Ṣiṣan Ilana iṣelọpọ ati Ṣiṣayẹwo Ṣiṣayẹwo

Pẹlu awọn oṣiṣẹ 9000 ti o ni oye pupọ ati awọn laini iṣelọpọ ilọsiwaju 293 ti o tan kaakiri awọn ile-iṣelọpọ 13, a ti ṣe agbejade awọn paipu irin toonu 20 million ni ọdun 2022, ati pe iye tita naa ti kọja 160 milionu dọla AMẸRIKA ni ọdun 2018. Fun awọn ọdun itẹlera 17, Youfa jẹ akọle laarin TOP Awọn ile-iṣẹ 500 ni Ile-iṣẹ iṣelọpọ Ilu China lati ọdun 2006.

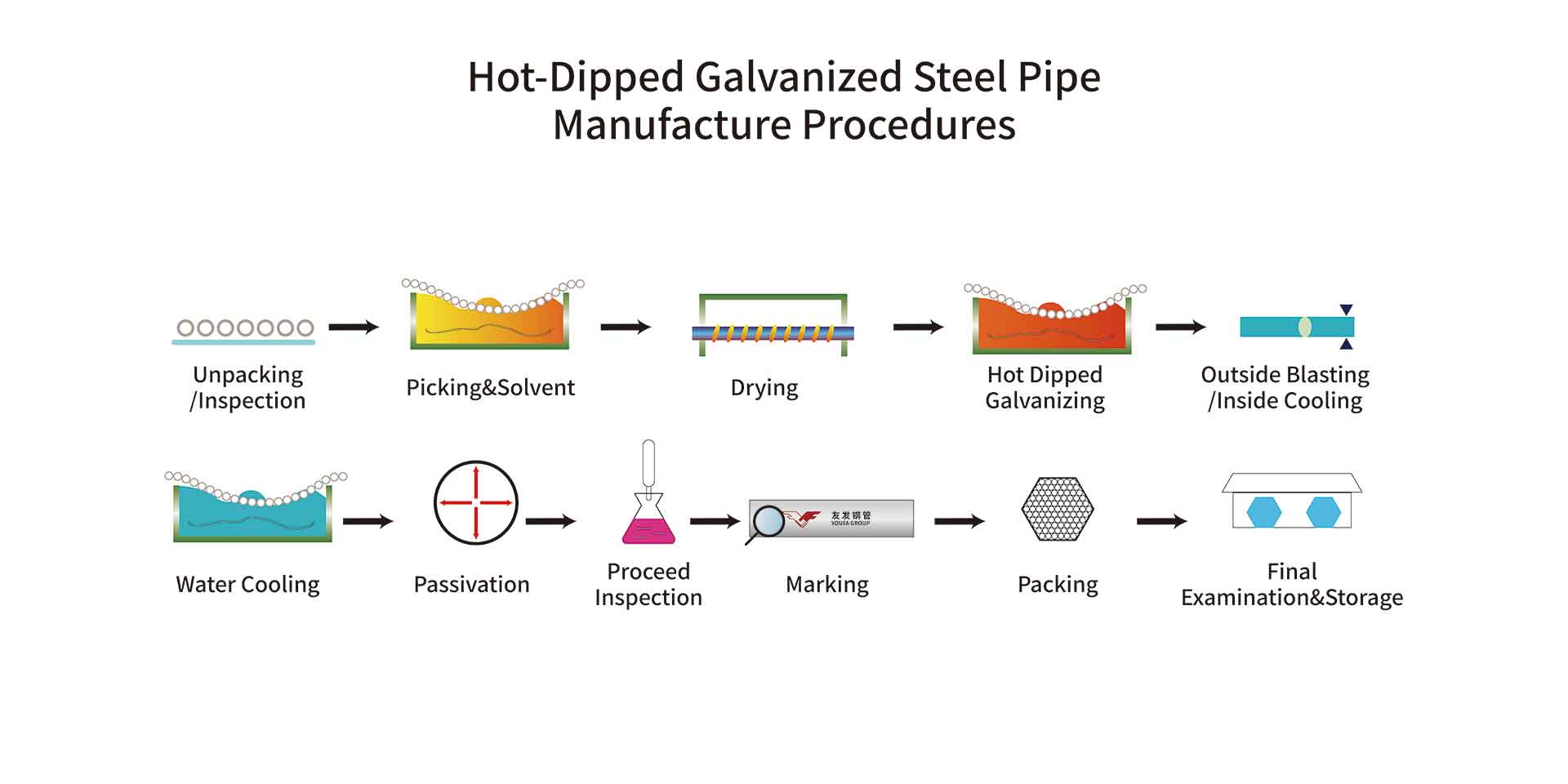

Gbona-Dipped Galvanized Irin Pipe

Awọn ilana iṣelọpọ

01.Unpacking/Inspection→02.Picking&solvent→03.Drying→04.SHot dipped galvanizing→05.Ide bugbamu ti ita/Inu itutu →06.Itutu omi →07.Passivation→08.Tẹsiwaju ayewo→09.Marking→10.Packing→ 11.Ipari idanwo & Ibi ipamọ

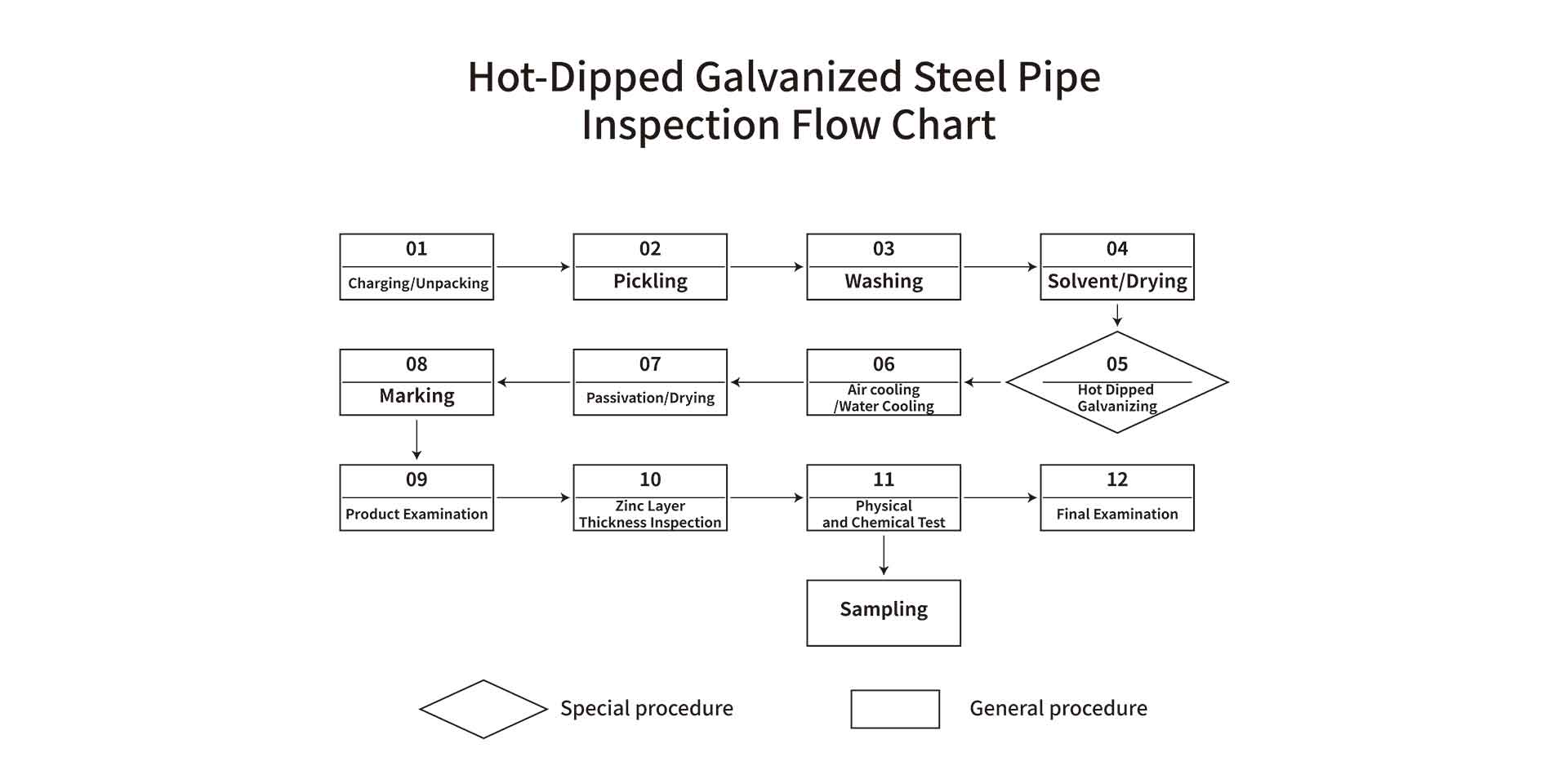

Gbona-Dipped Galvanized Irin Pipe

Ayẹwo Flow chart

01.Charging/Unpacking→02.Pickling→03.Washing→04.Solvent/Drying→05.Hot dipped galvanizing→06.Air cooling/Omi Cooling→07.Passivation/Drying→08.Marking→09.Ayẹwo ọja →10 .Zinc Layer sisanra ayewo → 11. Ti ara ati kemikali igbeyewo → 12.Ipari idanwo

