Grooved pipe fittingsomfetsje twa wichtige produktkategoryen:

Fittings dy't tsjinje as ferbinende sealen omfetsje stive koppelingen, fleksibele koppelingen, meganyske tees en groeven flanges.

Fittings dy't tsjinje as oergongsferbiningen omfetsje elbows, tees, krusingen, redukteurs, bline flanges, en oaren.

De groeven fittings dy't tsjinje as ferbinende sealen besteane benammen út trije komponinten: in dichte rubberen pakking, in koppelingshúsfesting en in slotbout. De rubberen pakking, leit binnen, wurdt pleatst oan 'e bûtenkant fan' e piip te ferbinen en aligns mei de pre-grooved piip. De coupling húsfesting wurdt dan befeilige om it bûtenste part fan de rubberen pakking, en úteinlik fêstmakke mei twa bouten. Troch it unike ûntwerp fan 'e rubberen pakking en koppeling hawwe groeven fittings poerbêste dichtingseigenskippen. As de floeistofdruk binnen de piip tanimt, wurdt de dichtingsmooglikheid fan 'e grooved ferbining navenant ferbettere.

Grooved pipe ferbining, as in avansearre pipeline ferbining metoade, kin brûkt wurde yn sawol bleatsteld as ferburgen tapassingen, en omfettet sawol stive en fleksibele gewrichten. Dêrom hat it in breed oanbod fan tapassingen:

Neffens systeemklassifikaasje: It kin brûkt wurde yn brânwettersystemen, klimaatsystemen foar hyt en kâld wetter, wetterfoarsjenningssystemen, petrochemyske pipelinesystemen, termyske krêft en militêre pipelinesystemen, pipelinesystemen foar rioelwettersuvering, ensfh.

Neffens pipe materiaal klassifikaasje: It kin brûkt wurde om te ferbinen stielen pipen, koperen pipen, RVS pipen, plestik-lined stielen buizen, ductile izeren buizen, dikke muorre plestik buizen, likegoed as slangen en fentyl fittings mei stielen piip gewrichten en flange gewrichten.

Standert: ANSI B36.10, JIS B2302, ASME/ANSI/BS1560/DIN2616 ensfh.

