thekiso e feta limilione tse 160 tsa Lidolara tsa US ka 2018. Ka lilemo tse 17 tse latellanang, Youfa e bitsoa har'a TOP. Likhoebo tse 500 ho indasteri ea tlhahiso ea China ho tloha ka 2006.

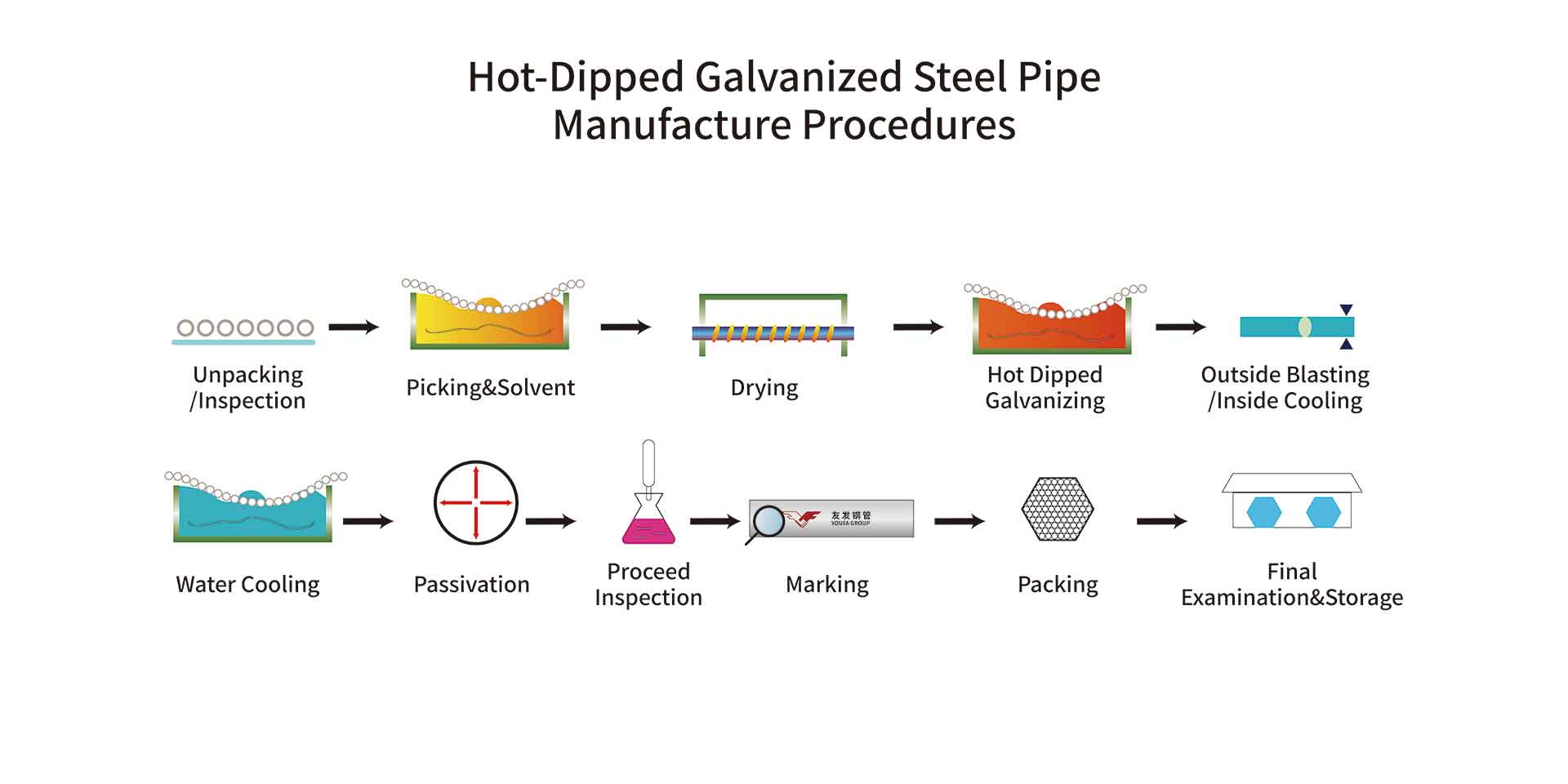

Pipe ea Tšepe e Kentsoeng ka Mocheso

Mekhoa ea Tlhahiso

01.Ho qhaqholla/Hlahloba→02.Ho phunya le ho qhibilihisa→03.Ho omisa→04.Tšhamo e kolobisitsoeng ka sekontiri→05.Ho phatloha ka ntle/ka hare ho pholile→06.Pholiso ea metsi→07.Pasition→08.Tsoela pele ho hlahloba→09.Ho tšoaea→10.Paka→ 11.Tlhahlobo ea ho qetela le Polokelo

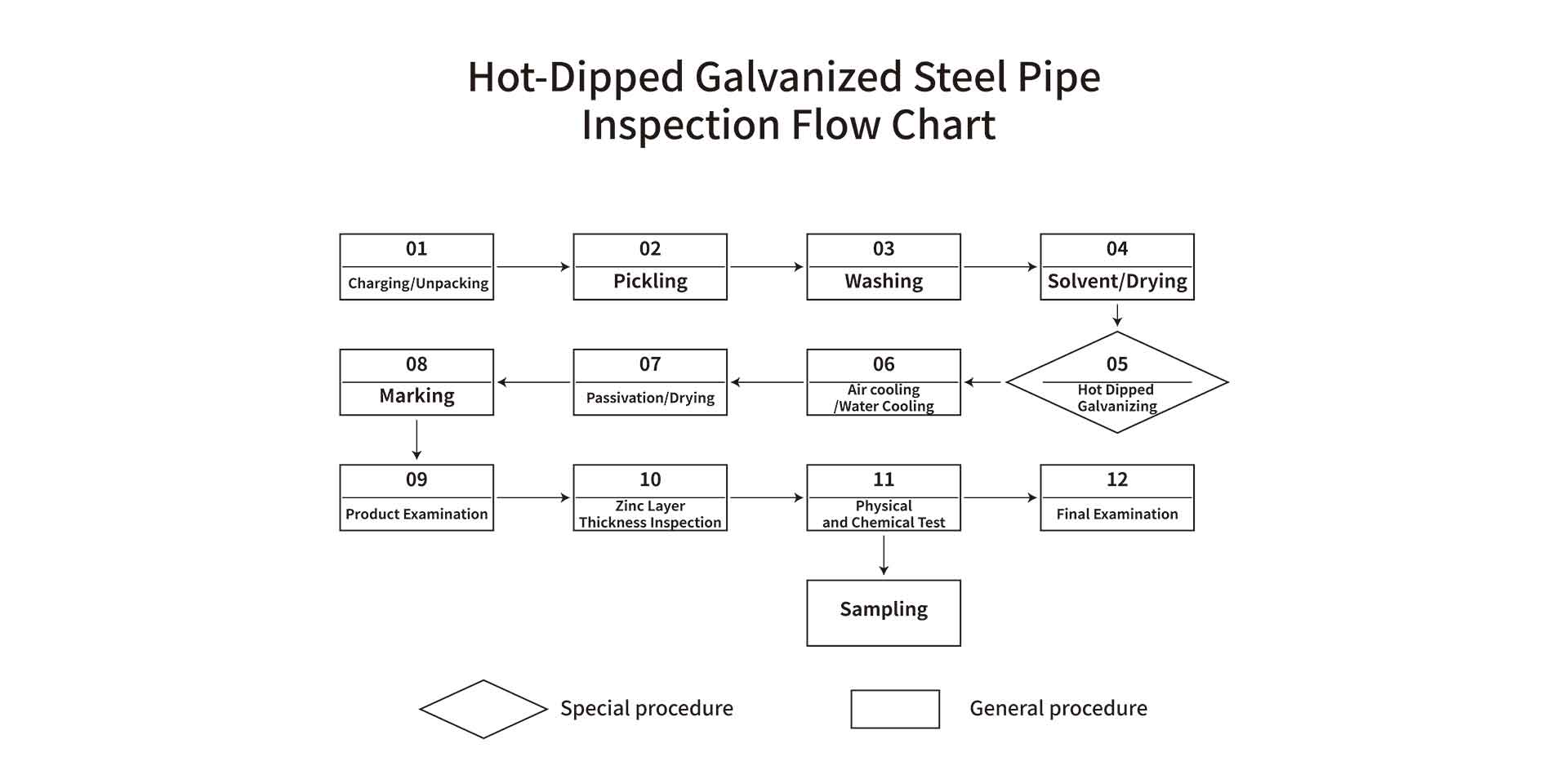

Pipe ea Tšepe e Kentsoeng ka Mocheso

Chate ea Phallo ea Tlhahlobo

01.Ho tjhaja/Ho pakela →02.Pickling→03.Ho Hlatsoa→04.Solvent/Drying→05.Sekontiri se kolobisitsoeng se chesang→06.Pholiso ea moea/Pholiso ea Metsi→07.Pasivation/Drying→08.Ho tšoaea→09.Tlhahlobo ea sehlahisoa→10 .Tlhahlobo ea botenya ba Zinc → 11. Teko ea 'mele le ea lik'hemik'hale → 12.Tlhahlobo ea ho qetela

