API 5L bututu marasa sumul ana amfani da su a cikin gininbututun safarar mai da iskar gasa kan nesa mai nisa, kuma ana amfani da shi wajen gina ababen more rayuwa ga masana'antar makamashi, kamar matatun mai da tsire-tsire masu sinadarai.

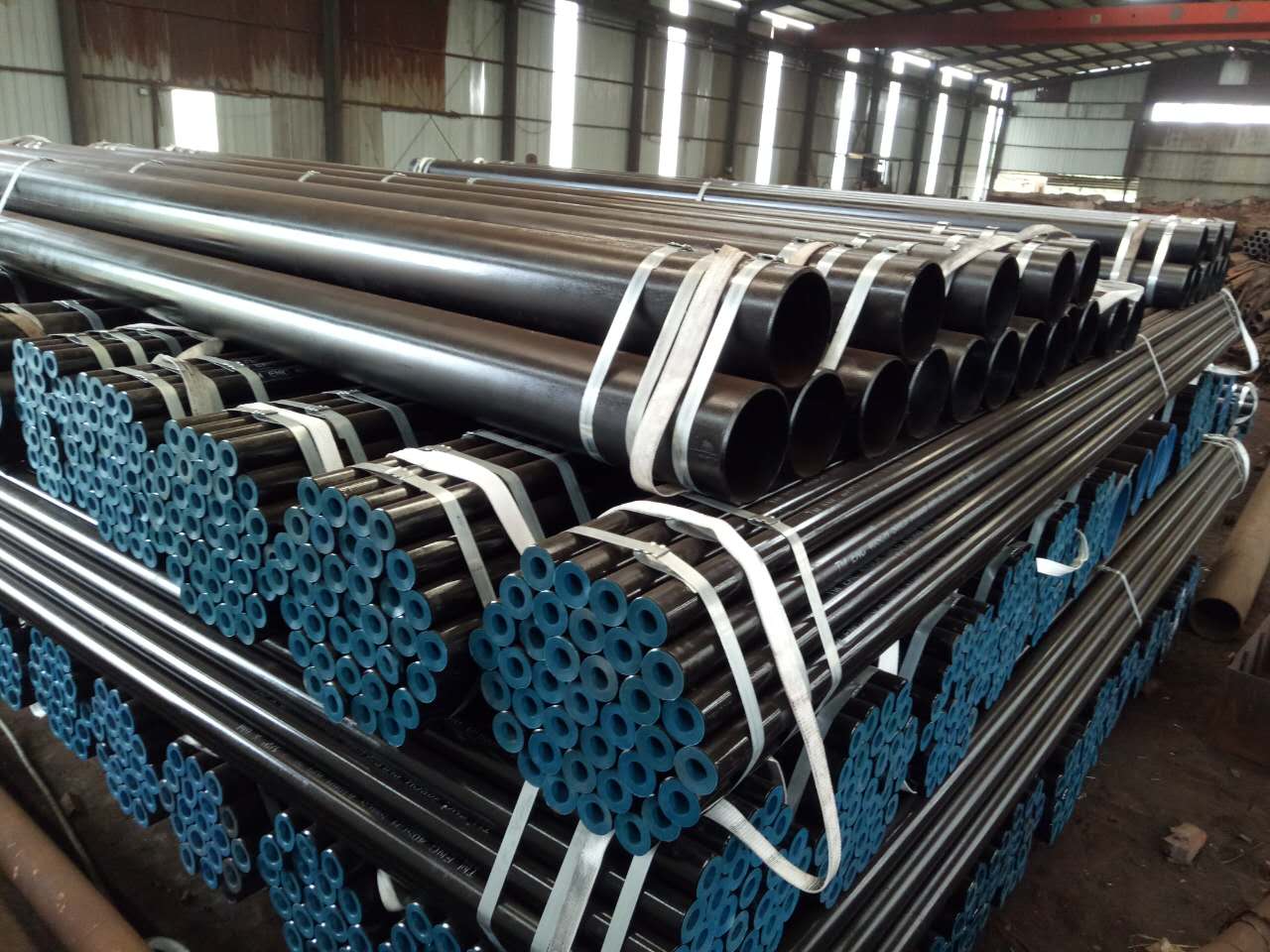

API 5L Taƙaitaccen Gabatarwar Bututun Karfe Mara Tsafta

| Samfura | API 5L Bututu Karfe mara Sumul | Ƙayyadaddun bayanai |

| Kayan abu | Karfe Karfe | OD: 13.7-610mm Kauri: sch40 sch80 sch160 Tsawon: 5.8-6.0m |

| Daraja | L245, API 5L B/ASTM A106 B | |

| Surface | Bare ko Baƙi | Amfani |

| Ƙarshe | Ƙarshen fili | Mai / Gas isar da bututu karfe |

| Ko Beveled ya ƙare |

Shiryawa da Bayarwa:

Cikakkun kayan tattarawa: a cikin daure masu kyau na teku mai hexagonal cike da ɗigon ƙarfe, Tare da majajjawa nailan biyu ga kowane daure.

Bayanin Bayarwa: Dangane da QTY, yawanci wata ɗaya.