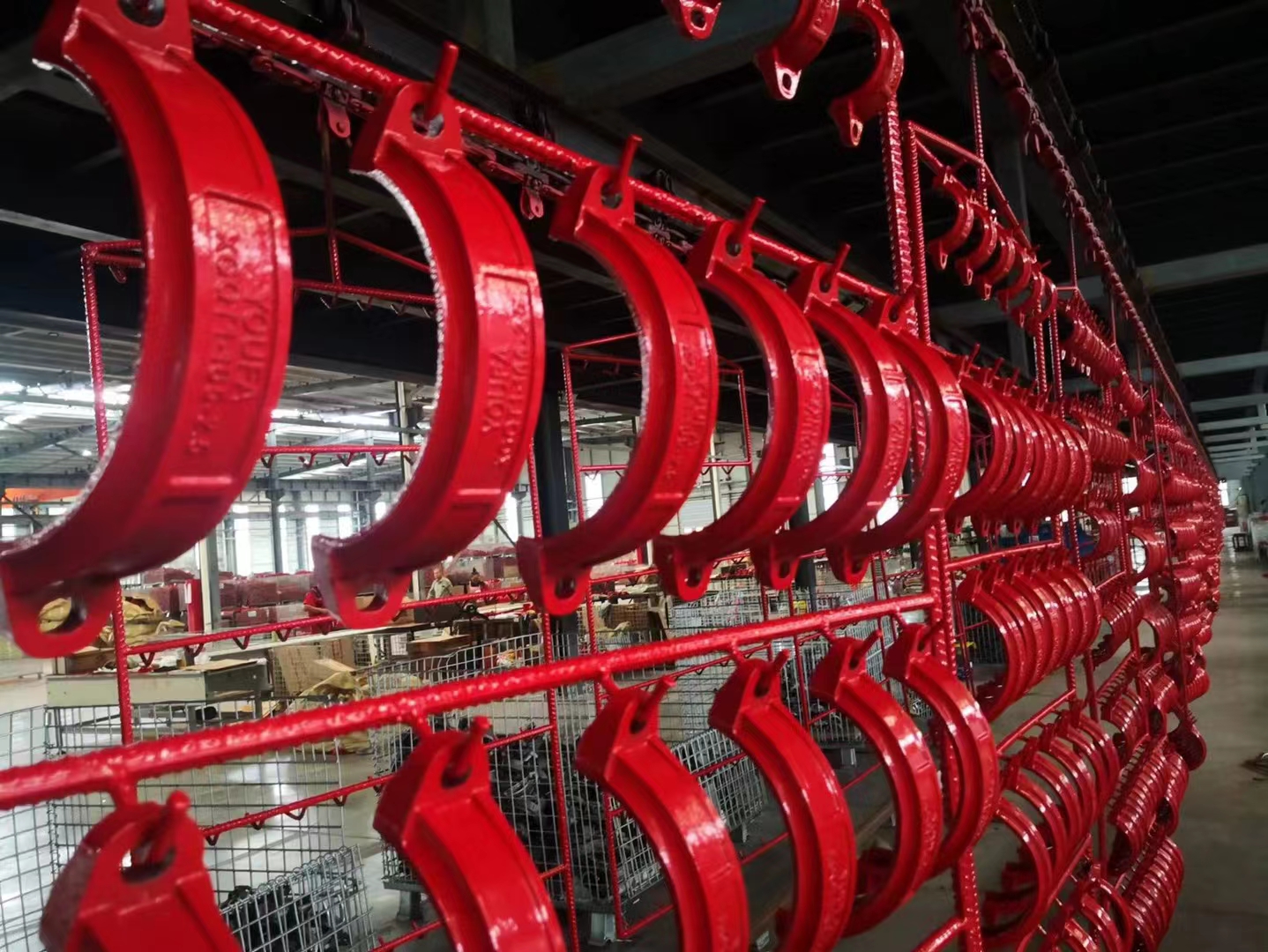

Materiaal: Gietijzer

Oerflak: Red Painted of Blue Painted of Silver Painted

MEGANICAL CRUS (GROOVED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 100x50 (4x2) | 114,3x60,3 |

| 100x65 (4x2-1/2) | 114,3x73 |

| 100x65 (4x2-1/2) | 114,3x76. 1 |

| 100x80 (4x3) | 114,3x88,9 |

| 125x65 (5x2-1/2) | 139.7x76. 1 |

| 125x80 (5x3) | 139,7x88,9 |

| 150x65 (6x2-1/2) | 165.1x 76. 1 |

| 150x80 (6x3) | 165.1x88.9 |

| 150x100 (6x4) | 165.1x114.3 |

| 200x65 (8x2-1/2) | 219.1x76.1 |

| 200x80 (8x3) | 219,1x88,9 |

| 200x100 (8x4) | 219.1x114.3 |

MEGANICAL CROSS (THREADED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 50x25 (2x1) | 60,3xRcl |

| 65x25 (2-1/2x1) | 76. lxRcl |

| 65x40 (2-1/2x1-1/2) | 76. lxRcl-1/2 |

| 80x25 (3x1) | 88,9xrcl |

| 80x50 (3x2) | 88,9xRc2 |

| 100x25 (4x1) | 108xrkl |

| 100x65 (4x2-1/2) | 114.3xRc2-1/2 |

| 125x25 (5x1) | 133xrkl |

| 125x80 (5x3) | 133xrc3 |

| 125x25 (5x1) | 139.7xRcl |

| 150x25 (6x1) | 159xRcl |

| 150x80 (6x3) | 165. 1xRc3 |

| 200x25 (8x1) | 219. lxRcl |

| 200x80 (8x3) | 219. 1xRc3 |

MECHANISCHE TEE (GROEF)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 100x50 (4x2) | 114,3x60,3 |