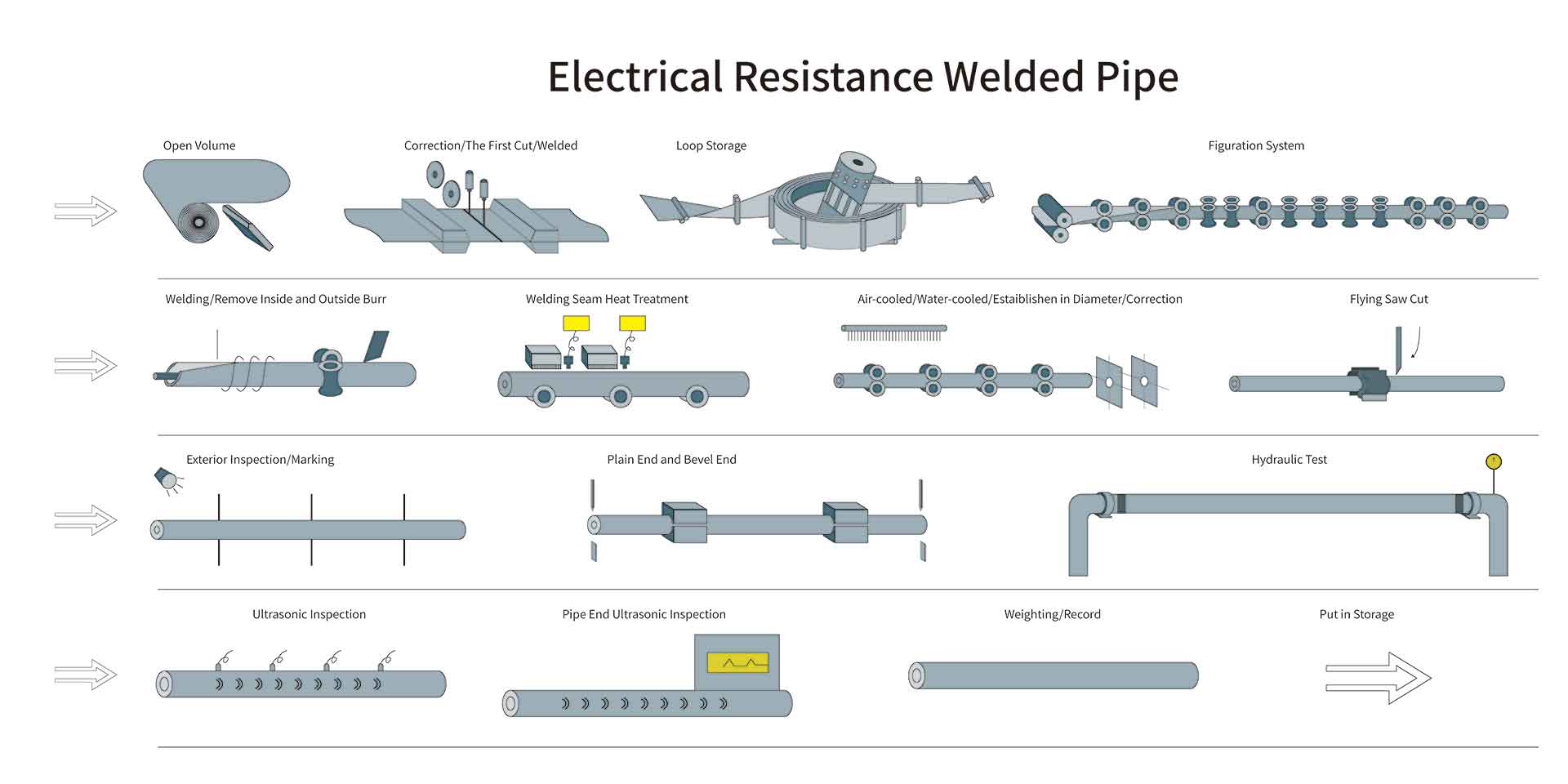

Motlakase Resistance Weld Pipe-ERW

Mekhoa ea Tlhahiso

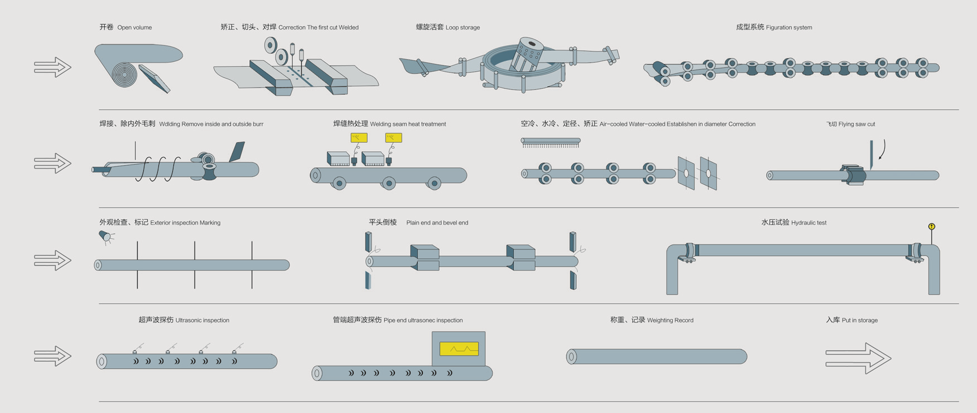

01.Bula bophahamo ba modumo→02.Corection/The first cut/Welded→03.Loop storage→04.Figuration system→05.Welding/Tlosa burr ka hare le ka ntle→06.Tsela ea ho cheselletsa seam →07.Moea o pholileng/Metsi- e pholisitsoeng/E thehile bophara ba/Tokiso→08.Seha se fofang→09.Ka ntle ho hlahloba / ho tšoaea → 10. Qetello e hlakileng le qetello ea bevel → 11. Teko ea Hydraulic → 12. Tlhahlobo ea Ultrasonic → 13. Qetello ea liphaephe Tlhahlobo ea Ultrasonic → 14. Weighting / Record → 15. Kenya polokelo

