Grooved tiyo ekipmanMete de gwo kategori pwodwi:

Ekipman ki sèvi kòm sele konekte gen ladan akoupleman rijid, akoupleman fleksib, Tees mekanik, ak bride kouliso.

Ekipman ki sèvi kòm koneksyon tranzisyon gen ladan koud, Tees, kwaze, redukteur, èl avèg, ak lòt moun.

Ekipman yo ranvèse ki sèvi kòm sele konekte sitou konpoze de twa konpozan: yon gasket kawotchou poze sele, yon lojman kouti, ak yon boulon bloke. Se gasket la kawotchou, ki chita andedan, yo mete sou deyò a nan tiyo a yo dwe konekte ak aliyen ak tiyo a pre-glooved. Se lojman an kouti Lè sa a, sekirite alantou pati a deyò nan gasket la kawotchou, epi finalman tache ak de boulon. Akòz konsepsyon inik nan gasket an kawotchou ak kouti, ekipman ranvèse gen ekselan pwopriyete poze sele. Kòm presyon an likid nan tiyo a ogmante, se kapasite a poze sele nan koneksyon an kouliso correspondant ogmante.

Koneksyon tiyo kouliso, kòm yon metòd avanse koneksyon tiyo, yo ka itilize nan tou de aplikasyon pou ekspoze ak kache, e li gen ladan tou de rijid ak jwenti fleksib. Se poutèt sa, li gen yon pakèt domèn aplikasyon pou:

Dapre klasifikasyon sistèm lan: li kapab itilize nan sistèm dlo dife, èkondisyone sistèm dlo cho ak frèt, sistèm ekipman pou dlo, sistèm tiyo petrochimik, pouvwa tèmik ak sistèm tiyo militè yo, sistèm tiyo tretman dlo egou, elatriye.

Dapre klasifikasyon materyèl tiyo: li kapab itilize yo konekte tiyo asye, tiyo kwiv, tiyo asye pur, tiyo plastik-aliyen asye, tiyo fè ductile, tiyo epè-ranpa yo nan plastik, osi byen ke tiyo ak ekipman valv ak jwenti tiyo asye ak Jwenti bride.

Creole: ANSI B36.10, JIS B2302, ASME/ANSI/BS1560/DIN2616 ETC.

Materyèl: fè jete

Sifas: wouj pentire oswa ble ki pentire oswa ajan ki pentire

Lakwa mekanik (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 100x50 (4x2) | 114.3x60.3 |

| 100x65 (4x2-1/2) | 114.3x73 |

| 100x65 (4x2-1/2) | 114.3x76. 1 |

| 100x80 (4x3) | 114.3x88.9 |

| 125x65 (5x2-1/2) | 139.7x76. 1 |

| 125x80 (5x3) | 139.7x88.9 |

| 150x65 (6x2-1/2) | 165.1x 76. 1 |

| 150x80 (6x3) | 165.1x88.9 |

| 150x100 (6x4) | 165.1x114.3 |

| 200x65 (8x2-1/2) | 219.1x76.1 |

| 200x80 (8x3) | 219.1x88.9 |

| 200x100 (8x4) | 219.1x114.3 |

Lakwa mekanik (Threaded)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 50x25 (2x1) | 60.3xrcl |

| 65x25 (2-1/2x1) | 76. LXRCL |

| 65x40 (2-1/2x1-1/2) | 76. LXRCL-1/2 |

| 80x25 (3x1) | 88.9xrcl |

| 80x50 (3x2) | 88.9xrc2 |

| 100x25 (4x1) | 108xrcl |

| 100x65 (4x2-1/2) | 114.3xrc2-1/2 |

| 125x25 (5x1) | 133xrcl |

| 125x80 (5x3) | 133xrc3 |

| 125x25 (5x1) | 139.7xrcl |

| 150x25 (6x1) | 159XRCL |

| 150x80 (6x3) | 165. 1xrc3 |

| 200x25 (8x1) | 219. LXRCL |

| 200x80 (8x3) | 219. 1XRC3 |

Tee mekanik (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 100x50 (4x2) | 114,3x60.3 |

