Ukuhamba kweNkqubo yeMveliso kunye nokuPhuhla koHlolo

Ngabasebenzi abangaphezu kwe-9000 abanezakhono eziphezulu kunye nemigca yemveliso ephuculweyo engama-293 esasazeka kwiifektri ezili-13, siye savelisa i-20 yezigidi zeetoni zemibhobho yentsimbi ngo-2022, kwaye imali yokuthengisa ingaphezu kwe-160 yezigidi zeedola zase-US ngo-2018. Kwiminyaka eyi-17 elandelelanayo, i-Youfa inesihloko phakathi kwe-TOP Amashishini angama-500 kwiShishini lokuVelisa laseTshayina ukusukela ngo-2006.

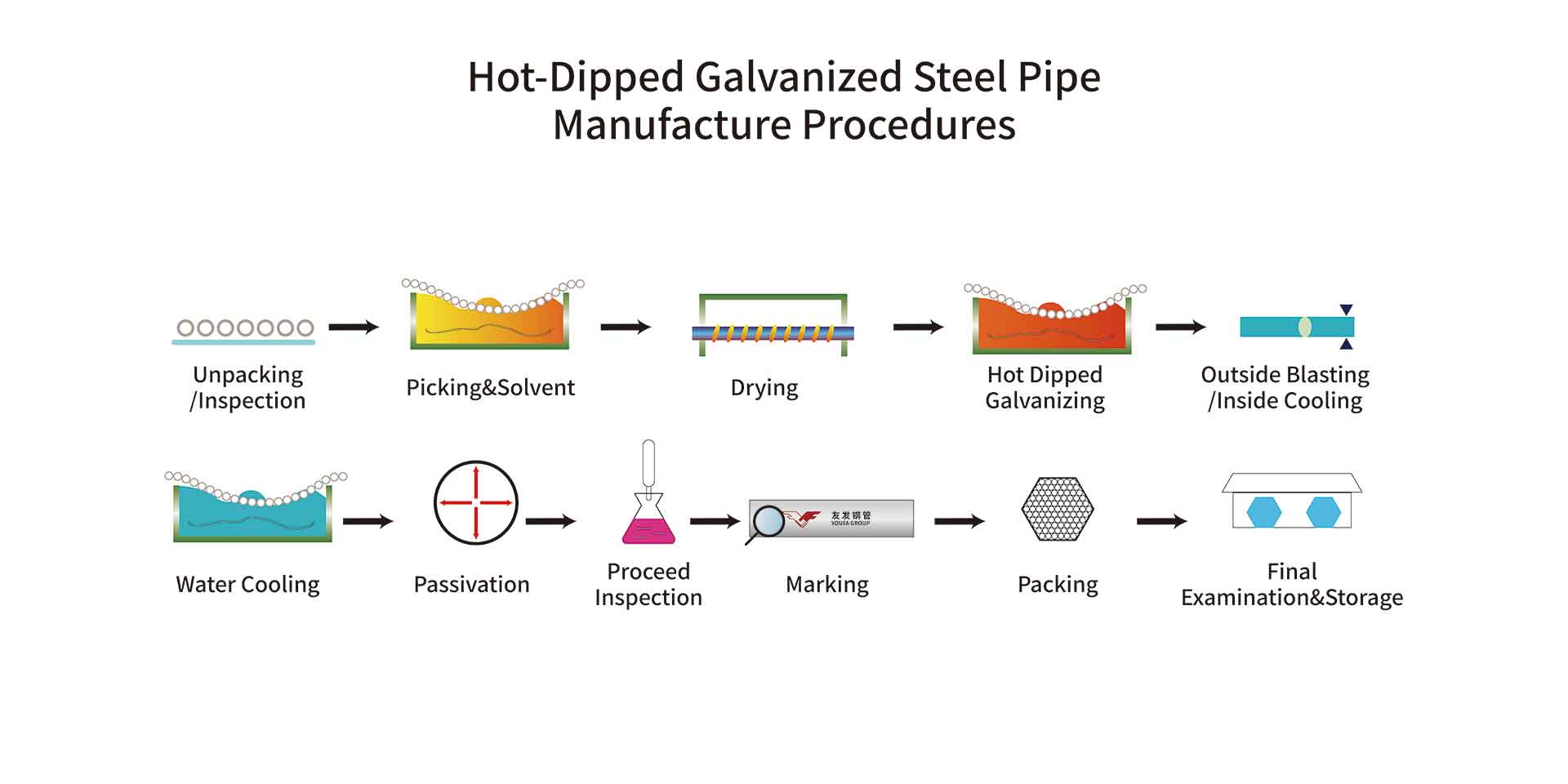

Umbhobho weNtsimbi oDidiweyo oshushu

Iinkqubo zokwenziwa

01.Ukungapakishi/Ukuhlola→02.Ukuchola nokunyibilikisa→03.Ukomisa→04.Itsho idiphu igalvanizing→05.Ukuqhushumba kwangaphandle/ukupholisa ngaphakathi→06.Ukupholisa kwamanzi→07.Ukuhamba →08.Qhubeka nokuhlola→09.Ukumakisha→10.Ukupakisha→ 11.Uviwo lokugqibela&Storage

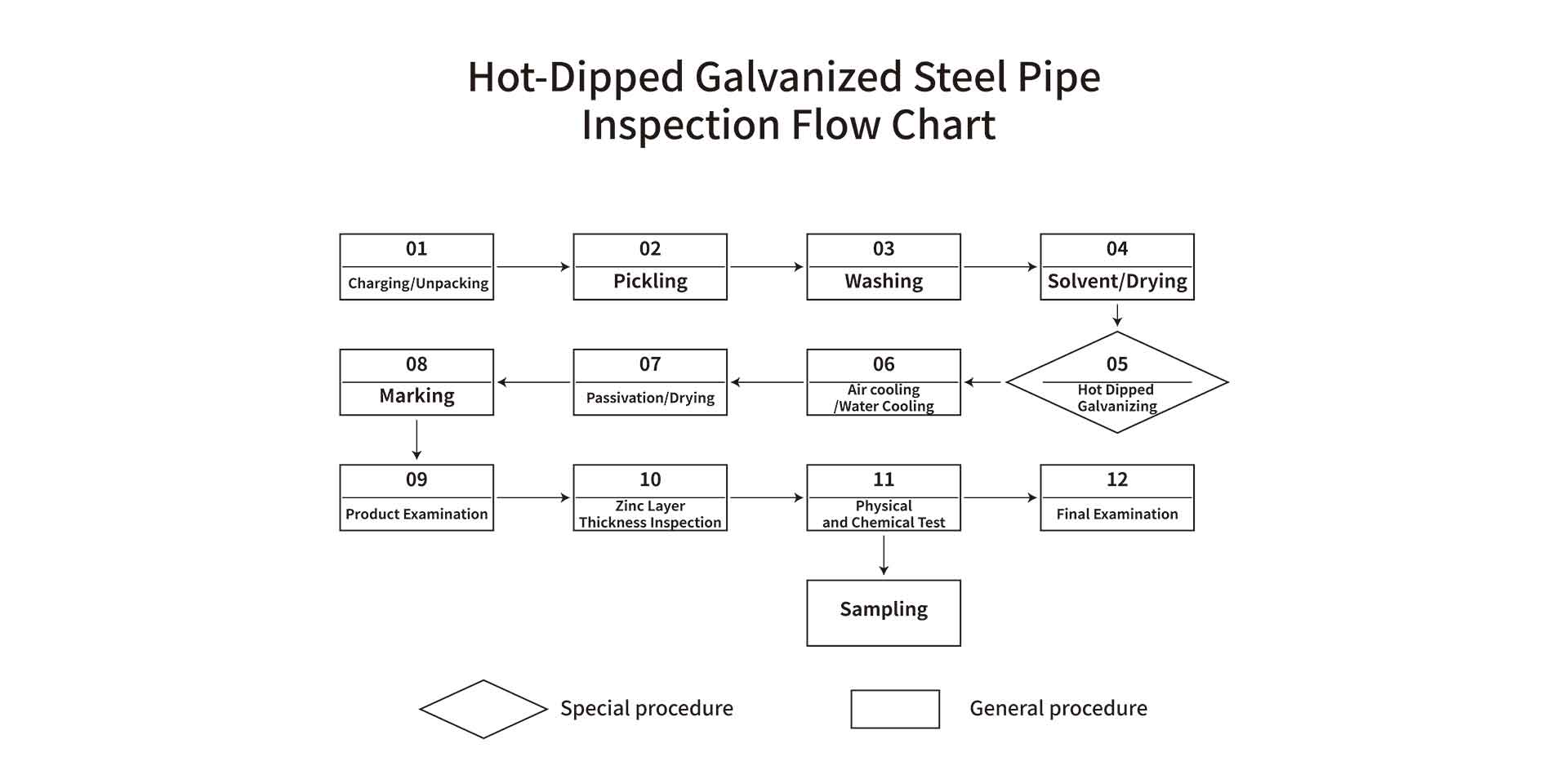

Umbhobho weNtsimbi oDidiweyo oshushu

Itshathi yokuHamba yoHlolo

01.Ukutshaja/Ukungapakishi→02.Ukupakisha→03.Ukuhlamba→04.Ukunyibilikisa/Ukomisa→05.Ukugalela amanzi ashushu okudipiweyo→06.Ukupholisa umoya/Ukupholisa amanzi→07.Ukwenza/ukomisa→08.Ukumakisha→09.Uvavanyo lwemveliso→10 .Ukuhlolwa kobungqingqwa beZinc→11.Uvavanyo lomzimba kunye neekhemikhali→12.Uviwo lokugqibela