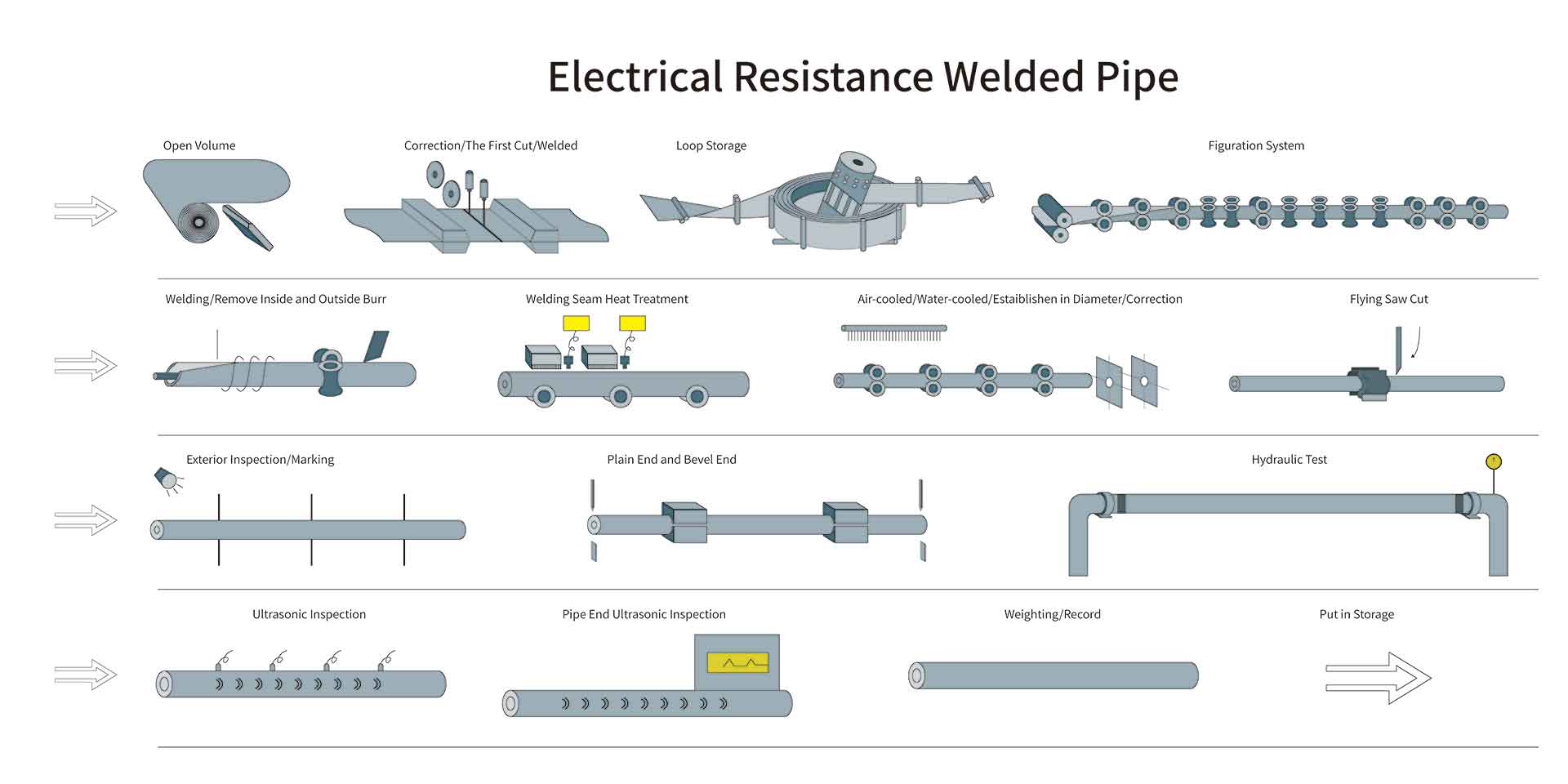

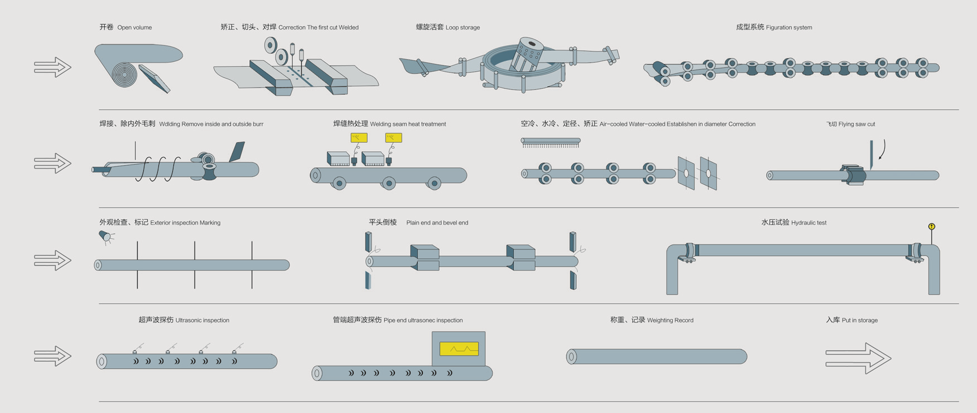

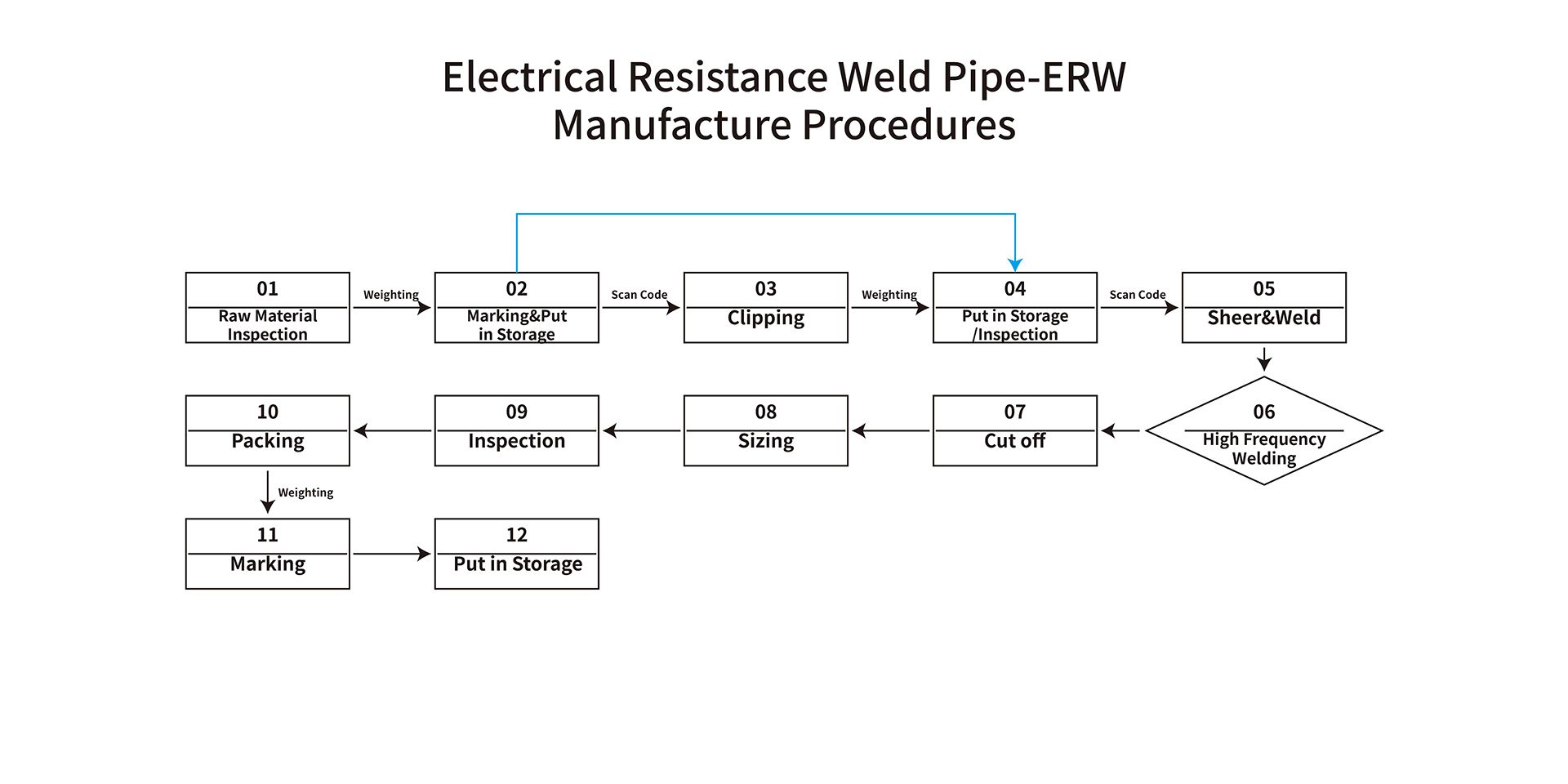

Itanna Resistance Weld Pipe-ERW

Awọn ilana iṣelọpọ

01.Open volume→02.Correction/Ni igba akọkọ ti ge / Welded→ 03.Loop ipamọ → 04.Figuration System → 05.Welding / Yọ inu ati ita burr → 06. Welding seaam heat treatment→ 07.Air-cooled / Water- tutu/Estaiblishen ni diamita/Atunse→08.Flying ri ge →09.Ode ayewo / Siṣamisi → 10.Plain opin ati bevel opin → 11.Hydraulic igbeyewo → 