Amapayipi angenamthungo e-API 5L avame ukusetshenziswa ekwakhiweni kweamapayipi okuthutha uwoyela negesiemabangeni amade, futhi iphinde isetshenziswe ekwakhiweni kwengqalasizinda yemboni yezamandla, njengezindawo zokuhluza kanye nezitshalo ze-petrochemical.

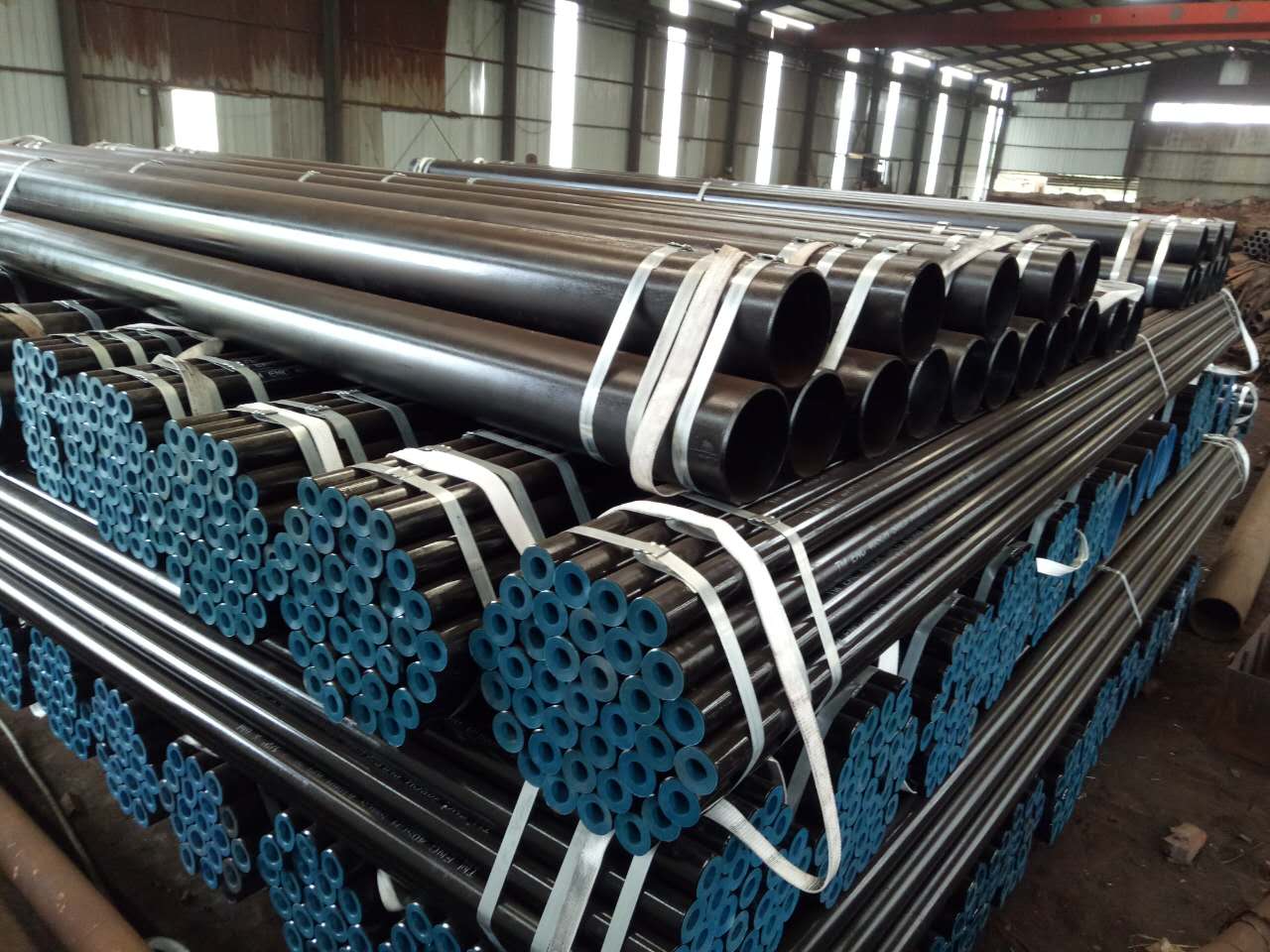

I-API 5L Amapayipi Ensimbi Angenamthungo Izingeniso Ezimfushane

| Umkhiqizo | Ipayipi Lensimbi Elingenamthungo le-API 5L | Ukucaciswa |

| Okubalulekile | Insimbi Yekhabhoni | OD: 13.7-610mm Ubukhulu: sch40 sch80 sch160 Ubude: 5.8-6.0m |