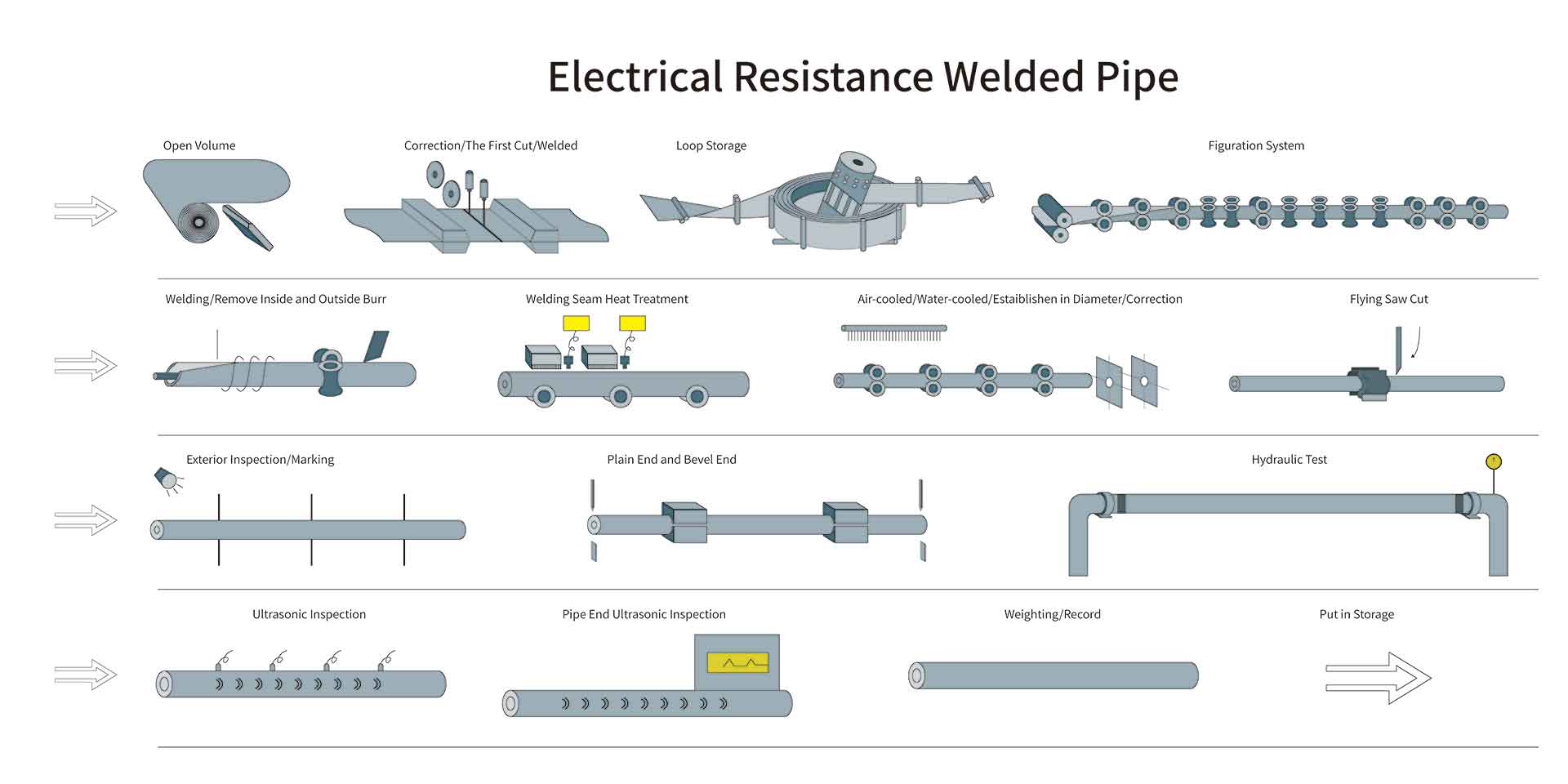

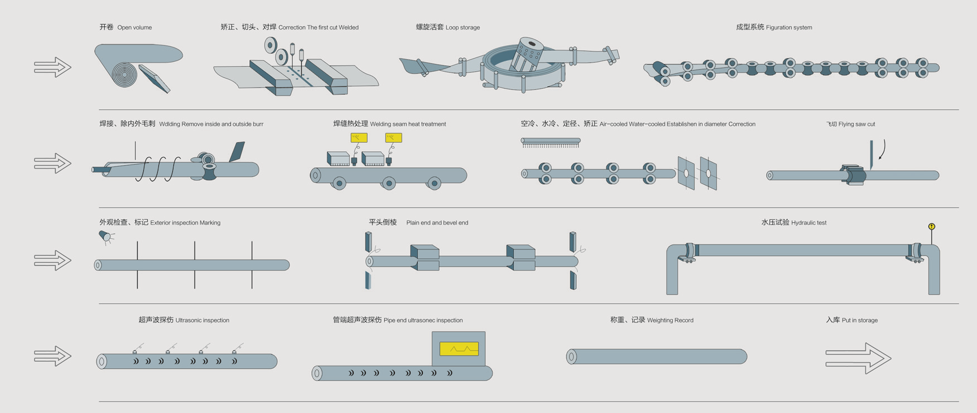

Ukuxhathisa koMbane weld Pipe-ERW

Iinkqubo zokwenziwa

01.Ivolyum evulekileyo→02.Ulungiso/Iyokuqala ukusika/iWelded→03.Indawo yokugcina iluphu→04.Inkqubo yomzobo→05.Ukuwelda/Susa ngaphakathi nangaphandle burr→06.Unyango lobushushu bomthungo wokuwelda→07.Ukupholisa umoya/Amanzi- ipholile/Yenza i-diameter/Ulungiso→08.Isarha ebhabhayo isike→09.Ngaphandle ukuhlola/ukumakisha→10.Isiphelo esingenanto kunye nebevel end→11.Uvavanyo lweHydraulic→12.Ukuhlolwa kweUltrasonic→13.Isiphelo sombhobho Ukuhlolwa kweUltrasonic→14.Ubunzima/Rekhoda→15.Beka kwindawo yokugcina