12. Ultrasonic ayewo → 13.Pipe opin Ultrasonic ayewo → 14.Weighting / Gbigbasilẹ → 15.Fi sii ni ibi ipamọ.

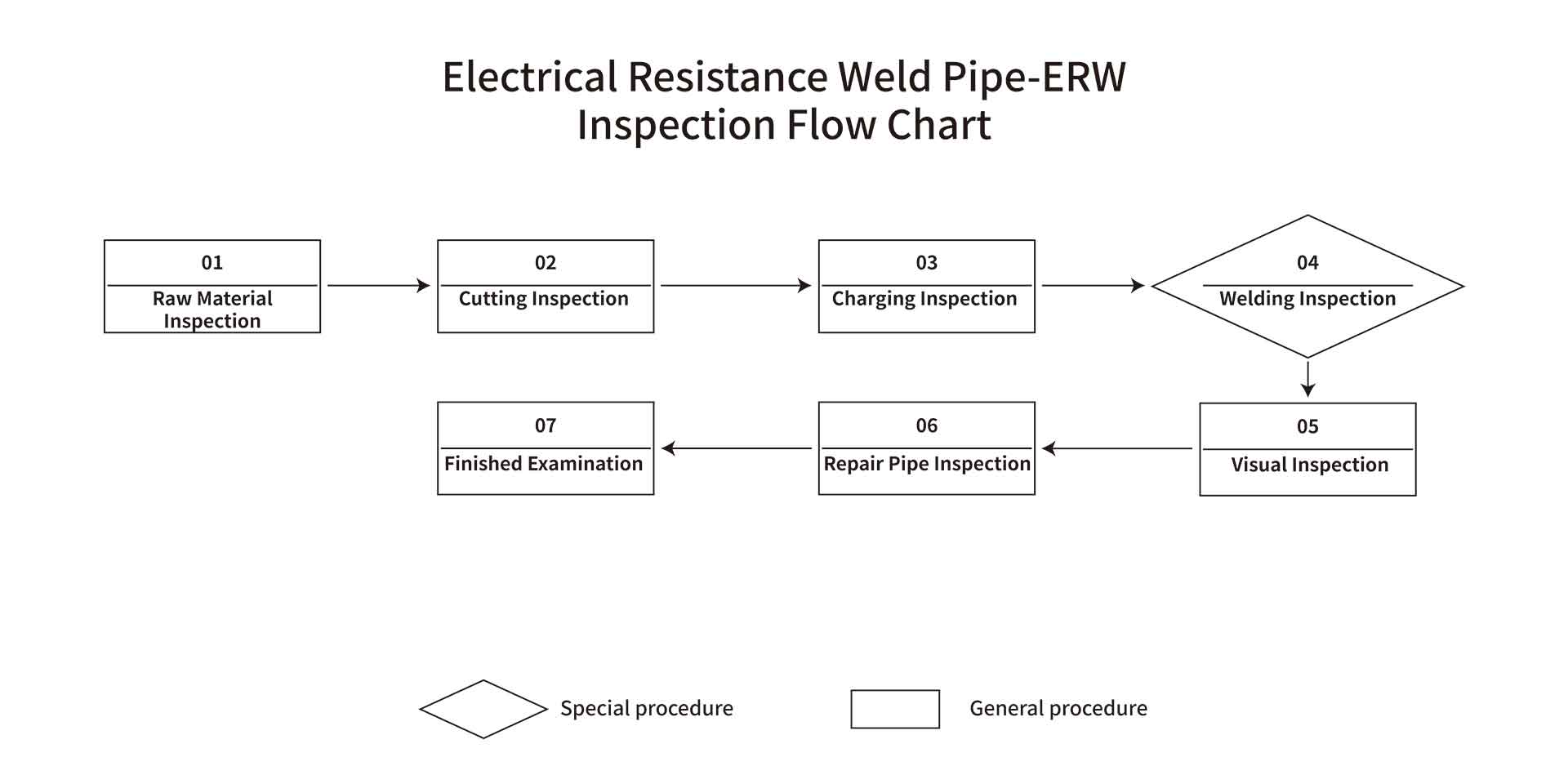

Itanna Resistance Weld Pipe-ERW

Ayẹwo Flow chart

01. Ayẹwo ohun elo aise → 02.Iyẹwo gige → 03. Ayẹwo gbigba agbara → 04. Ayẹwo Welding → 05. Ayẹwo wiwo → 06. Ayẹwo paipu atunṣe → 07. Iyẹwo ti pari

A yoo ṣe idanwo awọn ohun elo aise ati awọn ilana iṣelọpọ ni ibamu si awọn iṣedede oriṣiriṣi lati rii daju pe awọn ọja ba pade awọn iṣedede tabi awọn ibeere adehun.

