* HLOKOMELA

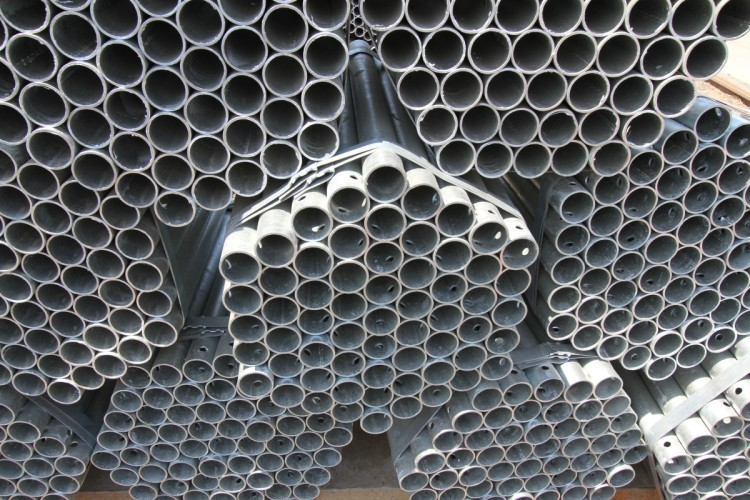

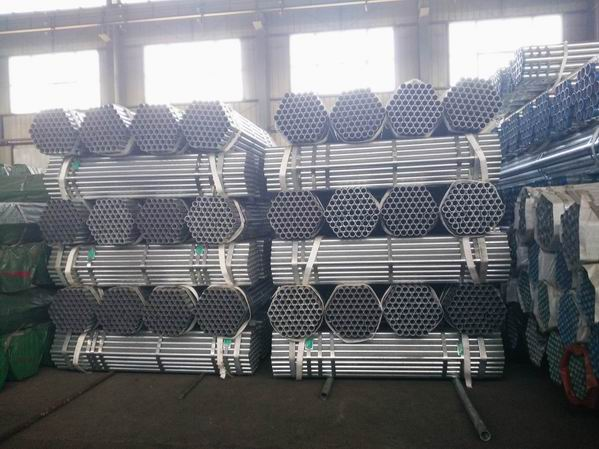

Pipe e entsoeng ka sekontiri se chesang ke ho etsa hore tšepe e qhibilihisitsoeng e sebetsane le matrix ea tšepe ho hlahisa lesela la alloy, kahoo e kopanya matrix le ho roala. Ho kenya metsi a chesang pele asiti ea pele e hlatsoa phala ea tšepe ho ntša oxide ea tšepe holim'a phala ea tšepe. Ka mor'a ho hlatsoa asiti, e hloekisoa ka tanka ka ammonium chloride kapa zinki chloride aqueous solution kapa motsoako oa ammonium chloride le zinc chloride aqueous solution, ebe e romelloa bateng ea metsi a chesang.

Hot-dip galvanizing e na le melemo ea ho roala ka mokhoa o ts'oanang, ho khomarela ka matla, khanyetso e ntle ea kutu, le bophelo bo bolelele ba ts'ebeletso. Haholo-holo libakeng tse thata, tse kang mongobo, pula, pula ea acid, setlolo sa letsoai le libaka tse ling, ts'ebetso ea hot-dip galvanizing e hlahella haholoanyane. Karolo e ka tlaase ea tšepe le tharollo ea ho qhibiliha ea tšepe e sebetsa ka thata 'meleng le lik'hemik'hale ho theha lesela le sa bolaeeng ke tšepe la zinc-alloy le sebopeho se thata. Lera la alloy, lesela le hloekileng la zinki, le substrate ea tšepe li kopantsoe hammoho. Ka hona, e na le khanyetso e matla ea kutu.

1. Ho se tšoane ha ho roala: Mohlala oa phala ea tšepe o ke ke oa fetoha o mofubelu ('mala o entsoeng ka koporo) ka mor'a ho qoelisoa ka tharollo ea sulfate ea koporo ka makhetlo a 5 a latellanang.