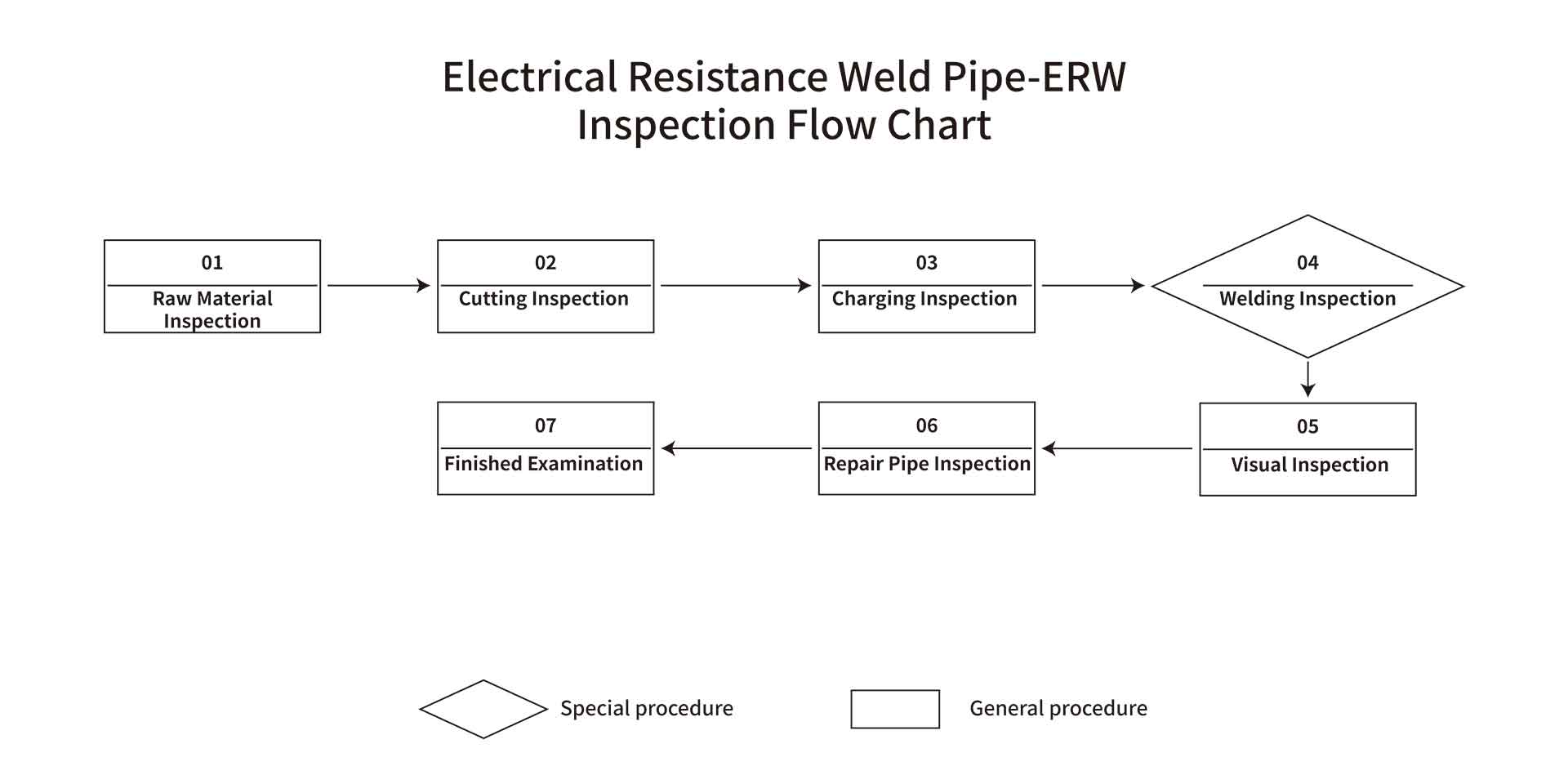

Ukuxhathisa koMbane weld Pipe-ERW

Itshathi yokuHamba yoHlolo

01. Uhlolo lwemathiriyeli ekrwada →02.Ukuhlolwa kokusikwa →03.Uhlolo lokutshaja →04.Uhlolo lwe-welding→05.Uhlolo olubonwayo→06.Ukuhlolwa kombhobho wokulungisa →07.Uviwo olugqityiweyo

Siza kuvavanya imathiriyeli ekrwada kunye neenkqubo zokuvelisa ngokwemigangatho eyahlukeneyo ukuqinisekisa ukuba iimveliso ziyahlangabezana nemigangatho okanye iimfuno zekhontrakthi.

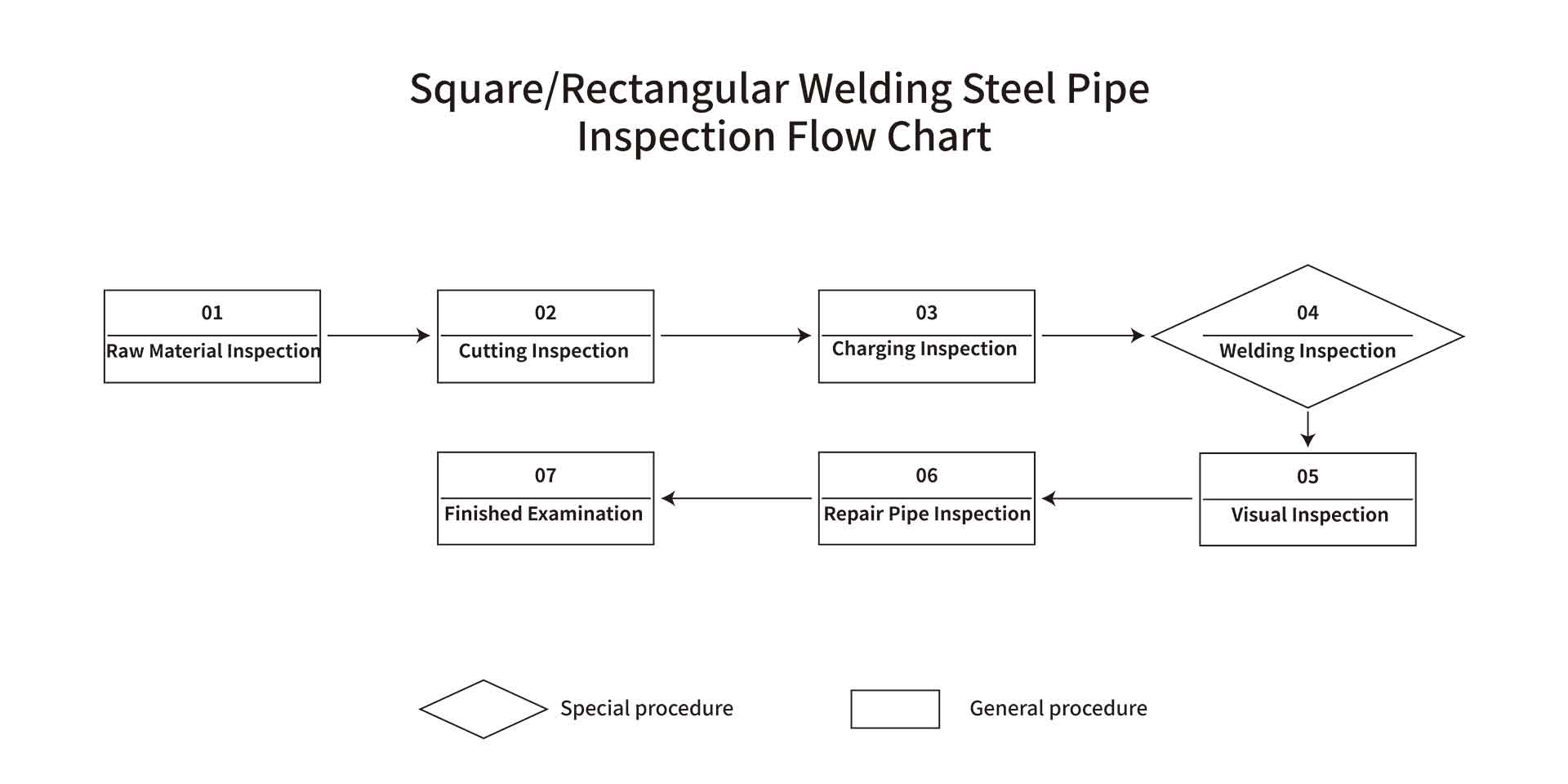

Umbhobho wentsimbi weSquare/Rectangular Welding

Itshathi yokuHamba yoHlolo

01. Uhlolo lwemathiriyeli ekrwada →02.Ukuhlolwa kokusikwa →03.Uhlolo lokutshaja →04.Uhlolo lwe-welding→05.Uhlolo olubonwayo→06.Ukuhlolwa kombhobho wokulungisa →07.Uviwo olugqityiweyo