| 100x80 (4x3) | 114.3x88.9 |

| 125x65 (5x2-1/2) | 139.7x76.1 |

| 125x80 (5x3) | 139.7x88.9 |

| 150x65 (6x2-1/2) | 165.1x76.1 |

| 150x100 (6x4) | 165.1x114.3 |

| 200x65 (8x2-1/2) | 219.1x76.1 |

| 200x100 (8x4) | 219.1x114.3 |

Tee mekanik (Threaded)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 50x25 (2x1) | 60.3xrcl |

| 65x25 (2-1/2x1) | 76. LXRCL |

| 65x40 (2-1/2x1-1/2) | 76. LXRCL-1/2 |

| 80x25 (3x1) | 88.9xrcl |

| 80x50 (3x2) | 88.9xrc2 |

| 100x25 (4x1) | 108xrcl |

| 100x65 (4x2-1/2) | 108xrc2-1/2 |

| 100x25 (4x1) | 114.3xrcl |

| 100x65 (4x2-1/2) | 114.3xrc2-1/2 |

| 125x25 (5x1) | 133xrcl |

| 125x80 (5x3) | 133xrc3 |

| 125x25 (5x1) | 139.7xrcl |

Redui Tee (Grooved)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 65x50 (2/1/2x2) | 76.1x60.3 |

| 80x65 (3x2-1/2) | 88.9x76.1 |

| 100x50 (4x2-1/2) | 108x76.1 |

| 100x50 (4x2) | 114.3x60.3 |

| 100x80 (4x3) | 114.3x88.9 |

| 125x100 (5x4) | 133x108 |

| 125x65 (5x2-1/2) | 139.7x76.1 |

| 125x100 (5x4) | 139.7x114.3 |

| 150x100 (6x4) | 159x108 |

| 150x125 (6x5) | 159x133 |

| 150x65 (6x2-1/2) | 165.1x 76. 1 |

| 150x125 (6x5) | 165.1x139.7 |

| 200x50 (8x2) | 219.1x60.3 |

| 200x150 (8x6) | 219.1x165.1 |

Tee (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 50 (2) | 60.3 |

| 65 (2-1/2) | 76.1 |

| 80 (3) | 88.9 |

| 100⑷ | 108 |

| 100⑷ | 114.3 |

| 125 (5) | 133 |

| 125 (5) | 139.7 |

| 150⑹ | 159 |

| 150 (6) | 165.1 |

| 150⑹ | 168.3 |

| 200⑻ | 219.1 |

Diminye kwa (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 100x65 (4x2-1/2) | 114.3x76 |

| 100x80 (4x3) | 114.3x88.9 |

| 125x65 (5x2-1/2) | 139.7x76 |

| 125x100 (5x4) | 139.7x114.3 |

| 150x65 (6x2-1/2) | 165.1x76 |

| 150x125 (6x5) | 165.1x139. 7 |

| 200x100 (8x4) | 219.1x114.3 |

| 200x150 (8x6) | 219.1x165.1 |

Travèse (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 65 (2-1/2) | 76.1 |

| 80⑶ | 88.9 |

| 100⑷ | 114.3 |

| 125⑸ | 139.7 |

| 150 (6) | 165 |

| 200⑻ | 219.1 |

45 ° koud

22.5 ° koud

90 °

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 50⑵ | 60.3 |

| 65 (2-1/2) | 76.1 |

| 80⑶ | 88.9 |

| 100⑷ | 108 |

| 100⑷ | 114.3 |

| 125⑸ | 133 |

| 125 (5) | 139.7 |

| 150⑹ | 159 |

| 150⑹ | 165 |

| 200⑻ | 219.1 |

Redukteur (Threaded)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 50x20 (2x3/4) | 60.3xrc3/4 |