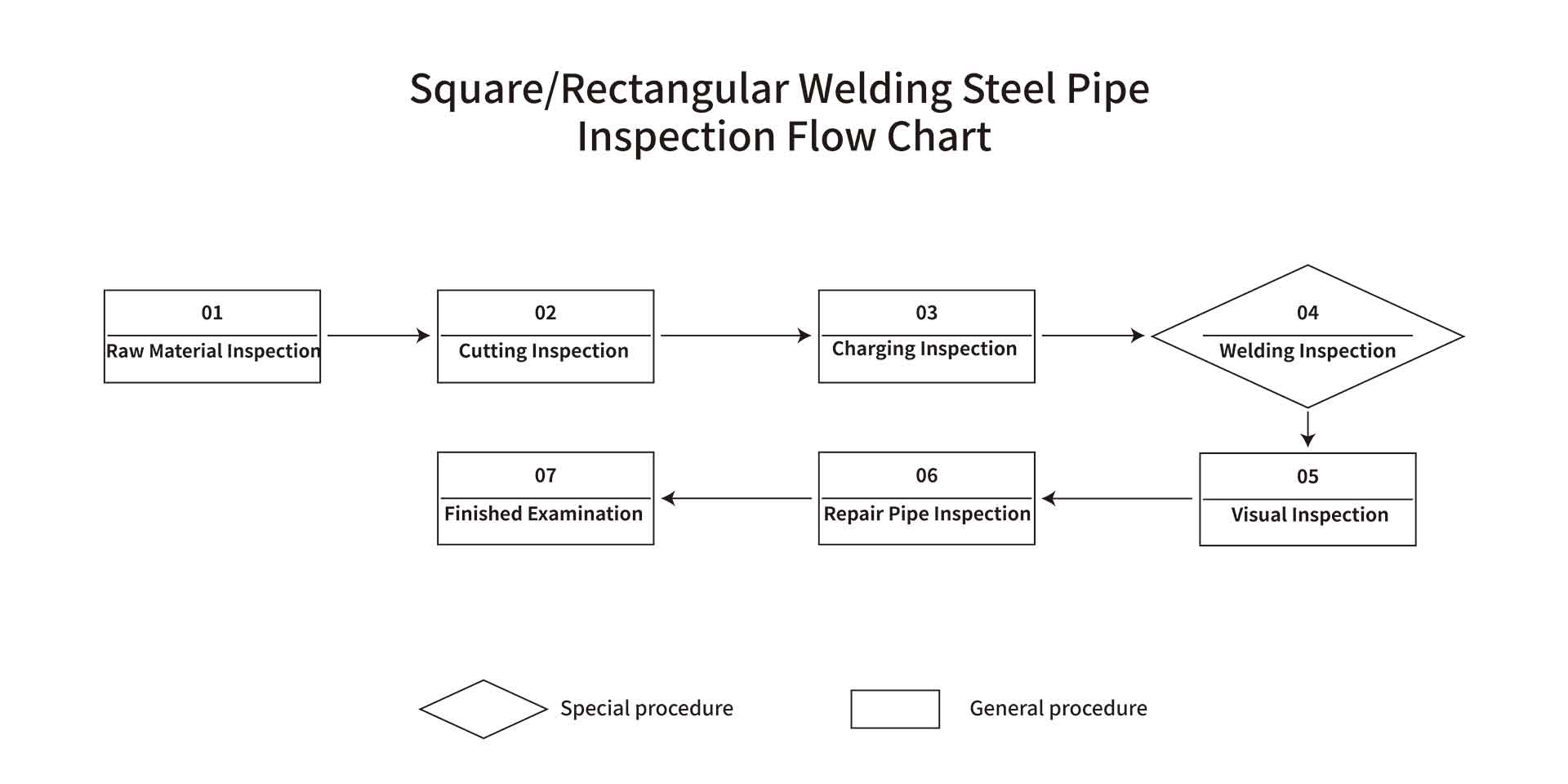

Square / onigun Alurinmorin Pipe

Ayẹwo Flow chart

01. Ayẹwo ohun elo aise → 02.Iyẹwo gige → 03. Ayẹwo gbigba agbara → 04. Ayẹwo Welding → 05. Ayẹwo wiwo → 06. Ayẹwo paipu atunṣe → 07. Iyẹwo ti pari

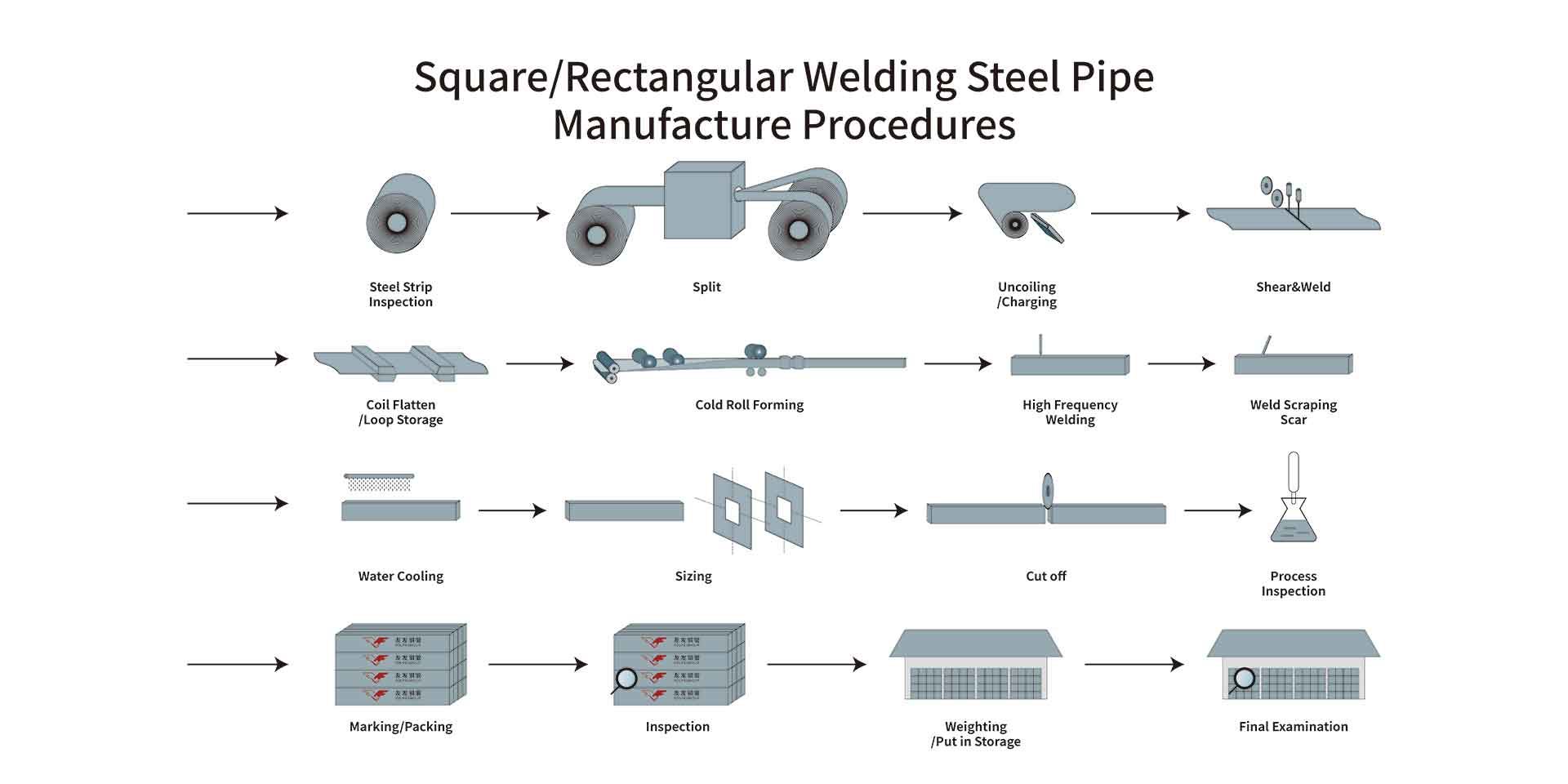

Square / onigun Alurinmorin Pipe

Awọn ilana iṣelọpọ

01. Irin rinhoho ayewo → 02.Split→ 03.Uncoiling / gbigba agbara → 04.Shear&Weld → 05.Coil Flatten / Loop ipamọ → 06. Cold Roll forming→ 07.High Frequency alurinmorin→08.Weld scraping aleebu →09.Omi itutu agbaiye →10.Sizing→11.Cut off→12.Ilana ayewo→13.Samisi/Packing→14.Ayẹwo→15.Iwọn wiwọn/Fi sinu ibi ipamọ→16.Ayẹwo ikẹhin

