Aliran Prosés Produksi sareng Aliran Inspeksi

Kalayan langkung ti 9000 karyawan anu terampil sareng 293 jalur produksi canggih anu sumebar ka 13 pabrik, kami parantos ngahasilkeun 20 juta ton pipa baja di 2022, sareng jumlah penjualan langkung ti 160 juta dolar AS dina 2018. Pikeun 17 taun berturut-turut, Youfa dijudulan diantara TOP 500 Usaha di Industri Manufaktur Cina saprak 2006.

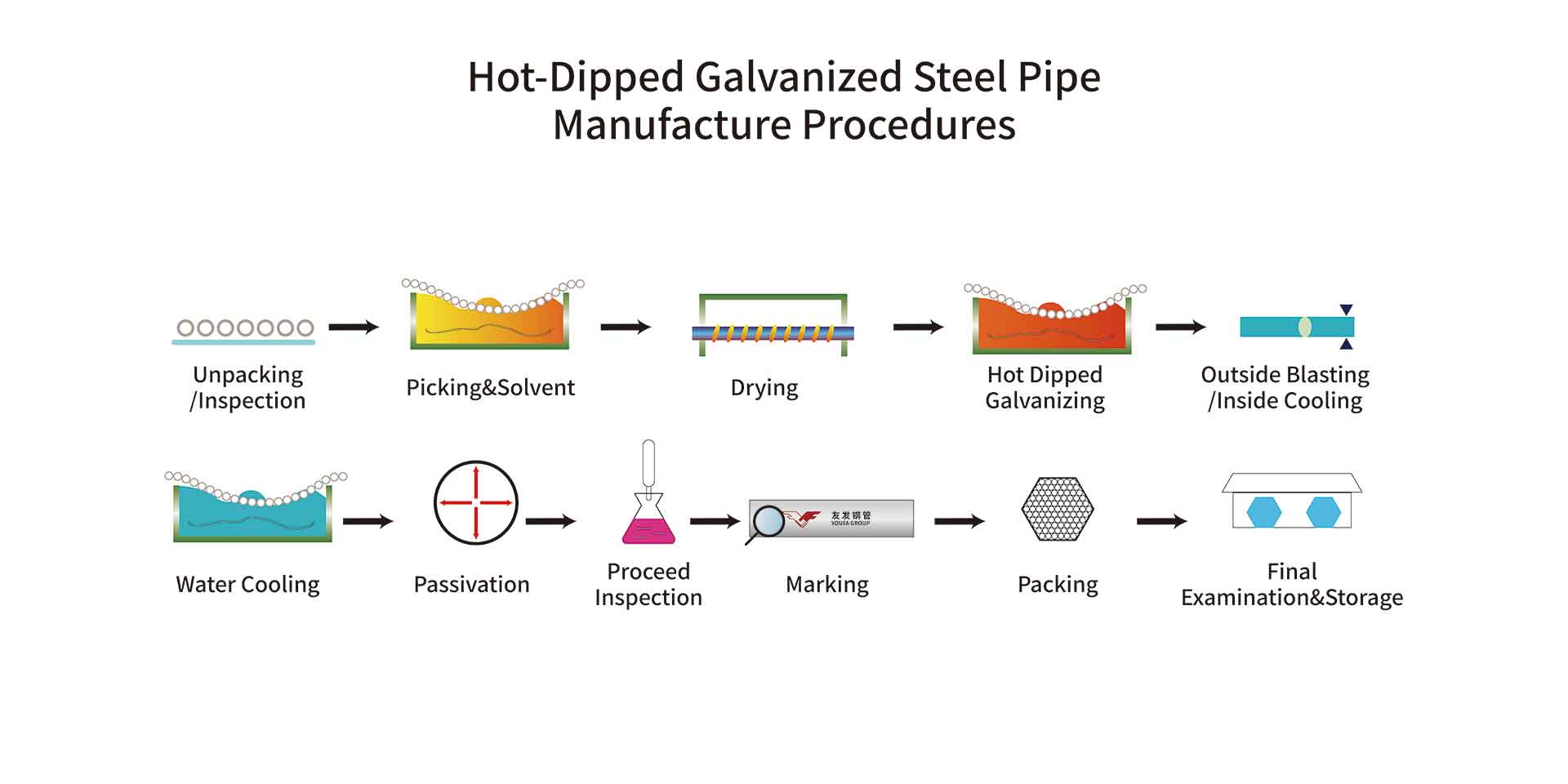

Hot-dipped Galvanized Steel Pipa

Prosedur manufaktur

01. Unpacking / Inspection → 02. Picking & Solvent → 03. Drying → 04. SHot dipped galvanizing → 05. Outside blasting / Jero cooling → 06. Water cooling → 07. Pasivation → 08. Neruskeun inspeksi → 09. Marking → 10. Packaging → 11. Ujian ahir & Panyimpenan

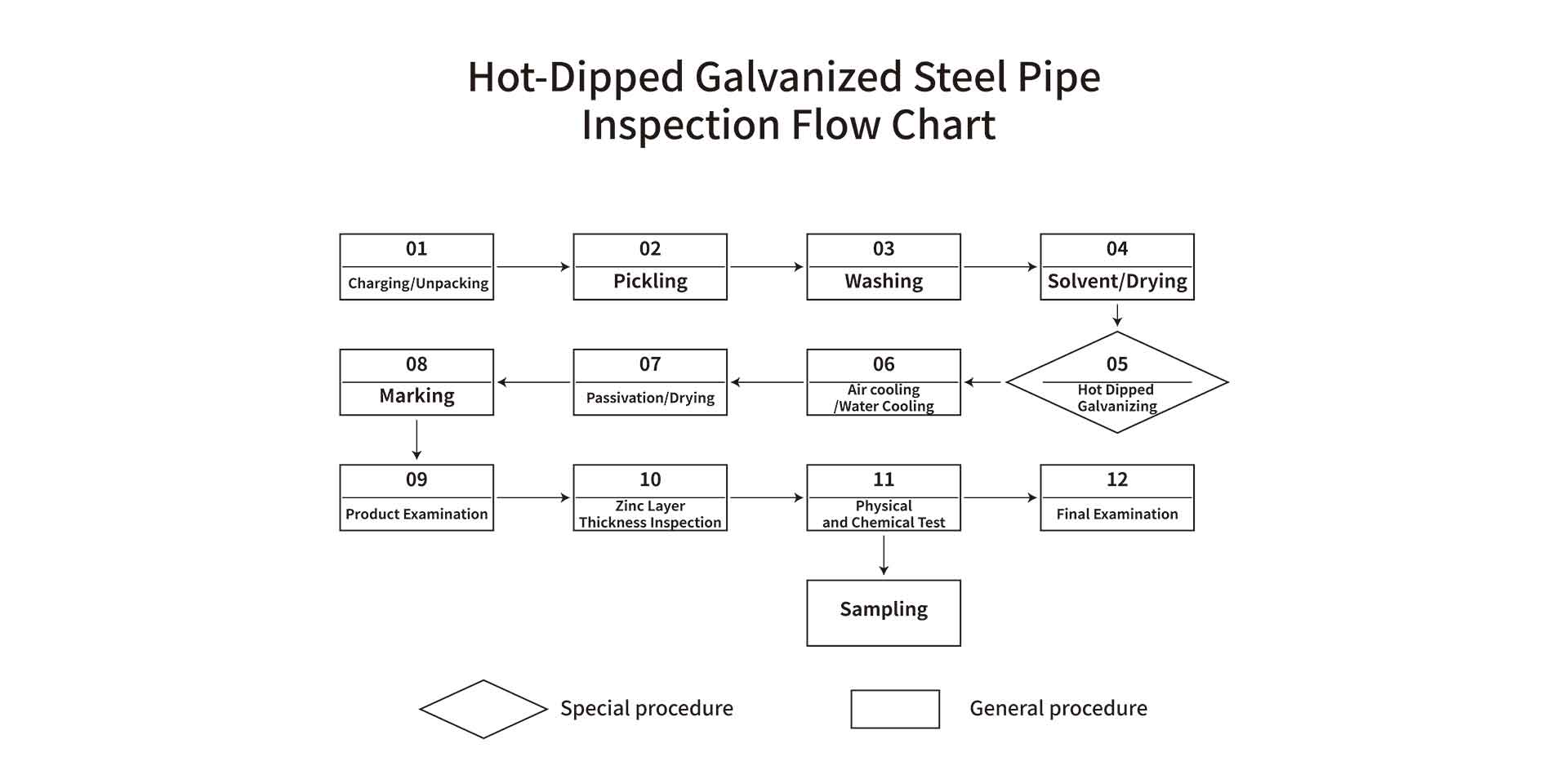

Hot-dipped Galvanized Steel Pipa

Bagan alur pamariksaan

01. Ngecas / Ngabongkar → 02. Acar → 03. Cuci → 04. Pangleyur / Pangeringan → 05. Panas dicelup galvanizing → 06. Pendinginan Udara / Penyejukan Cai → 07. Pasipasi / Pangeringan → 08. Nyirian → 09. Pemeriksaan Produk → 10 .Inspeksi ketebalan lapisan séng → 11. Uji fisik jeung kimia → 12. Ujian ahir

