Imibhobho ye-API 5L engenamthungo isetyenziswa ngokuqhelekileyo ekwakhiweni kweimibhobho yokuthutha i-oyile negesikwimigama emide, kwaye ikwasetyenziswa kulwakhiwo lweziseko ezingundoqo kushishino lwamandla, njengemizi yokucoca kunye nezityalo zepetrochemical.

I-API 5L ye-Seamless Steel Pipes iintshayelelo ezimfutshane

| Imveliso | I-API 5L i-Seamless Steel Pipe | Inkcazo |

| Izinto eziphathekayo | Intsimbi yeCarbon | OD: 13.7-610mm Ukutyeba: sch40 sch80 sch160 Ubude: 5.8-6.0m |

| IBanga | L245,API 5L B /ASTM A106 B | |

| Umphezulu | I-Bare okanye i-Black Painted | Ukusetyenziswa |

| Iyaphela | Isiphelo esicacileyo | Umbhobho wentsimbi wokuhanjiswa kwe-oyile/igesi |

| Okanye iBeveled iphela |

Ukupakisha kunye nokuhanjiswa:

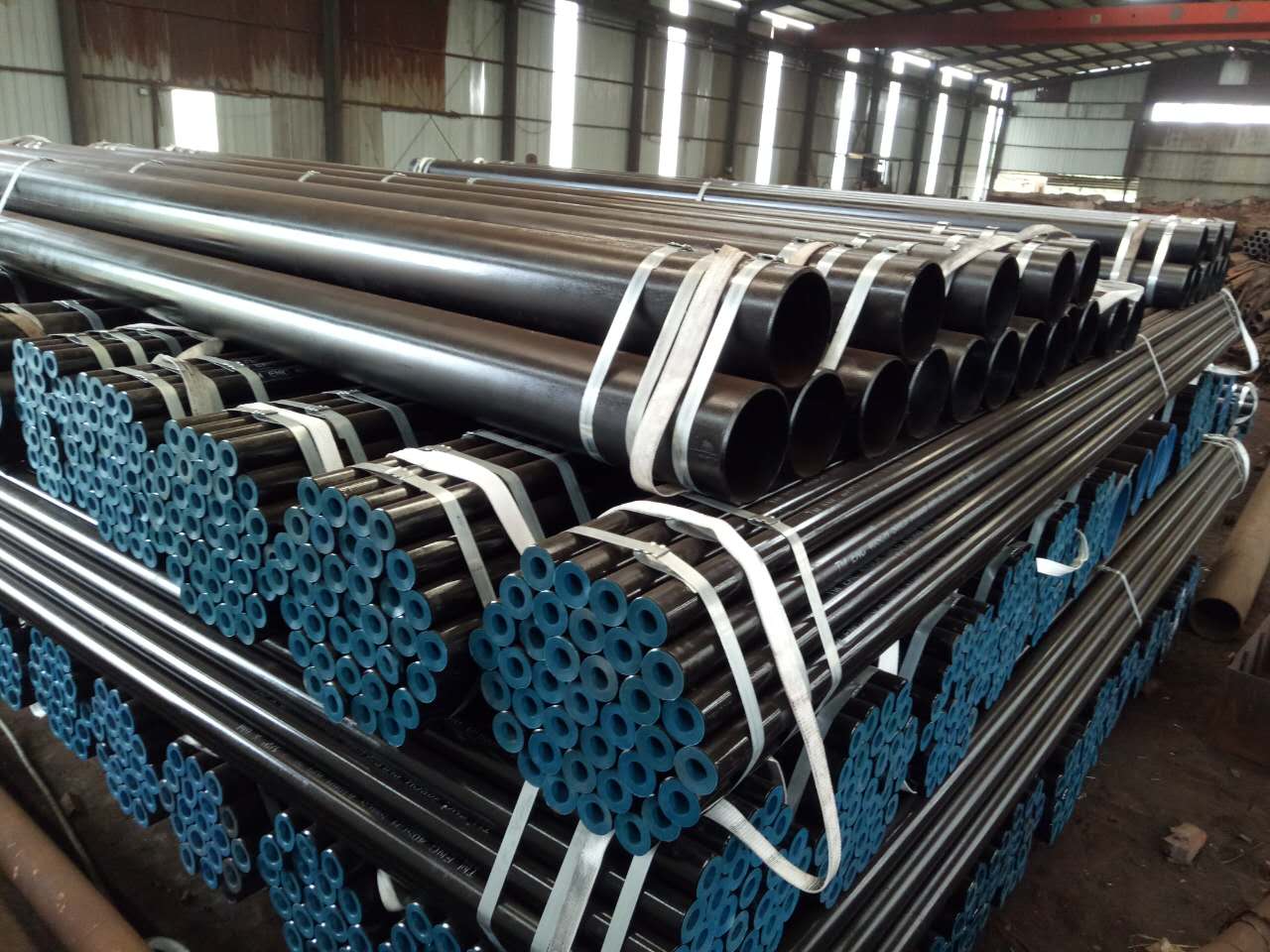

Iinkcukacha zokuPakisha : kwimiyanda engama-hexagonal ekulungele ulwandle epakishwe ngemicu yentsimbi, Nezilingi ezimbini zenayiloni kwimiqulu nganye.

Iinkcukacha zokuhanjiswa : Kuxhomekeka kwi-QTY, ngokwesiqhelo inyanga enye.

I-API 5L engenamthungo yeCarbon Steel Pipe Steel Grade

| IBanga lentsimbi yombhobho engenamthungo | Ukuqulunqwa kwemichiza ye-PSL 1 umbhobho one-WT ≤25mm (0.984 inc) | ||||

| C (ubuninzi.)% | Mn (ubuninzi.)% | P (ubuninzi.)% | S (ubuninzi.)% | V + Nb + Ti | |