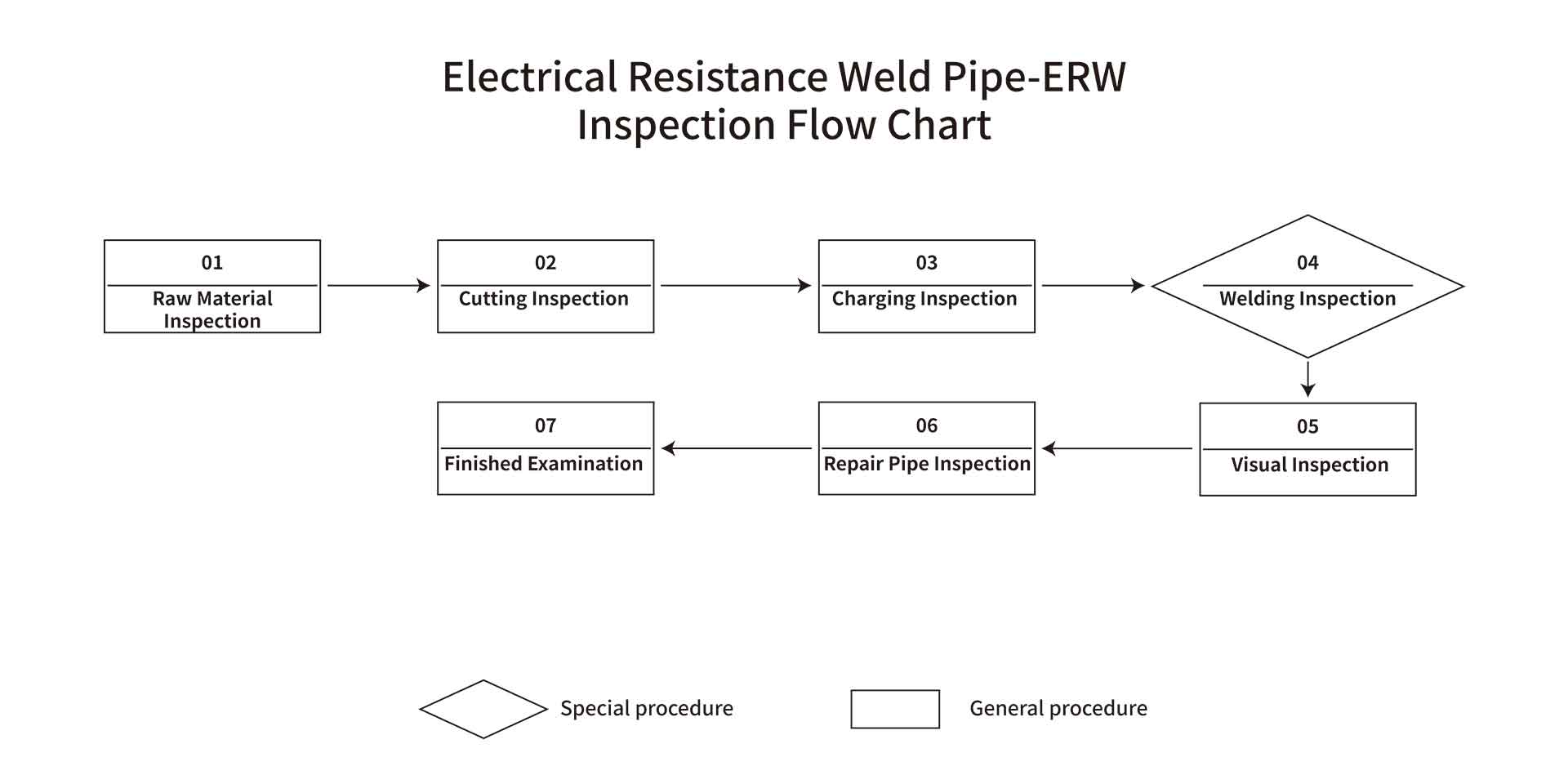

Motlakase Resistance Weld Pipe-ERW

Chate ea Phallo ea Tlhahlobo

01. Tlhahlobo ea thepa e tala →02.Tlhahlobo ea ho seha →03.Tlhahlobo ea ho tjhaja →04.Tlhahlobo ea ho cheselletsa →05.Tlhahlobo e bonoang→06.Tlhahlobo ea lipeipi tsa ho lokisa →07.Tlhahlobo e phethiloeng

Re tla leka lisebelisoa tse tala le lits'ebetso tsa tlhahiso ho latela maemo a fapaneng ho netefatsa hore lihlahisoa li fihlella maemo kapa litlhoko tsa konteraka.

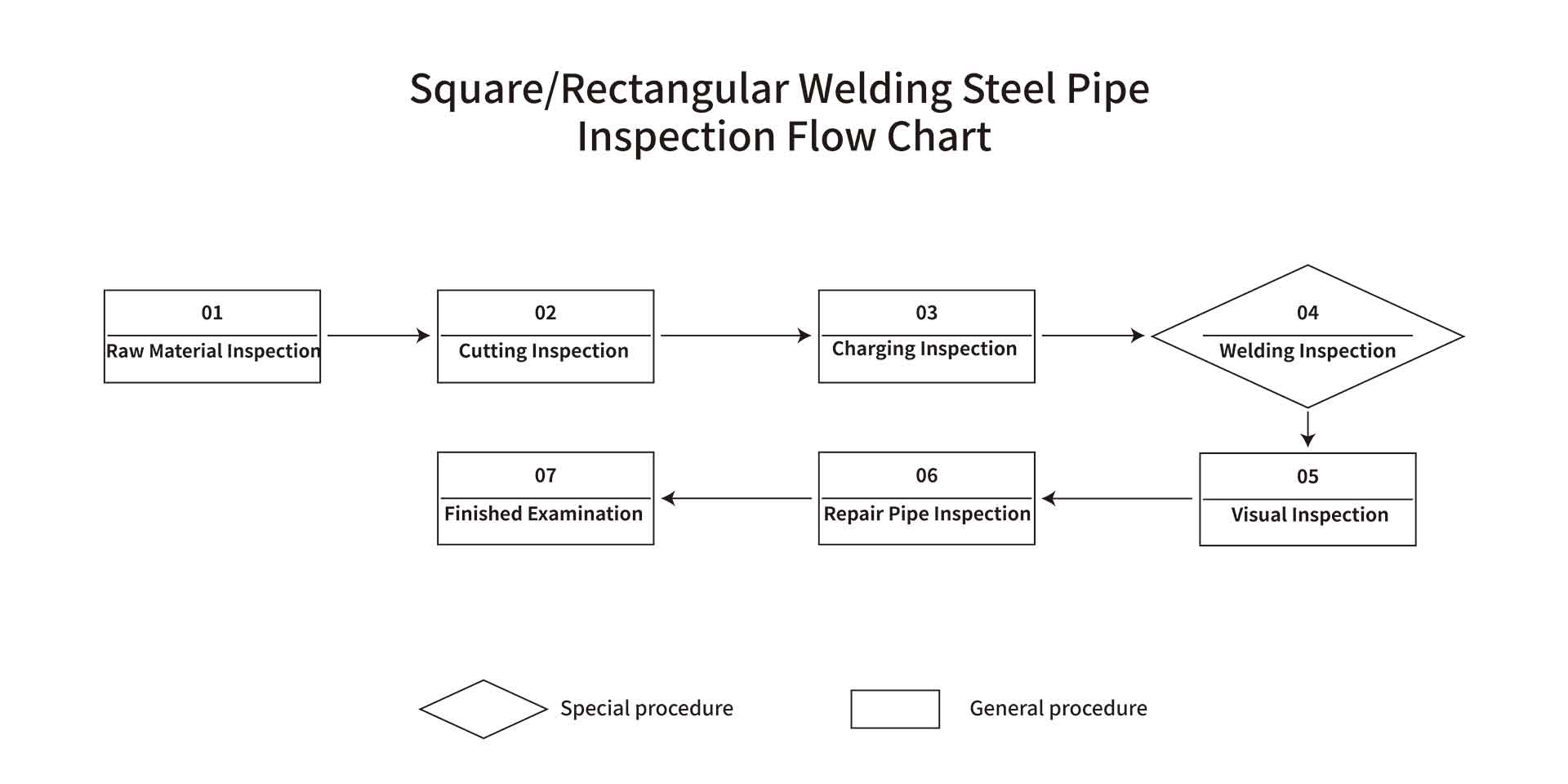

Pipe ea tšepe ea Sekwere / Rectangular Welding

Chate ea Phallo ea Tlhahlobo

01. Tlhahlobo ea thepa e tala →02.Tlhahlobo ea ho seha →03.Tlhahlobo ea ho tjhaja →04.Tlhahlobo ea ho cheselletsa →05.Tlhahlobo e bonoang→06.Tlhahlobo ea lipeipi tsa ho lokisa →07.Tlhahlobo e phethiloeng