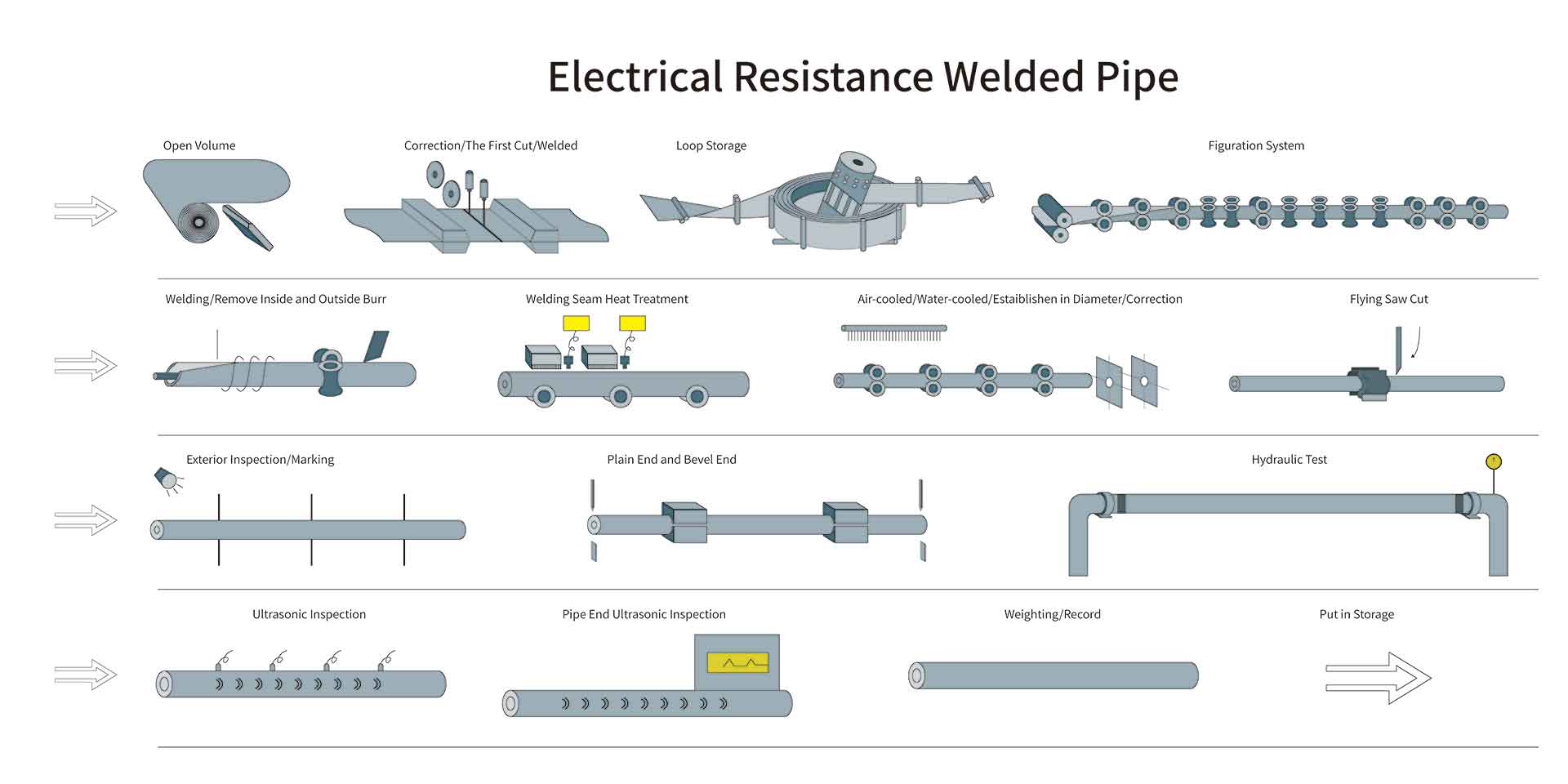

Résistansi listrik Weld pipe-ERW

Prosedur manufaktur

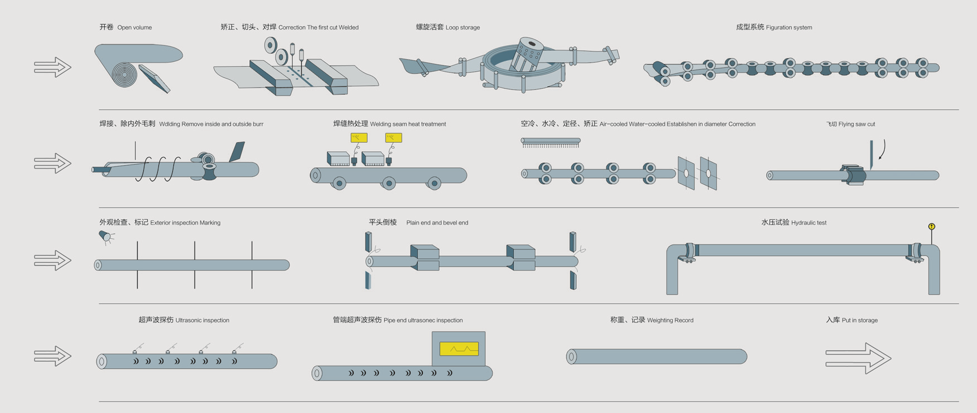

01. Buka volume → 02. Koreksi / The cut munggaran / Welded → 03. Loop gudang → 04. Sistim Figuration → 05. Welding / Cabut jero jeung luar burr → 06. Welding perlakuan panas kelim → 07. Air-cooled / Water- tiis / Estaiblishen diaméterna / Koreksi → 08. Flying saw cut → 09. Exterior inspeksi / Nyirian → 10. Plain tungtung na bevel tungtung → 11. Hydraulic test → 12. Ultrasonic inspeksi → 13. Pipe tungtung inspeksi ultrasonik → 14. Weighting / Rékam→ 15. Nempatkeun di gudang

