API 5L fistulae inconsutiles communiter adhibentur in constructionepipelines ad transportandum oleum et gasper longa spatia, et etiam in constructione infrastructurae industriae industriae adhibentur, sicut refineries et plantae petrochemicae.

API 5L Seamless Steel Pipes Introductiones breves

| Productum | API 5L Seamless Steel Pipe | Specification |

| Materia | Carbon Steel | OD: 13.7-610mm Crassitudo: sch40 sch80 sch160 Longitudo: 5.8-6.0m |

| Gradus | L245,API 5L B /ASTM A106 B | |

| Superficies | Nuda aut Nigrum picta | Usage |

| Ends | Patet terminos | Oleum / Gas traditio tibia ferro |

| aut fines Beveled |

Stipare et Delivery:

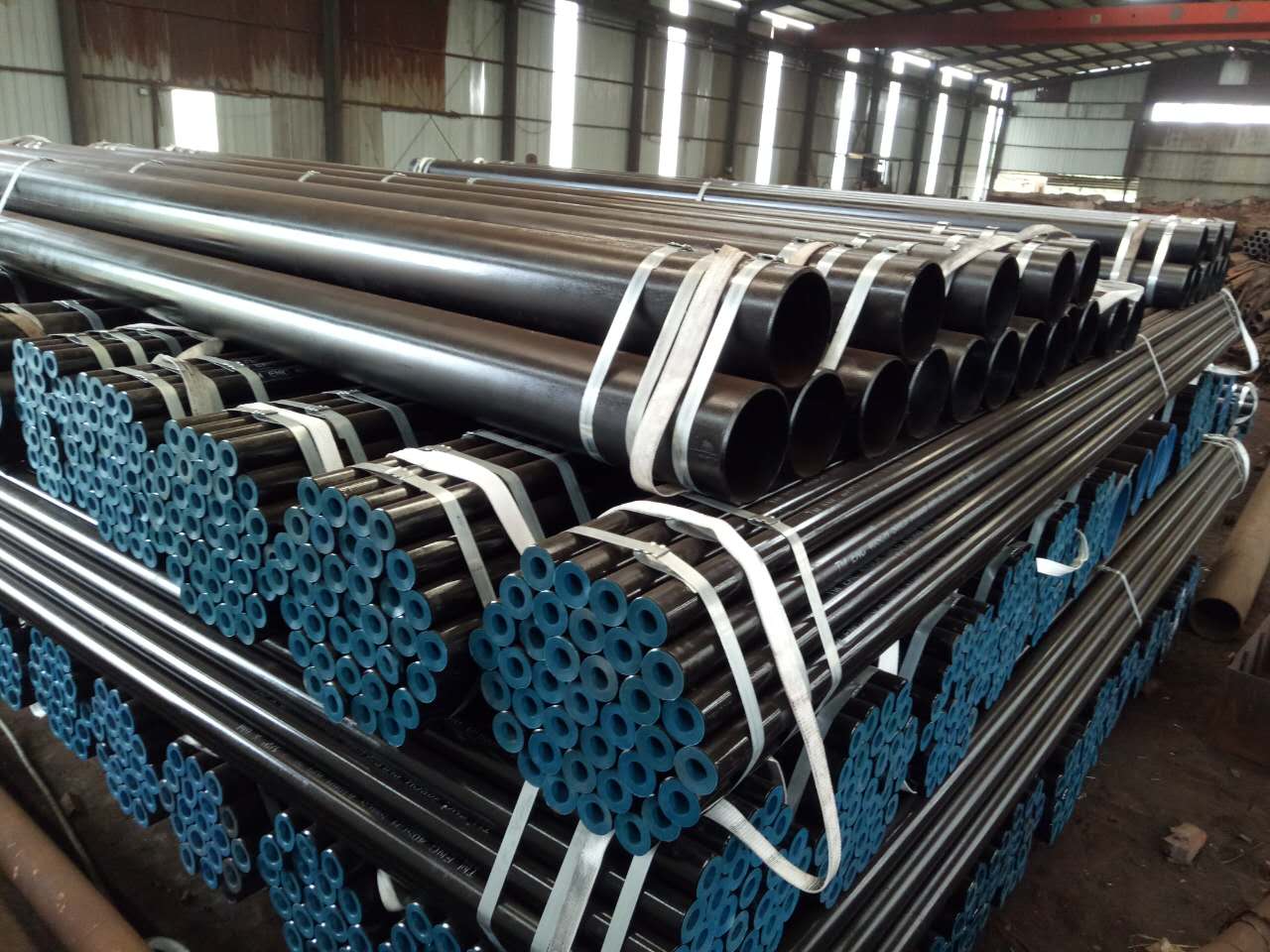

Stipare Singula: in hexagonis dignis fasciculis refertum clavo ferro, cum binis fundis nylon pro singulis fasciculis.