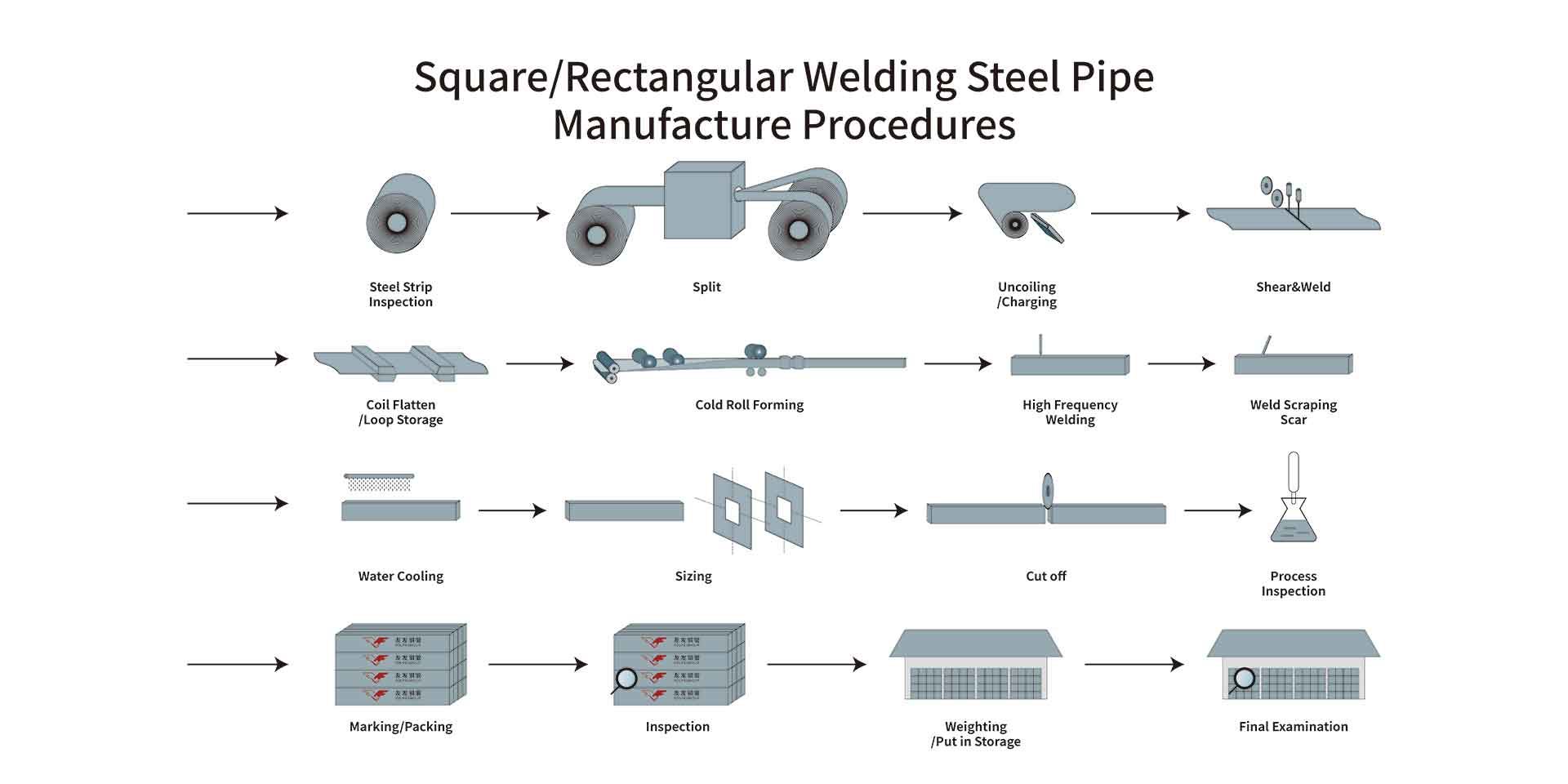

Pipe ea tšepe ea Sekwere / Rectangular Welding

Mekhoa ea Tlhahiso

01. Tlhahlobo ea likhoele tsa tšepe→ 02. Arohane→ 03.Uncoiling/Charging→04.Shear&Weld→05.Coil Flatten/Loop storage→06. Cold roll forming→07.High Frequency welding→08.Weld scraping scar→09.Ho pholisa metsi →10.Ho lekanya→11.Khaola→12.Tsebetso tlhatlhobo→13.Ho tshwaya/Ho Paka→14.Tlhahlobo→15.Boima/Beha polokelo→16.Tlhahlobo ya ho qetela

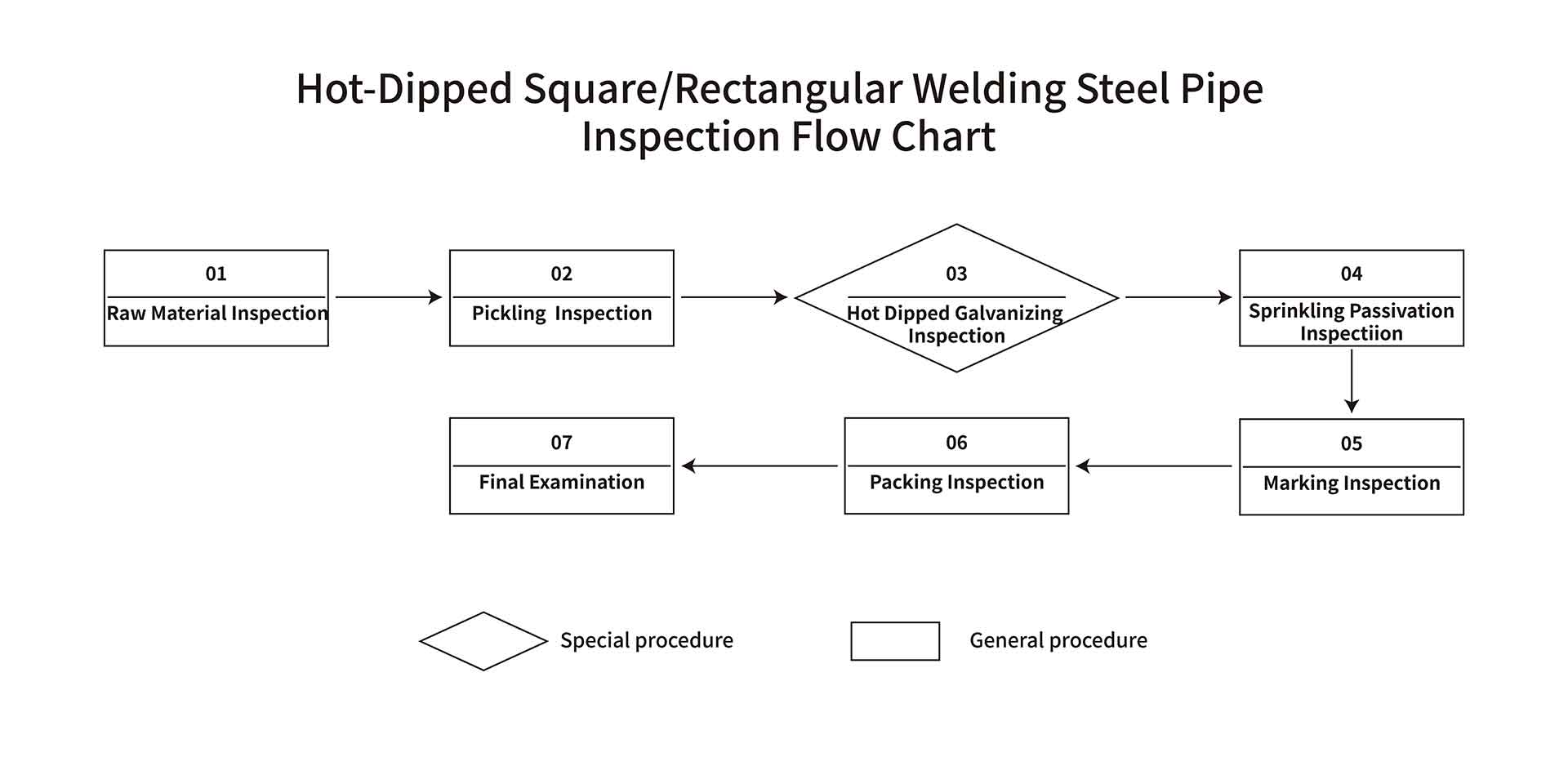

Pipe ea tšepe e kentsoeng ka ho Chesa / Rectangular Welding

Chate ea Phallo ea Tlhahlobo

01. Tlhahlobo ea thepa ea Raq→ 02.Tlhaloso ea Pickling→03.Tlhahlobo ea Sekontiri se Chesang →04.Tekolo ea Phahamiso ea Phahamiso→05.Tlhahlobo ea ho tšoaea→06.Tlhahlobo ea ho paka →07.Tlhahlobo ea ho qetela.

Re tla leka lisebelisoa tse tala le lits'ebetso tsa tlhahiso ho latela maemo a fapaneng ho netefatsa hore lihlahisoa li fihlella maemo kapa litlhoko tsa konteraka.