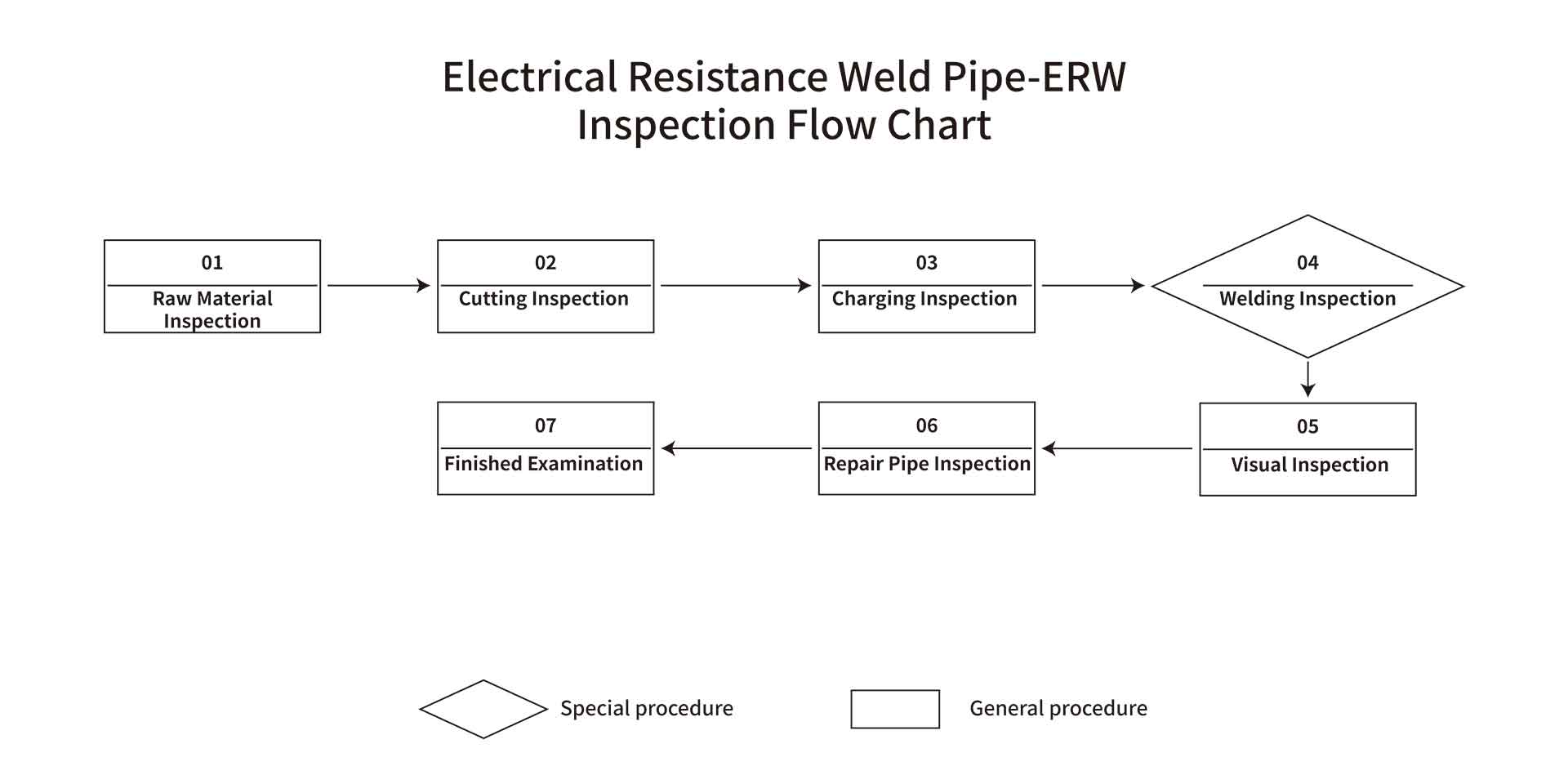

Résistansi listrik Weld pipe-ERW

Bagan alur pamariksaan

01. Inspeksi bahan baku → 02. Inspeksi motong → 03. Inspection ngecas → 04. Inspection las → 05. Inspection Visual → 06. Inspection pipe repair → 07. Rengse pamariksaan

Kami bakal nguji bahan baku sareng prosés produksi dumasar kana standar anu béda pikeun mastikeun yén produk nyumponan standar atanapi syarat kontrak.

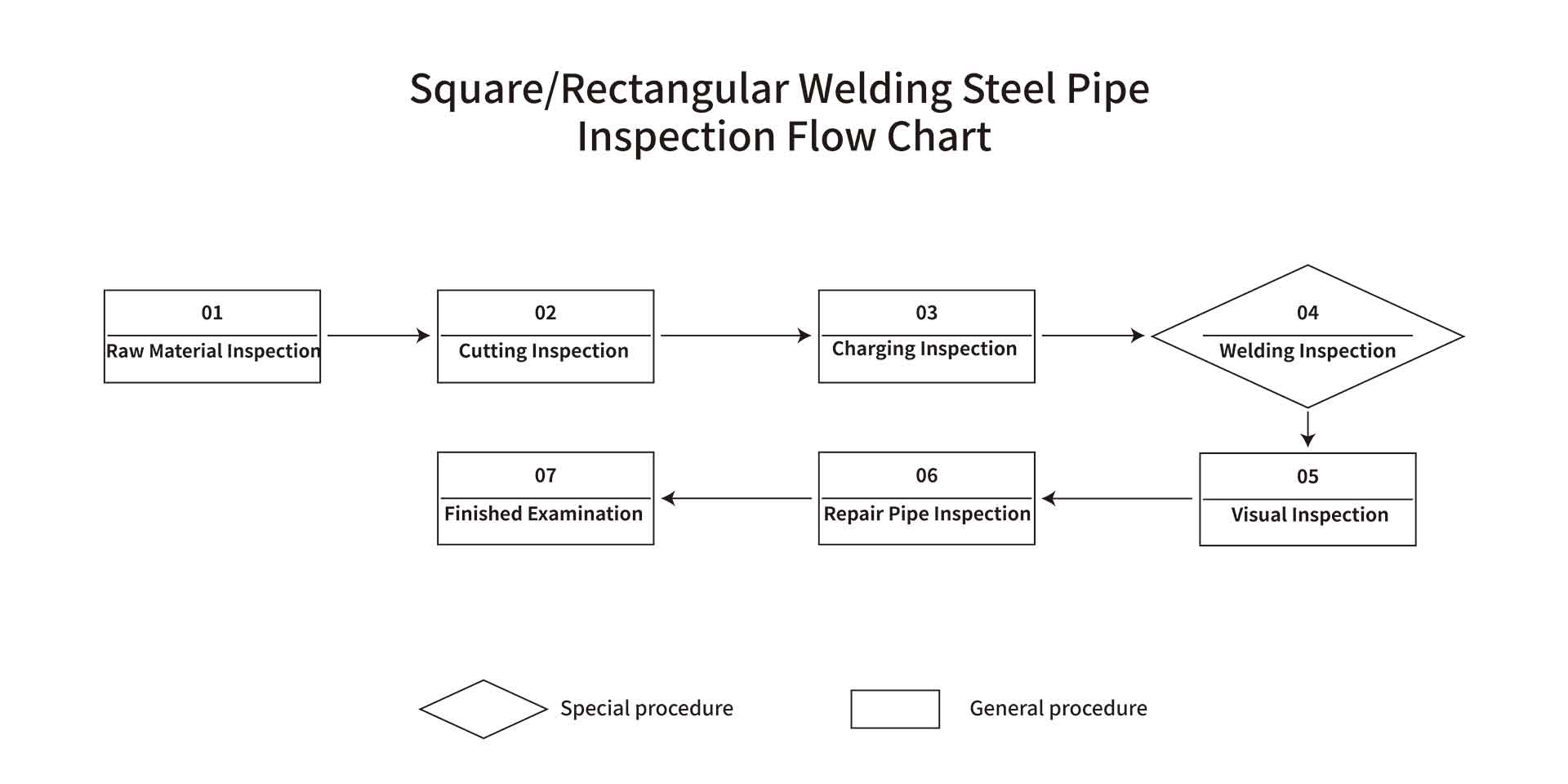

pasagi / Rectangular las Steel pipe

Bagan alur pamariksaan

01. Inspeksi bahan baku → 02. Inspeksi motong → 03. Inspection ngecas → 04. Inspection las → 05. Inspection Visual → 06. Inspection pipe repair → 07. Rengse pamariksaan