| 50x40 (2x1-1/2) | 60.3xrcl-1/2 |

| 65x25 (2-1/2x1) | 76. LXRCL |

| 65 x 50 (2-1/2 x 2) | 76. 1xrc2 |

| 80x25 (3x1) | 88.9xrcl |

| 80x65 (3x2-1/2) | 88.9xrc2-1/2 |

| 100x25 (4x1) | 108xrcl |

| 100x25 (4x1) | 114.3xrcl |

| 125x25 (5x1) | 133xrcl |

| 125x25 (5x1) | 139.7xrcl |

| 150x25 (6x1) | 159XRCL |

| 150x80 (6x3) | 159xrc3 |

| 150x25 (6x1) | 165. LXRCL |

| 150x80 (6x3) | 165. 1xrc3 |

| 200x25 (8xrcl) | 219. LXRCL |

| 200x80 (8x3) | 219. 1XRC3 |

Redukteur (kouliso)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) |

| 65 x 50 (2-1/2 x 2) | 76.1x60.3 |

| 80x50 (3x2) | 88.9x60.3 |

| 80x65 (3x2-1/2) | 88.9x76.1 |

| 100x65 (4x2-1/2) | 108x76.1 |

| 100x80 (4x3) | 108x88.9 |

| 100x50 (4x2) | 114.3x60.3 |

| 100x80 (4x3) | 114.3x88.9 |

| 125x65 (5x2-1/2) | 133x76.1 |

| 125x100 (5x4) | 133x114.3 |

| 125x50 (5x2) | 139.7x60.3 |

| 125x100 (5x4) | 139.7x114.3 |

| 150x65 (6x2-1/2) | 159x76.1 |

| 150x125 (6x5) | 159x139.7 |

| 150x50 (6x2) | 165.1x60.3 |

| 150x125 (6x5) | 165.1x139.7 |

| 200x65 (8x2) | 219.1x60.3 |

| 200x150 (8x6) | 219.1x165.1 |

Bride devwa lou

(Grooved)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) | Travay Presyon (MPA) | Dimansyon (mm) | Non. Nan twou | |||

| A | B | c | D | ||||

| 65 (2-1/2) | 76.1 | 2.5 | 63.5 | 17 | 185 | 145 | 8 |

| 65⑶ | 88.9 | 2.5 | 63.5 | 17 | 200 | 160 | 8 |

| 100⑷ | 108 | 2.5 | 67.5 | 16.5 | 235 | 190 | 8 |

| 100⑷ | 114.3 | 2.5 | 68 | 15 | 230 | 190 | 8 |

| 150⑹ | 159 | 2.5 | 68 | 17 | 300 | 250 | 8 |

| 150⑹ | 165.1 | 2.5 | 68 | 17 | 300 | 250 | 8 |

| 200⑻ | 219.1 | 2.5 | 77 | 20 | 360 | 310 | 12 |

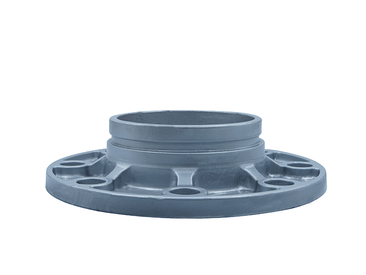

Adaptè bride

(Grooved)

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) | Travay Presyon (MPA) | Dimansyon (mm) | Non. Nan twou | |||

| A | B | c | D | ||||

| 50⑵ | 60.3 | 1.6 | 50 | 15 | 160 | 125 | 4 |

| 65 (2-1/2) | 76.1 | 1.6 | 50 | 15 | 178 | 145 | 4 |

| 80⑶ | 88.9 | 1.6 | 50 | 15 | 194 | 160 | 8 |

| 100⑷ | 108 | 1.6 | 55 | 15 | 213 | 180 | 8 |

| 100⑷ | 114.3 | 1.6 | 55 | 15 | 213 | 180 | 8 |

| 125⑸ | 133 | 1.6 | 58 | 17 | 243 | 210 | 8 |

| 125⑸ | 139.7 | 1.6 | 58 | 17 | 243 | 210 | 8 |

| 150⑹ | 159 | 1.6 | 65 | 17 | 280 | 240 | 8 |

| 150⑹ | 165.1 | 1.6 | 65 | 17 | 280 | 240 | 8 |

| 200⑻ | 219.1 | 1.6 | 78 | 19 | 340 | 295 | 812 |

Bride avèg

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) | Travay Presyon (MPA) | Wotè (mm) | |