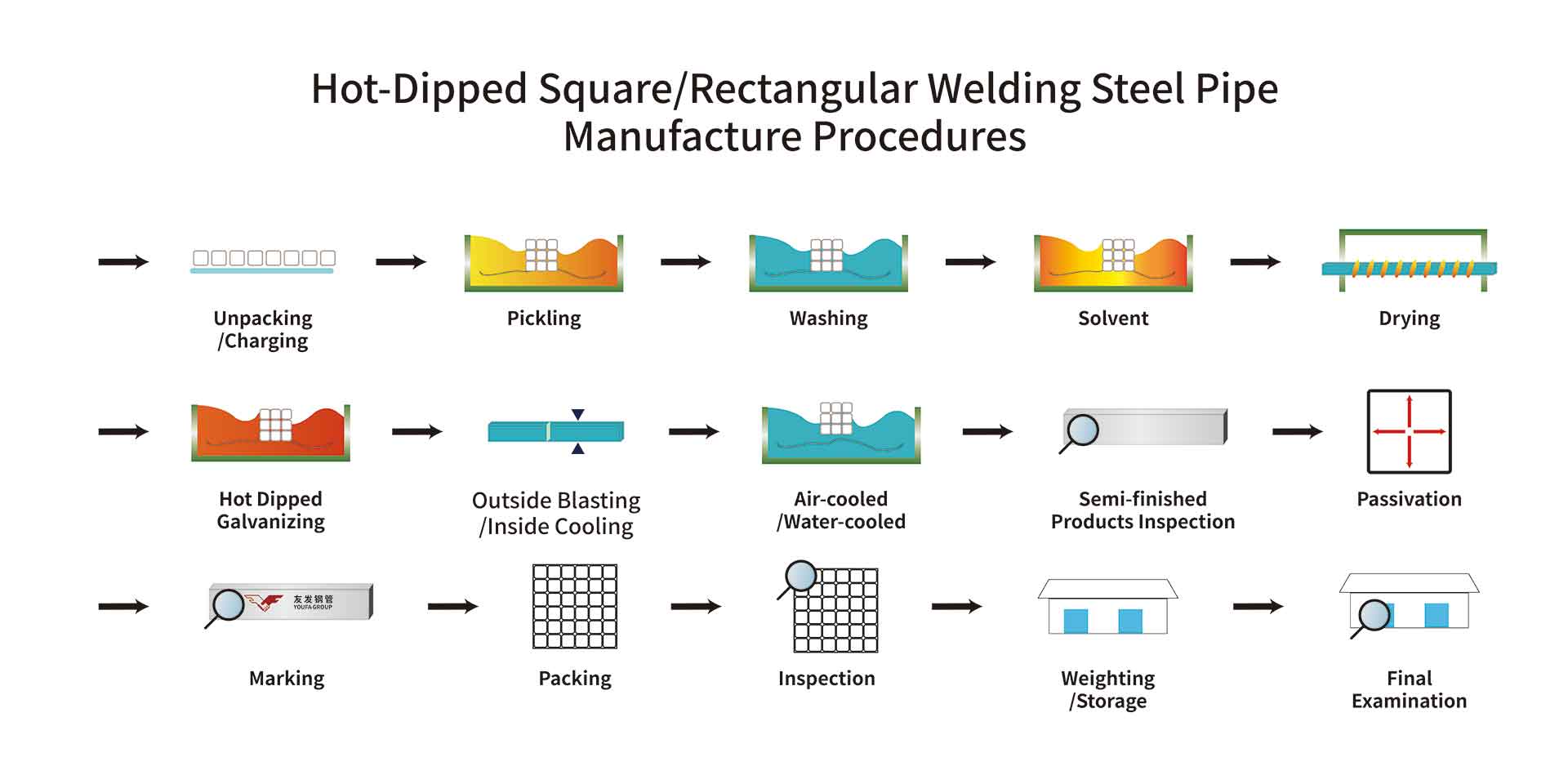

Pipe ea tšepe e kentsoeng ka ho Chesa / Rectangular Welding

Mekhoa ea Tlhahiso

01.Peipi ea tšepe ea ho tjheseletsa→02.Ho manolla/Ho tjhaja→03.Pickling→04.Ho hlatsoa→05.Solvent→06.Ho omisa→07.Mocheso o Kentsoeng ka Galvanizing→08.Ho phatloha ka Ntle→09.Ho Pholisa ka Hare→10.Ho pholile moea/ Metsi a pholileng→ 11.Lihlahisoa tse felileng ka halofo tlhahlobo→ 12.Pasition→13.Ho tšoaea→14.Ho paka→15.Tlhahlobo→16.Boima/Bobolokelo→17.Tlhahlobo ea ho Qetela

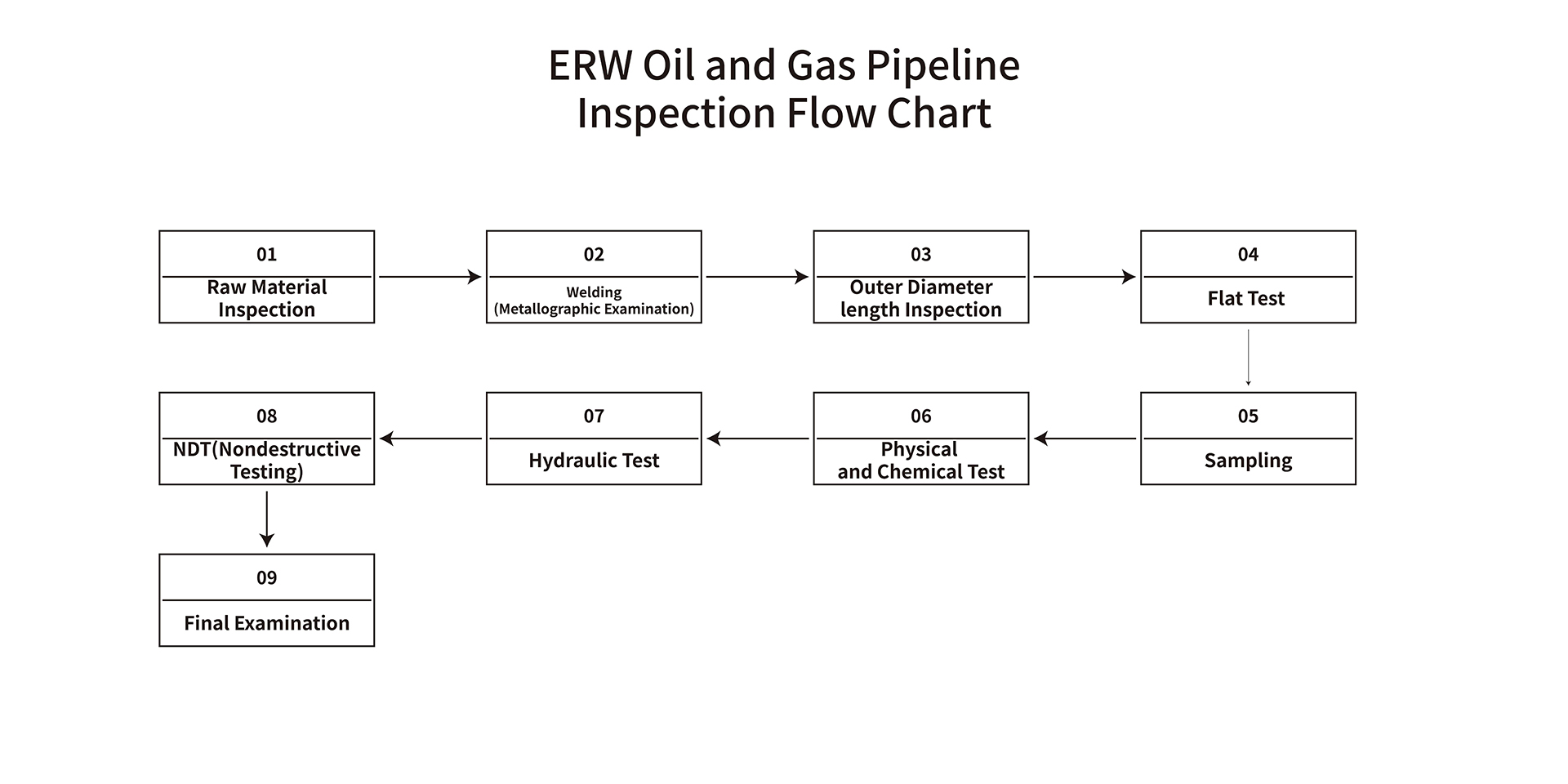

Phaephe ea oli le khase ea ERW

Chate ea Phallo ea Tlhahlobo

01. Tlhahlobo ea thepa e tala→ 02. Welding(tlhahlobo ea Metallographic)→03.Tlhahlobo ea bolelele ba bophara ba ka ntle→04.Teko ea Flat→05.Sampling→06.Teko ea 'mele le ea lik'hemik'hale→07.Teko ea Hydraulic→08.NDT(teko e sa senyeheng)→ 09.Tlhahlobo ea ho Qetela

Re tla leka lisebelisoa tse tala le lits'ebetso tsa tlhahiso ho latela maemo a fapaneng ho netefatsa hore lihlahisoa li fihlella maemo kapa litlhoko tsa konteraka.