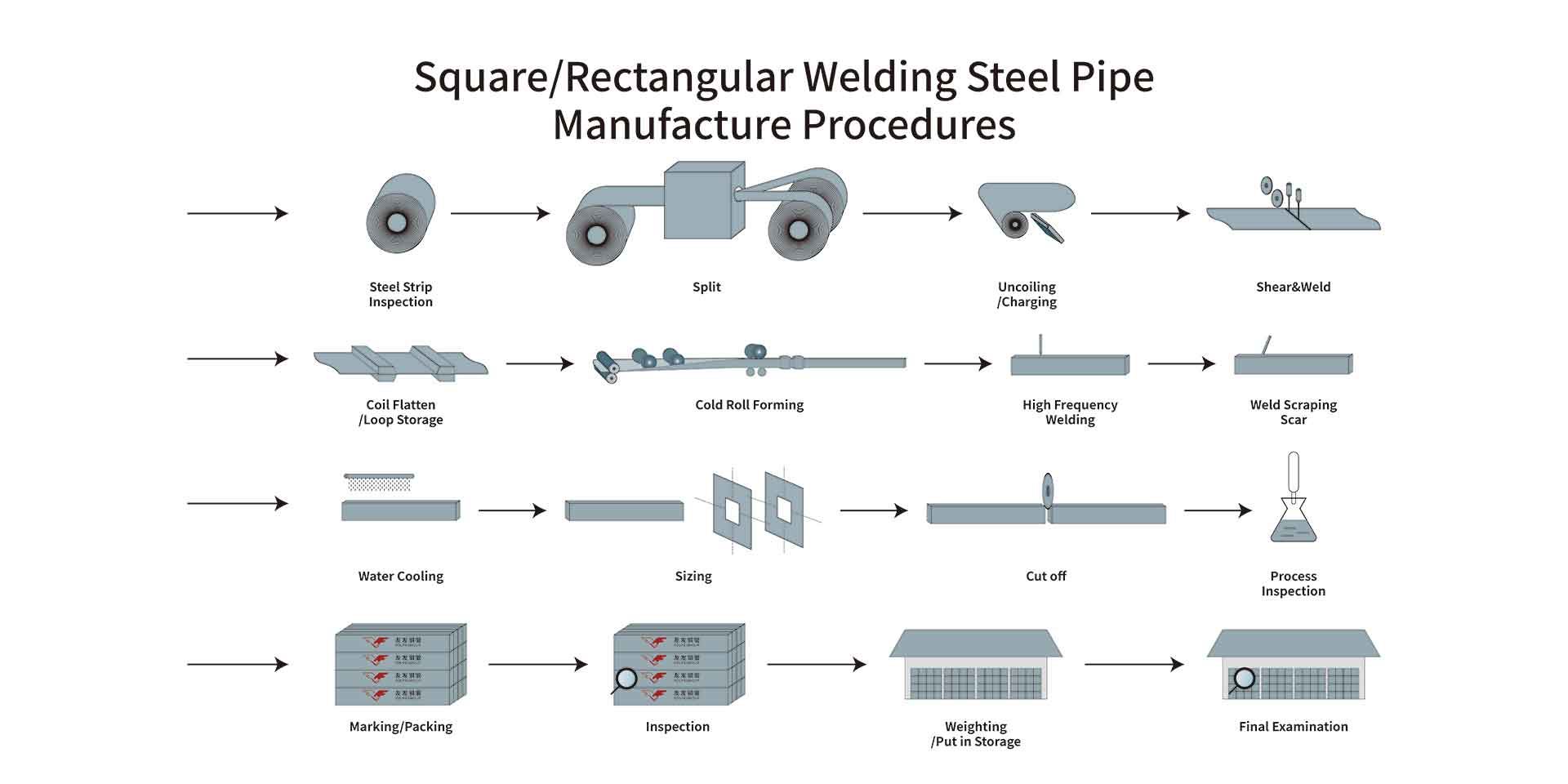

pasagi / Rectangular las Steel pipe

Prosedur manufaktur

01. Inspeksi strip baja → 02. Split → 03. Uncoiling / Ngecas → 04. Shear & Weld → 05. Coil Flatten / Loop neundeun → 06. Cold roll ngabentuk → 07. High Frequency welding → 08. Weld scraping scar → 09. Water cooling → 10. Ukuran → 11. Potong → 12. Prosés pamariksaan → 13. Nyirian / Bungkusan → 14. Inspection → 15. Timbangan / Simpen di gudang→ 16. Ujian ahir

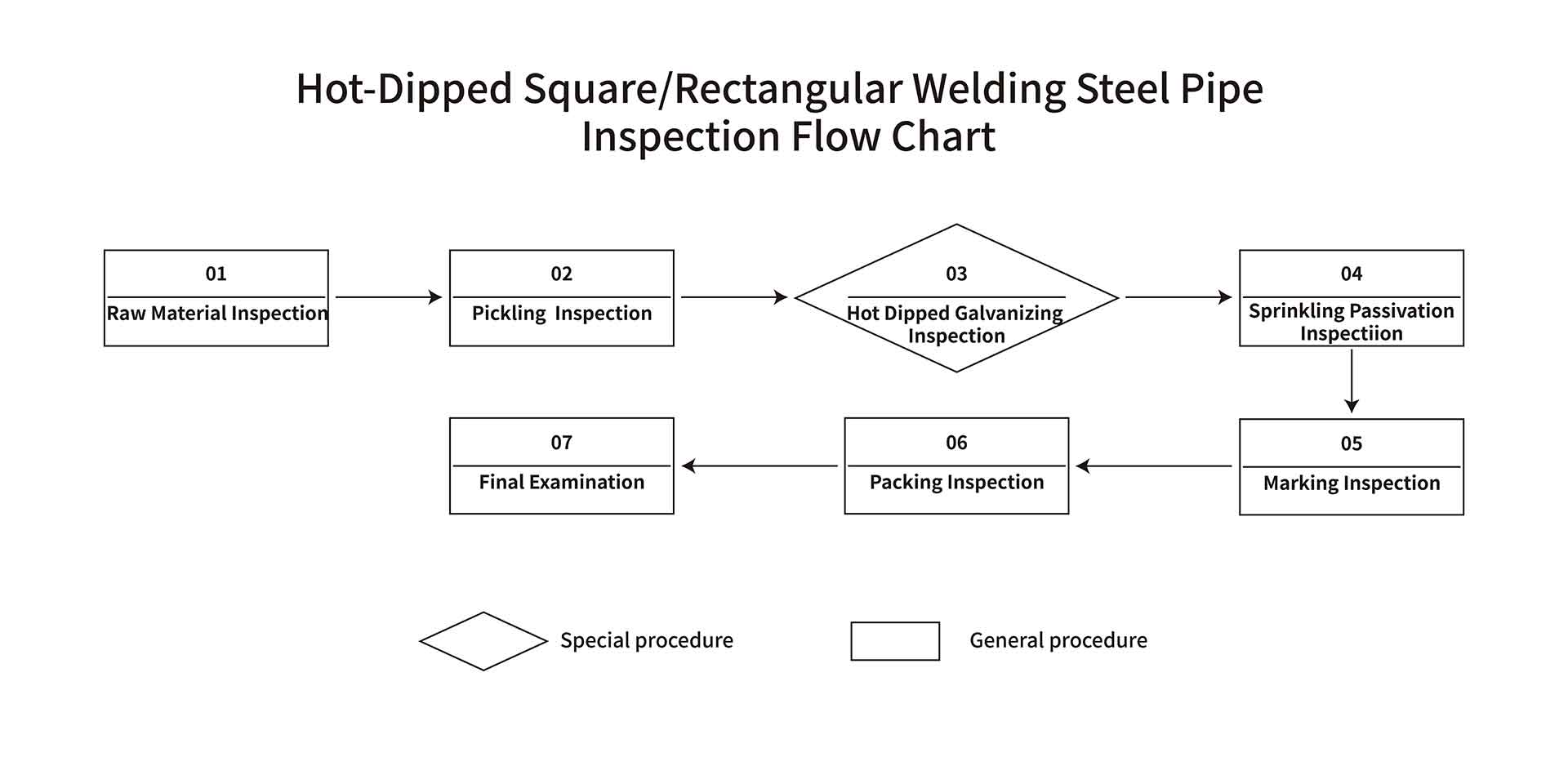

Hot-dipped Square / Rectangular las Steel pipe

Bagan alur pamariksaan

01. Raq material inspection→02.Pickling inspection→03.Hot Dipped Galvanizing inspection→04.Sprinkling Passivation inspectiion→05.Marking inspection→06.Packing inspection→07.Final examination

Kami bakal nguji bahan baku sareng prosés produksi dumasar kana standar anu béda pikeun mastikeun yén produk nyumponan standar atanapi syarat kontrak.