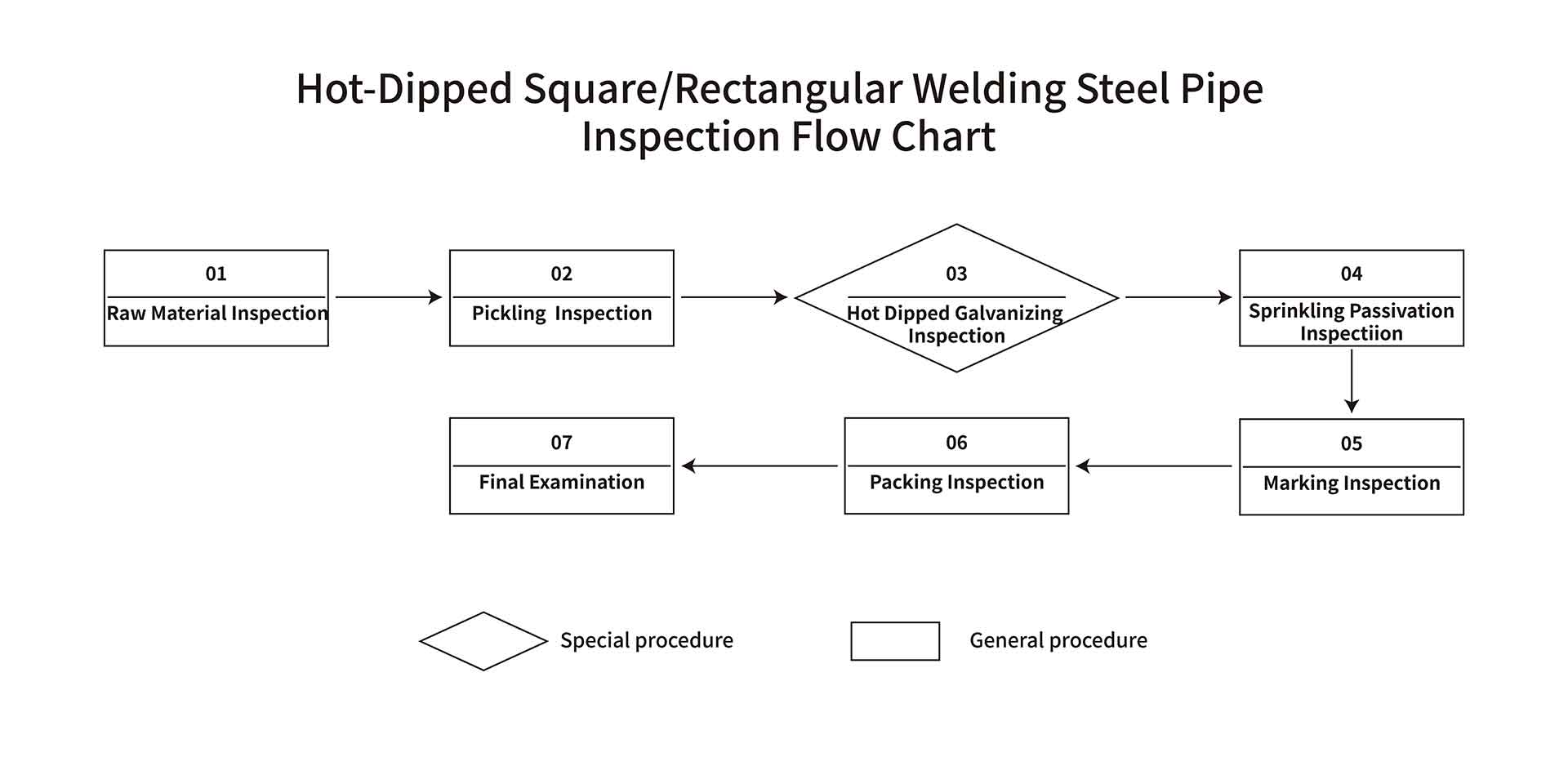

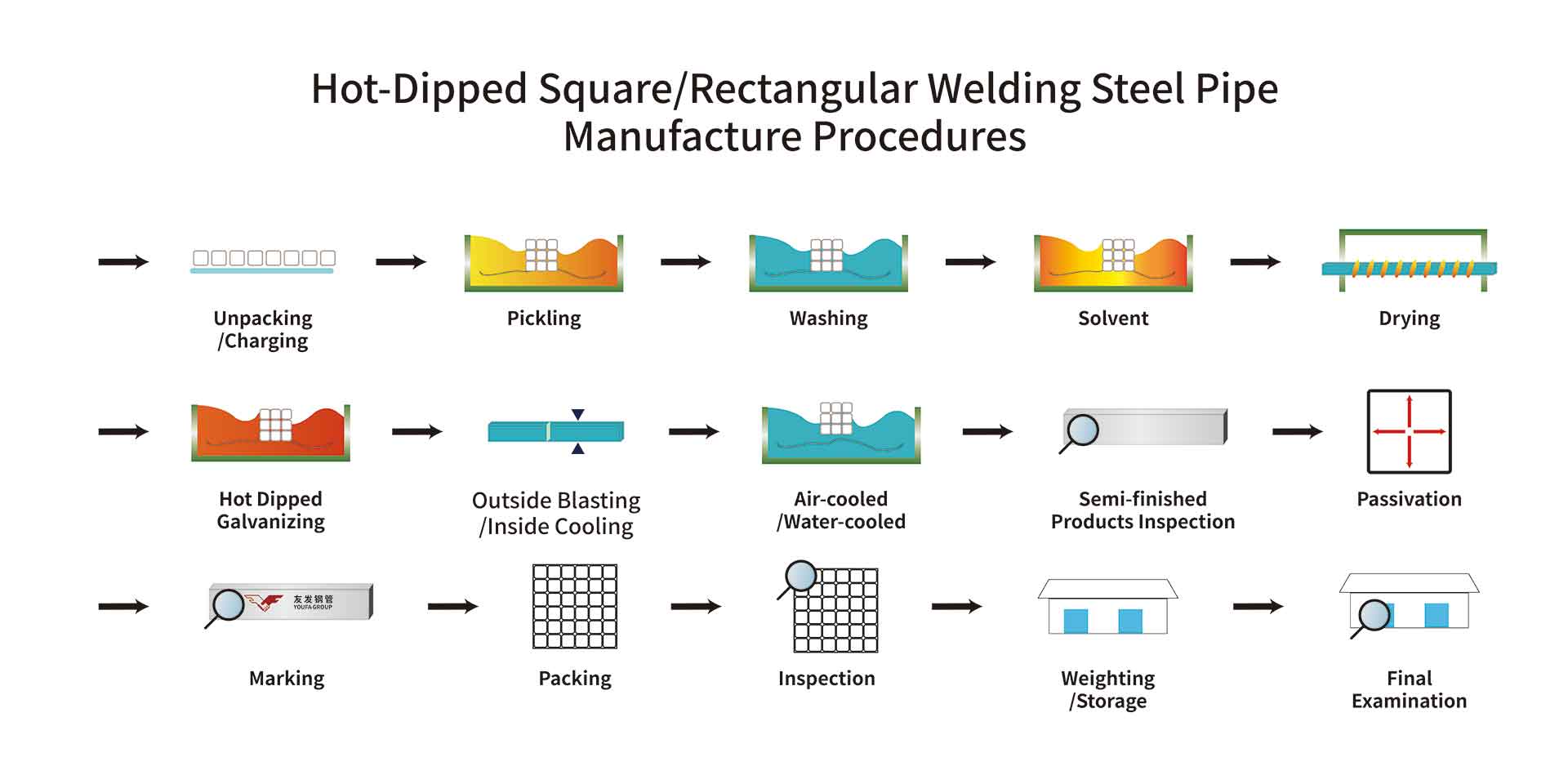

Gbona-Dipped Square/ Onigun Alurinmorin Pipe

Ayẹwo Flow chart

01. Ayẹwo ohun elo Raq → 02.Ayẹwo pickling → 03. Hot Dipped Galvanizing inspection→ 04.Sprinkling Passivation inspection→ 05.Ayẹwo isamisi → 06.Ayẹwo iṣakojọpọ → 07.Iyẹwo ikẹhin

A yoo ṣe idanwo awọn ohun elo aise ati awọn ilana iṣelọpọ ni ibamu si awọn iṣedede oriṣiriṣi lati rii daju pe awọn ọja ba pade awọn iṣedede tabi awọn ibeere adehun.

Gbona-Dipped Square/ Onigun Alurinmorin Pipe

Awọn ilana iṣelọpọ

01.Welding irin pipe → 02.Unpacking / gbigba agbara → 03.Pickling → 04. Fifọ → 05. Solvent → 06. Gbigbe → 07. Hot Dipped Galvanizing → 08. Ita Blasting → 09.Inu Itutu → 10.Air-tutu/ Omi-tutu → 11.Awọn ọja ti o pari-meji ayewo→12.Passivation→13.Samisi→14.Packing→15.Ayẹwo→16.Iwọnwọn/Ibipamọ→17.Ayẹwo Ipari