| 100x80 (4x3) | 114,3x88,9 |

| 125x65 (5x2-1/2) | 139,7x76,1 |

| 125x80 (5x3) | 139,7x88,9 |

| 150x65 (6x2-1/2) | 165.1x76.1 |

| 150x100 (6x4) | 165.1x114.3 |

| 200x65 (8x2-1/2) | 219.1x76.1 |

| 200x100 (8x4) | 219.1x114.3 |

MEGANISCHE TEE (DREADED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 50x25 (2x1) | 60,3xRcl |

| 65x25 (2-1/2x1) | 76. lxRcl |

| 65x40 (2-1/2x1-1/2) | 76. lxRcl-1/2 |

| 80x25 (3x1) | 88,9xrcl |

| 80x50 (3x2) | 88,9xRc2 |

| 100x25 (4x1) | 108xrkl |

| 100x65 (4x2-1/2) | 108xRc2-1/2 |

| 100x25 (4x1) | 114.3xRcl |

| 100x65 (4x2-1/2) | 114.3xRc2-1/2 |

| 125x25 (5x1) | 133xrkl |

| 125x80 (5x3) | 133xrc3 |

| 125x25 (5x1) | 139.7xRcl |

REDUCERING TEE (GROOVED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 65x50 (2/1/2x2) | 76,1x60,3 |

| 80x65 (3x2-1/2) | 88.9x76.1 |

| 100x50 (4x2-1/2) | 108x76.1 |

| 100x50 (4x2) | 114,3x60,3 |

| 100x80 (4x3) | 114,3x88,9 |

| 125x100 (5x4) | 133x108 |

| 125x65 (5x2-1/2) | 139,7x76,1 |

| 125x100 (5x4) | 139,7x114,3 |

| 150x100 (6x4) | 159x108 |

| 150x125 (6x5) | 159x133 |

| 150x65 (6x2-1/2) | 165.1x 76. 1 |

| 150x125 (6x5) | 165,1x139,7 |

| 200x50 (8x2) | 219.1x60.3 |

| 200x150 (8x6) | 219.1x165.1 |

TEE (GROEF)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 50(2) | 60,3 |

| 65 (2-1/2) | 76.1 |

| 80(3) | 88,9 |

| 100⑷ | 108 |

| 100⑷ | 114.3 |

| 125(5) | 133 |

| 125(5) | 139,7 |

| 150⑹ | 159 |

| 150(6) | 165.1 |

| 150⑹ | 168,3 |

| 200⑻ | 219.1 |

REDUCERING CRUS (GROOVED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 100x65 (4x2-1/2) | 114.3x76 |

| 100x80 (4x3) | 114,3x88,9 |

| 125x65 (5x2-1/2) | 139.7x76 |

| 125x100 (5x4) | 139,7x114,3 |

| 150x65 (6x2-1/2) | 165.1x76 |

| 150x125 (6x5) | 165.1x139. 7 |

| 200x100 (8x4) | 219.1x114.3 |

| 200x150 (8x6) | 219.1x165.1 |

KRUIS (GROEF)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 65 (2-1/2) | 76.1 |

| 80⑶ | 88,9 |

| 100⑷ | 114.3 |

| 125⑸ | 139,7 |

| 150(6) | 165 |

| 200⑻ | 219.1 |

45° Elbow

22,5° Elbow

90° Elbow

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 50⑵ | 60,3 |

| 65 (2-1/2) | 76.1 |

| 80⑶ | 88,9 |

| 100⑷ | 108 |

| 100⑷ | 114.3 |

| 125⑸ | 133 |

| 125(5) | 139,7 |

| 150⑹ | 159 |

| 150⑹ | 165 |

| 200⑻ | 219.1 |

REDUCER (THREADED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 50x20 (2x3/4) | 60.3xRc3/4 |