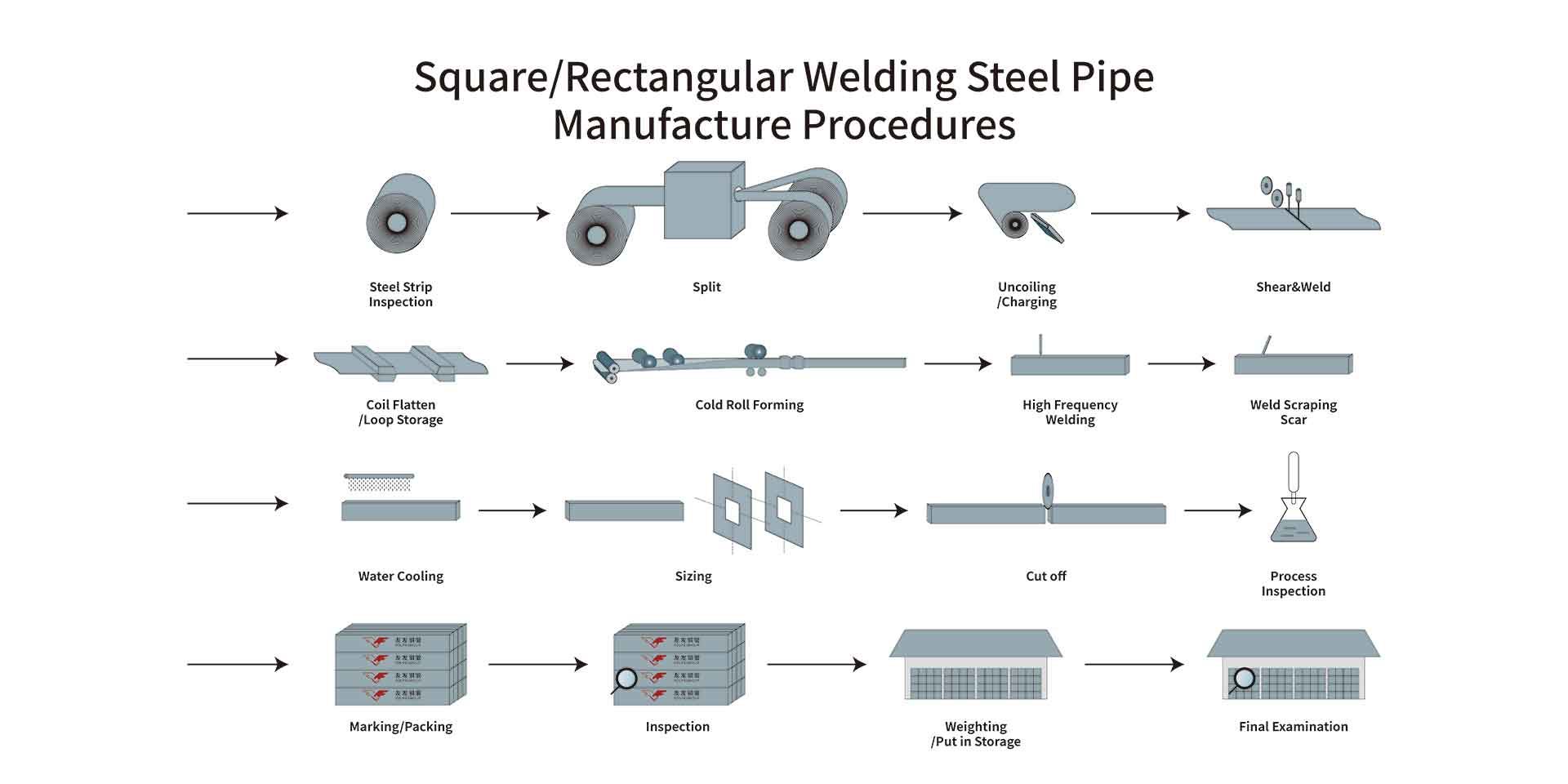

Umbhobho wentsimbi weSquare/Rectangular Welding

Iinkqubo zokwenziwa

01. Ukuhlolwa komcwe wentsimbi→02.Yahlula→03.Ukuqhaqheka/Ukutshaja→04.Cheba&Weld→05.Ugcino lweCoil Flatten/Loop→06.Ukwenziwa komqulu obandayo→07.Ubuxhakaxhaka bokuwelda →08.Isiva sokukhuhla iWeld→09.Ukupholisa kwamanzi →10.Ubungakanani→11.Sika→12.Inkqubo ukuhlola→13.Ukumakisha/UkuPakisha→14.Ukuhlola→15.Ukulinganisa/Ukubeka kwindawo yokugcina→16.Uviwo lokugqibela