01.Bula bophahamo ba modumo→02.Corection/The first cut/Welded→03.Loop storage→04.Figuration system→05.Welding/Tlosa burr ka hare le ka ntle→06.Tsela ea ho cheselletsa seam →07.Moea o pholileng/Metsi- e pholisitsoeng/E thehile bophara ba/Tokiso→08.Seha se fofang→09.Ka ntle ho hlahloba / ho tšoaea → 10. Qetello e hlakileng le qetello ea bevel → 11. Teko ea Hydraulic → 12. Tlhahlobo ea Ultrasonic → 13. Qetello ea liphaephe Tlhahlobo ea Ultrasonic → 14. Weighting / Record → 15. Kenya polokelo

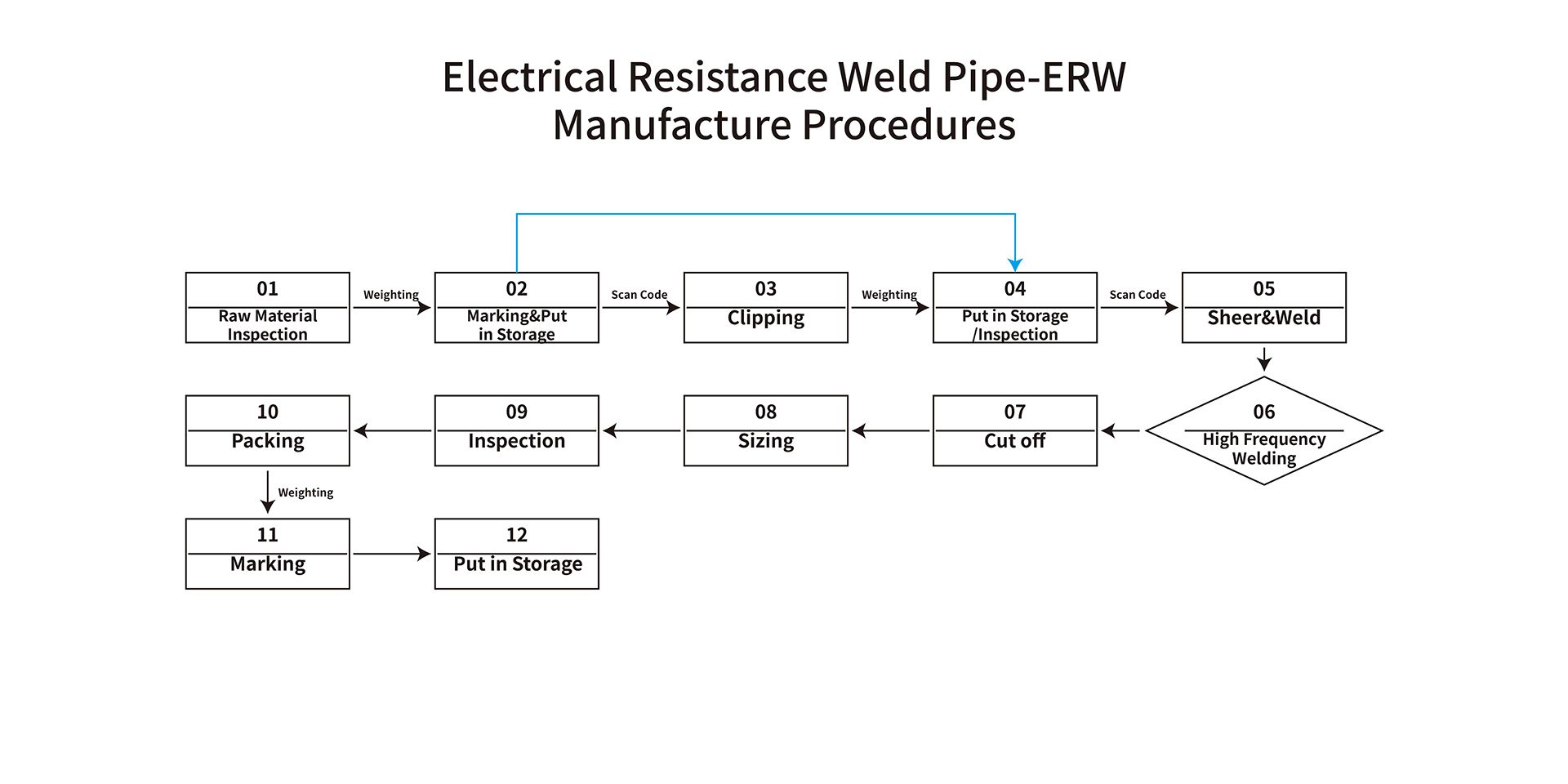

Motlakase Resistance Weld Pipe-ERW

Mekhoa ea Tlhahiso

01. Tlhahlobo ea thepa e tala→02.Ho tšoaea&Beha polokelo→03.clipping→04.Beha polokelong/Tlhahlobo→05.Sheer&Weld→06.Teko ea’mele le ea lik’hemik’hale→07.Khaola→08.Sizing→09.Tlhahlobo→10. Ho paka→11.Boima→12.Skena likhoutu

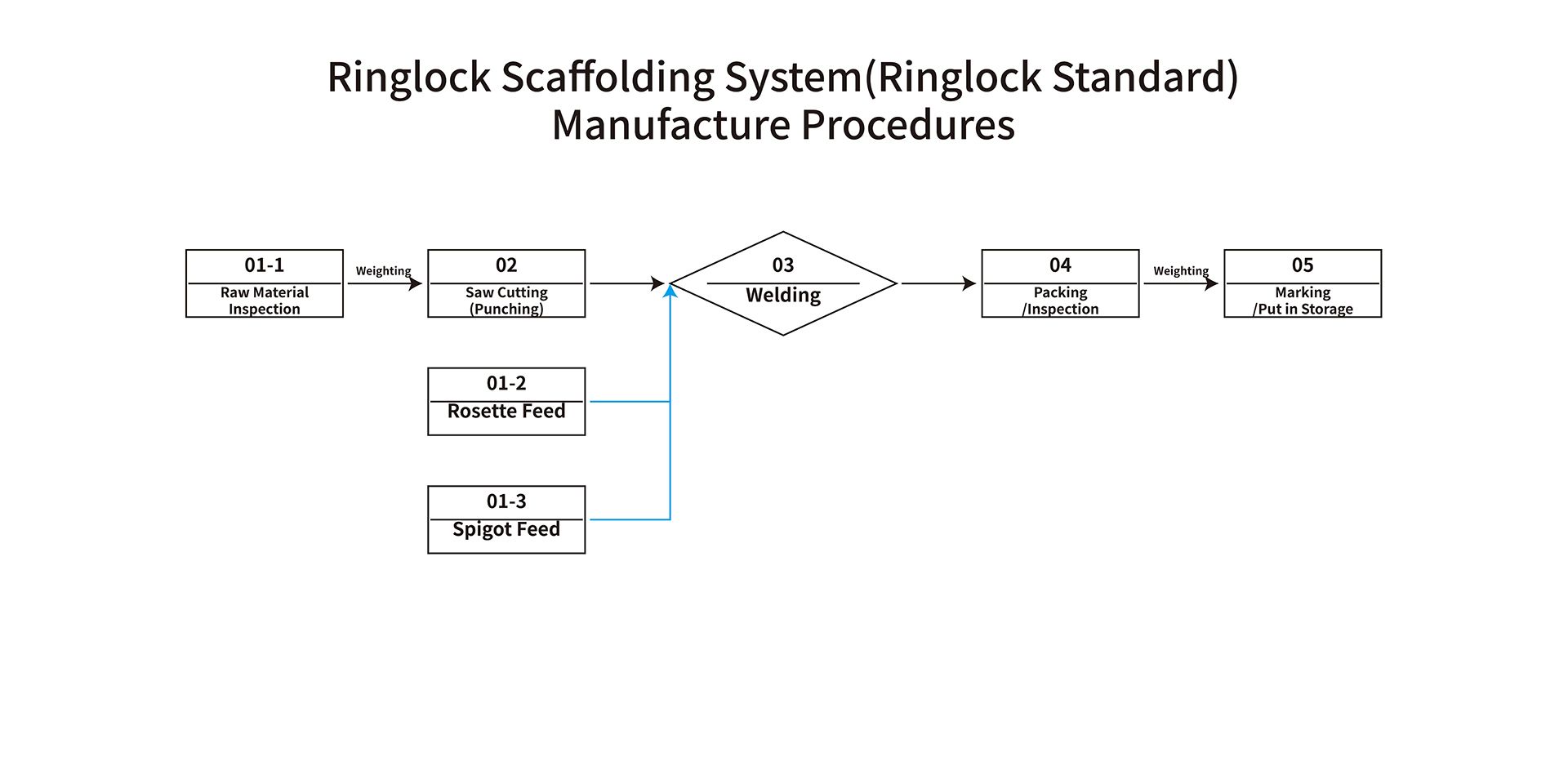

Sistimi ea Sekafo ea Ringlock(Tsela ea Ringlock)