2. Boleng ba bokaholimo: Bokaholimo ba peipi ea tšepe ea masenke e tla ba le lera le felletseng la masenke, 'me ho ke ke ha e-ba le matheba a matšo le lipululana tse sa tlotsoang. E lumelletsoe ho ba le sebaka se mahoashe hanyenyane le maqhutsu a zinki a sebakeng seo a leng teng.

| Phapano ke efe lipakeng tsa hot dip galvanized le pre galvanized? | |||||||

| Pipe ea Tšepe e Chesang ea Dip | Pipe ea tšepe ea pele ea Galvanized | ||||||

| Botenya ba Pipe ea tšepe | 1.0mm le ho feta | 0.8mm ho isa ho 2.2mm | |||||

| Ho roala ka Zinc | karolelano ea 200g/m2 ho isa ho 500g/m2 (30um ho isa ho 70um) | karolelano ea 30g/m2 ho isa ho 100g/m2 (li-microns tse 5 ho isa ho tse 15) | |||||

| Molemo | esita le ho roala, ho khomarela ka matla, ho tiisa hantle, le nako e telele ea bophelo | bokaholimo bo boreleli, 'mala o khanyang, le ho roala ho tšesaane | |||||

| Tšebeliso | e sebelisoang haholo ho lipalangoang tsa metsi a tlaase bakeng sa metsi, likhoerekhoere, khase, moea, mocheso oa mocheso, kaho ea masepala, petrochemical, shipbuilding le masimo a mang. | boenjiniere ba meralo, tlhahiso ea thepa ea ka tlung le mafapha a mang. | |||||