| 50x40 (2x1-1/2) | 60.3xRcl-1/2 |

| 65x25 (2-1/2x1) | 76. lxRcl |

| 65 x 50 (2-1/2 x 2) | 76. 1xRc2 |

| 80x25 (3x1) | 88,9xrcl |

| 80x65 (3x2-1/2) | 88.9xRc2-1/2 |

| 100x25 (4x1) | 108xrkl |

| 100x25 (4x1) | 114.3xRcl |

| 125x25 (5x1) | 133xrkl |

| 125x25 (5x1) | 139.7xRcl |

| 150x25 (6x1) | 159xRcl |

| 150x80 (6x3) | 159xrc3 |

| 150x25 (6x1) | 165. lxRcl |

| 150x80 (6x3) | 165. 1xRc3 |

| 200x25 (8xRcl) | 219. lxRcl |

| 200x80 (8x3) | 219. 1xRc3 |

REDUCER (GROOVED)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) |

| 65 x 50 (2-1/2 x 2) | 76,1x60,3 |

| 80x50 (3x2) | 88,9x60,3 |

| 80x65 (3x2-1/2) | 88.9x76.1 |

| 100x65 (4x2-1/2) | 108x76.1 |

| 100x80 (4x3) | 108x88,9 |

| 100x50 (4x2) | 114,3x60,3 |

| 100x80 (4x3) | 114,3x88,9 |

| 125x65 (5x2-1/2) | 133x76.1 |

| 125x100 (5x4) | 133x114,3 |

| 125x50 (5x2) | 139,7x60,3 |

| 125x100 (5x4) | 139,7x114,3 |

| 150x65 (6x2-1/2) | 159x76.1 |

| 150x125 (6x5) | 159x139,7 |

| 150x50 (6x2) | 165.1x60.3 |

| 150x125 (6x5) | 165,1x139,7 |

| 200x65 (8x2) | 219.1x60.3 |

| 200x150 (8x6) | 219.1x165.1 |

HEAVY DUTY FLANGE

(GROOT)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) | WERKDRUK (MPA) | DIMENSJES (MM) | NEE. FAN GATTEN | |||

| A | B | c | D | ||||

| 65 (2-1/2) | 76.1 | 2.5 | 63,5 | 17 | 185 | 145 | 8 |

| 65⑶ | 88,9 | 2.5 | 63,5 | 17 | 200 | 160 | 8 |

| 100⑷ | 108 | 2.5 | 67,5 | 16.5 | 235 | 190 | 8 |

| 100⑷ | 114.3 | 2.5 | 68 | 15 | 230 | 190 | 8 |

| 150⑹ | 159 | 2.5 | 68 | 17 | 300 | 250 | 8 |

| 150⑹ | 165.1 | 2.5 | 68 | 17 | 300 | 250 | 8 |

| 200⑻ | 219.1 | 2.5 | 77 | 20 | 360 | 310 | 12 |

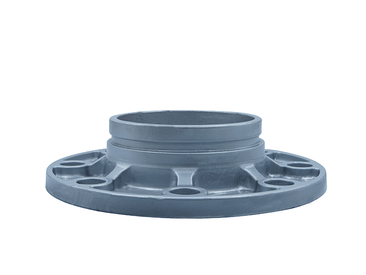

ADAPTER FLANGE

(GROOT)

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) | WERKDRUK (MPA) | DIMENSJES (MM) | NEE. FAN GATTEN | |||

| A | B | c | D | ||||

| 50⑵ | 60,3 | 1.6 | 50 | 15 | 160 | 125 | 4 |

| 65 (2-1/2) | 76.1 | 1.6 | 50 | 15 | 178 | 145 | 4 |

| 80⑶ | 88,9 | 1.6 | 50 | 15 | 194 | 160 | 8 |

| 100⑷ | 108 | 1.6 | 55 | 15 | 213 | 180 | 8 |

| 100⑷ | 114.3 | 1.6 | 55 | 15 | 213 | 180 | 8 |

| 125⑸ | 133 | 1.6 | 58 | 17 | 243 | 210 | 8 |

| 125⑸ | 139,7 | 1.6 | 58 | 17 | 243 | 210 | 8 |

| 150⑹ | 159 | 1.6 | 65 | 17 | 280 | 240 | 8 |

| 150⑹ | 165.1 | 1.6 | 65 | 17 | 280 | 240 | 8 |

| 200⑻ | 219.1 | 1.6 | 78 | 19 | 340 | 295 | 812 |

BLIND FLANGE

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) | WERKDRUK (MPA) | HOOGTE (MM) | |

