*UKUGQIBELA

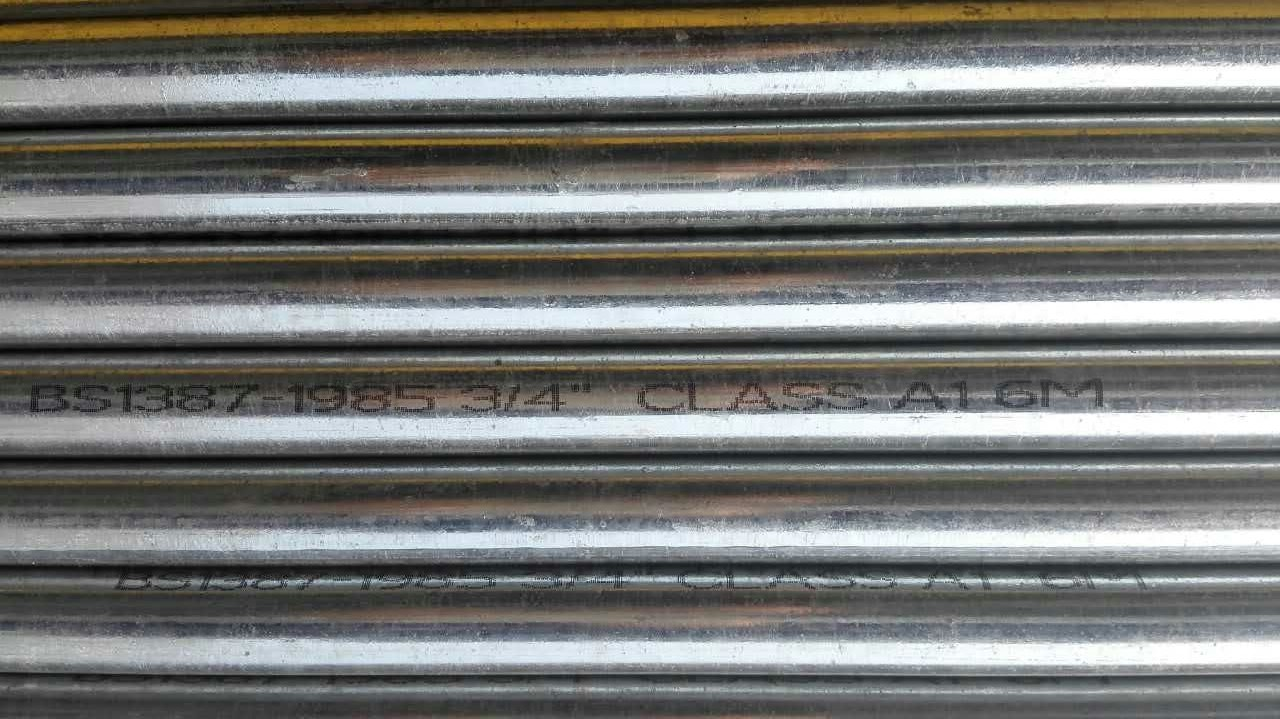

Ipayipi elinothayela le-hot-dip liwukwenza insimbi encibilikisiwe isabelane ne-iron matrix ukuze ikhiqize ungqimba lwengxubevange, ngaleyo ndlela kuhlanganiswe i-matrix kanye nokunameka. I-acid-dip galvanizing yokuqala igeza ipayipi lensimbi ukuze kukhishwe i-iron oxide ebusweni bepayipi lensimbi. Ngemuva kokugeza i-asidi, ihlanzwa ethangini nge-ammonium chloride noma i-zinc chloride isixazululo samanzi noma ingxube ye-ammonium chloride ne-zinc chloride isixazululo samanzi, bese ithunyelwa okugeza okushisayo kwe-dip galvanizing.

I-hot-dip galvanizing inezinzuzo zokunamathela okufanayo, ukunamathela okuqinile, ukumelana nokugqwala okuhle, nempilo ende yesevisi. Ikakhulukazi ezindaweni ezinokhahlo, ezifana nemvula enomswakama, imvula, i-asidi, isifutho sikasawoti kanye nezinye izindawo, ukusebenza kwe-hot-dip galvanizing kugqame kakhulu. I-substrate yensimbi kanye nesixazululo se-plating esincibilikisiwe sibhekana nokusabela okuyinkimbinkimbi ngokomzimba namakhemikhali ukuze kwakhe ungqimba lwengxube ye-zinc-iron engagqwali enesakhiwo esiqinile. I-alloy layer, i-zinc ehlanzekile, ne-steel substrate kuhlanganiswe ndawonye. Ngakho-ke, inokumelana nokugqwala okuqinile.