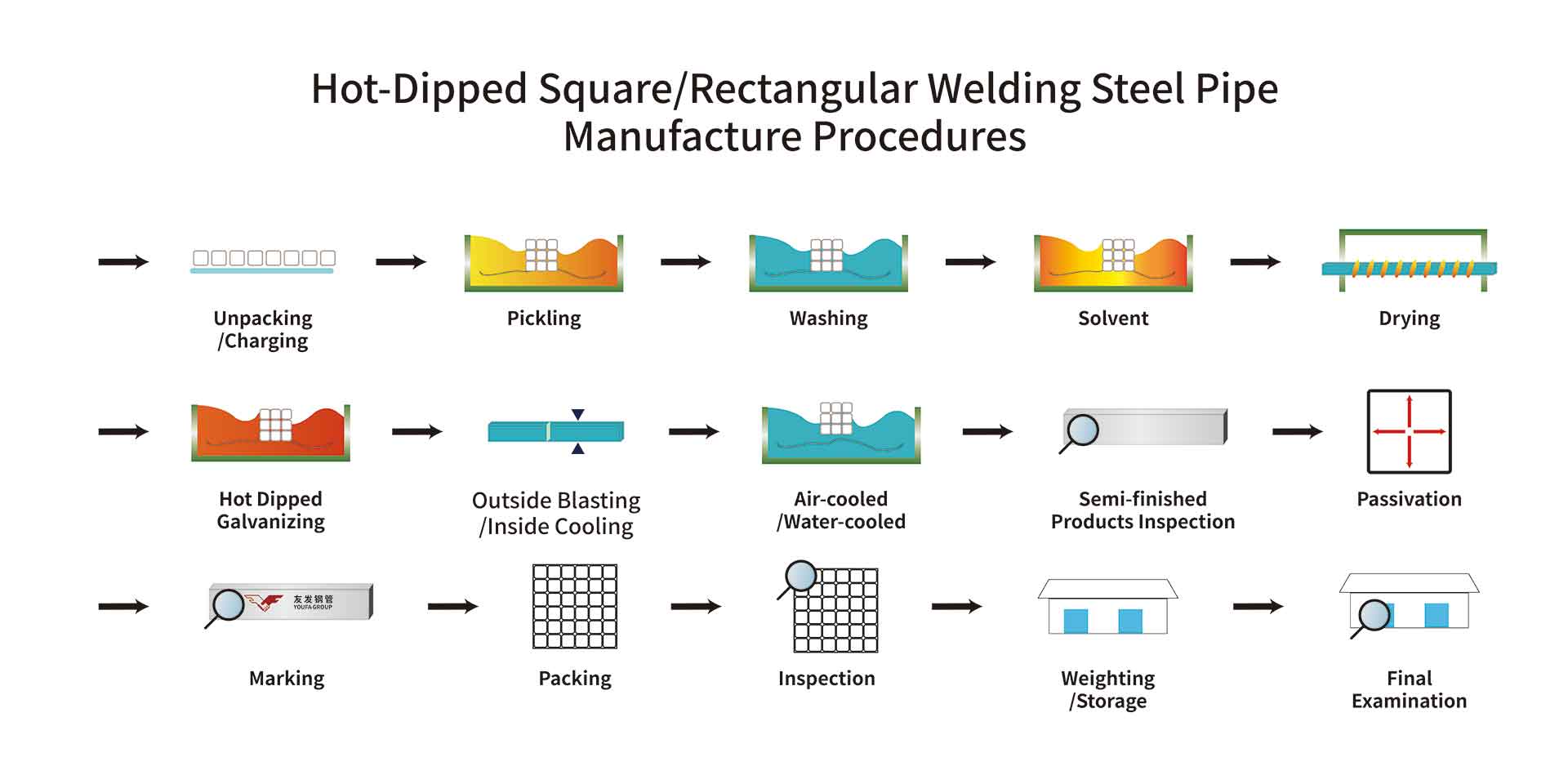

Hot-dipped Square / Rectangular las Steel pipe

Prosedur manufaktur

01. Welding steel pipe → 02. Unpacking / Ngecas → 03. Pickling → 04. Washing → 05. Solvent → 06. Drying → 07. Hot Dipped Galvanizing → 08. Outside Blasting → 09. Inside Cooling → 10. Air-cooled / Cai-tiis→11.Produk semi-rengse pamariksaan → 12. Pasivation → 13. Nyirian → 14. Packing → 15. Inspection → 16. Timbangan / Panyimpenan → 17. Ujian Akhir

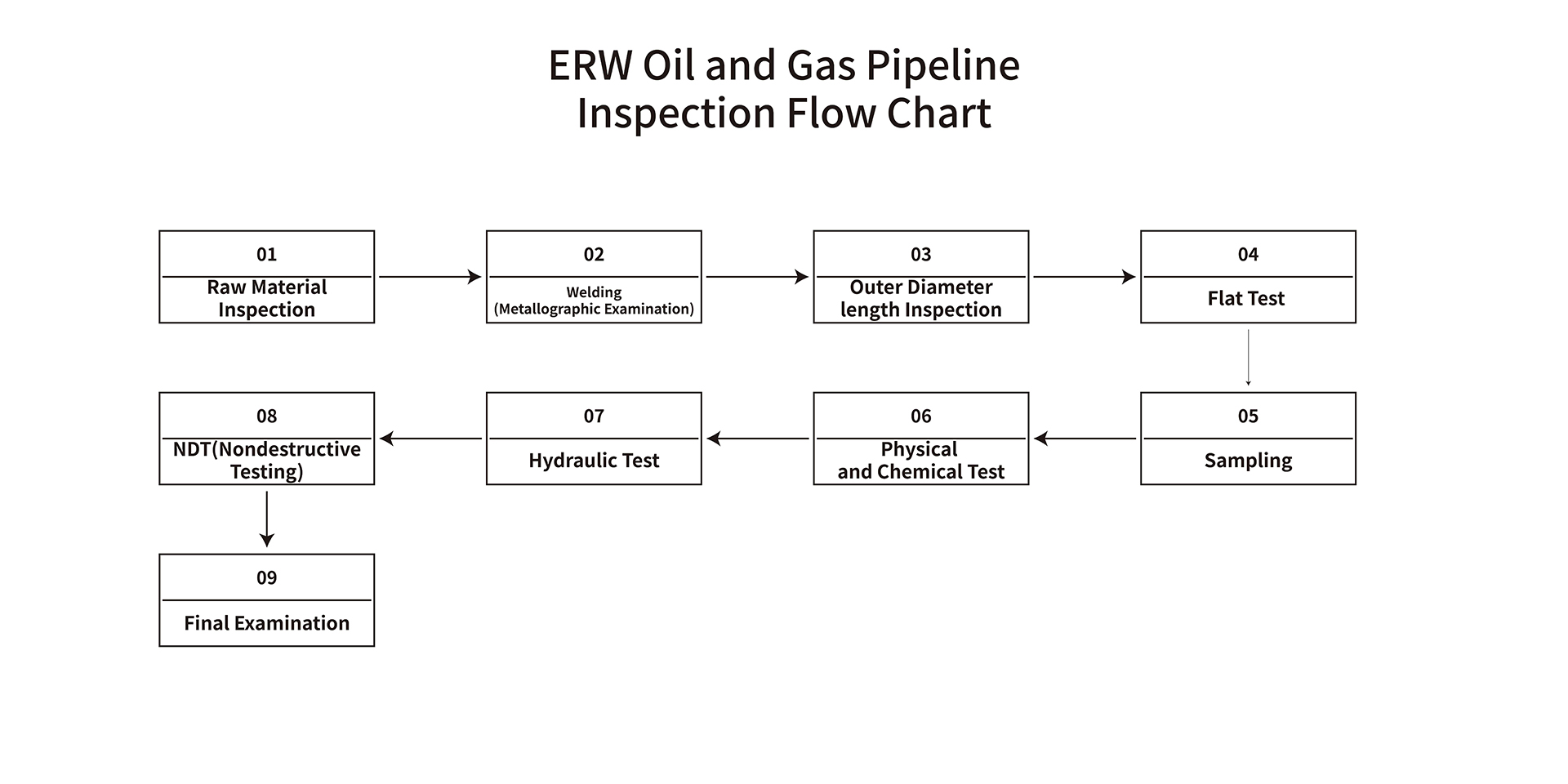

ERW pipa minyak jeung gas

Bagan alur pamariksaan

01. Inspeksi bahan baku → 02. Welding (ujian Metallographic) → 03. Outer diaméterna inspeksi panjang → 04. Datar test → 05. Sampling → 06. Test fisik jeung kimia → 07. Test hidrolik → 08. NDT (uji nondestructive) → 09. Ujian Akhir

Kami bakal nguji bahan baku sareng prosés produksi dumasar kana standar anu béda pikeun mastikeun yén produk nyumponan standar atanapi syarat kontrak.