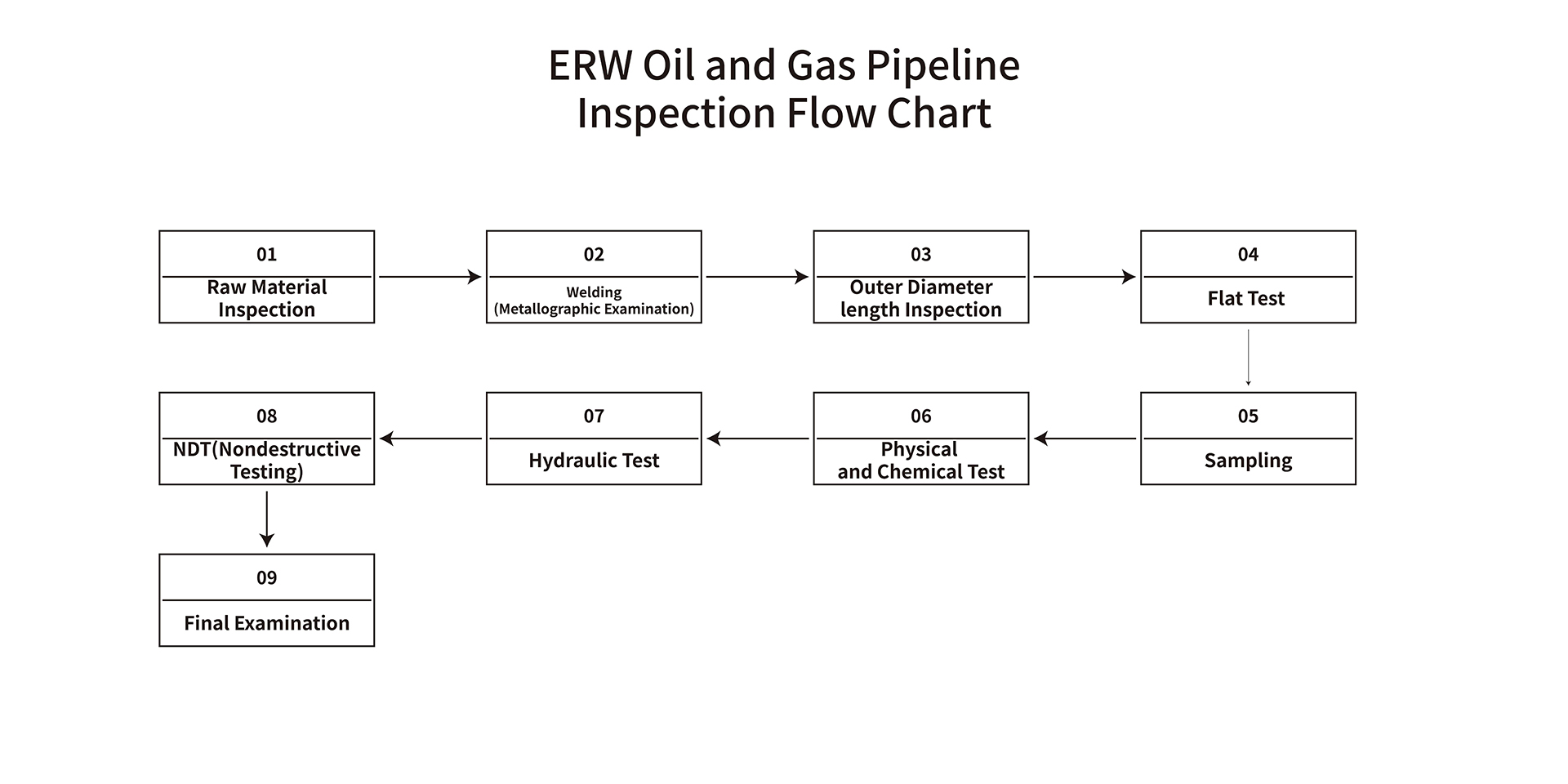

ERW epo ati gaasi opo

Ayẹwo Flow chart

01. Ayẹwo ohun elo aise → 02. Welding (Iyẹwo Metallographic) → 03. Ayewo ipari ipari opin ita → 04.Flat test→ 05.Sampling → 06. Ti ara ati kemikali 09.Ipari Ayẹwo

A yoo ṣe idanwo awọn ohun elo aise ati awọn ilana iṣelọpọ ni ibamu si awọn iṣedede oriṣiriṣi lati rii daju pe awọn ọja ba pade awọn iṣedede tabi awọn ibeere adehun.

01.Open volume→02.Correction/Ni igba akọkọ ti ge / Welded→ 03.Loop ipamọ → 04.Figuration System → 05.Welding / Yọ inu ati ita burr → 06. Welding seaam heat treatment→ 07.Air-cooled / Water- tutu/Estaiblishen ni diamita/Atunse→08.Flying ri ge →09.Ode ayewo / Siṣamisi → 10.APlain opin ati opin bevel → 11.Hydraulic test → 12. Ultrasonic inspection→ 13.Pipe end Ultrasonic inspection→14.Weighting/Record→15.Fi sii ni ibi ipamọ.

Itanna Resistance Weld Pipe-ERW

Awọn ilana iṣelọpọ

01. Ayẹwo ohun elo aise→ 02.Samisi&Fi sinu ibi ipamọ → 03.clipping→ 04.Fi sinu ibi ipamọ / Ayewo 05.Sheer&Weld→ 06. Idanwo ti ara ati kemikali Iṣakojọpọ → 11.Iwọn → 12.Scan awọn koodu

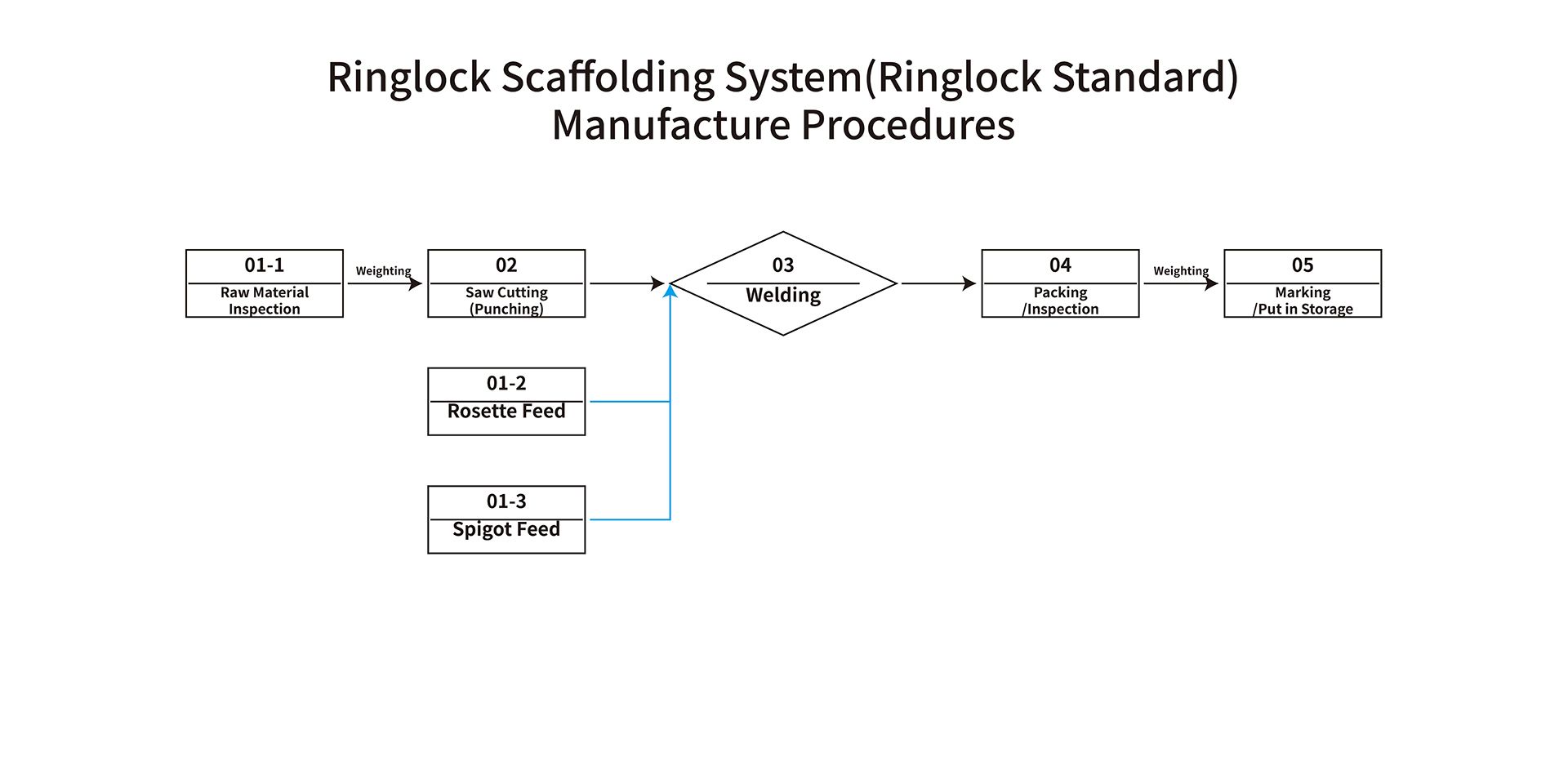

Eto Titiipa Titiipa (Iwọn Titiipa Iwọn)