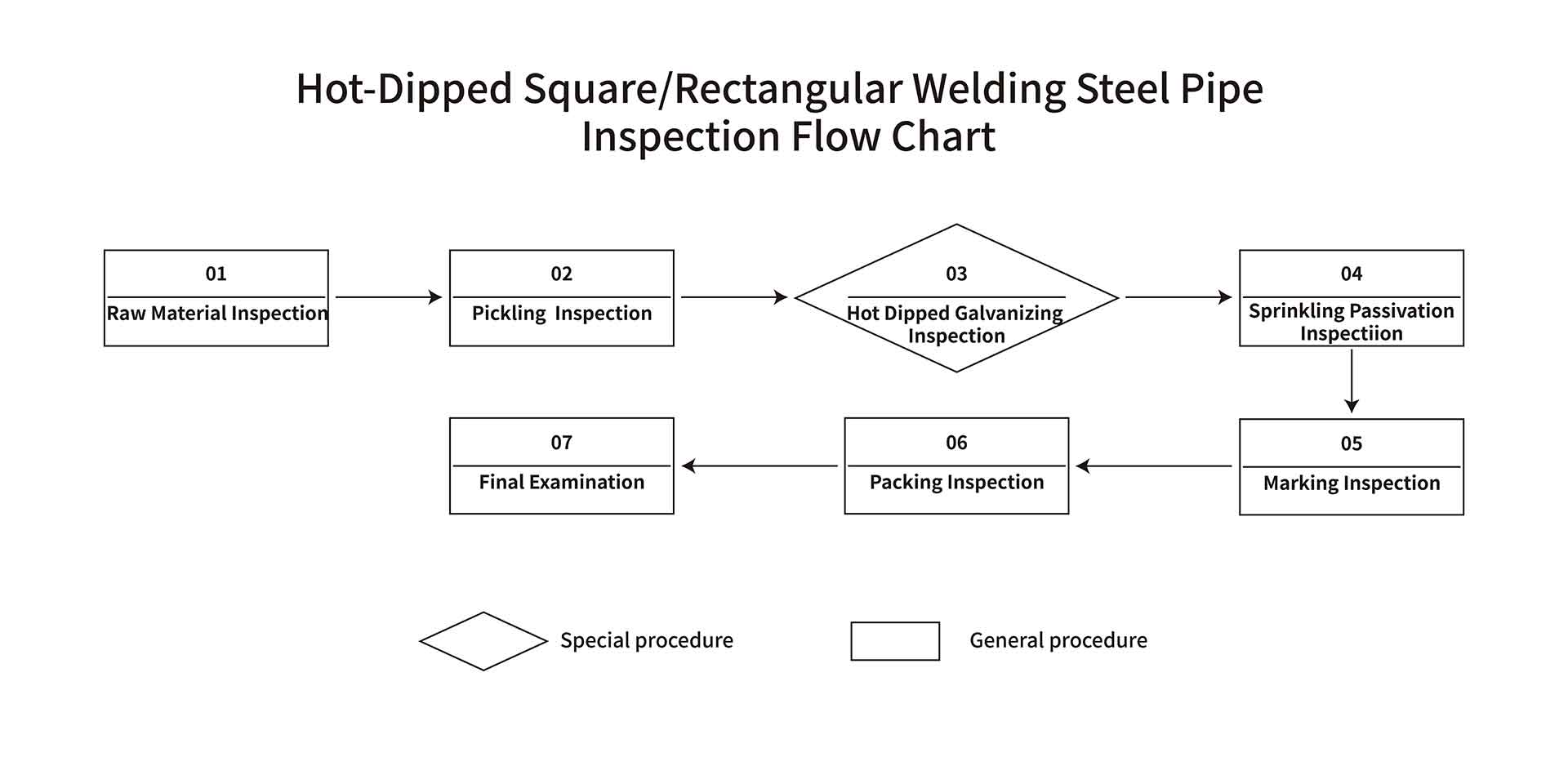

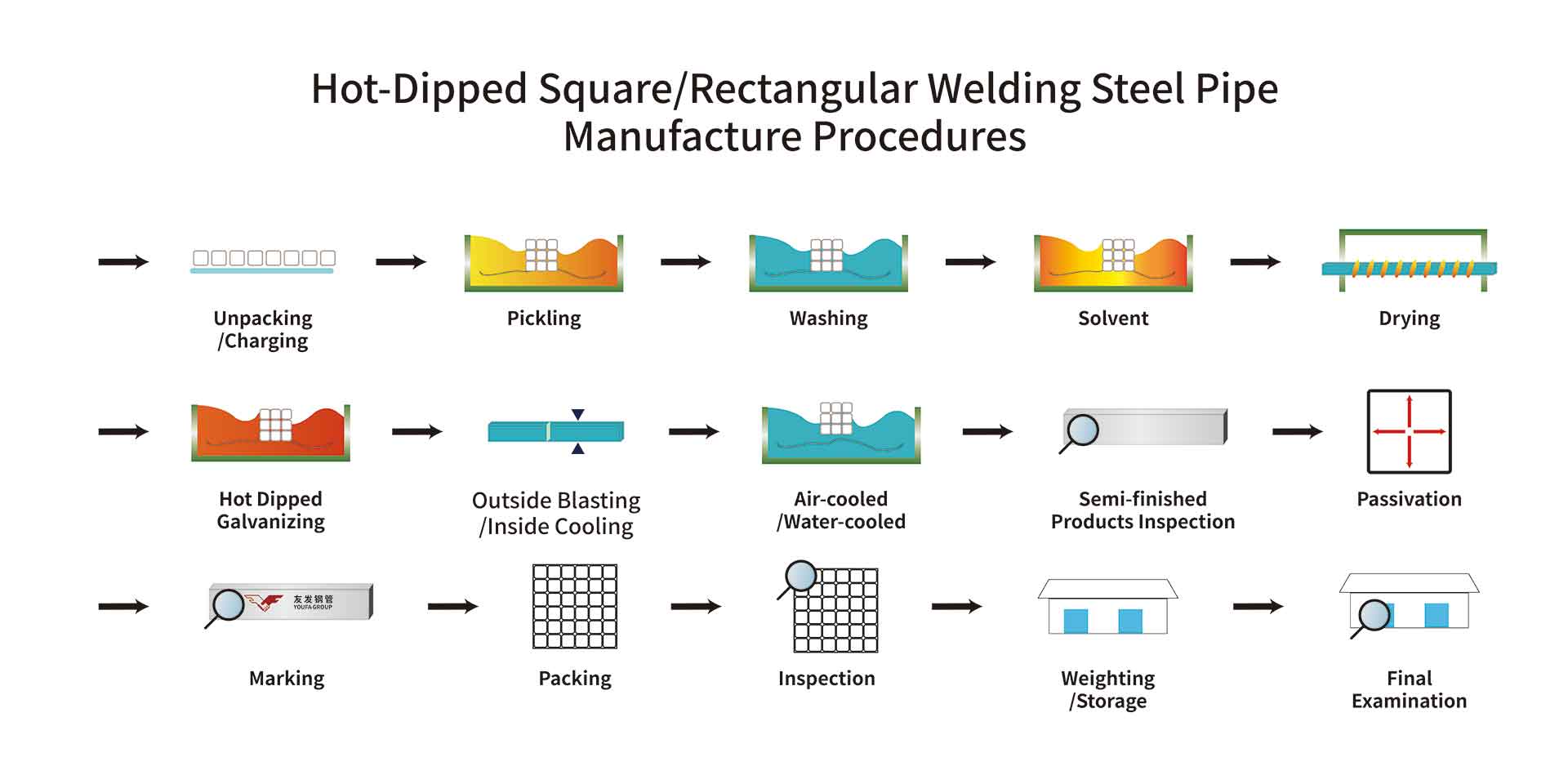

Isikwere esishushu esiDitshwe kwiSikwere/iRectangular Welding Steel Pipe

Itshathi yokuHamba yoHlolo

01. Ukuhlolwa kwemathiriyeli yeRaq→02.Uhlolo lwepickling→03.Uhlolo lweGalavanyisi eDiditshulwe eHot→04.Uhlolo lokuFafaza lokuFafaza→05.Uhlolo lokumakisha→06.Uhlolo lokupakisha→07.Uviwo lokugqibela.

Siza kuvavanya imathiriyeli ekrwada kunye neenkqubo zokuvelisa ngokwemigangatho eyahlukeneyo ukuqinisekisa ukuba iimveliso ziyahlangabezana nemigangatho okanye iimfuno zekhontrakthi.

Isikwere esishushu esiDitshwe kwiSikwere/iRectangular Welding Steel Pipe

Iinkqubo zokwenziwa

01.Umbhobho wentsimbi yokuwelda→02.Ukungapakishi/Ukutshaja→03.Ukupakisha→04.Ukuhlamba→05.Ukunyibilikisa→06.Ukomisa→07.Ukugalela iGalanti eshushu →08.UkuqhushumbaNgaphandle→09.Ukupholisa ngaphakathi→10.Ukupholisa umoya/ Ukupholiswa kwamanzi→11.Imveliso ezigqityiweyo ukuhlola→12.Ukwenza lula→13.Ukumakisha→14.Ukupakisha→15.Ukuhlola→16.Ubunzima/uGcino→17.Uviwo lokugqibela.

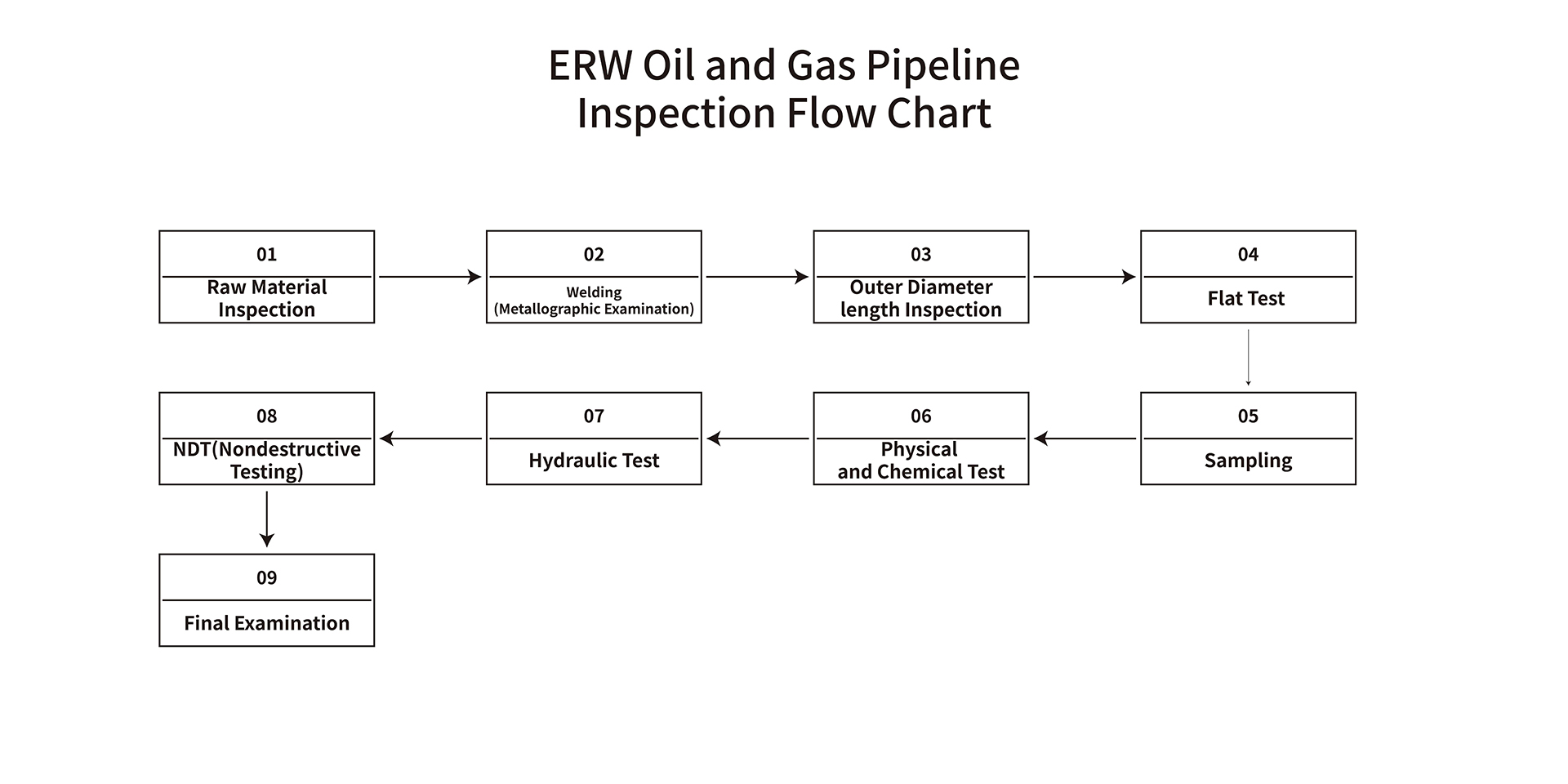

I-ERW yombhobho we-oyile nerhasi

Itshathi yokuHamba yoHlolo

01. Ukuhlolwa kwezinto ezikrwada→02.Welding(uviwo lweMetallographic)→03.Ukuhlola ubude bedayamitha yangaphandle→04.Flat test→05.Sampling→06.Uvavanyo lomzimba kunye neekhemikhali→07.Uvavanyo lwehydraulic→08.NDT(uvavanyo olungonakalisiyo)→ 09. Uviwo lokugqibela

Siza kuvavanya imathiriyeli ekrwada kunye neenkqubo zokuvelisa ngokwemigangatho eyahlukeneyo ukuqinisekisa ukuba iimveliso ziyahlangabezana nemigangatho okanye iimfuno zekhontrakthi.