01. Buka volume → 02. Koreksi / The cut munggaran / Welded → 03. Loop gudang → 04. Sistim Figuration → 05. Welding / Cabut jero jeung luar burr → 06. Welding perlakuan panas kelim → 07. Air-cooled / Water- tiis / Estaiblishen diaméterna / Koreksi → 08. Flying saw cut → 09. Exterior inspeksi / Nyirian → 10. APlain tungtung na bevel tungtung → 11. Hydraulic test → 12. Ultrasonic inspeksi → 13. Pipe tungtung inspeksi ultrasonik → 14. Weighting / Rékam→ 15. Nempatkeun di gudang

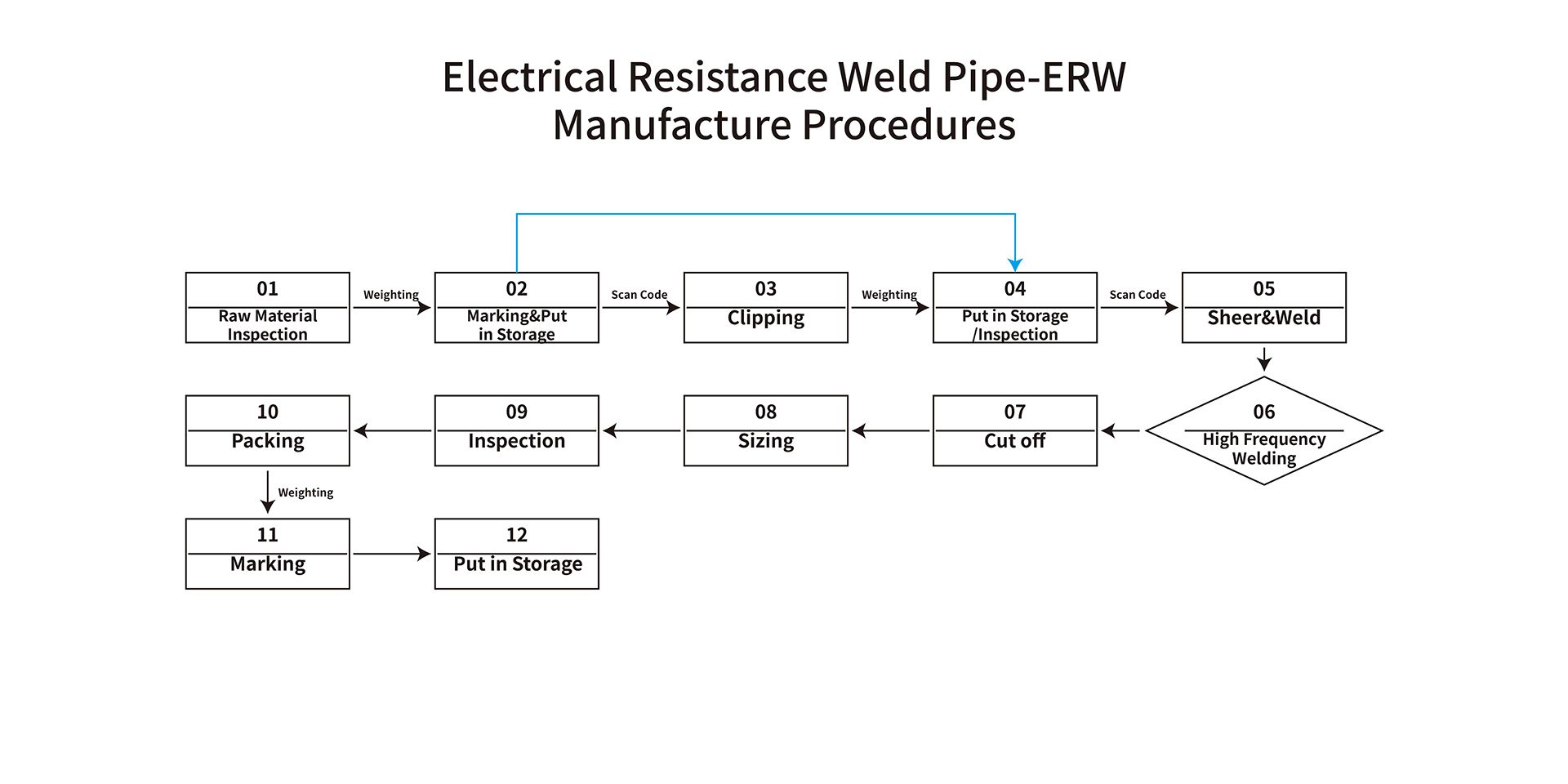

Résistansi listrik Weld pipe-ERW

Prosedur manufaktur

01. Inspeksi bahan baku → 02. Nyirian & Nempatkeun di gudang→ 03. clipping → 04. Nempatkeun di gudang / Inspection → 05. Sheer & Weld → 06. Test fisik jeung kimia → 07. Cut off → 08. Sizing → 09. Inspection → 10. Packing → 11. Weighting → 12. Kode scan

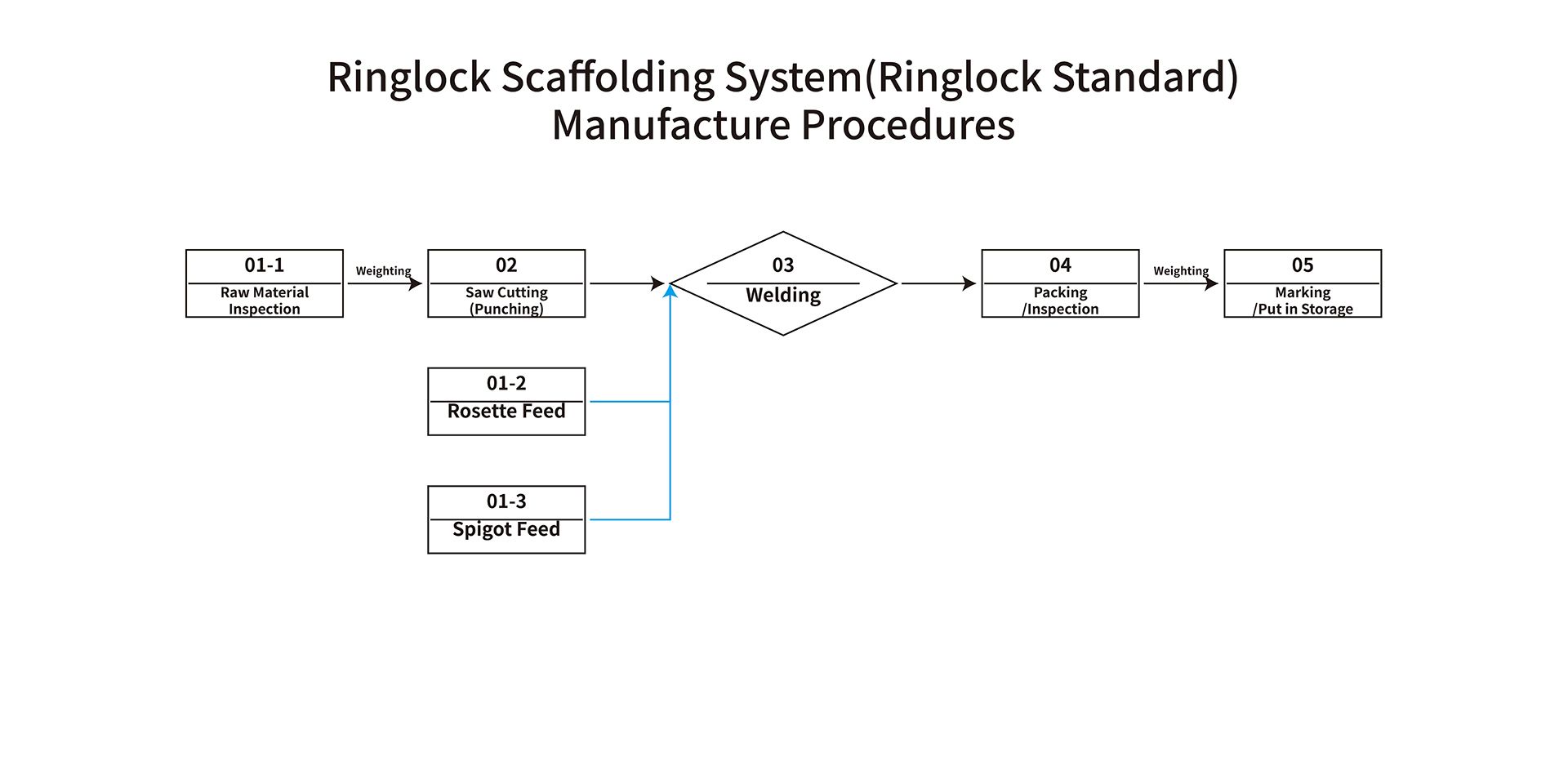

Sistem Parancah Ringlock (Standar Ringlock)

Prosedur manufaktur

01. Inspeksi bahan baku → 02. Saw motong (punching) / Rosette feed / Spigot feed → 03. Welding → 04. Bungkusan / inspeksi → 05. Nyirian / Nempatkeun di gudang