1. Ukufana kwe-coating: Isampula yepayipi yensimbi akufanele iphenduke ibe bomvu (umbala ohlanganiswe ngethusi) ngemva kokucwiliswa kwisisombululo se-copper sulfate izikhathi ezingu-5 ezilandelanayo.

2. Ikhwalithi yobuso: Ingaphezulu lepayipi lensimbi eliyisithako lizoba nongqimba oluphelele lukathayela, futhi akumele kube namachashaza namabhamuza amnyama angamboziwe. Ivunyelwe ukuthi ibe nendawo ebukekayo futhi ibe namaqhuqhuva e-zinc wendawo.

| Uyini umehluko phakathi kwediphu elishisayo elinothayela kanye ne-pre galvanized ? | |||||||

| Ipayipi Elishisayo Le-Dip Lensimbi | Ipayipi Lensimbi Yangaphambili | ||||||

| Ukuqina Kwepayipi Lensimbi | 1.0mm nangaphezulu | 0.8mm ukuze 2.2mm | |||||

| I-Zinc Coating | isilinganiso esingu-200g/m2 kuya ku-500g/m2 (30um kuya ku-70um) | isilinganiso esingu-30g/m2 kuya ku-100g/m2 (ama-microns angu-5 kuya kwangu-15) | |||||

| Inzuzo | ngisho nokunamathela, ukunamathela okuqinile, ukubekwa uphawu okuhle, nokuphila isikhathi eside | ubuso obubushelelezi, umbala ogqamile, noqweqwe oluncane | |||||

| Ukusetshenziswa | esetshenziswa kabanzi ekuthuthweni kwe-Low-pressure fluid yamanzi, indle, igesi, umoya, ukushisa umusi, ukwakhiwa kukamasipala, i-petrochemical, i-shipbuilding kanye nezinye izinkambu. | ubunjiniyela besakhiwo, ukukhiqizwa kwefenisha neminye imikhakha. | |||||