01.Ivolyum evulekileyo→02.Ulungiso/Iyokuqala ukusika/iWelded→03.Indawo yokugcina iluphu→04.Inkqubo yomzobo→05.Ukuwelda/Susa ngaphakathi nangaphandle burr→06.Unyango lobushushu bomthungo wokuwelda→07.Ukupholisa umoya/Amanzi- ipholile/Yenza i-diameter/Ulungiso→08.Isarha ebhabhayo isike→09.Ngaphandle ukuhlola/ukumakisha→10.Isiphelo esicacileyo kunye nebevel end→11.Uvavanyo lweHydraulic→12.Ukuhlolwa kweUltrasonic→13.Ukuphela kombhobho Ukuhlolwa kweUltrasonic→14.Ubunzima/Rekhoda→15.Beka kwindawo yokugcina

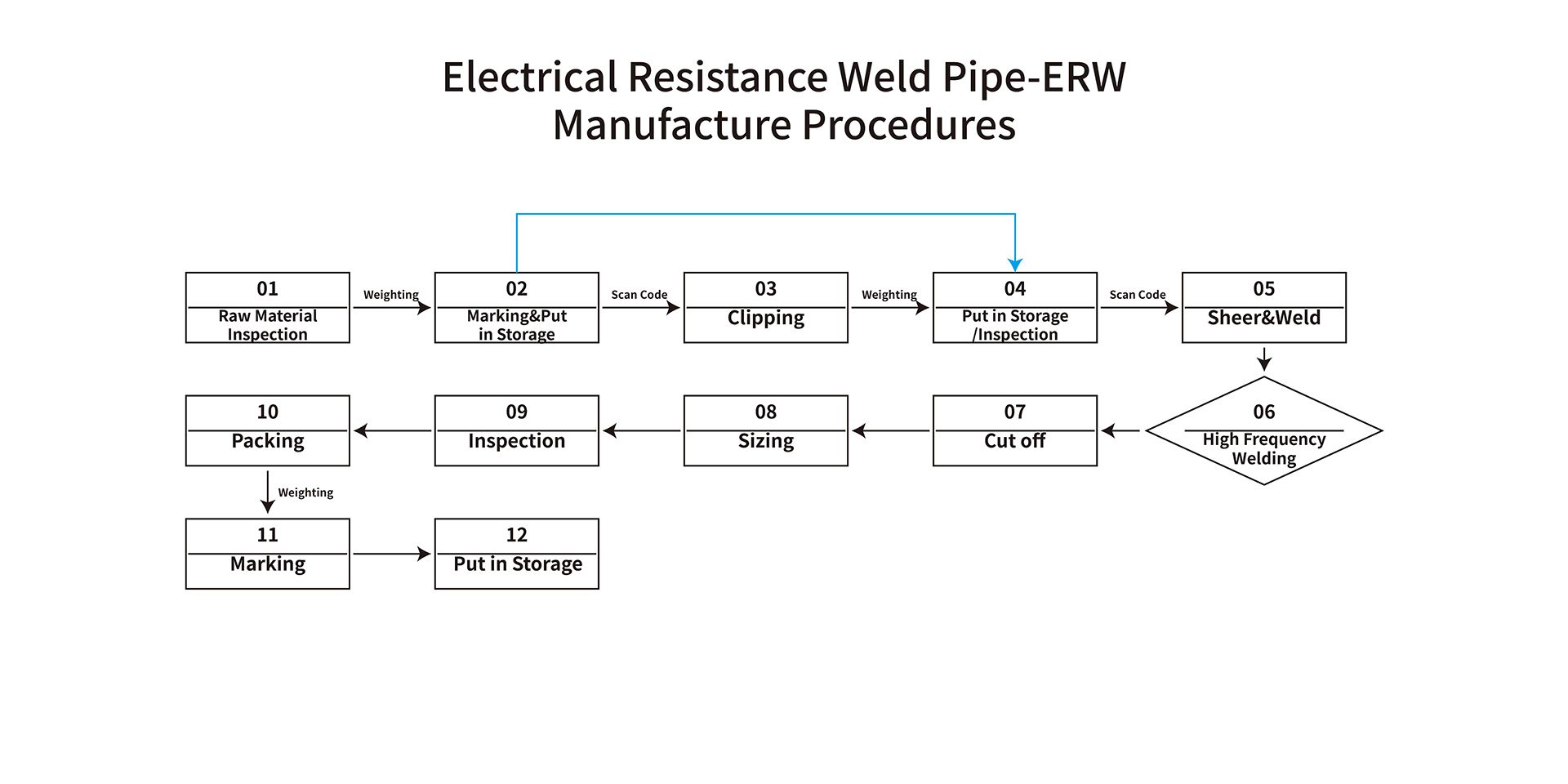

Ukuxhathisa koMbane weld Pipe-ERW

Iinkqubo zokwenziwa

01. Ukuhlolwa kwemathiriyeli ekrwada→02.Ukumakishwa nokuBeka kwindawo yogcino→03.ukucofa→04.Beka kwindawo yokugcina/ukuhlola→05.Sheer&Weld→06.Uvavanyo lomzimba kunye neekhemikhali→07.Sika→08.Ubungakanani→09.Ukuhlola→10. Ukupakisha→11.Ubunzima→12.Skena iikhowudi

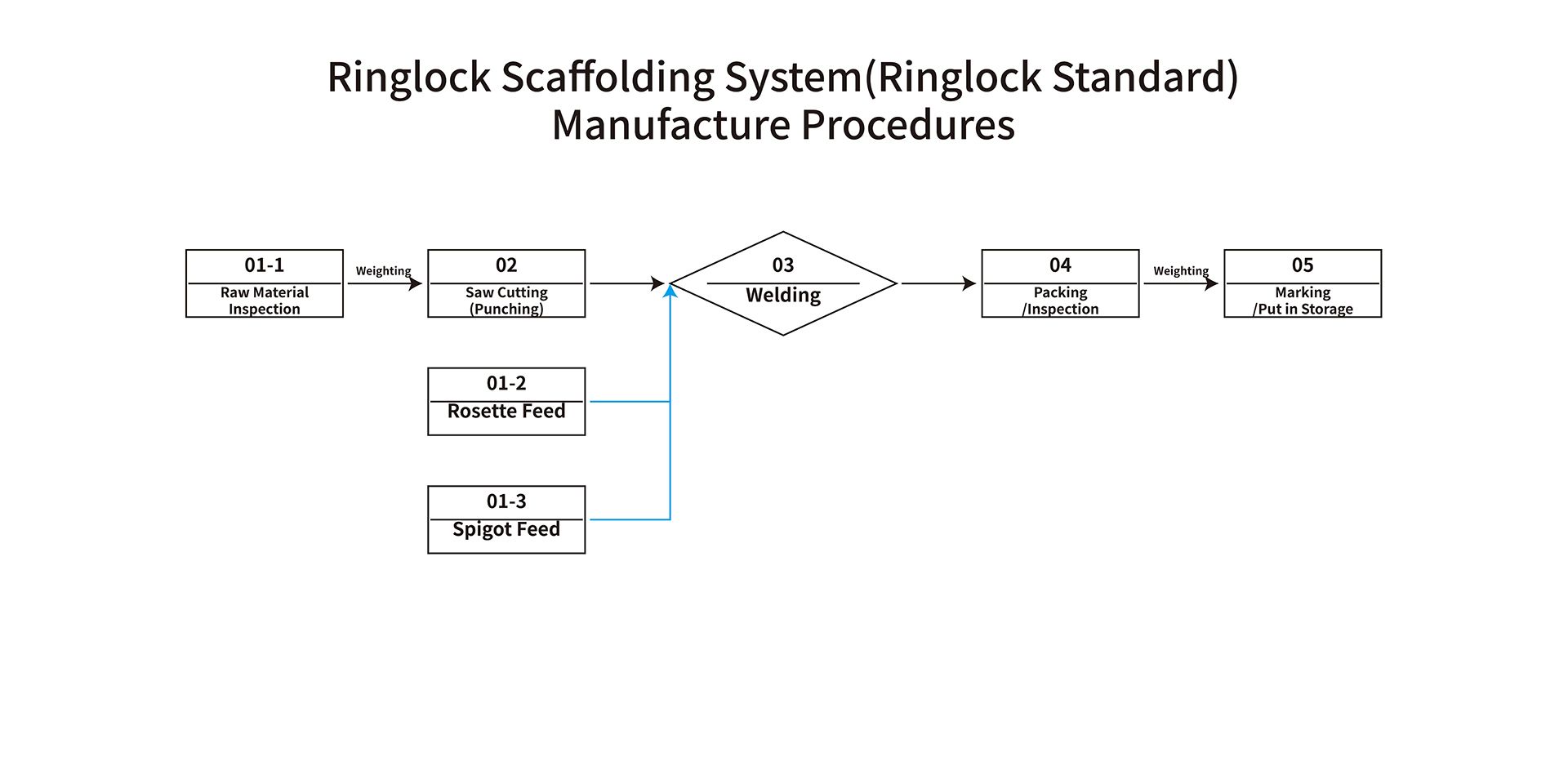

Inkqubo yokuvala isikafula seringi(uMgangatho wokutshixa)