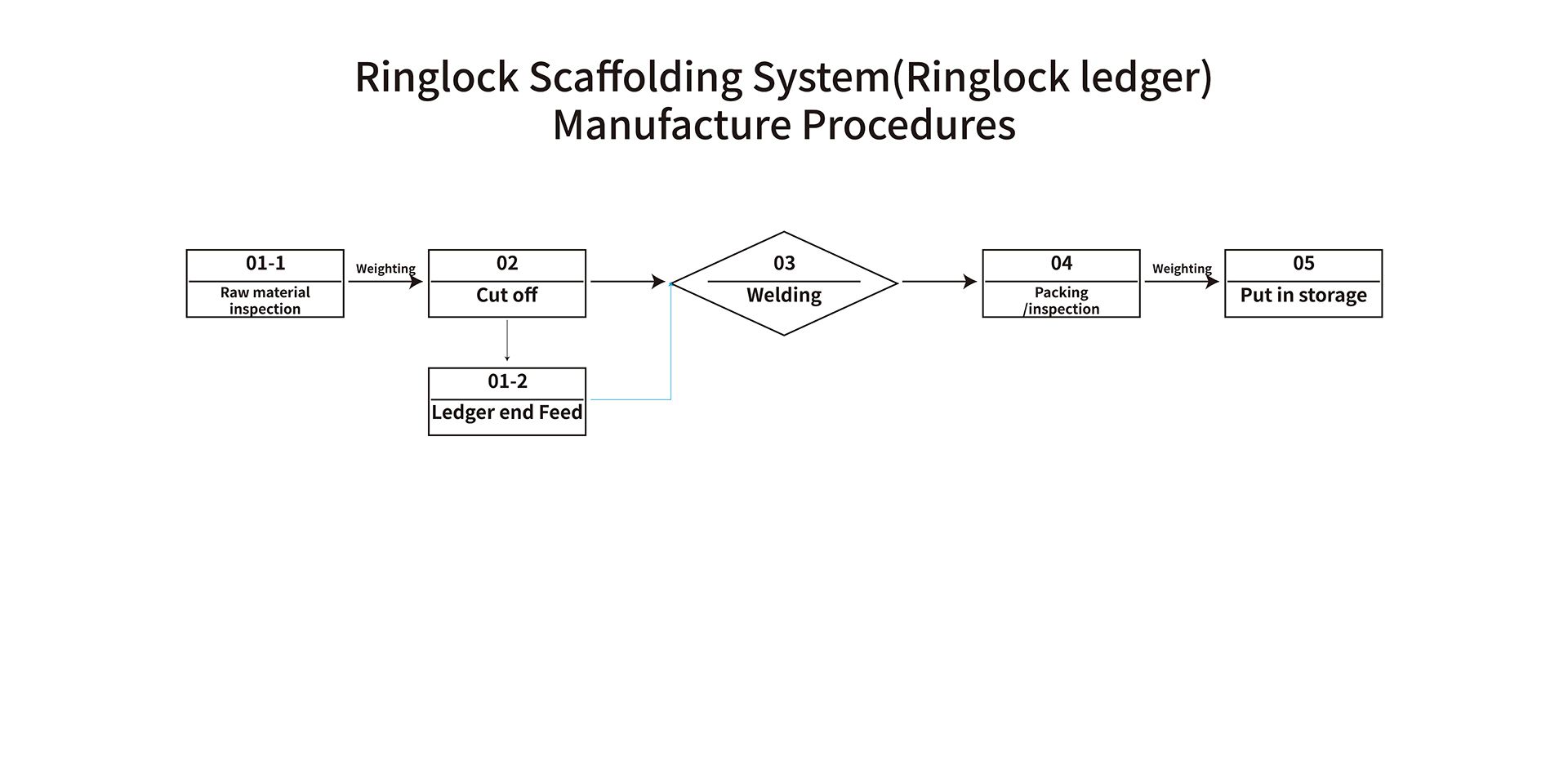

Sistem Parancah Ringlock (Ringlock ledger)

Prosedur manufaktur

01. Inspeksi bahan baku → 02. Cut off / Ledger tungtung Feed → 03. Welding → 04. Packing / inspeksi → 05. Nyirian / Nempatkeun di gudang

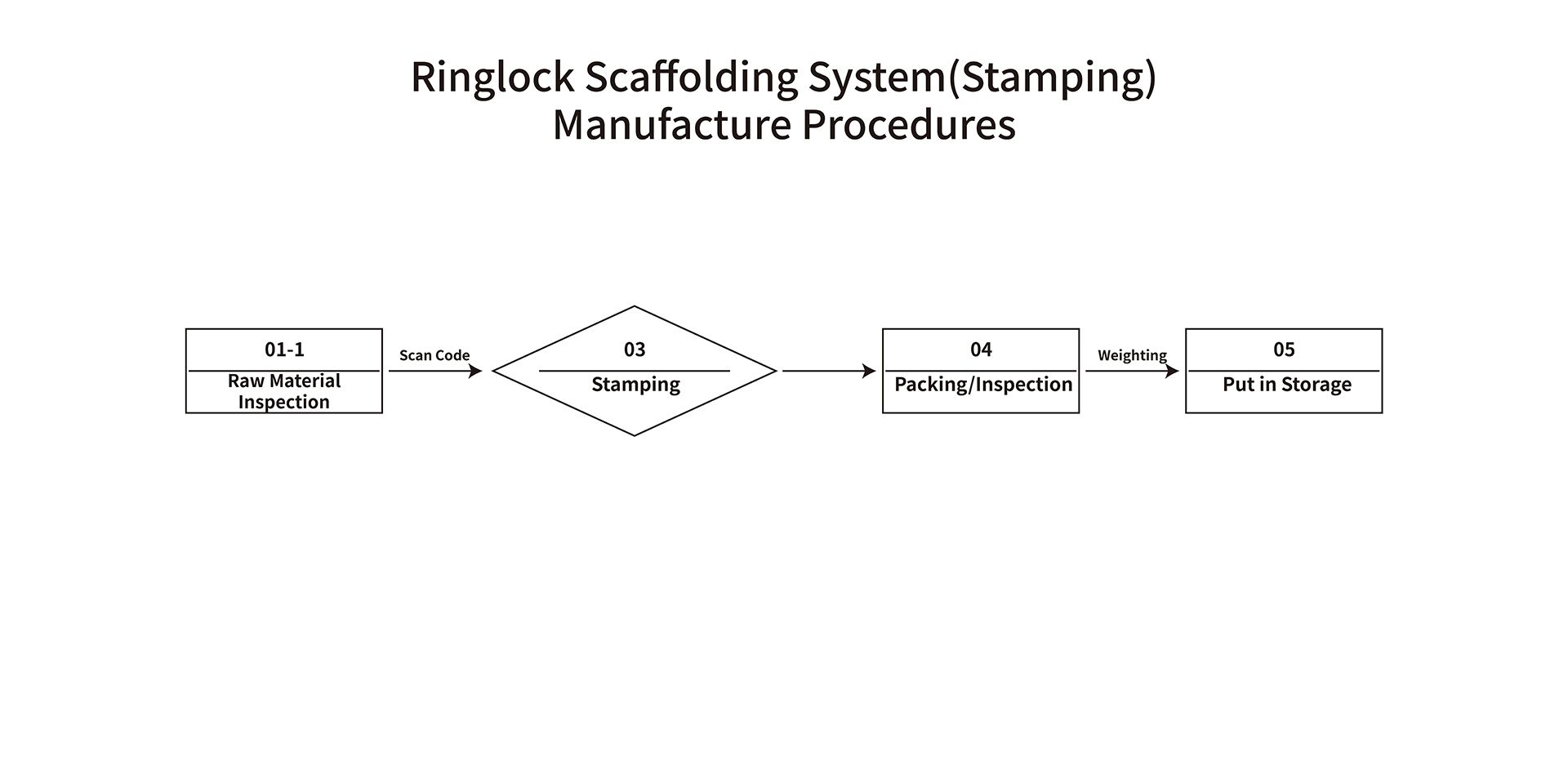

Sistem Parancah Ringlock (Stamping)