* UKUPANDA

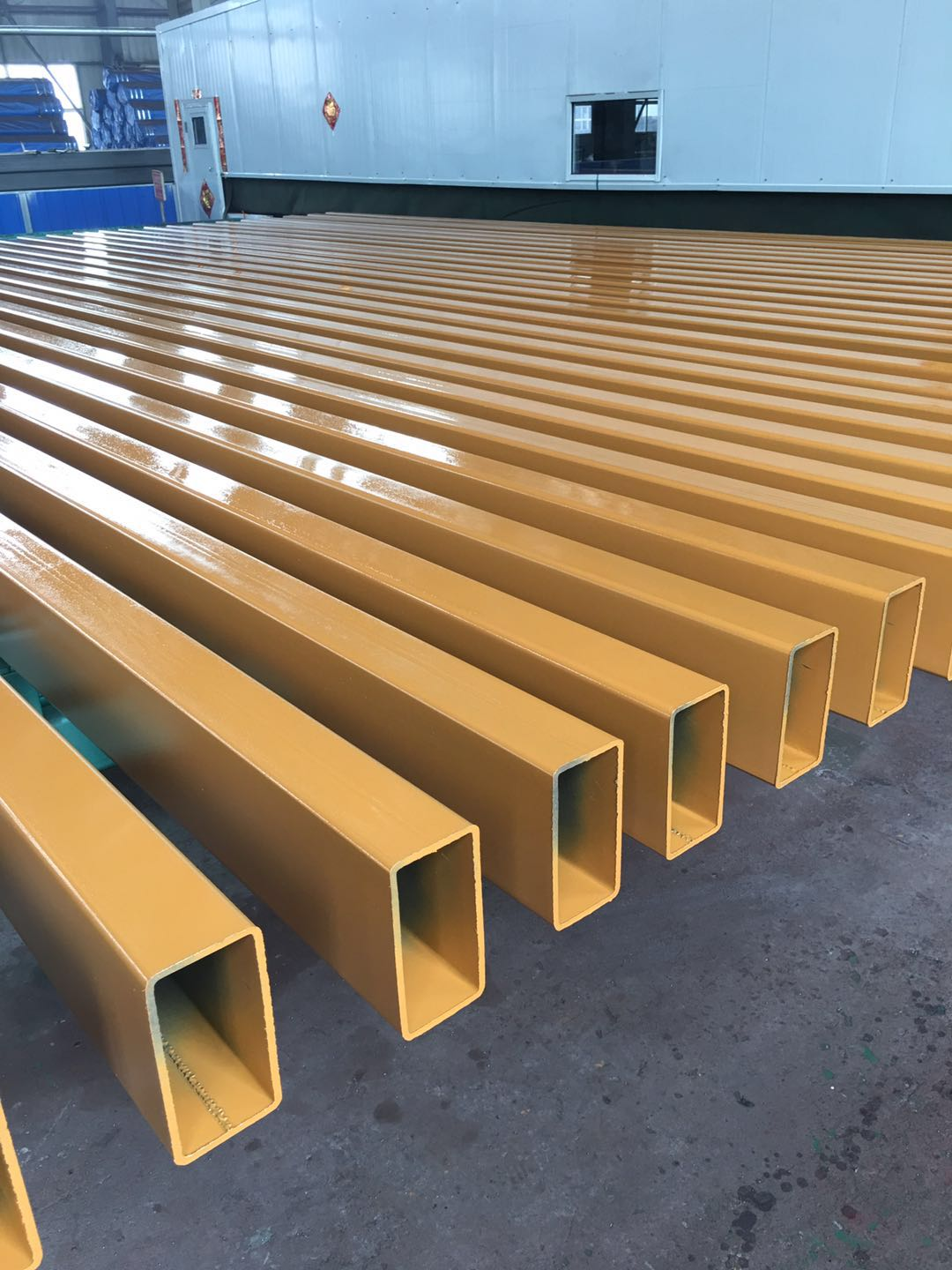

Ipayipi lensimbi elipendiwe wukufafaza izigqoko ezinemibala ehlukene ebusweni bepayipi lensimbi ukuze kuthuthukiswe ukumelana nokugqwala kanye nobuhle bepayipi. Amapayipi ensimbi apendiwe ahlanganisa amapayipi ensimbi afakwe isifutho namapayipi ensimbi apendiwe.

Ipayipi lensimbi elakhiwe ngesifutho liqale ligezwe nge-asidi, lifakwe uthayela kanye ne-phosphated, bese lifuthwa nge-electrostatic. Izinzuzo zale ndlela ukunamathela okuqinile kokugqoka, akulula ukukhipha, ukusebenza kahle kokuzivikela, imibala ekhanyayo nenhle; okubi ukuthi izindleko ziphakeme uma kuqhathaniswa, futhi imishini ekhethekile yokufutha kanye nabasebenzi abanekhono eliphezulu bayadingeka ukuze basebenze.

Ipayipi lensimbi elipendiwe lifafazwa ngokuqondile ngezingubo ezinemibala ehlukene ebusweni bepayipi lensimbi ngaphandle kokugeza nge-asidi, uthayela noma i-phosphating, ukuze kuthuthukiswe ukumelana nokugqwala kanye nobuhle bepayipi. Izinzuzo zale ndlela yizindleko eziphansi kanye nokucubungula okulula nokulula; ukungalungi ukunamathela okubuthakathaka, kunzima ukufeza umphumela wokumelana nokugqwala wesikhathi eside, nombala oyisidina.

Uma usebenzisa amapayipi ensimbi apendiwe, kuyadingeka ukukhetha uhlobo lopende olufanele, umbala nobukhulu ngokuya ngemibandela ethile yokusetshenziswa nezidingo. Ngesikhathi esifanayo, kufanele kuqinisekiswe ukuthi indawo yepayipi yensimbi yomile, ihlanzekile futhi ibushelelezi ukuze kuqinisekiswe umphumela wokunamathela kokunamathela kanye nempilo yesevisi.