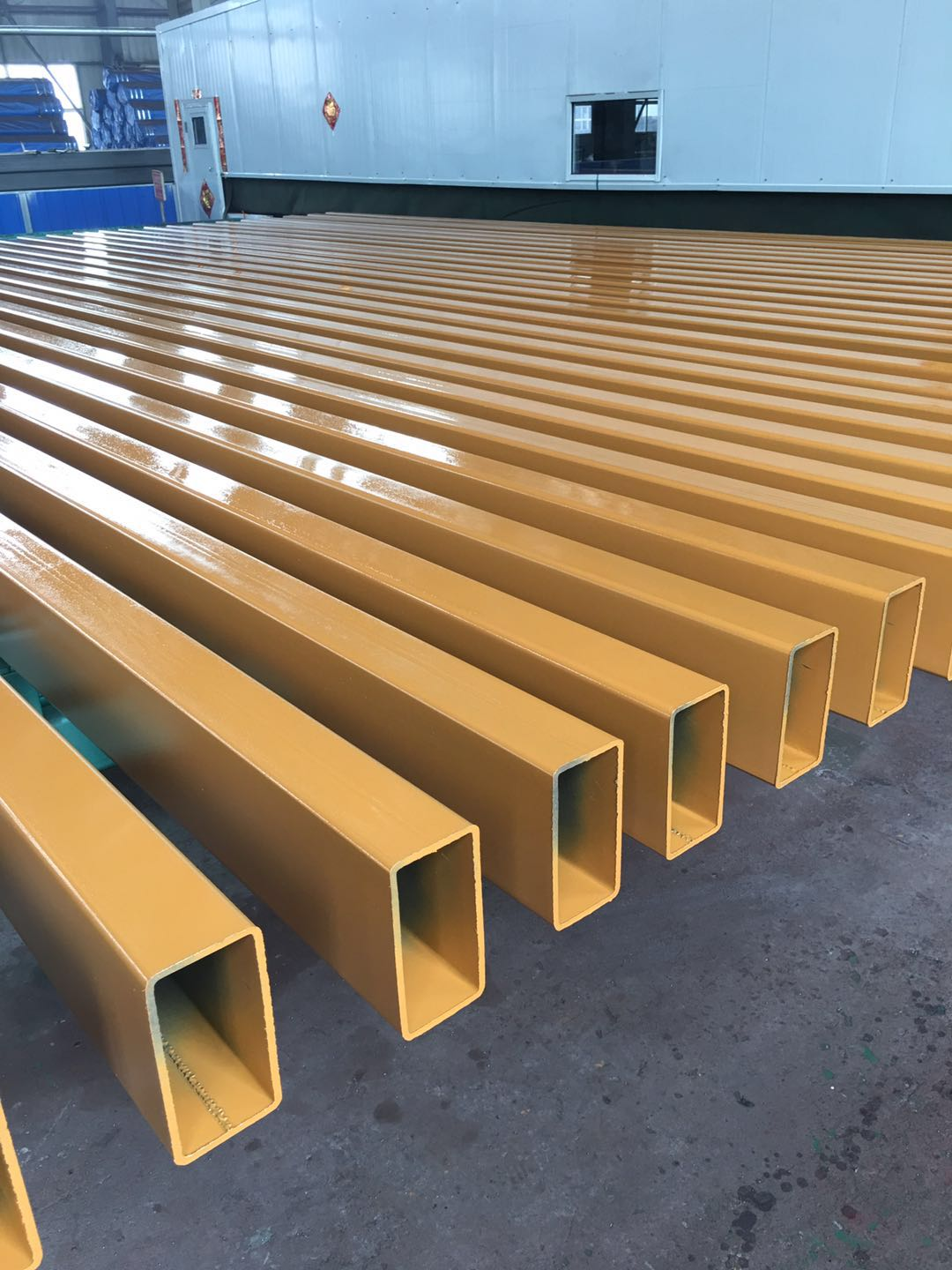

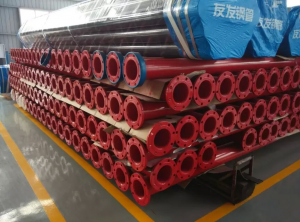

* PENTHA

Peipi ea tšepe e pentiloeng ke ho fafatsa liphahlo tse mebala e fapaneng holim'a phala ea tšepe e le ho ntlafatsa ho hanyetsa ha kutu le botle ba phala. Liphaephe tsa tšepe tse pentiloeng li kenyelletsa liphaephe tsa tšepe tse tlositsoeng ka spray le lipeipi tsa tšepe tse pentiloeng.

Peipi ea tšepe e koahetsoeng ka spray e qala ho hlatsuoa ka asiti, ka galvanized le phosphated, ebe e fafatsoa ka electrostatic. Melemo ea mokhoa ona ke ho khomarela ka matla ha ho roala, ha ho bonolo ho ebola, ts'ebetso e ntle ea tšireletso, mebala e khanyang le e ntle; bothata ke hore litšenyehelo li batla li phahame, 'me lisebelisoa tse khethehileng tsa ho fafatsa le basebetsi ba nang le tsebo e phahameng ba hlokeha ho sebetsa.

Penta tšepe phala ke ka ho toba fafatsa-pente mebala e fapaneng barbotage ka holim'a phala tšepe ntle ho hlatsoa acid, galvanized kapa phosphating, e le hore ho ntlafatsa ho hanyetsa kutu le aesthetics ea phala. Melemo ea mokhoa ona e batla e le theko e tlaase le ts'ebetso e bonolo le e bonolo; mefokolo ke ho khomarela ho fokolang, ho thata ho finyella phello ea nako e telele ea ho hanyetsa ha kutu, le 'mala o batlang o le monotonous.

Ha u sebelisa liphaephe tsa tšepe tse pentiloeng, ho hlokahala hore u khethe mofuta o nepahetseng oa pente, 'mala le botenya ho latela maemo a khethehileng a tšebeliso le litlhoko. Ka nako e ts'oanang, e lokela ho netefatsoa hore holim'a phala ea tšepe e omme, e hloekile ebile e boreleli ho netefatsa hore phello ea ho khomarela litlolo le bophelo ba tšebeletso.

Pipe ea tšepe e tlotsitsoeng ka spray

Peipi ea tšepe e pentiloeng

* 3PE FBE

3PE (3-Layer Polyethylene) le FBE (Fusion Bonded Epoxy) ke mefuta e 'meli ea liphahlo tse sebelisoang liphaepheng le liphaepheng tsa indasteri ea oli le khase ho fokotsa kapa ho thibela ho bola.

3PE ke lesela le mekato e meraro le nang le epoxy primer, sekhomaretsi sa copolymer, le topcoat ea polyethylene. The epoxy primer e fana ka sebaka se setle sa ho tlama bakeng sa sekhomaretsi sa copolymer, seo ka lehlakoreng le leng se fanang ka sebaka se tlamang bakeng sa topcoat ea polyethylene. Likarolo tsena tse tharo li sebetsa 'moho ho sireletsa phala hore e se ke ea bola, e senyehile, 'me e senyehe.