Iinkqubo zokwenziwa

01.Uhlolo lwemathiriyeli ekrwada→02.Ukusika isarha (ukubetha)/iRosette feed/Spigot feed→03.Welding→04.Ukupakisha/ukuhlola→05.Ukumakisha/Beka kwindawo yokugcina

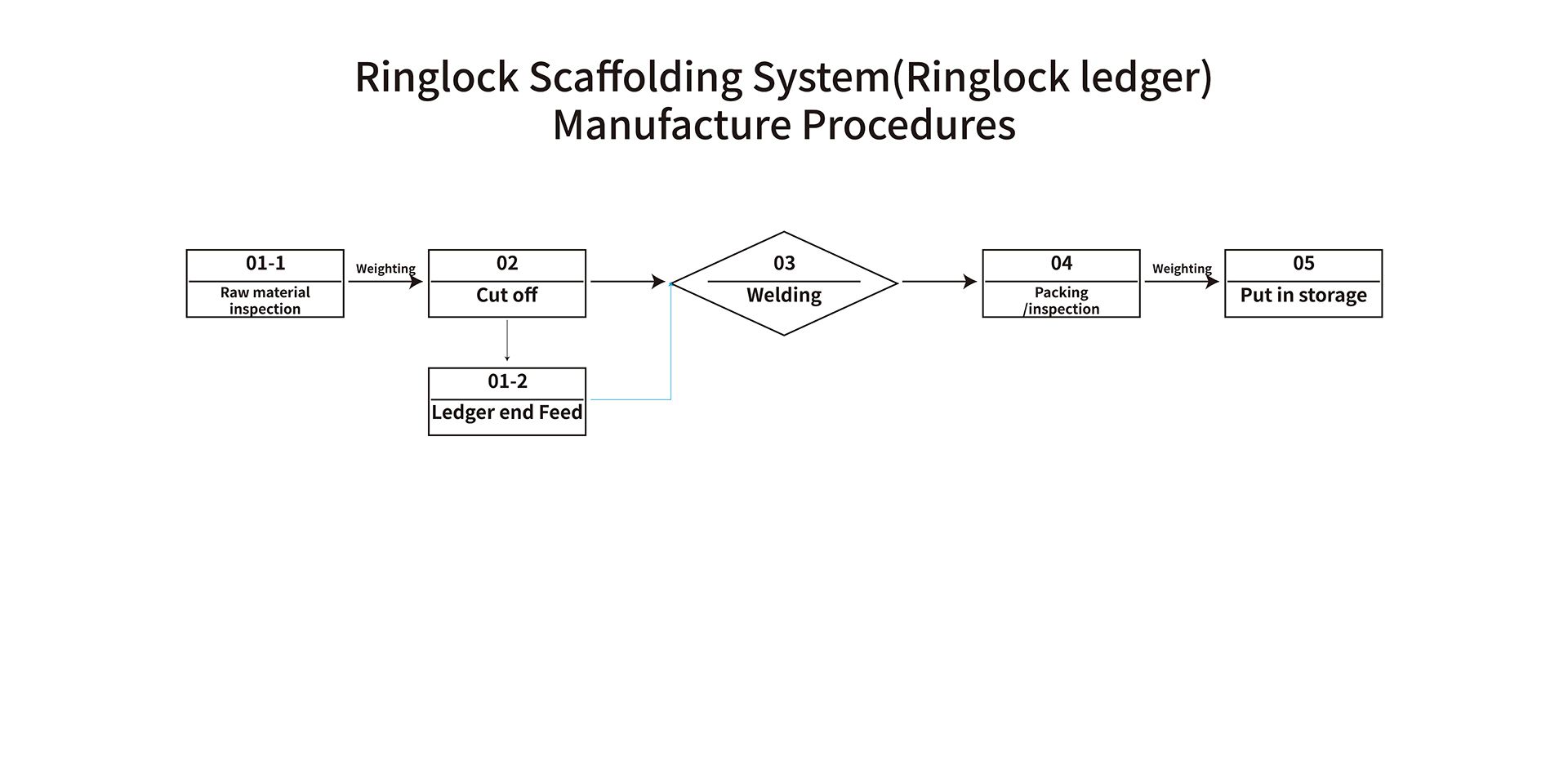

Inkqubo yokutshixa isikafula (Ileja yokutshixa)

Iinkqubo zokwenziwa

01.Uhlolo lwemathiriyeli ekrwada→02.Sika/Isiphelo seLedger →03.Ukuwelda→04.Ukupakisha/ukuhlola→05.Ukumakisha/Beka kwindawo yokugcina

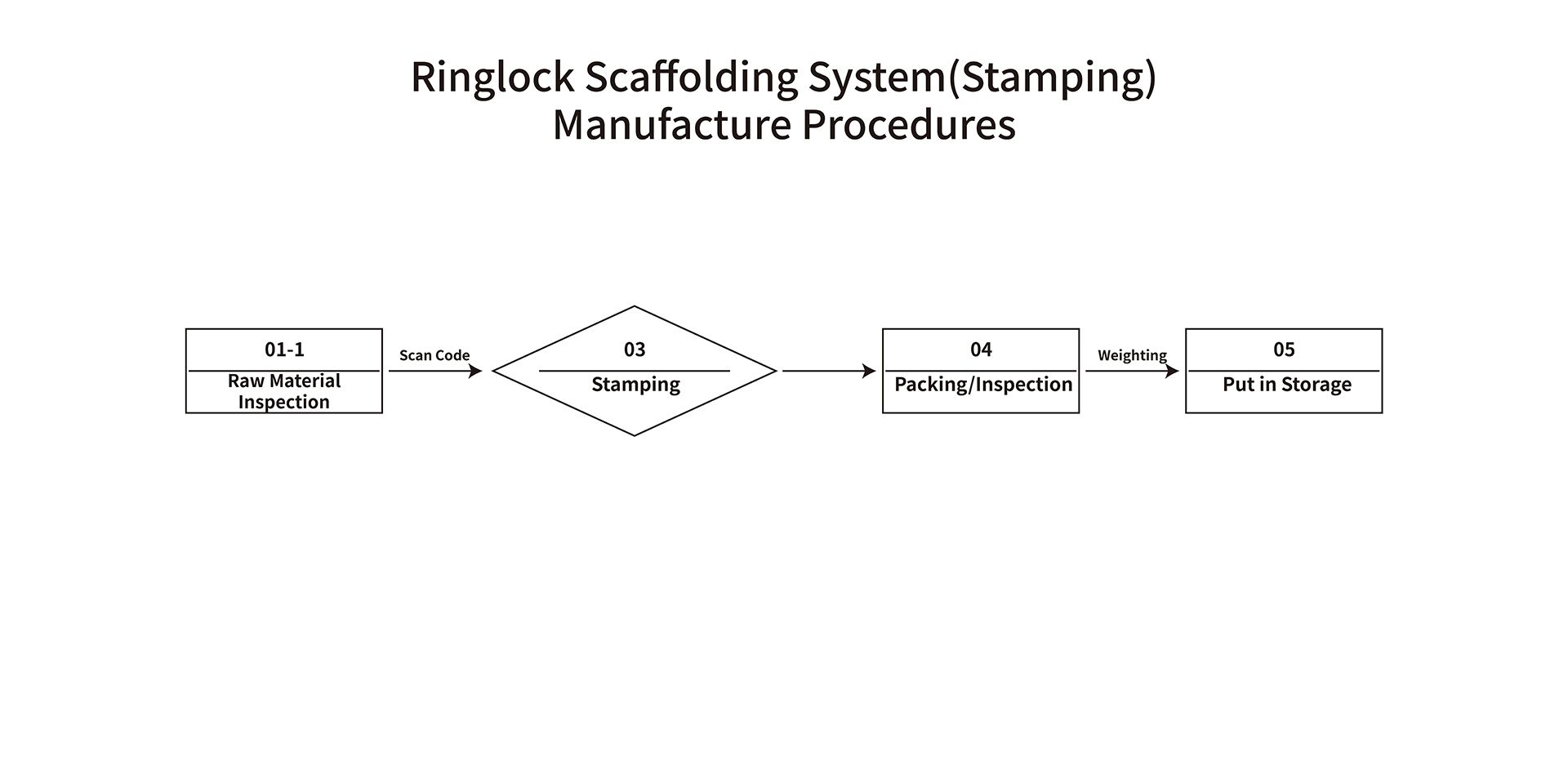

Inkqubo ye-Ringlock scaffolding (Istampu)

Iinkqubo zokwenziwa

01.Uhlolo lwemathiriyeli ekrwada→02.Isitampu→03.Ukupakisha/Ukuhlola→04.Beka kwindawo yokugcina