| 50⑵ | 60.3 | 2.5 | 28 | |

| 65 (2-1/2) | 76.1 | 2.5 | 28 | |

| 80⑶ | 88.9 | 2.5 | 29 | |

| 100⑷ | 108 | 2.5 | 31 | |

| 100⑷ | 114.3 | 2.5 | 31 | |

| 125 (5) | 133 | 2.5 | 31.5 | |

| 125⑸ | 139.7 | 2.5 | 31.5 | |

| 150⑹ | 159 | 2.5 | 31.5 | |

| 150⑹ | 165.1 | 2.5 | 31 | |

| 200⑻ | 219.1 | 2.5 | 36.5 | |

Bride

| Gwosè nòmal (mm/nan) | Dyamèt deyò (mm) | Travay Presyon (MPA) | Dimansyon (mm) | Non. Nan twou | |||

| A | B | c | D | ||||

| 25⑴ | Rcl | 1.6 | 18 | 10 | 85 | 110 | 4 |

| 32 (1-1/4) | RCL-1/4 | 1.6 | 18 | 11 | 100 | 130 | 4 |

| 40 (1-1/2) | RCL-1/2 | 1.6 | 19 | 13 | 110 | 145 | 4 |

| 50 (2) | RC2 | 1.6 | 20 | 13 | 125 | 155 | 4 |

| 65 (2-1/2) | RC2-1/2 | 1.6 | 21 | 15 | 144 | 178 | 4 |

| 80⑶ | RC3 | 1.6 | 25.5 | 15 | 160 | 193.5 | 8 |

| 100⑷ | RC4 | 1.6 | 25.75 | 15 | 180 | 213.5 | 8 |

Boulon & nwa

| Tay | Threaded longè L1 | Longè total | Fishtail boulon lajè | Nwa widht |

| M10 x 55 | 30 ± 3 | 55 ± 1.2 | 14. 5 ± 0. 5 | 9. 6 ~ 10 |

| M10 x 60 | 30 ± 3 | 60 ± 1.2 | 14.5 + 0.5 | 9. 6 ~ 10 |

| M10 x 65 | 30 ± 3 | 65 ± 1.2 | 14. 5 ± 0. 5 | 9. 6 ~ 10 |

| M12 x 65 | 36+4 | 65 ± 1.2 | 15.2 ± 0.4 | 11. 6 ~ 12 |

| M12 x 70 | 36+4 | 70+1. 2 | 15.2 ± 0.4 | 11. 6 ~ 12 |

| M12 x 75 | 41+4 | 75+1. 2 | 15.2 ± 0.4 | 11. 6 ~ 12 |

| M16 x 85 | 44+4 | 85+1. 2 | 19. 0-19. 9 | 15. 3 ~ 16 |

| M20 x 120 | 50+5 | 120+2. 0 | 24 ± 0.8 | 18. 9 ~ 20 |

Pwopriyete mekanik boulon yo pa dwe pi ba pase klas 8.8 ki espesifye nan GB / T 3098.1, epi tolerans fil la dwe 6G. Pwopriyete mekanik nwa a dwe konfòme li avèk kondisyon klas 8 ki espesifye pou nwa nan GB / T 3098.2, tolerans fil 6h.

Bag gasket

| Non | Sèmante | Rekòmandasyon Sèvis Jeneral | Range Tanperati |

| EPDM | E | Rezèv dlo, drenaj, dlo egou ak lè tanperati nòmal, asid fèb ak alkali fèb | -30 ° C ~+130 ° C |

| Nbr | D | Petwòl ki baze sou lwil | -20 ° C〜+80 ° C |

| Kawotchou silicomn | S | Dlo pou bwè, lè sèk cho ak kèk pwodwi chimik cho | -40 ° C ~+180 ° C |