FBE, ka lehlakoreng le leng, ke mokhoa oa ho roala ka mekhahlelo e 'meli o nang le motheo oa epoxy resin e tletseng likaroloana le topcoat eo e leng polyamide. Epoxy e tletseng likaroloana e fana ka mokhoa o babatsehang oa ho khomarela likarolo tsa tšepe, ha topcoat e fana ka lik'hemik'hale tse ntle haholo tsa lik'hemik'hale le ho hanyetsa abrasion. Liaparo tsa FBE li sebelisoa lits'ebetsong tse fapaneng, ho tloha ho lipeipi tsa oli le khase ho ea ho metsi le lits'ebetso tsa metsi a litšila.

Liaparo tse peli tsa 3PE le FBE li sebetsa hantle ho sireletseng liphaephe le liphaephe hore li se ke tsa bola, ho itšetlehile ka litlhoko tse khethehileng tsa kopo. Khetho pakeng tsa tse peli hangata e tsamaisoa ke lintlha tse kang mofuta oa lipeipi, maemo a ho sebetsa le litšenyehelo.

| 3PE VS FBE | |||||||

| Matla a ho khomarela | Ho roala ha 3PE ho fana ka matla a phahameng a ho khomarela ho feta FBE, kaha sekhomaretsi sa copolymer ho 3PE se thusa ho kopanya hantle pakeng tsa epoxy primer le polyethylene topcoat layers. | ||||||

| Tšusumetso le Abrasion | The polyethylene topcoat ka 3PE barbotage e fana ka khanyetso e betere khahlanong le tšusumetso le abrasion ha e bapisoa le FBE. | ||||||

| Tšebeliso | Liaparo tsa FBE li khethoa liphaepheng moo mocheso o sebetsang o leng holimo kaha o khona ho mamella mocheso o phahameng ho feta 3PE. Ka lehlakoreng le leng, liphahlo tsa 3PE li khethoa lits'ebetsong moo pipeline e pepesetsoang mobu le metsi, kaha e fana ka tšireletso e ntle khahlanong le ho senya le mafome. | ||||||

* Ho tlotsa oli

Ho sebelisa oli karolong e ka ntle ea phala ea tšepe ke mokhoa oa ho fana ka tšireletso ea kutu le tšireletso ho pipe ea tšepe. Oling e ka fokotsa ho kopana pakeng tsa phala ea tšepe le tikoloho e ka ntle, le ho thibela phala ea tšepe hore e se ke ea angoa ke oxidation, corrosion, ho apara, joalo-joalo.