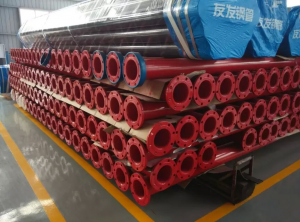

Ipayipi lensimbi elifakwe ngesifutho

Ipayipi lensimbi elipendiwe

* 3PE FBE

I-3PE (3-Layer Polyethylene) kanye ne-FBE (Fusion Bonded Epoxy) izinhlobo ezimbili zokumboza ezisetshenziswa emapayipini nasemapayipini embonini kawoyela negesi ukuze zehlise noma kuvinjwe ukugqwala.

I-3PE iyi-coat enezendlalelo ezintathu ehlanganisa i-epoxy primer, i-copolymer adhesive, kanye ne-polyethylene topcoat. I-epoxy primer inikeza indawo enhle yokubopha i-copolymer adhesive, yona futhi inikeza indawo ehlangene ye-polyethylene topcoat. Izendlalelo ezintathu zisebenza ndawonye ukuze zivikele ipayipi ekugqwaleni, ekuhuzukeni, nasekulimaleni komthelela.

I-FBE, ngakolunye uhlangothi, iyisistimu yokuhlanganisa enezendlalelo ezimbili ehlanganisa isisekelo se-epoxy resin egcwele ingxenye kanye nejazi eliphezulu eliyi-polyamide. I-epoxy egcwele izinhlayiya inikeza ukunamathela okuhle kakhulu ezindaweni zensimbi, kuyilapho i-topcoat inikeza ukumelana kwamakhemikhali okuhle kakhulu nokumelana nokuhuzuka. Izembatho ze-FBE zisetshenziswa emisebenzini ehlukahlukene, kusukela kumapayipi kawoyela negesi kuya emanzini kanye nezinhlelo zamanzi angcolile.

Kokubili okunamathelayo kwe-3PE ne-FBE kusebenza ngempumelelo ekuvikeleni amapayipi namapayipi ekugqwaleni, kuye ngezidingo ezithile zohlelo lokusebenza. Ukukhetha phakathi kwalokhu kokubili kuvame ukuqhutshwa izici ezifana nohlobo lwepayipi, izimo zokusebenza, kanye nezindleko.

| 3PE VS FBE | |||||||

| Amandla Anamathela | Ukunamathela kwe-3PE kunikeza amandla aphezulu okunamathela kune-FBE, njengoba ingcina ye-copolymer ku-3PE isiza ekuxhumaneni okungcono phakathi kwe-epoxy primer ne-polyethylene topcoat izendlalelo. | ||||||

| Umthelela kanye Nokuhushulwa | I-polyethylene topcoat ekunambeni kwe-3PE inikeza ukumelana okungcono nomthelela nokuhuzuka uma kuqhathaniswa ne-FBE. | ||||||

| Ukusetshenziswa | Izingubo ze-FBE zikhethwa kumapayipi lapho izinga lokushisa lokusebenza liphezulu njengoba likwazi ukumelana nezinga lokushisa eliphakeme kangcono kunezimbobo ze-3PE. Ngakolunye uhlangothi, izimbotshana ze-3PE zikhethwa ezinhlelweni lapho ipayipi livezwa khona emhlabathini nasemanzini, njengoba linikeza isivikelo esingcono ekugqwaleni nokugqwala. | ||||||

*Ukugcoba

Ukufaka amafutha endaweni yangaphandle yepayipi yensimbi kuyindlela yokuhlinzeka ngokuvikelwa kokugqwala nokuvikela ipayipi lensimbi. Ukugcoba amafutha kunganciphisa ukuthintana phakathi kwepayipi lensimbi nendawo yangaphandle, futhi kuvimbele ipayipi lensimbi ukuthi lingaphazanyiswa yi-oxidation, ukugqwala, ukuguga, njll.

*Isitembu noma isitembu

Isitembu

I-stencil

*Ukushaya

Sebenzisa umshini wokubhoboza oyimishini ukufaka ingcindezi ku-punch usebenzisa i-punching die. Gcina ingcindezi engaguquki kuze kube yilapho isibhakela singena odongeni lwepayipi lensimbi, lenze imbobo ehlanzekile nenembayo.