| L245 okanye iBanga B | 0.28 | 1.2 | 0.03 | 0.03 | Ngaphandle kokuba kuvunyelwene ngenye indlela, isixa se-niobium kunye ne-vanadium contents iya kuba ngu-0,06%. Isimbuku se-niobium, i-vanadium kunye ne-titanium concentrations iya kuba ngu-0,15%. |

| IBanga lentsimbi yombhobho engenamthungo | Iimvavanyo zokuqinakuba PSL 1 umzimba umbhobho | |||

| Amandla eSivuno (imiz.) MPa | Amandla Okuqina (min.) MPa | |||

| L245 okanye iBanga B | 245 | 415 | ||

Itshathi ye-API 5L yentsimbi engenamthungo yeMibhobho yobungakanani

| INCH | OD | API 5L ASTM A106 Strandard Wall Ukutyeba | |||||||

| (MM) | I-SCH 10 | I-SCH 20 | I-SCH 40 | I-SCH 60 | I-SCH 80 | I-SCH 100 | I-SCH 160 | XXS | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Inkqubo yokwenziwa kwemibhobho ye-SMLS engenamthungo

Ukukhethwa kweMathiriyeli ekrwada:Umgangatho ophezulu wekhabhoni yentsimbi ukhethwa njengezinto eziluhlaza kwimibhobho yentsimbi yekhabhoni engenamthungo. Umxholo wekhabhoni kwintsimbi yinto ephambili ekunqumeni iimpawu zayo kunye nokufaneleka kwezicelo ezahlukeneyo.

Ukufudumeza nokugqobhoza:Impahla ekrwada ifudunyezwa kubushushu obuphezulu kwaye emva koko igqojozwe ukwenza iqokobhe elingenamngxuma. Le nkqubo ibalulekile ekudaleni ubume bokuqala bombhobho kwaye ngokuqhelekileyo iphunyezwa ngeendlela ezinjengokugqobhoza okujikelezayo, ukukhutshwa, okanye ezinye iindlela ezikhethekileyo.