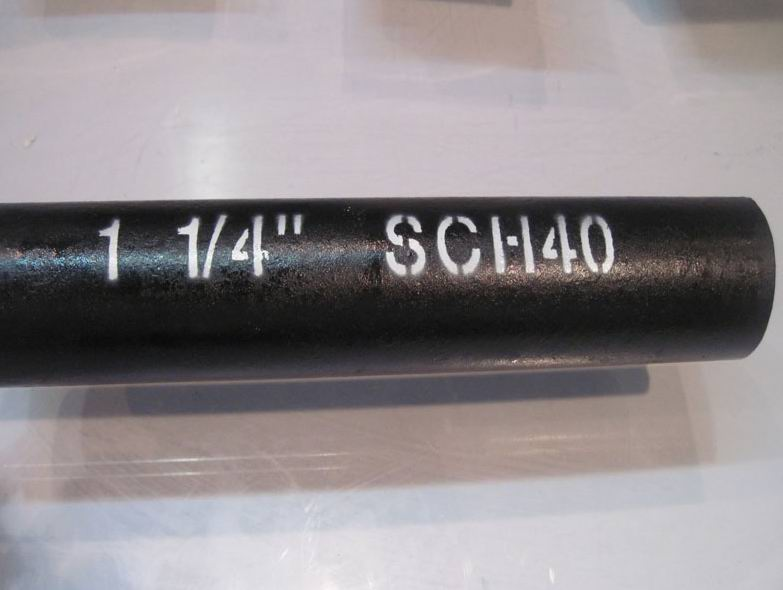

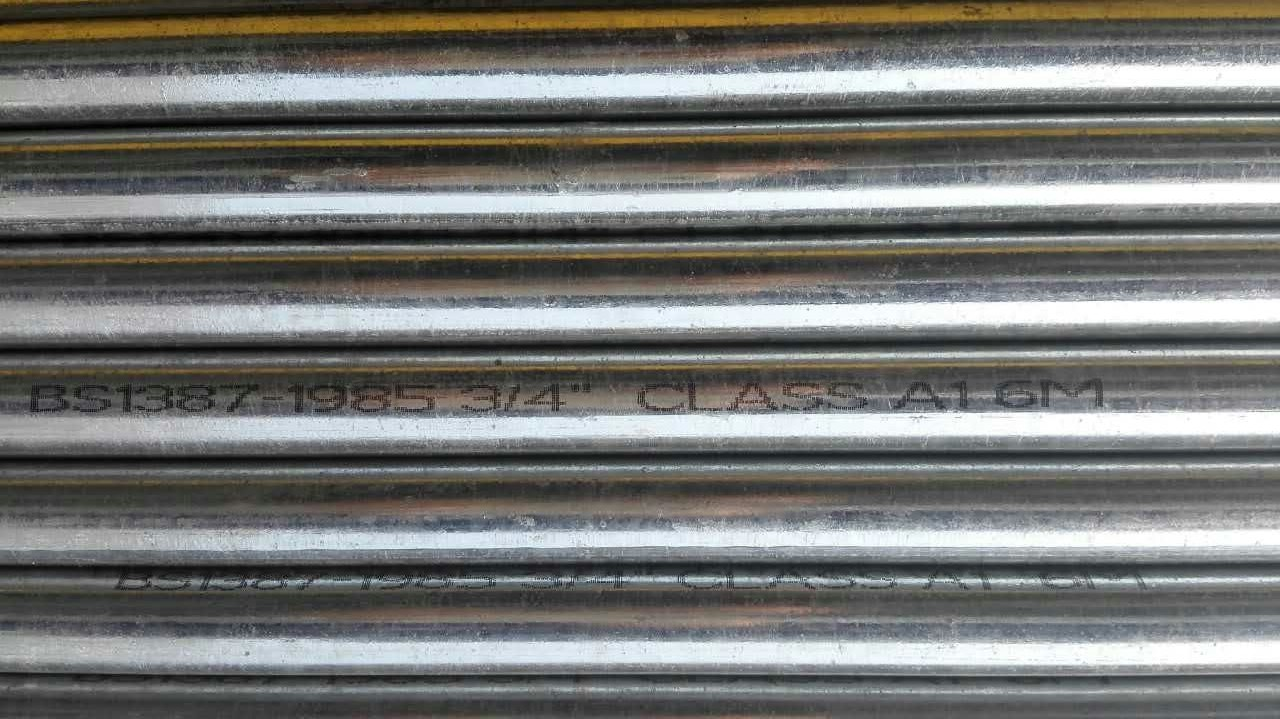

*Stencil kapa setempe

Setempe

Stencil

*Ho phunya

Sebetsa mochini oa ho phunya ka mochini ho kenya khatello ho punch o sebelisa mochini oa ho phunya. Boloka khatello e tsitsitseng ho fihlela punch e kenella leboteng la phala ea tšepe, e etsa lesoba le hloekileng le le nepahetseng.

Ts'ebetso ea ho cheka lipeipi tsa tšepe e na le mefuta e mengata ea lits'ebetso, ho kenyelletsa empa e sa felle ho tse latelang:

1. Ho hokela lipeipi tsa tšepe: Ho cheka ke o mong oa mekhoa e sebelisoang ka tloaelo bakeng sa ho hokahanya lipeipi tsa tšepe. Ka mokhoa oa ho cheka lipeipi tsa tšepe, likoti li ka buloa phala ea tšepe, e le hore liboutu le linate li kenngoe manonyeletsong le li-flanges, e le ho fihlela sepheo sa ho hokahanya.