Inqubo yokumba amapayipi ensimbi inezinhlobonhlobo zezicelo, okuhlanganisa kodwa kungagcini kulokhu okulandelayo:

1. Ukuxhunywa kwamapayipi ensimbi: Ukubhoboza kungenye yezindlela ezivame ukusetshenziswa zokuxhuma amapayipi ensimbi. Ngenqubo yokumba ipayipi yensimbi, izimbobo zingavulwa epayipini lensimbi, ukuze ama-bolts namantongomane afakwe kumalunga nama-flanges, ukuze kuzuzwe inhloso yokuxhuma.

2. Ukulungiswa kwamapayipi ensimbi: Kubuye kube isicelo esivamile ukulungisa amapayipi ensimbi ezindongeni noma kwezinye izindawo ngokusebenzisa inqubo yokumba ipayipi yensimbi.

Ukusetshenziswa kwesakhiwo sensimbi solar panel bracke

Ukusetshenziswa komgwaqo onguthelawayeka

*Uchungechunge

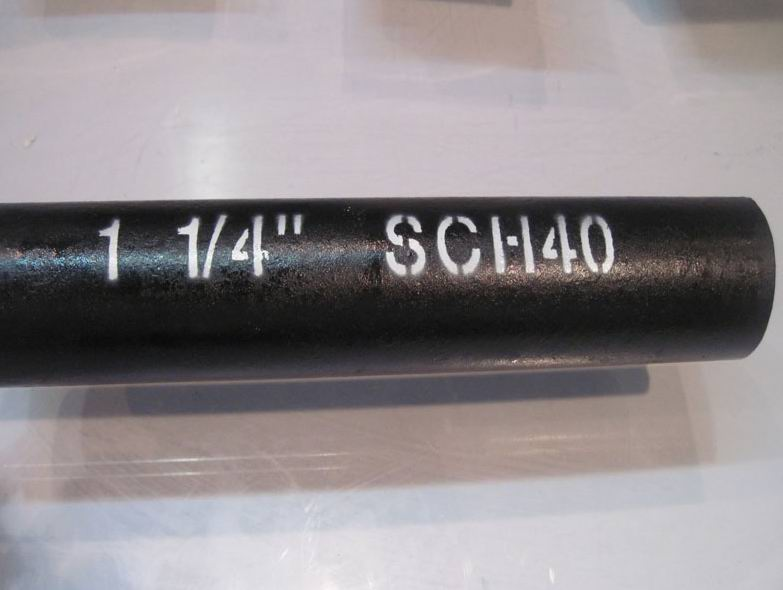

I-NPT (National Pipe Thread) kanye ne-BSPT (British Standard Pipe Thread) kungamazinga amabili ajwayeleke ukuba yipayipi.

Imicu ye-NPT ivame ukusetshenziswa eNyakatho Melika futhi imicu ye-BSPT isetshenziswa kakhulu eYurophu nase-Asia.

Womabili la mazinga anemicu ecijile eyenza uphawu oluqinile uma luqiniswa ndawonye. Isetshenziswa kakhulu ekuxhumeni amanzi, igesi, uwoyela namanye amapayipi.

2. Ukulungiswa kwamapayipi ensimbi: Kubuye kube isicelo esivamile ukulungisa amapayipi ensimbi ezindongeni noma kwezinye izindawo ngokusebenzisa inqubo yokumba ipayipi yensimbi.

*Isikiwe

Ukuxhumeka kwe-Roll Groove kuyindlela ethandwayo yokuxhuma amapayipi okuvikela umlilo ngoba inikeza izinzuzo eziningi. Nazi ezinye zezinzuzo eziyinhloko:

1. Ukufakwa okulula nokushesha: Ukuxhumeka kwe-Roll Groove kuvumela ukufakwa okusheshayo nokulula kwamapayipi nokufakwa, njengoba asikho isidingo sokushisela noma ukuthunga.

2. Ukuvikelwa kwezomnotho kanye nemvelo: Le ndlela yokuxhuma ibiza kakhulu kunezinye izindlela, okwenza kube ukukhetha okudumile ezinhlelweni eziningi. Ibuye ivikele imvelo njengoba inciphisa ukungcola futhi isebenzisa izinsiza ezimbalwa.