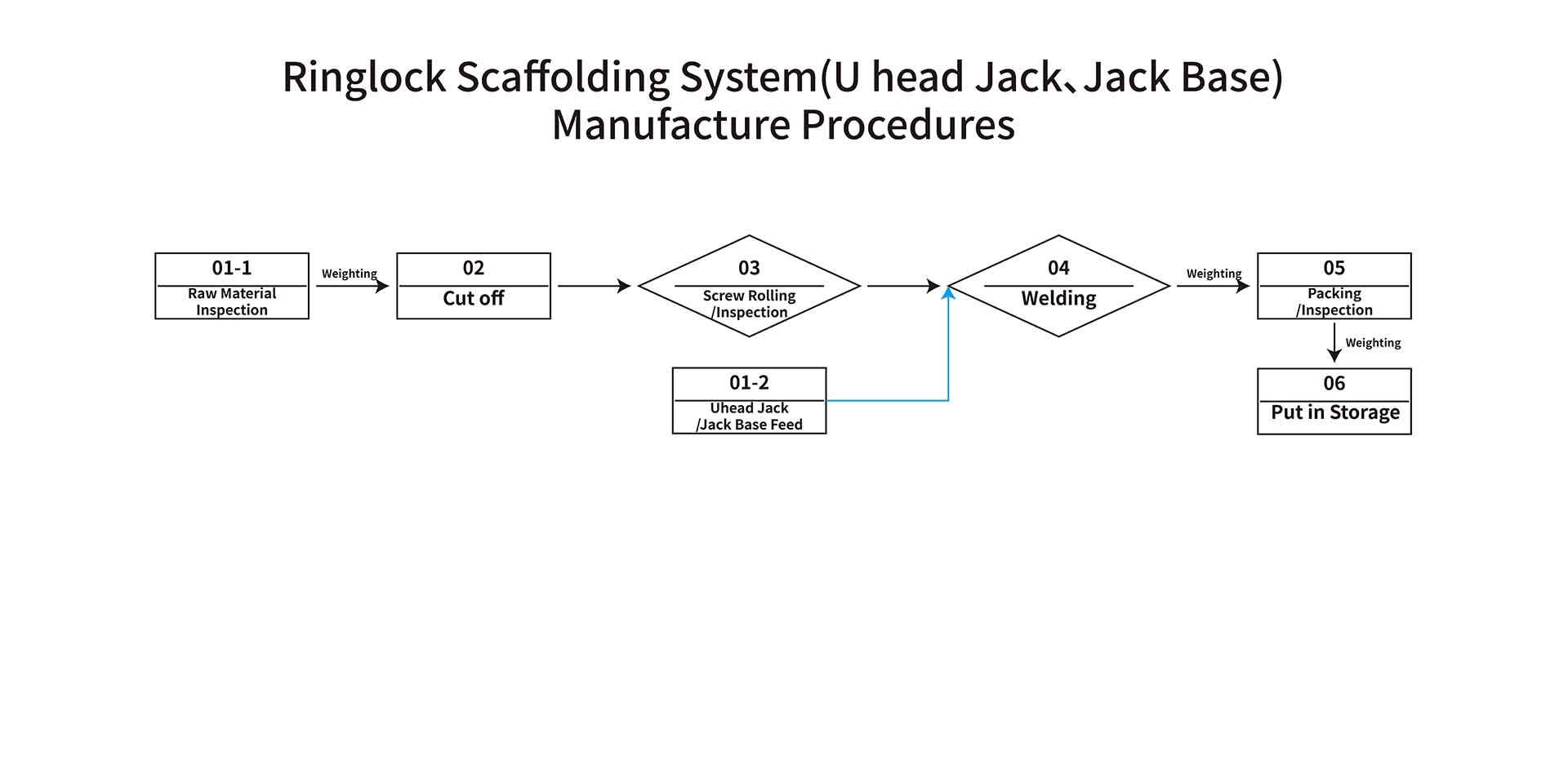

I-Ringlock scaffolding System (U jakhi wentloko, isiseko sikaJack)

Iinkqubo zokwenziwa

01.Ukuhlolwa kwemathiriyeli ekrwada→02.Sika→03.Ukurola/Ukuhlola/Ijekhi yasentloko/ijekhi yesiseko →04.Welding→05.Ukupakisha/ukuhlola→06.Beka kwindawo yokugcina

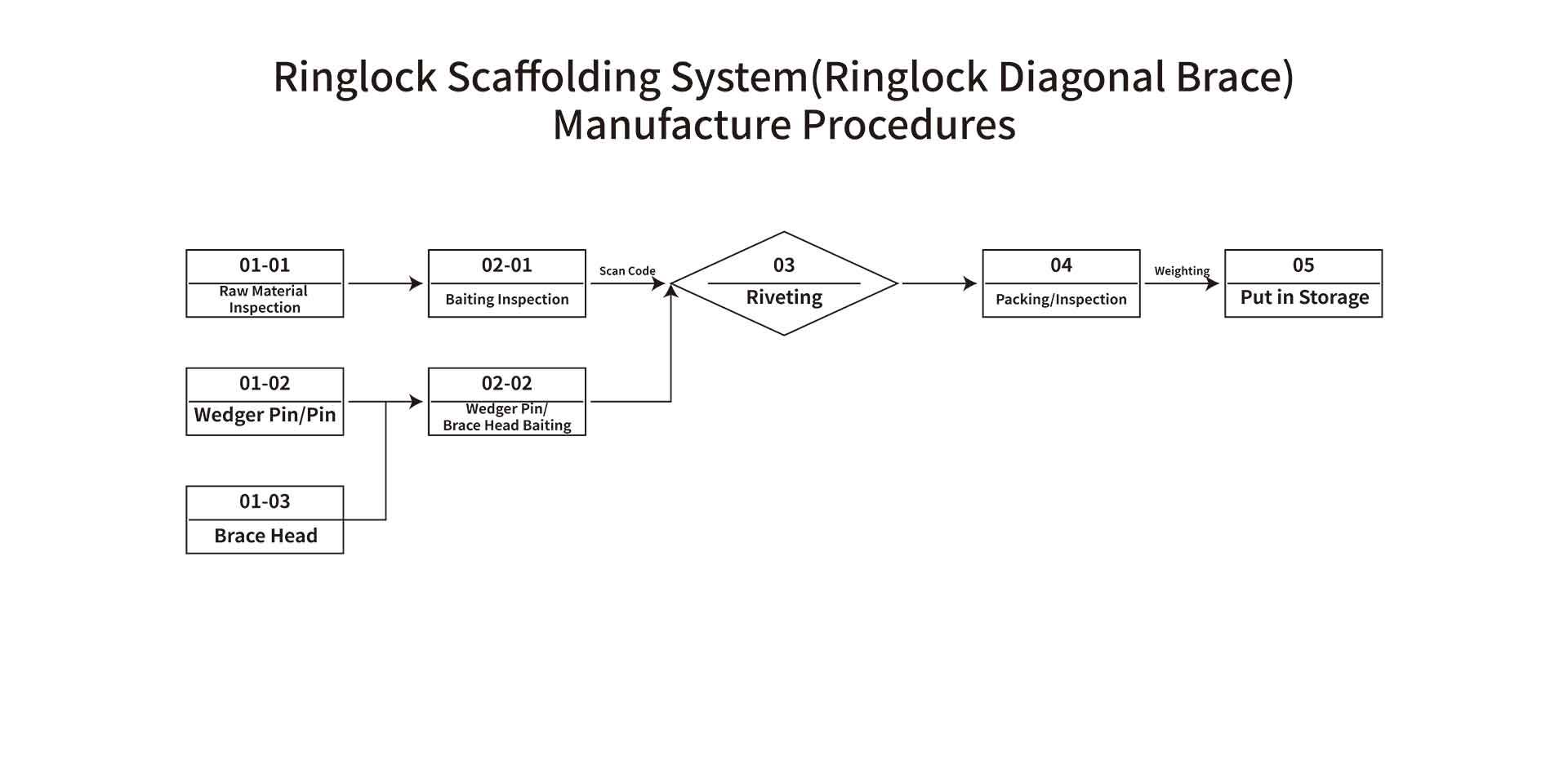

Inkqubo yokuvala isikafula seRing(iqhaga lekhonkco elinediagonal)

Iinkqubo zokwenziwa

01.Ukuhlolwa kwemathiriyeli ekrwada/Ipini yeWedger/Iphini/intloko yeBrace→02.Ukuhlolwa kokuxhonywa/intsimbi yokuqhoqhobala/isibambiso sentloko yeBrace→03.Ukuwelda→04.Ukupakisha/ukuhlola→05.Beka kwindawo yokugcina