2. Ho lokisoa ha liphaephe tsa tšepe: Hape ke kopo e tloaelehileng ea ho lokisa liphaephe tsa tšepe marakong kapa libakeng tse ling ka mokhoa oa ho phunya lipeipi tsa tšepe.

Tšebeliso ea tšepe sebopeho sa solar panel bracke

Tšebeliso ea thepa ea litsela tse kholo

* Ho khoele

NPT (National Pipe Thread) le BSPT (British Standard Pipe Thread) ke maemo a mabeli a tloaelehileng a liphaephe.

Likhoele tsa NPT li sebelisoa hangata Amerika Leboea mme likhoele tsa BSPT li sebelisoa haholo Europe le Asia.

Maemo ana ka bobeli a na le likhoele tse tepeletseng tse etsang tiiso e tiileng ha e tiisa hammoho. E sebelisoa haholo ho hokahanya ha metsi, khase, oli le liphaephe tse ling.

2. Ho lokisoa ha liphaephe tsa tšepe: Hape ke kopo e tloaelehileng ea ho lokisa liphaephe tsa tšepe marakong kapa libakeng tse ling ka mokhoa oa ho phunya lipeipi tsa tšepe.

* E hahiloe

Khokahano ea Roll Groove ke mokhoa o tsebahalang oa ho hokahanya liphaephe tsa ts'ireletso ea mollo hobane o fana ka melemo e mengata. Melemo e meng ea mantlha ke ena:

1. Ho kenngoa ha bonolo le ka potlako: Khokahano ea Roll Groove e lumella ho kenya liphaephe le lisebelisoa tse potlakileng le tse bonolo, kaha ha ho hlokahale hore ho be le welding kapa khoele.

2. Tšireletso ea moruo le ea tikoloho: Mokhoa ona oa ho hokahanya o na le litšenyehelo tse ngata ho feta mekhoa e meng, e leng se etsang hore e be khetho e ratoang bakeng sa likopo tse ngata. E boetse e baballa tikoloho kaha e fokotsa litšila ebile e sebelisa lisebelisoa tse fokolang.

3. E boloka litšobotsi tsa pele tsa liphaephe: Khokahano ea Roll Groove ha e ame thepa ea pele ea liphaephe, tse kang matla a tsona, nako e telele le ho hanyetsa ho bola.

4. Tlhokomelo e loketse: Haeba ho hlokomeloa le ho lokisoa ho hlokahala, khokahanyo ea Roll Groove e etsa hore ho be bonolo ho qhaqha le ho fetola likarolo, ntle le ho hloka lisebelisoa kapa lisebelisoa tse khethehileng.

| DN | Kantle Diameter | Ho Tiisa Bophara ba Sebaka ± 0.76 | Bophara ba Groove ±0.76 | Groove Bottom Diameter | |

| mm | Mamello | ||||

| 50 | 60.3 | 15.88 | 8.74 | 57.15 | -0.38 |

| 65 | 73 | 15.88 | 8.74 | 69.09 | -0.46 |

| 65 | 76.1 | 15.88 | 8.74 | 72.26 | -0.46 |

| 80 | 88.9 | 15.88 | 8.74 | 84.94 | -0.46 |

| 100 | 114.3 | 15.88 | 8.74 | 110.08 | -0.51 |

| 125 | 141.3 | 15.88 | 8.74 | 137.63 | -0.56 |

| 150 | 165.1 | 15.88 | 8.74 | 160.78 | -0.56 |

| 150 | 168.3 | 15.88 | 8.74 | 163.96 | -0.56 |

| 200 | 219.1 | 19.05 | 11.91 | 214.4 | -0.64 |

* Ho hlolloa

Diameter e kholoanyane ho feta NPS 11⁄2 [DN 40] e bevele e bataletseng e nang le lipheletso tse kobelitsoeng ho ea ho 30°, +5°, -0°

* Liphello tse hlakileng

Ho khaola mahlakore ka bobeli a liphaephe tsa tšepe ka lifofane tse 90◦ ho ea ho axis ke ntho e tloaelehileng e hlokahalang liindastering tse ngata moo liphaephe li sebelisoang teng. Hangata sena se etsoa ho lokisa phala bakeng sa tjheseletsa kapa mefuta e meng ea likhokahano, le ho etsa bonnete ba hore lipheletsong li bataletse ebile li lebile holima axis ea phala.