Awọn ilana iṣelọpọ

01.Ayẹwo ohun elo aise → 02.Saw gige (punching) / kikọ sii Rosette / kikọ sii Spigot → 03. Welding → 04.Packing / ayewo → 05.Marking / Fi sinu ibi ipamọ

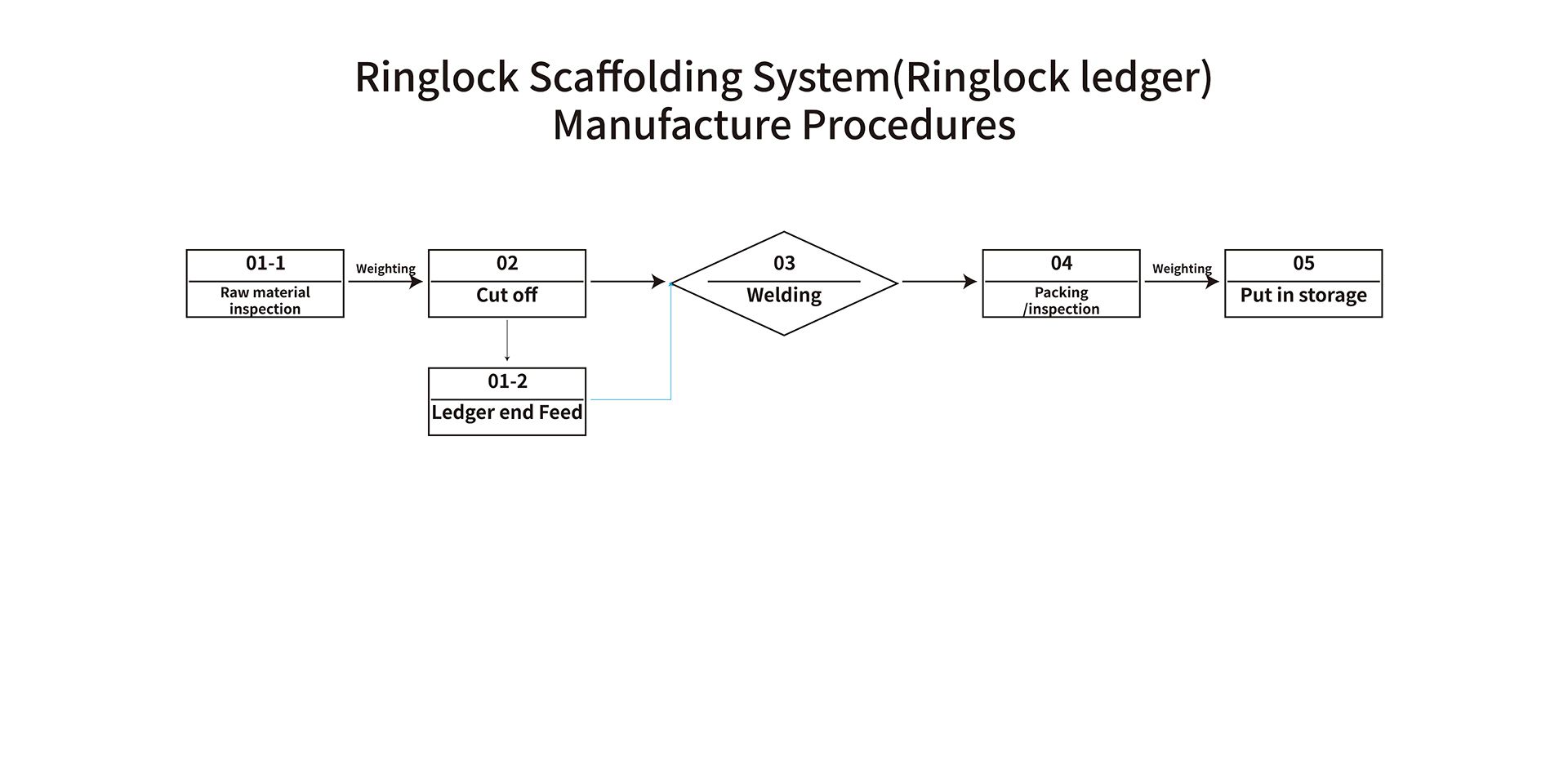

Eto Titiipa Titiipa (ikọsilẹ Titiipa)

Awọn ilana iṣelọpọ

01.Ayẹwo ohun elo Raw→ 02.Cut off/Ledger end Feed→03.Welding→04.Packing/inspection→05.Marking/Fit in storage

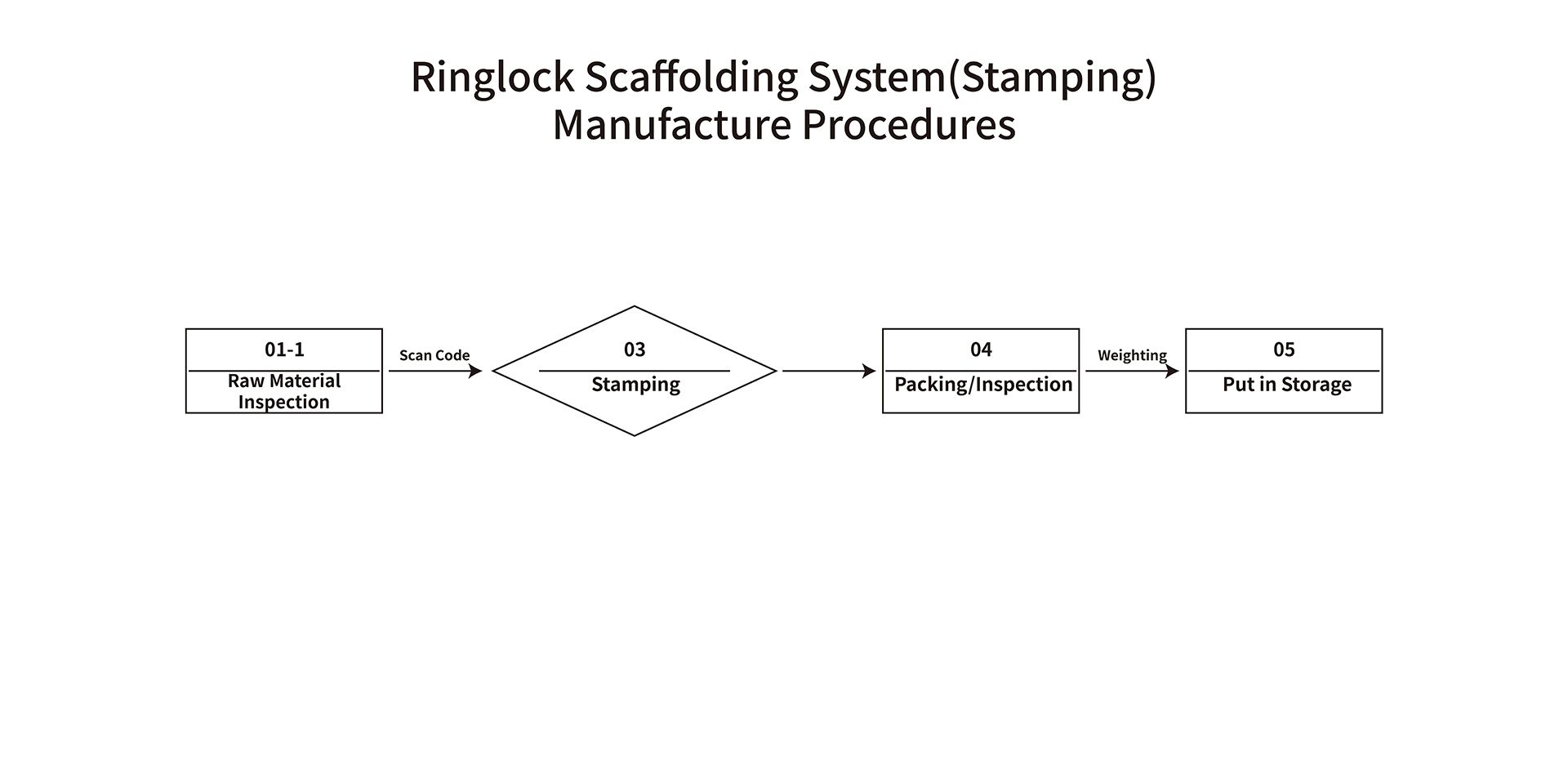

Eto Titiipa Titiipa (Titiipa)