Prosedur manufaktur

01. Inspeksi bahan baku → 02. Stamping → 03. Packing / Inspection → 04. Nempatkeun di gudang

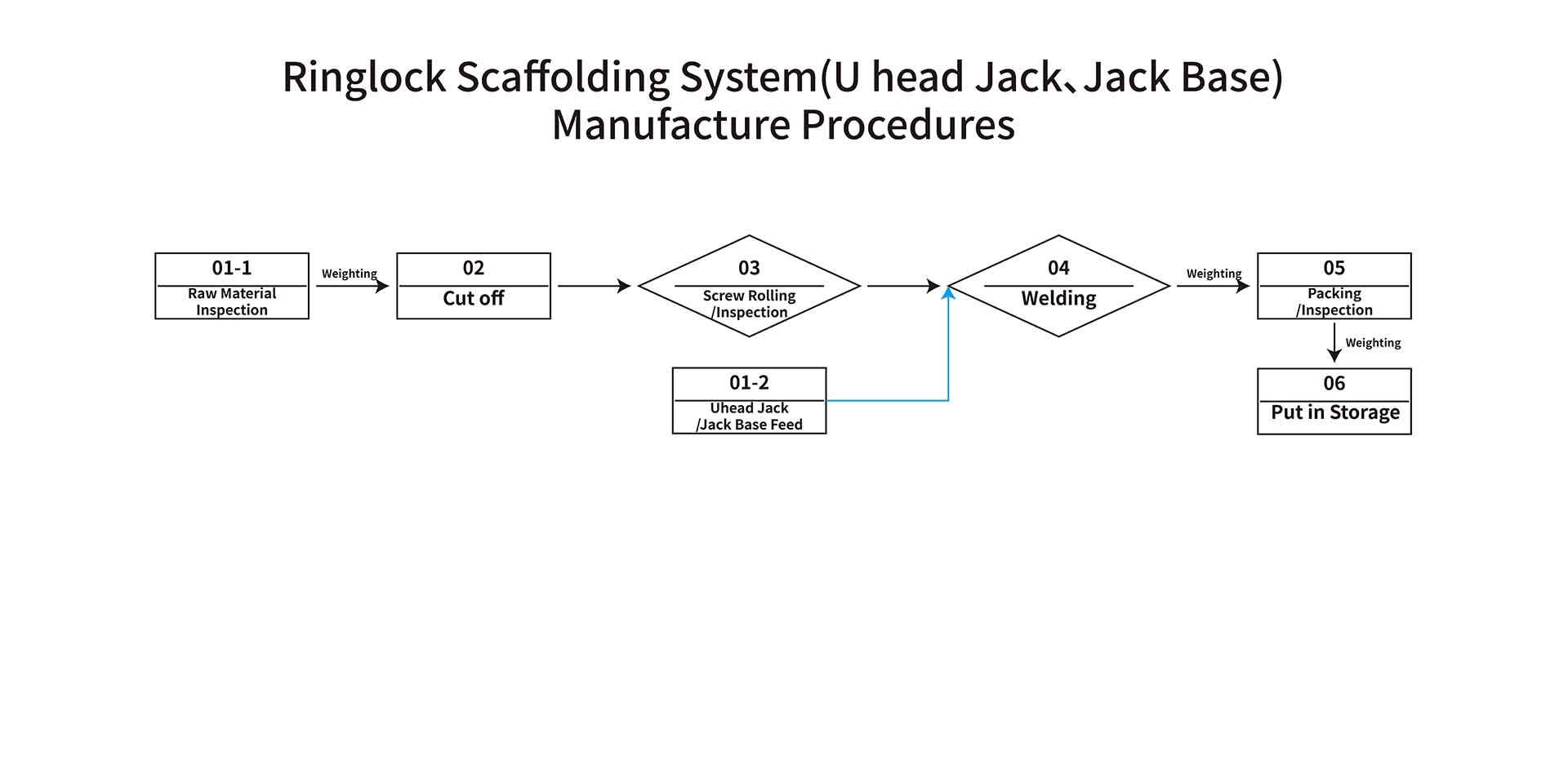

Ringlock Parancah System (U sirah jack, Jack base)

Prosedur manufaktur

01. Inspeksi bahan baku → 02. Cut off → 03. Screw rolling / Inspection / Uhead jack / jack base feed → 04. Welding → 05. Packing / inspeksi → 06. Nempatkeun di gudang

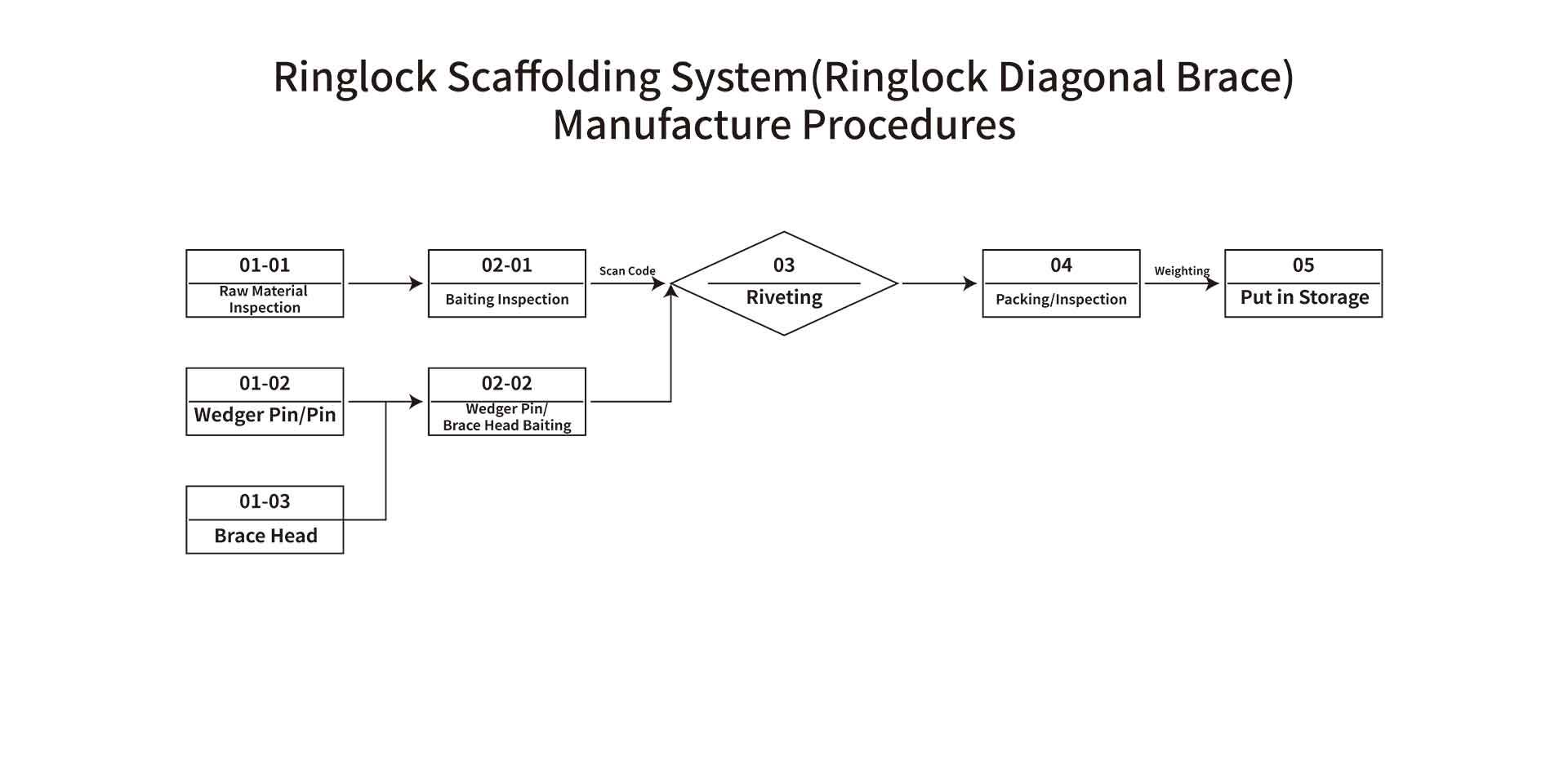

Sistem Parancah Ringlock (Ringlock diagonal brace)

Prosedur manufaktur

01. Inspeksi bahan baku / Wedger pin / Pin / Brace sirah → 02. Baiting inspection / edger pin / Brace sirah baiting → 03. Welding → 04. Packing / inspeksi → 05. Nempatkeun di gudang