* E khutsitse

Pipe ea tšepe e nang le flanged ke mofuta oa phala e nang le flange e khomaretsoeng ka lehlakoreng le le leng kapa ka bobeli. Li-flanges ke li-discs tse chitja tse nang le masoba le liboutu tse sebelisetsoang ho hokahanya liphaephe, li-valve kapa lisebelisoa tse ling. Peipi ea tšepe e nang le flang hangata e etsoa ka ho cheselletsa flange ho fihlela qetellong ea phala ea tšepe.

Lipeipi tsa tšepe tse nang le flanged li sebelisoa hangata liindastering tse kang phepelo ea metsi, oli le khase, le ts'ebetso ea lik'hemik'hale. Li khethoa ho feta mefuta e meng ea liphaephe hobane li ka kenngoa habonolo ebile li tšoarella haholo. Liphaephe tse nang le flanged li ka mamella khatello e phahameng 'me li ka qhaqhoa habonolo bakeng sa tlhokomelo kapa ho lokisoa.

Li-flange tse peiping ea tšepe e nang le flanged li tla ka libopeho le boholo bo fapaneng ho lumellana le litlhoko tsa ho hokahanya. Mefuta e tloaelehileng e kenyelletsa li-slip-on flanges, li-weld neck flanges, li-threaded flanges, le li-socket weld flanges.

Ka kakaretso, liphaephe tsa tšepe tse nang le flanged ke khetho e ratoang bakeng sa liindasteri tse ngata hobane li fana ka kamano e ka tšeptjoang le e tšoarellang pakeng tsa liphaephe le lisebelisoa.

*Bolelele ba ho Seha

Theknoloji ea ho khaola metsi e tsebahala ka ho nepahala le ho nepahala, hammoho le bokhoni ba eona ba ho hlahisa likarolo tse boreleli, tse se nang burr.

E 'ngoe ea melemo e meholo ea theknoloji ea ho itšeha metsi ke hore ke mokhoa o batang oa ho itšeha, ho bolelang hore ha ho na sebaka se amehang ke mocheso (HAZ) ho potoloha sehiloeng.

Ho khaola jete ea metsi ho boetse ho na le tikoloho, kaha ha e hlahise litšila kapa mesi e kotsi. Sistimi e sebelisa feela metsi le abrasive, 'me lihlahisoa tsa litšila li ka bokelloa habonolo le ho lahloa ka mokhoa o sireletsehileng.

* Ho paka le ho tsamaisoa

Packaging ea polasetiki ea PVC

Ho sireletsa liphaephe tsa tšepe nakong ea lipalangoang le polokelo, hangata li phutheloa ka liphutheloana tsa polasetiki tsa PVC ho fana ka lera le sireletsang le thibelang mengoallo, maqeba le mefuta e meng ea tšenyo.

Ntle le ho sireletsa lipeipi tsa tšepe, liphutheloana tsa polasetiki tsa PVC li boetse li thusa ho li boloka li hloekile ebile li omme. Sena se bohlokoa haholo bakeng sa lipeipi tse tla sebelisoa lits'ebetsong moo bohloeki bo leng bohlokoa, joalo ka lits'ebetsong tsa phepelo ea metsi kapa lifemeng tsa ho lokisa lijo.

* Tsohle liphutheloana tsa pvc;

* Peipi feela e fella ka pvc e pakiloeng;

* Ke feela pipe body pvc e pakiloeng.

Ho Paka ka Lehong

Ho sireletsa lisebelisoa tsa tšepe nakong ea lipalangoang le ho ts'oaroa, bareki ba ka khetha mabokose a tloaelehileng a lehong, hape a ka hlophisoa ka li-labels tsa bareki bakeng sa ho khetholla habonolo.

Molemo oa ho sebelisa mabokose a mapolanka a tloaelehileng a nang le litšehetso tsa ho qetela ke hore a fana ka tšireletso e eketsehileng le ho fokotsa kotsi ea ho senya lihlahisoa tsa tšepe. Li boetse li etsa hore ho be bonolo ho sebetsana le lipalangoang, kaha mabokose a ka phutheloa le ho bolokoa holim'a liphalete bakeng sa ho tsamaisoa ka mobu, leoatle kapa moea.