3. Ilondoloza izici zokuqala zamapayipi: Ukuxhumeka kwe-Roll Groove akuthinti izakhiwo zangempela zamapayipi, njengamandla awo, ukuqina, nokumelana nokugqwala.

4. Ukugcinwa kulula: Uma ukugcinwa nokulungiswa kuyadingeka, uxhumano lwe-Roll Groove lwenza kube lula ukuqaqa nokushintsha izingxenye, ngaphandle kokudinga amathuluzi akhethekile noma imishini.

| DN | Ngaphandle Ububanzi | Ububanzi Bendawo Yokuvala ±0.76 | Ububanzi be-Groove ±0.76 | I-Groove Bottom Diameter | |

| mm | Ukubekezelelana | ||||

| 50 | 60.3 | 15.88 | 8.74 | 57.15 | -0.38 |

| 65 | 73 | 15.88 | 8.74 | 69.09 | -0.46 |

| 65 | 76.1 | 15.88 | 8.74 | 72.26 | -0.46 |

| 80 | 88.9 | 15.88 | 8.74 | 84.94 | -0.46 |

| 100 | 114.3 | 15.88 | 8.74 | 110.08 | -0.51 |

| 125 | 141.3 | 15.88 | 8.74 | 137.63 | -0.56 |

| 150 | 165.1 | 15.88 | 8.74 | 160.78 | -0.56 |

| 150 | 168.3 | 15.88 | 8.74 | 163.96 | -0.56 |

| 200 | 219.1 | 19.05 | 11.91 | 214.4 | -0.64 |

*Beveled

Ububanzi obukhulu kune-NPS 11⁄2 [DN 40] esiphelweni esingenalutho esibhantshiwe ngeziphetho ezihlotshiswe ku-engeli engu-30°, +5°, -0°

*Iziphetho Ezilula

Ukusika iziphetho zombili zepayipi lensimbi zibe izindiza eziku-90◦ ukuya eksisi kuyisidingo esivamile ezimbonini eziningi lapho kusetshenziswa khona amapayipi. Lokhu kuvame ukwenziwa ukuze kulungiswe ipayipi lokushisela noma ezinye izinhlobo zokuxhuma, futhi kuqinisekiswe ukuthi iziphetho ziyisicaba futhi zihambisana ne-axis yepayipi.

*Igcwele

Ipayipi yensimbi ene-flanged wuhlobo lwepayipi eline-flange exhunywe ekugcineni noma kokubili. Ama-flange angamadiski ayindilinga anezimbobo namabhawodi asetshenziselwa ukuxhuma amapayipi, ama-valve, noma ezinye izinto zokusebenza. Ipayipi yensimbi ene-flang ngokuvamile yenziwa ngokufaka i-flange ekupheleni kwepayipi yensimbi.

Amapayipi ensimbi ane-Flanged avame ukusetshenziswa ezimbonini ezifana nokuhlinzekwa kwamanzi, uwoyela negesi, kanye nokucutshungulwa kwamakhemikhali. Zikhethwa ngaphezu kwezinye izinhlobo zamapayipi ngoba angafakwa kalula futhi ahlala isikhathi eside kakhulu. Amapayipi ane-flanged angakwazi ukumelana nokucindezela okuphezulu futhi angahlakazwa kalula ukuze agcinwe noma alungiswe.

Ama-flange epayipi lensimbi eline-flanged eza ngomumo nobukhulu obuhlukene ukuze ahambisane nezidingo zokuxhuma. Izinhlobo ezijwayelekile zifaka ama-slip-on flanges, ama-weld neck flanges, ama-flange anemicu, nama-socket weld flange.

Kafushane, amapayipi ensimbi ane-flanged ayisinqumo esithandwayo ezimbonini eziningi ngoba ahlinzeka ngoxhumano oluthembekile noluqinile phakathi kwamapayipi nemishini.

*Ukusika Ubude

Ubuchwepheshe bokusika amanzi baziwa ngokunemba nokunemba, kanye nekhono labo lokukhiqiza imiphetho ebushelelezi, engena-burr.

Enye yezinzuzo ezinkulu zobuchwepheshe bokusika amanzi ukuthi kuyindlela yokusika ebandayo, okusho ukuthi ayikho indawo ethintekile ukushisa (i-HAZ) ezungeze ukusika.