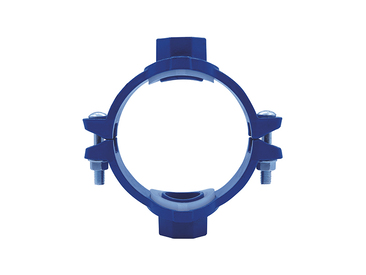

Ble pentire ekipman tiyo tiyo

Tablo gwosè tankou pi wo a

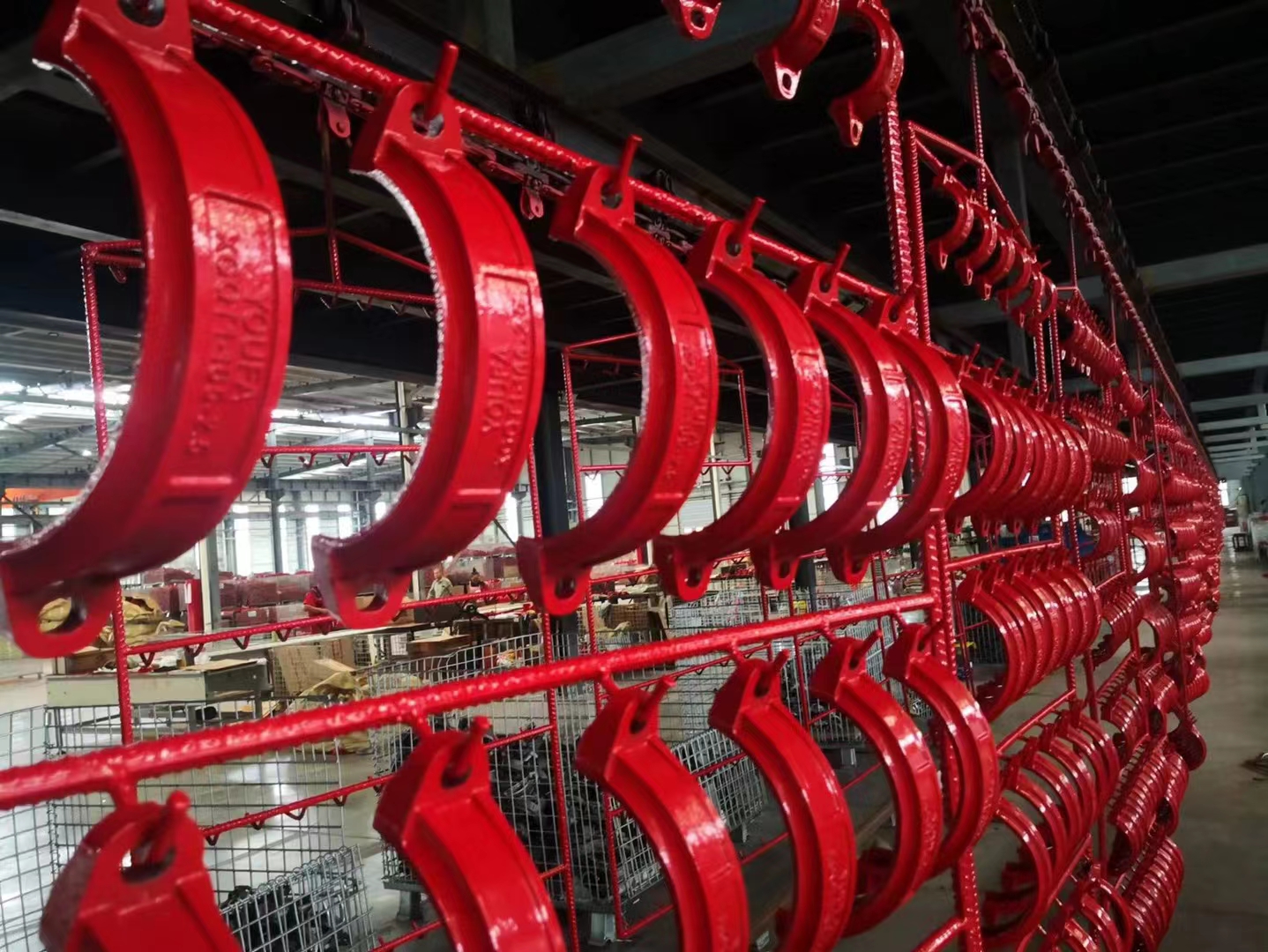

Tranch pentire ekipman tiyo tiyo

Tablo gwosè tankou pi wo a