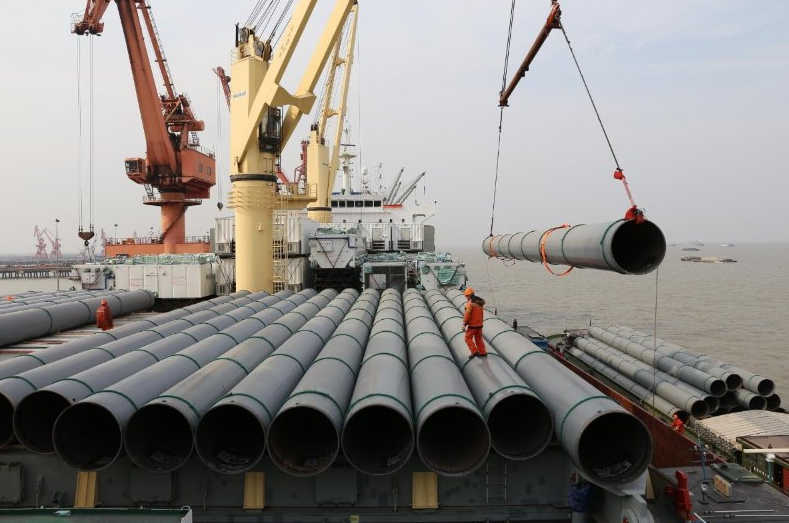

Ho tsamaisa ka sekepe

Lihlahisoa tse ngata tsa tšepe hangata li tsamaisoa ka lipalangoang tsa leoatle, fatše kapa moeeng, 'me boholo ba thepa e tsoang likoung tsa Tianjin.

Bakeng sa lipalangoang tsa leoatle, ho na le mekhoa e 'meli e meholo: ho tsamaisa thepa kapa ho tsamaisa thepa ka bongata.

Lipalangoang tsa fatše hangata li etsoa ka terene kapa teraka, ho ipapisitse le sebaka se eang le khamphani ea lipalangoang e sebelisoang.

*Ts'ehetso

Litšebeletso tsa pele ho thekiso:

1. Sampole ea mahala: Bolelele ba 20cm mahala sampuli ea tšepe ea tšepe e nang le litšenyehelo tsa ho fana tse lefelloang ke moreki.

2. Litlhahiso tsa lihlahisoa: ho sebelisa tsebo ea rona ea litsebi tsa lihlahisoa ho li khothaletsa ho bareki.

Litšebeletso tse bohareng ba thekiso:

1. Ho latela litaelo: re tla tsebisa bareki ka tlhahiso le boemo ba ho romella litaelo tsa bona ka imeile kapa fono, ho netefatsa hore ba na le kutloisiso e hlakileng ea tsoelo-pele ea litaelo tsa bona.

2. Ho fana ka litšoantšo tsa ho hlahloba le ho romella: re tla fana ka lifoto tsa sehlahisoa pele re romelloa bakeng sa bareki ho netefatsa hore na ba finyella litlhoko. Ka nako e ts'oanang, re tla boela re etse tlhahlobo e tiileng le taolo ea boleng pele re romelloa ho netefatsa hore li finyella litekanyetso tsa rona tsa boleng bo phahameng.

Litšebeletso tsa ka mor'a thekiso:

1. Ho latela maikutlo a bareki ka mor'a ho fumana thepa: re ananela maikutlo a bareki 'me re tla latela ho utloisisa tšebeliso ea bona le maikutlo a lihlahisoa tsa rona, e le hore re tsoele pele ho ntlafatsa boleng le litšebeletso tsa bona.

2. Mekhoa ea theko le tlhahisoleseding ea indasteri: rea utloisisa hore bareki ba ka 'na ba tobana le liphetoho tsa' maraka le mekhoa ea indasteri, kahoo re tla lula re fana ka tlhahisoleseding mabapi le 'maraka le matla a indasteri ho thusa bareki ho utloisisa liphetoho tsa' maraka le indasteri ka nako e loketseng, ho ba nolofalletsa ho tseba haholoanyane. le liqeto tse molemo.