Ukusika i-jet yamanzi nakho kuyahambisana nemvelo, njengoba kungakhiqizi noma iyiphi imfucuza eyingozi noma igesi. Uhlelo lusebenzisa amanzi kuphela kanye ne-abrasive, futhi imikhiqizo engcolile ingaqoqwa kalula futhi ilahlwe ngokuphepha.

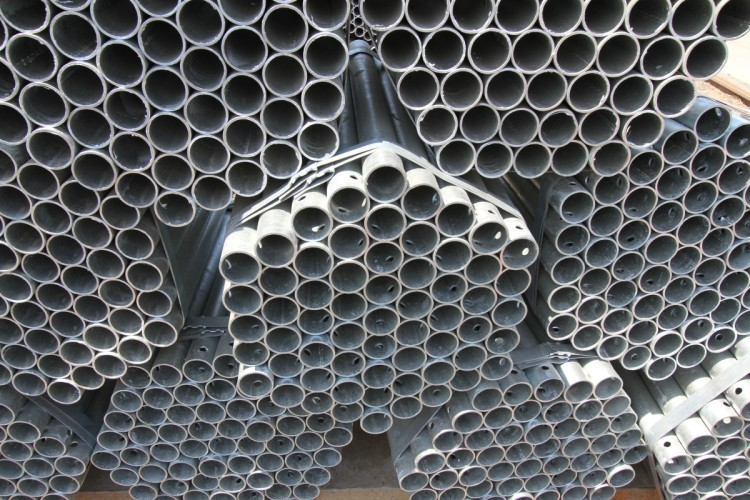

*Ukupakisha nokudiliva

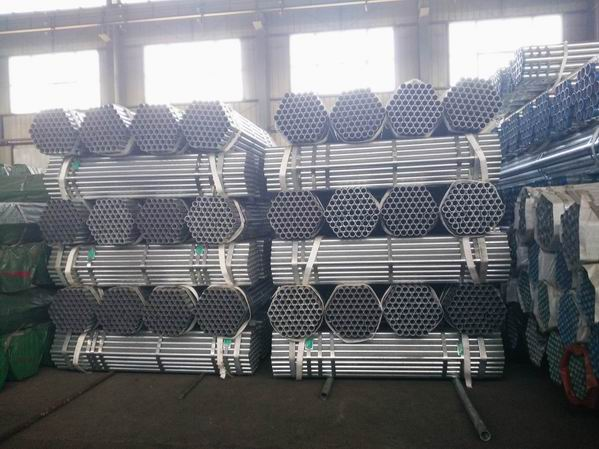

I-PVC Plastic Packaging

Ukuze kuvikelwe amapayipi ensimbi ngesikhathi sokuthutha nokugcinwa, avame ukupakishwa ngepulasitiki ye-PVC ukuze anikeze isendlalelo esivikelayo esivimbela imihuzuko, ama-dent, nezinye izinhlobo zomonakalo.

Ngaphezu kokuvikela amapayipi ensimbi, ukupakishwa kwePVC kwepulasitiki kuyasiza ukuwagcina ehlanzekile futhi omile. Lokhu kubaluleke kakhulu kumapayipi azosetshenziswa ezicelweni lapho ukuhlanzeka kubaluleke khona, njengasezinhlelweni zokuhlinzeka ngamanzi noma ezimbonini ezilungisa ukudla.

* Wonke ama-pvc ahlanganisiwe;

*Ipayipi kuphela eligcina i-pvc lipakishiwe;

*I-pvc yomzimba wepayipi kuphela epakishiwe.

Ukupakisha Ngokhuni

Ukuze kuvikelwe izinsimbi zensimbi ngesikhathi sokuthutha nokuphatha, amakhasimende angakhetha amabhokisi okhuni angokwezifiso, futhi angenziwa ngokwezifiso namalebula ekhasimende ukuze abonakale kalula.

Inzuzo yokusebenzisa amabhokisi okhuni ngokwezifiso anezisekelo zokugcina ukuthi ahlinzeka ngokuvikeleka okwengeziwe futhi anciphise ingozi yokulimala emikhiqizweni yensimbi. Futhi zenza kube lula ukuphatha nokuhamba, njengoba amabhokisi angapakishwa futhi agcinwe kuma-pallets ukuze athuthwe emhlabeni, ulwandle, noma emoyeni.