| 50⑵ | 60,3 | 2.5 | 28 | |

| 65 (2-1/2) | 76.1 | 2.5 | 28 | |

| 80⑶ | 88,9 | 2.5 | 29 | |

| 100⑷ | 108 | 2.5 | 31 | |

| 100⑷ | 114.3 | 2.5 | 31 | |

| 125(5) | 133 | 2.5 | 31.5 | |

| 125⑸ | 139,7 | 2.5 | 31.5 | |

| 150⑹ | 159 | 2.5 | 31.5 | |

| 150⑹ | 165.1 | 2.5 | 31 | |

| 200⑻ | 219.1 | 2.5 | 36,5 | |

THREADED FLANGE

| NORMAAL SIZE (mm/in) | BUITENDIAMETER (mm) | WERKDRUK (MPA) | DIMENSJES (MM) | NEE. FAN GATTEN | |||

| A | B | c | D | ||||

| 25⑴ | Rcl | 1.6 | 18 | 10 | 85 | 110 | 4 |

| 32 (1-1/4) | Rcl-1/4 | 1.6 | 18 | 11 | 100 | 130 | 4 |

| 40 (1-1/2) | Rcl-1/2 | 1.6 | 19 | 13 | 110 | 145 | 4 |

| 50(2) | Rc2 | 1.6 | 20 | 13 | 125 | 155 | 4 |

| 65 (2-1/2) | Rc2-1/2 | 1.6 | 21 | 15 | 144 | 178 | 4 |

| 80⑶ | Rc3 | 1.6 | 25.5 | 15 | 160 | 193,5 | 8 |

| 100⑷ | Rc4 | 1.6 | 25.75 | 15 | 180 | 213,5 | 8 |

BOLTS & NUTS

| GRUTTE | THREADED LENGTE L1 | TOTAL LENGTE | FISHTAIL BOLT BREEDTE | NUT WIDHT |

| M10x55 | 30±3 | 55±1,2 | 14. 5±0. 5 | 9. 6~10 |

| M10 x 60 | 30±3 | 60±1,2 | 14,5 + 0,5 | 9. 6~10 |

| M10x65 | 30±3 | 65±1,2 | 14. 5±0. 5 | 9. 6~10 |

| M12x65 | 36+4 | 65±1,2 | 15,2±0,4 | 11. 6~12 |

| M12 x 70 | 36+4 | 70+1. 2 | 15,2±0,4 | 11. 6 ~12 |

| M12x75 | 41+4 | 75+1. 2 | 15,2±0,4 | 11. 6 ~12 |

| m16x85 | 44+4 | 85+1. 2 | 19. 0-19. 9 | 15. 3~16 |

| M20 x 120 | 50+5 | 120+2. 0 | 24±0,8 | 18. 9~20 |

De meganyske eigenskippen fan bouten moatte net leger wêze as klasse 8.8 spesifisearre yn GB / T 3098.1, en de tried tolerânsje sil wêze 6G. De meganyske eigenskippen fan 'e moer moatte foldwaan oan Grade 8 easken spesifisearre foar moeren yn GB / T 3098.2, thread tolerânsje 6h.

DICHTING RING

| NAMME | DICHTING | ALGEMENE SERVICE-oanbefelling | TEMPERATUURBERIK |

| EPDM | E | Wetterfoarsjenning, ôfwettering, rioelwetter en normale temperatuerlucht, swakke soer en swak alkali | -30°C~+130°C |

| NBR | D | Petroleum basearre oaljes | -20°C〜+80°C |

| SILICOMN RUBBER | S | Drinkwetter, waarme droege loft en wat hjitte gemikaliën | -40°C~+180°C |

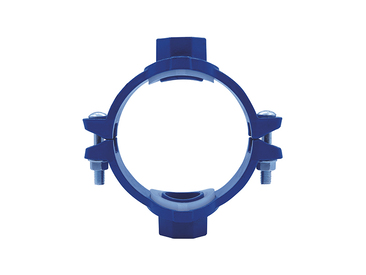

Blau ferve Grooved Pipe Fittings

Grutte chart lykas hjirboppe

Sliver Painted Grooved Pipe Fittings

Grutte chart lykas hjirboppe