Awọn ilana iṣelọpọ

01.Ayẹwo ohun elo Raw→02.Stamping→03.Packing/Ayẹwo→04.Fi si ibi ipamọ

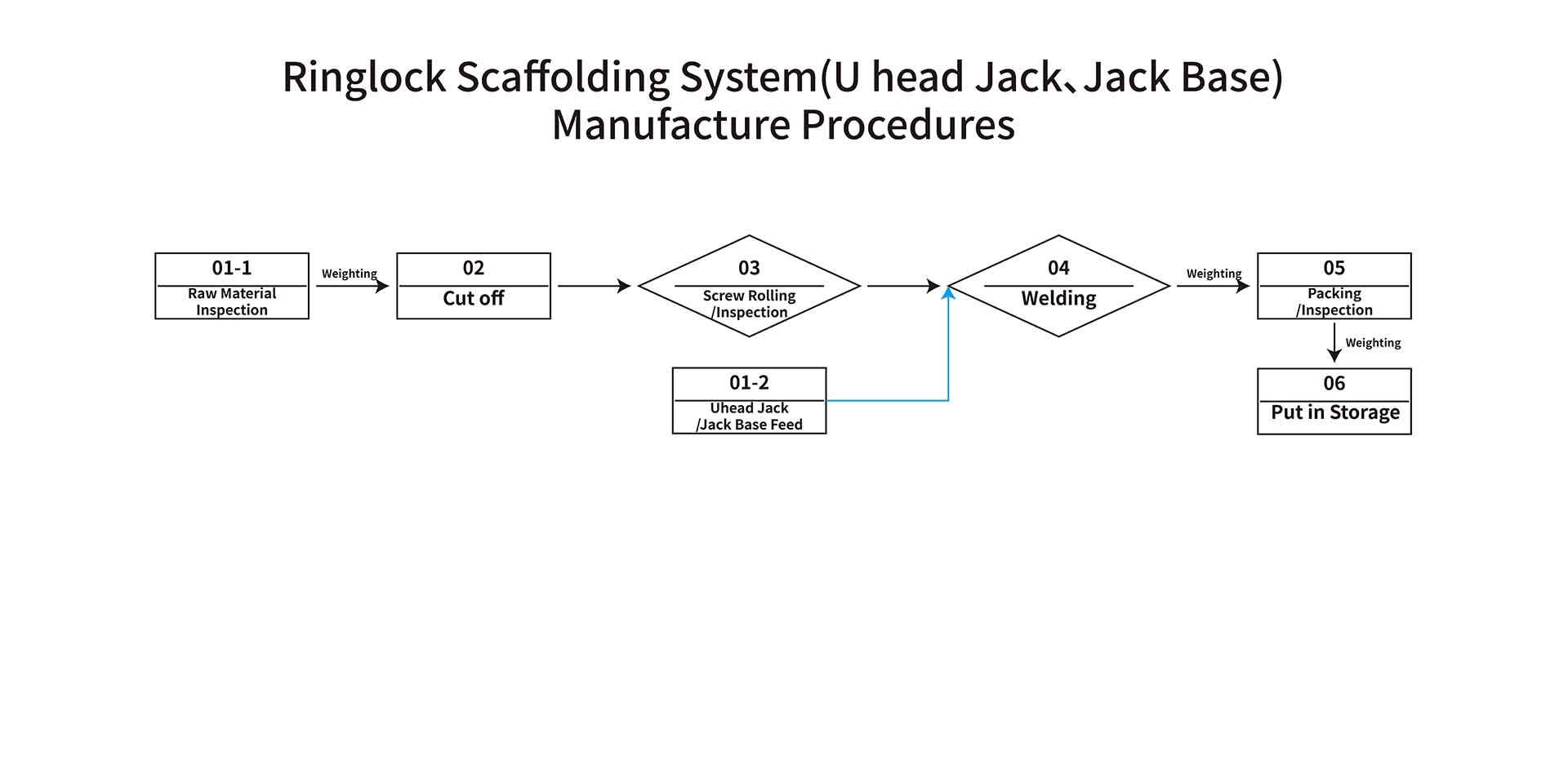

Eto Scafolding Titiipa (Jack ori U, Jack mimọ)

Awọn ilana iṣelọpọ

01.Ayẹwo ohun elo Raw→02.Ge kuro→ 03.Skru yiyi / Ayewo / Jack Uhead / Jack base feed→ 04.Welding→ 05.Packing/inspection→06.Fi sinu ibi ipamọ

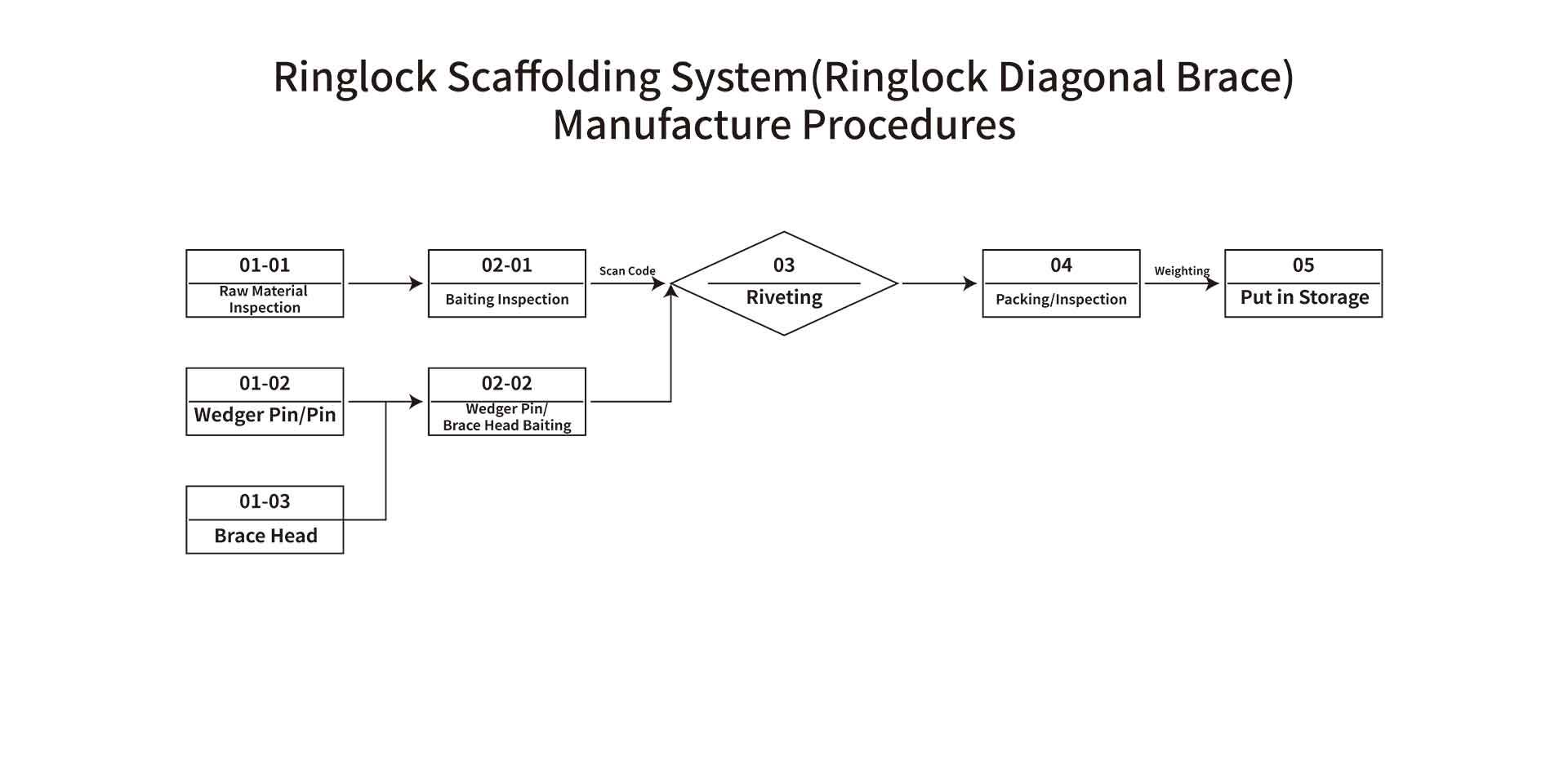

Eto Scafolding Titiipa oruka (àmúró akọ-rọsẹ)

Awọn ilana iṣelọpọ

01.Ayẹwo ohun elo Raw / Wedger pin / Pin / ori àmúró → 02.Ayẹwo Baiting / PIN eti / Brace head baiting → 03. Welding → 04.Packing / inspection→ 05.Fi sii ni ibi ipamọ