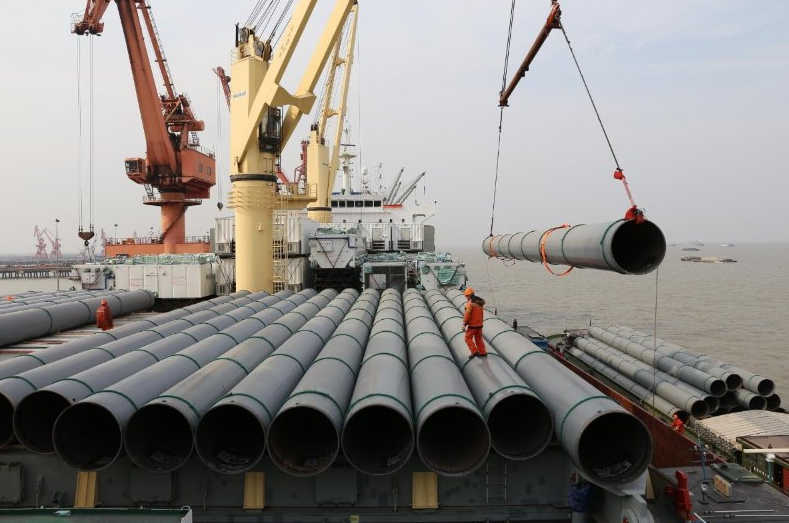

Ukuthumela ngomkhumbi

Imikhiqizo eminingi yensimbi ivamise ukuthuthwa ngolwandle, umhlaba, noma ngezokuthutha zasemoyeni, kanti iningi lempahla ethunyelwayo isuka emachwebeni aseTianjin.

Ezokuthutha olwandle, kunezindlela ezimbili eziyinhloko: ukuthunyelwa kweziqukathi noma ukuthumela ngobuningi.

Izinto zokuthutha ezihamba phansi ngokuvamile zihamba ngesitimela noma ngeloli, kuya ngendawo okuyiwa kuyo kanye nenkampani yezokuthutha esetshenziswayo.

*Ukusekela

Amasevisi okuthengisa ngaphambilini:

1. Isampula yamahhala: Ubude besampula yepayipi lensimbi yamahhala engu-20cm nezindleko zokulethwa ezikhokhelwa ikhasimende.

2. Izincomo zomkhiqizo: sisebenzisa ulwazi lwethu lochwepheshe lwemikhiqizo ukuyincoma kumakhasimende.

Amasevisi okuthengisa amaphakathi:

1. Ukulandelela ama-oda: sizokwazisa amakhasimende ngesimo sokukhiqiza nokuthumela sama-oda awo nge-imeyili noma ngocingo, siqinisekisa ukuthi anokuqonda okucacile ngenqubekelaphambili yama-oda awo.

2. Ukunikeza izithombe zokuhlola nokuthumela: sizohlinzeka ngezithombe zomkhiqizo ngaphambi kokuthunyelwa ukuze amakhasimende aqinisekise uma ehlangabezana nezimfuneko. Ngesikhathi esifanayo, sizophinda senze ukuhlola okuqinile kanye nokulawula ikhwalithi ngaphambi kokuthunyelwa ngomkhumbi ukuze siqinisekise ukuthi ziyahlangabezana nezindinganiso zethu zekhwalithi ephezulu.

Amasevisi angemuva kokuthengisa:

1. Ukulandelela impendulo yekhasimende ngemva kokuthola izimpahla: siyayazisa impendulo yamakhasimende futhi sizolandelela ukuze siqonde ukusebenzisa kwawo kanye nempendulo yemikhiqizo yethu, ukuze siqhubeke sithuthukisa ikhwalithi namasevisi awo.

2. Izitayela zamanani nolwazi lwemboni: siyaqonda ukuthi amakhasimende angase abhekane nezinguquko zemakethe kanye nezimo zemboni, ngakho-ke sizohlinzeka njalo ngolwazi mayelana nezimakethe nezimboni ukuze sisize amakhasimende aqonde izinguquko zemakethe nemboni ngesikhathi esifanele, okubenza bakwazi ukwenza ukwaziswa okwengeziwe. nezinqumo ezivunayo.