Partus Details: Secundum QTY, normaliter unum mensem.

API 5L Seamless Carbon Steel Pipe Steel Grade

| Seamless Pipe Steel Grade | Compositio chemica pro PSL 1 fistula cum WT ≤25mm (0.984 inc) | ||||

| C (max.)% | Mn (max.)% | P (max.)% | S (max.)% | V + Nb + Ti | |

| L245 vel Grade B | 0.28 | 1.2 | 0.03 | 0.03 | Nisi aliter convenerit, summa contentorum niobium et vanadium erit u 0,06%. Summa niobium, vanadium et titanium concentratio erit u 0,15%. |

| Seamless Pipe Steel Grade | Tests distrahentesfor PSL 1 tibia corporis | |||

| Virtus cedet (min.) MPa | Tensile Fortitudo (min.) MPa | |||

| L245 vel Grade B | 245 | 415 | ||

API 5L Steel Seamless Pipes Sizes Chart

| UNCIA | OD | API 5L ASTM A106 Strandard Wall Crassitudo | |||||||

| (MM) | SCH 10 | SCH 20 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 160 | XXS | |

| (mm) | (mm) | (mm* | (mm) | mm) | (mm) | mm) | (mm) | ||

| 1/4" | 13.7 | 2.24 | 3.02 | ||||||

| 3/8" | 17.1 | 2.31 | 3.2 | ||||||

| 1/2" | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 2191 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Seamless SMLS Pipe Vestibulum Processus

Rudis Materialis Electio:Summus qualitas carbonis chalybea eligitur ut materia rudis ad fistulas carbo carbonis inconsutiles. Contentum carbonii in ferro elementum clavis est ad determinandas proprietates eius et idoneitatem ad varias applicationes.

Calefaciens et Piercing:Materia rudis ad caliditatem calefacta et postea perforata ad formam cavae testam. Hic processus pendet ad figuram initialem organi conficiendam et per methodos typice obtinetur ut in gyratorio pungendo, extrudendo, vel aliis artificiis specialibus.

Rolling and Sizing:Testa perforata volvens et sestimationem patitur processus eius diametri et parietis crassitudinem reducere ad mensuras debitas. Hoc typice consecutum est utens seriem molendinorum volubilium et molendinorum capiendorum ad optatam formam ac dimensionem consequendam.

Curatio caloris:Fistula carbo inconsutilis calori curationi subiecta est processibus tractationis, sicut furnum, normalizing, exstinguere et temperare ad augendas suas mechanicas proprietates et quaslibet residuas passiones removent. Curatio caloris etiam adiuvat ad microstructuram desideratam et proprietates chalybis carbonis assequendas.

Testis et inspectio:Per processum fabricandi, inconsutilem carbonis fistulam varias tentationes non perniciosas et perniciosas patitur, ut occurrat signa qualitatis requisitae. Hoc includere potest ultrasonica probatio, hydrostatica probatio, torrens probatio, et inspectio visualis.

Finiendi et Coating:Tibia inconsutibilitatis cum specificationibus requisitis occurrit, processus finitos subit ut rectius, secans, et finiens. Praeterea fistula obductis materiis tutelaribus ut illitus, pingere vel movere potest ad resistentiam corrosionis augendam, praesertim in chalybe carbonii.

Inspectionis finalis et Packaging:Fistula ferri inconsutilem perfecti ultimam inspectionem subit ut omnibus signis qualitatibus et emptoribus requisitis occurrat. Tunc diligenter fasciculatum est et ad naves ad emptorem praeparatum.

API 5L Carbon Steel Seamless Pipe Quality Assurance and Test

Hydrostatic test

inconsutilem fistulam hydrostaticum experimentum sine lacus per commissurae vel organi corporis coagmentatum sustinebit.

Patientia diametri, muri crassitudinis, longitudinis et rectitudinis

| Certa extra diameter | Diameter tolerances fistula | Out-of-rotunditatem tolerances | ||

| Fistula praeter finem | Finis pipe | Fistula praeter finem | Finis pipe | |

| <60.3mm | 0.8mm ad + 0.4mm | 0.4mm ad + 1.6mm | ||

| ≥60.3mm ad ≤168.3mm | ± 0.0078 D | 0.003 D | 0.014 D | |

| >168.3mm to ≤610mm | ± 0.0078 D | ± 0.005 D, sed maximum of ± 1.6mm | ||

| >610mm ad ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, sed maximus of 15mm; ad D/T≤75 | 0.01 D, sed maximus of 13mm; ad D/T≤75 |

| per consensum ad D/T>75 | per consensum ad D/T>75 | |||

D: OD extra diametrum T: murum crassitudinis WT