API 5L Matsayin Karfe Karfe Ba Tare da Sumul ba

| Bututu Karfe Grade mara kyau | Haɗin Sinadari don bututu PSL 1 tare da WT ≤25mm (0.984 inc) | ||||

| C (max.)% | Mn (max.)% | P (max.)% | S (max.)% | V + Nb + Ti | |

| L245 ko B | 0.28 | 1.2 | 0.03 | 0.03 | Sai dai in akasin haka, jimillar abubuwan da ke cikin niobium da vanadium za su zama u 0,06 %. Jimlar adadin niobium, vanadium da titanium za su kasance u 0,15 %. |

| Bututu Karfe Grade mara kyau | Gwaje-gwajen Tensiledon PSL 1 tube jiki | |||

| Ƙarfin Haɓaka (minti.) MPa | Ƙarfin Ƙarfi (minti.) MPa | |||

| L245 ko B | 245 | 415 | ||

API 5L Jadawalin Girman Bututu Mara Sulun Karfe

| INCH | OD | API 5L ASTM A106 Strandard Kaurin bango | |||||||

| (MM) | Farashin SC10 | Farashin SC20 | Farashin SC40 | Farashin SCH60 | Farashin SCH80 | Farashin SCH100 | Farashin SC160 | XXS | |

| (mm) | (mm) | (mm) | (mm) | (mm) da | (mm) | (mm) da | (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Tsarin Kera bututun SMLS mara kyau

Zabin Danyen Abu:An zaɓi ƙarfe mai inganci mai inganci azaman albarkatun ƙasa don bututun ƙarfe maras kyau. Abubuwan da ke cikin carbon a cikin karfe shine maɓalli mai mahimmanci don ƙayyade kaddarorinsa da dacewa don aikace-aikace daban-daban.

Dumama da Hudawa:Za a yi zafi da ɗanyen kayan zuwa zafin jiki mai zafi sannan a huda shi ya zama harsashi mai zurfi. Wannan tsari yana da mahimmanci don ƙirƙirar sifar farko na bututu kuma yawanci ana samun su ta hanyoyi kamar hujin rotary, extrusion, ko wasu fasaha na musamman.

Juyawa da Girma:Harsashin da aka soke yana jujjuyawa da matakan girma don rage diamita da kaurin bango zuwa girman da ake buƙata. Ana samun wannan yawanci ta hanyar amfani da jerin injinan birgima da masu girma dabam don cimma siffar da ake so.

Maganin zafi:Bututun carbon karfe maras sumul yana ƙarƙashin tafiyar matakai na zafi na zafi kamar annealing, normalizing, ko quenching da tempering don haɓaka kaddarorin injinsa da cire duk wani damuwa. Har ila yau, maganin zafi yana taimakawa wajen cimma abubuwan da ake so microstructure da kaddarorin karfen carbon.

Gwaji da Dubawa:A cikin tsarin masana'antu, bututun carbon da ba shi da kyau yana fuskantar hanyoyi daban-daban na gwaji marasa lalacewa da lalata don tabbatar da ya cika ka'idodin ingancin da ake buƙata. Wannan na iya haɗawa da gwajin ultrasonic, gwajin hydrostatic, gwajin eddy na yanzu, da duban gani.

Kammalawa da Rufewa:Da zarar bututu maras nauyi ya cika ƙayyadaddun da ake buƙata, ana gudanar da ayyukan gamawa kamar daidaitawa, yanke, da ƙarewa. Bugu da ƙari, ana iya lulluɓe bututu da kayan kariya kamar varnish, fenti, ko galvanizing don haɓaka juriyar lalatarsa, musamman a yanayin ƙarfe na carbon.

Binciken Ƙarshe da Marufi:Ƙarshen bututun ƙarfe mara nauyi yana jurewa dubawa na ƙarshe don tabbatar da cewa ya dace da duk matakan inganci da buƙatun abokin ciniki. Sa'an nan kuma an shirya shi a hankali kuma a shirya don aikawa ga abokin ciniki.

API 5L Ƙarfe Karfe Mara Tabbaci da Gwaji

Gwajin Hydrostatic

bututu maras nauyi ba zai jure gwajin hydrostatic ba tare da yayyo ta hanyar walda ko jikin bututu ba.

Haƙuri don diamita, kauri na bango, tsayi da madaidaiciya

| Ƙayyadaddun diamita na waje | SMLS bututu tolerances | Haƙuri na waje-na-zagaye | ||

| Bututu banda karshen | Ƙarshen bututu | Bututu banda karshen | Ƙarshen bututu | |

| <60.3mm | - 0.8mm zuwa + 0.4mm | - 0.4mm zuwa + 1.6mm | ||

| ≥60.3mm zuwa ≤168.3mm | ± 0.0075 D | 0.020 D | 0.015 D | |

| 168.3mm zuwa ≤610mm | ± 0.0075 D | ± 0.005 D, amma matsakaicin ± 1.6mm | ||

| 610mm zuwa ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, amma matsakaicin da 15 mm, don D/T≤75 | 0.01 D, amma matsakaicin da 13mm, don D/T≤75 |

| bisa yarjejeniya don D/T>75 | bisa yarjejeniya don D/T>75 | |||

D: OD diamita na waje T: WT kauri