Mekhoa ea Tlhahiso

01.Tlhahlobo ea thepa e tala→02.Seha (ho phunya)/Rosette feed/Spigot feed→03.Welding→04.Ho paka/hlahloba→05.Ho tšoaea/Beha polokelong

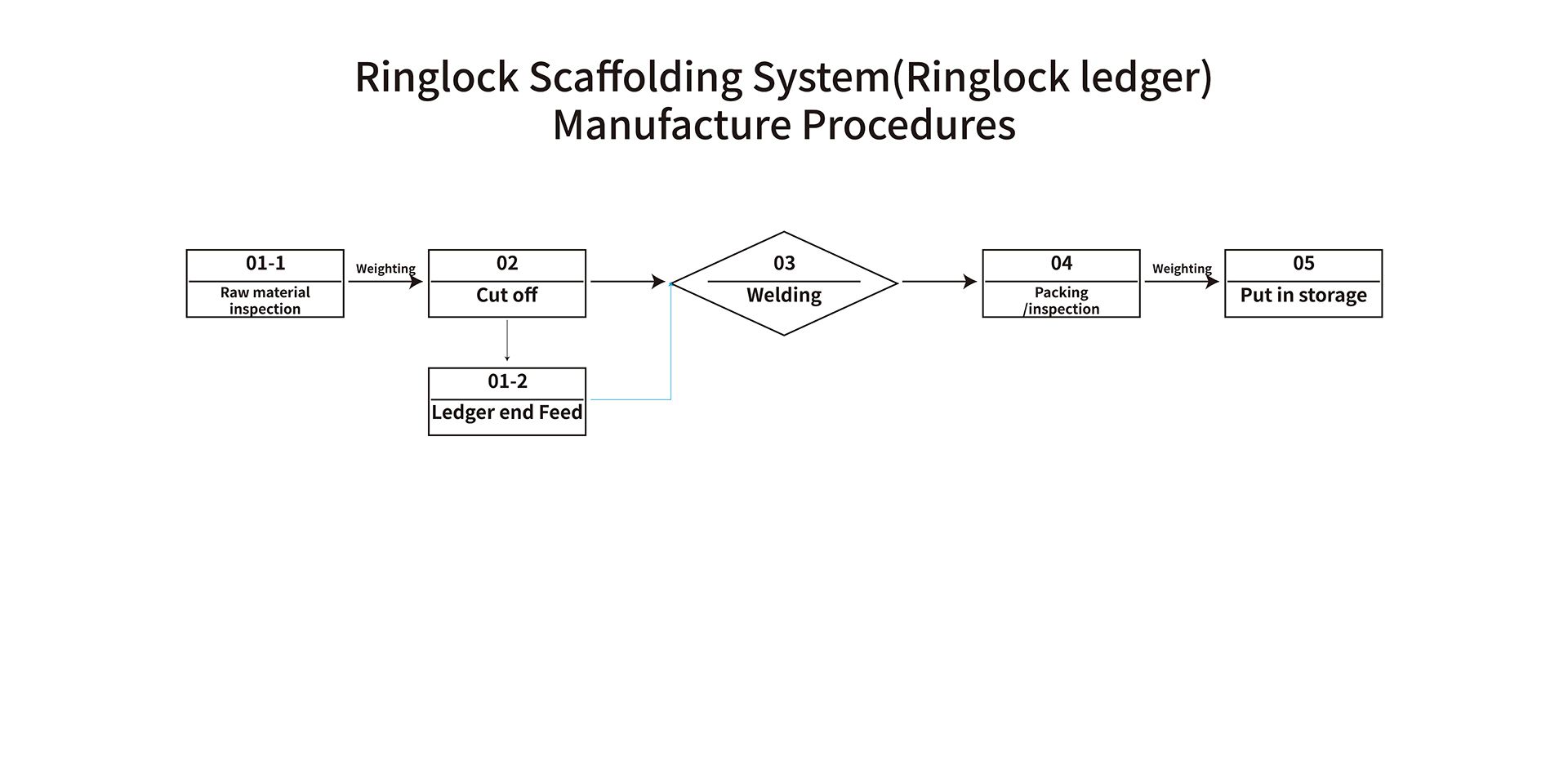

Ringlock Scaffolding System(Ledger ea Ringlock)

Mekhoa ea Tlhahiso

01.Tlhahlobo ea thepa e tala→02.Khaoha/Sephepelo sa Ledger→03.Welding→04.Ho paka/hlahloba→05.Ho tšoaea/Beha polokelong

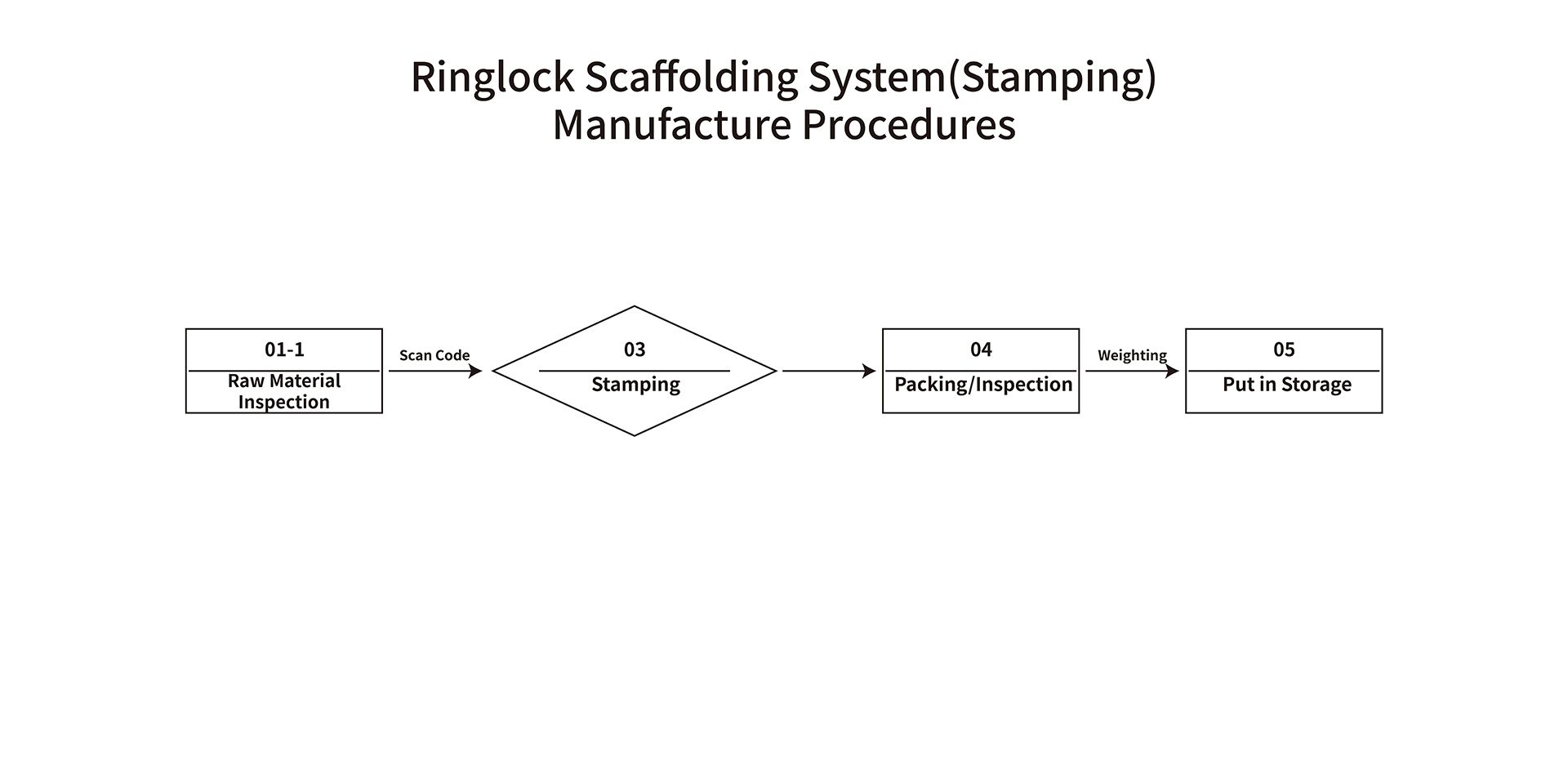

Sistimi ea Sekafo ea Ringlock(Ho hatakela)