Ukuqengqeleka kunye nobungakanani:Iqokobhe elihlatyiweyo liqhuba iinkqubo zokuqengqeleka kunye nokulinganisa ukunciphisa ububanzi kunye nobukhulu bodonga ukuya kwimilinganiselo efunekayo. Oku kudla ngokuphunyezwa kusetyenziswa uthotho lwezingqusho eziqengqelekayo kunye nemilinganiselo yokusila ukufikelela kwimilo efunekayo kunye nemilinganiselo.

Unyango loBubushushu:Umbhobho we-carbon steel ongenamthungo uphantsi kweenkqubo zonyango lobushushu ezifana nokucima, ukunyanzeliswa, okanye ukucima kunye nokufudumala ukunyusa iimpawu zayo zomatshini kunye nokususa naluphi na uxinzelelo olushiyekileyo. Unyango lokushisa lukwanceda ekufezekiseni i-microstructure efunwayo kunye neempawu ze-carbon steel.

Uvavanyo kunye noHlolo:Kuyo yonke inkqubo yokuvelisa, umbhobho wekhabhoni ongenamthungo uhamba ngeendlela ezahlukeneyo zokuvavanya ezingonakalisi kunye nezonakalisayo zokuqinisekisa ukuba ihlangabezana nemigangatho yomgangatho ofunekayo. Oku kunokubandakanya uvavanyo lwe-ultrasonic, uvavanyo lwe-hydrostatic, uvavanyo lwangoku lwe-eddy, kunye nokuhlolwa okubonakalayo.

Ukugqiba kunye noKwaleka:Emva kokuba umbhobho ongenamthungo udibana neenkcukacha ezifunekayo, uqhuba iinkqubo zokugqiba ezifana nokulungelelanisa, ukusika, kunye nokuphela kokugqiba. Ukongezelela, umbhobho unokufakwa ngezinto zokukhusela ezifana ne-varnish, ipeyinti, okanye i-galvanizing ukunyusa ukuxhathisa ukubola, ngakumbi kwimeko ye-carbon steel.

Uhlolo lokugqibela kunye nokuPakisha:Umbhobho ogqityiweyo wensimbi ongenamthungo uhlolwa okokugqibela ukuqinisekisa ukuba uhlangabezana nayo yonke imigangatho yomgangatho kunye neemfuno zabathengi. Emva koko ipakishwe ngononophelo kwaye ilungiselelwe ukuthunyelwa kumthengi.

I-API 5L yeCarbon Steel Seamless iSiqinisekiso soMgangatho wePipe kunye noVavanyo

Uvavanyo lweHydrostatic

umbhobho ongenamthungo uya kumelana novavanyo lwe-hydrostatic ngaphandle kokuvuza ngomthungo we-weld okanye umzimba wombhobho.

Ukunyamezela ububanzi, ubukhulu bodonga, ubude kunye nokuthe tye

| Icacisiwe ngaphandle kwedayimitha | Ukunyamezelana kombhobho we-SMLS Ububanzi | Ukunyamezela ngaphandle kokujikeleza | ||

| Umbhobho ngaphandle kokuphela | Ukuphela kombhobho | Umbhobho ngaphandle kokuphela | Ukuphela kombhobho | |

| <60.3mm | - 0.8mm ukuya + 0.4mm | - 0.4mm ukuya + 1.6mm | ||

| ≥60.3mm ukuya ≤168.3mm | ± 0.0075 D | 0.020 D | 0.015 D | |

| > 168.3mm ukuya ≤610mm | ± 0.0075 D | ± 0.005 D, kodwa ubuninzi ± 1.6mm | ||

| > 610mm ukuya ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, kodwa ubuninzi malunga ne-15mm, ye-D/T≤75 | 0.01 D, kodwa ubuninzi malunga ne-13mm, ye-D/T≤75 |

| ngesivumelwano yeD/T>75 | ngesivumelwano yeD/T>75 | |||

D: OD ngaphandle ububanzi T: WT udonga ubukhulu