Mekhoa ea Tlhahiso

01.Tlhahlobo ea thepa e tala→02.Ho hatakela →03.Ho paka/Hlahloba→04.Beha polokelong

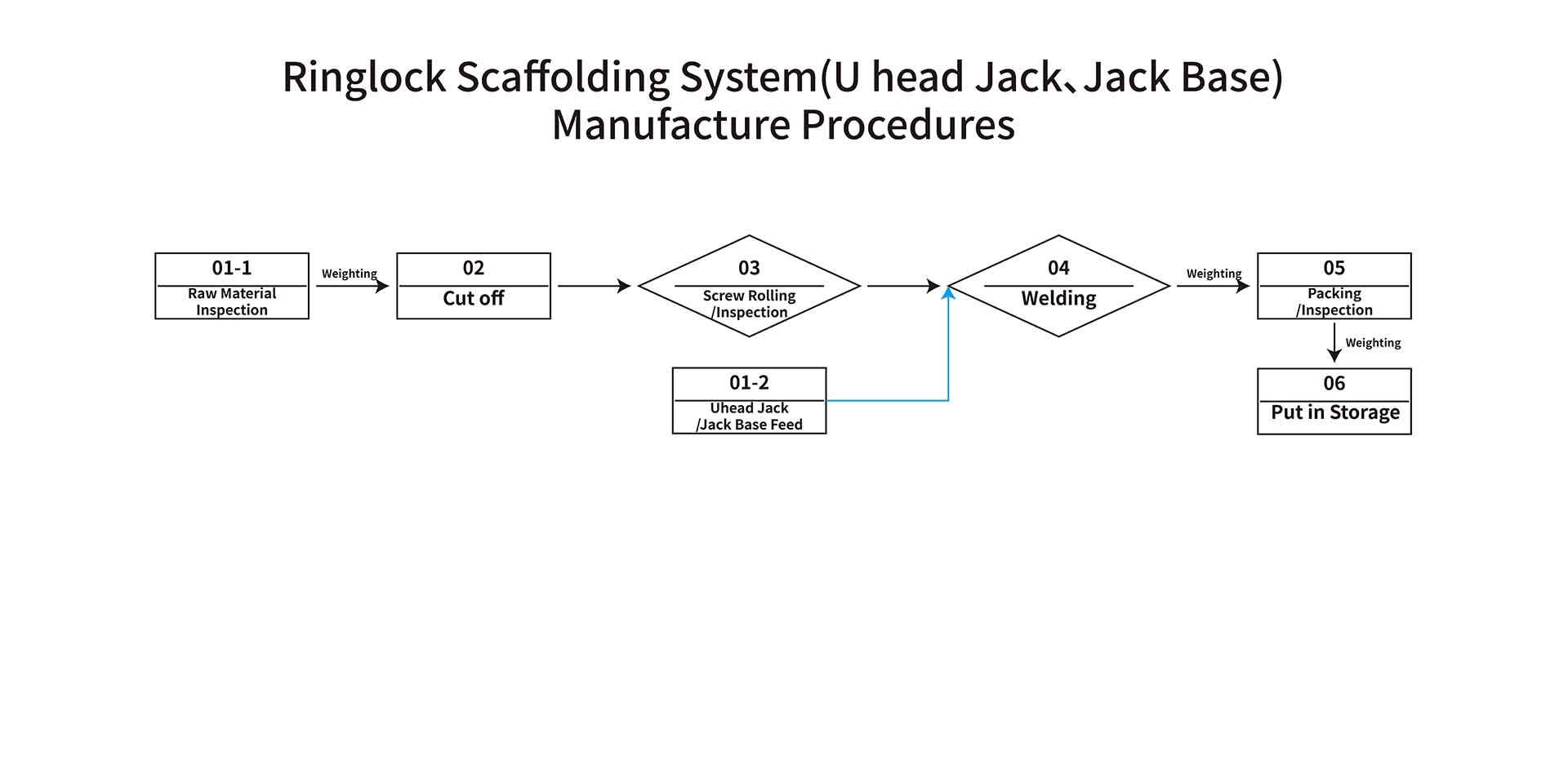

Ringlock Scaffolding System (U hlooho jack, Jack base)

Mekhoa ea Tlhahiso

01.Tlhahlobo ea thepa e tala→ 02.Khaola →03.Screw rolling/Inspection/The Head Jack /jack base feed→04.Welding→05.Packing/inspection→06.Beha polokelong

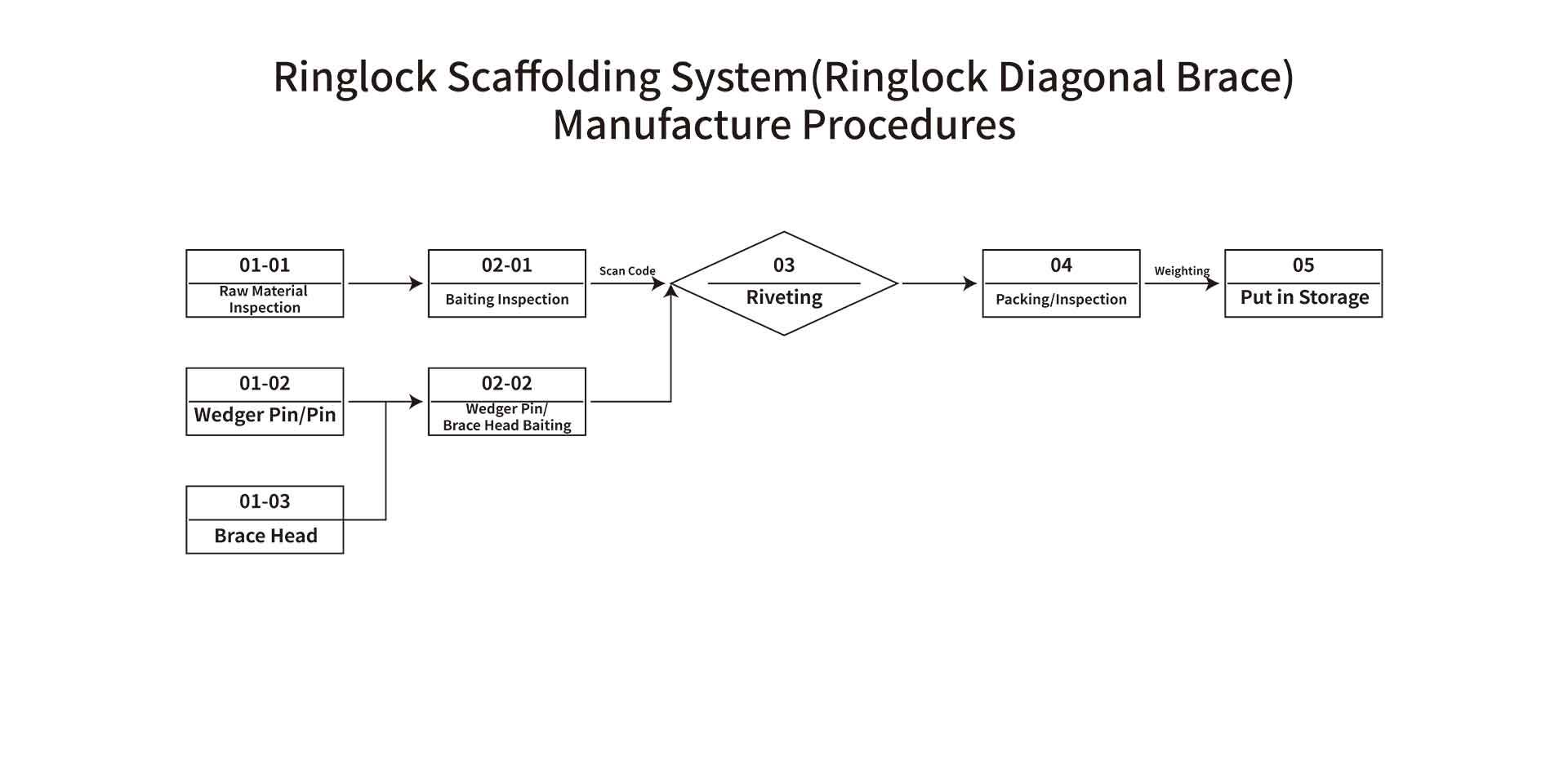

Ringlock Scaffolding System (Ringlock diagonal brace)

Mekhoa ea Tlhahiso

01.Tlhahlobo ea thepa e tala/Wedger Pin/Pin/Hlooho → 02.Tlhahlobo ea Baiting/edger pin/Baiting ea hlooho ea Brace→03.Welding→04.Paka/tlhahlobo→05.Beha polokelong