| Ibanga | L245,API 5L B/ASTM A106 B | |

| Ubuso | Ipendiwe Engenalutho noma Emnyama | Ukusetshenziswa |

| Iyaphela | I-Plain iphela | Ipayipi lensimbi yokulethwa kukawoyela/igesi |

| Noma i-Beveled iphela |

Ukupakisha Nokulethwa:

Imininingwane Yokupakisha : kuzinyanda ezinama-hexagonal ezifanele ulwandle ezipakishwe ngemicu yensimbi, Nezihlilingi ezimbili zenayiloni zenqwaba ngayinye.

Imininingwane Yokulethwa : Kuye nge-QTY, ngokuvamile inyanga eyodwa.

API 5L Seamless Carbon Steel Pipe Steel Ibanga

| Ibanga Lensimbi Elingenamthungo | Ukwakheka Kwamakhemikhali ngepayipi le-PSL 1 eline-WT ≤25mm (0.984 inc) | ||||

| C (ubuningi.)% | Mn (ubuningi.)% | P (ubuningi.)% | S (ubuningi.)% | V + Nb + Ti | |

| L245 noma iBanga B | 0.28 | 1.2 | 0.03 | 0.03 | Ngaphandle uma kuvunyelwene ngenye indlela, isamba sokuqukethwe kwe-niobium ne-vanadium sizoba u-0,06 %. Isamba sokugxilwa kwe-niobium, i-vanadium ne-titanium sizoba u-0,15 %. |

| Ibanga Lensimbi Elingenamthungo | Ukuhlolwa kwe-Tensilengomzimba wepayipi we-PSL 1 | |||

| Amandla Esivuno (min.) MPa | Amandla Okuqina (min.) MPa | |||

| L245 noma iBanga B | 245 | 415 | ||

Ishadi Lobukhulu Bamapayipi Ensimbi Angenazihibe le-API 5L

| INCH | OD | API 5L ASTM A106 Strandard Wall Ukujiya | |||||||

| (MM) | I-SCH 10 | I-SCH 20 | I-SCH 40 | I-SCH 60 | I-SCH80 | I-SCH 100 | I-SCH 160 | XXS | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

Inqubo Yokukhiqiza Ipayipi Le-SMLS engenamthungo

Ukukhethwa Kwezinto Ezingavuthiwe:I-carbon steel yekhwalithi ephezulu ikhethwa njengento eluhlaza yamapayipi ensimbi angenamthungo. Okuqukethwe kwekhabhoni ensimbi kuyisici esibalulekile ekunqumeni izakhiwo zayo kanye nokufaneleka kwezicelo ezihlukahlukene.

Ukushisisa nokubhoboza:Impahla eluhlaza ishiselwa ezingeni lokushisa eliphezulu bese ibhobozwa ukwenza igobolondo elingenalutho. Le nqubo ibalulekile ekudaleni umumo wokuqala wepayipi futhi ngokuvamile ifinyelelwa ngezindlela ezinjengokubhoboza ngokuzungezayo, ukukhipha, noma amanye amasu akhethekile.

Ukugoqa kanye nosayizi:Igobolondo elibhoboziwe lingena ezinqubweni zokugingqika kanye nokulinganisa ukuze kuncishiswe ububanzi balo nobukhulu bodonga libe izilinganiso ezidingekayo. Lokhu ngokuvamile kufinyelelwa kusetshenziswa uchungechunge lwezigayo ezigoqayo nezigayo zokulinganisa ukuze kuzuzwe umumo nobukhulu obufunekayo.

Ukwelashwa Kokushisa:Ipayipi lensimbi le-carbon steel elingenamthungo lingaphansi kwezinqubo zokwelashwa kokushisa okufana nokucwiliswa, ukujwayela, noma ukucisha kanye nokushisa ukuze kuthuthukiswe izici zayo zomshini futhi kususe noma yikuphi ukucindezelwa okusalayo. Ukwelashwa kokushisa nakho kusiza ekuzuzeni i-microstructure oyifunayo kanye nezakhiwo ze-carbon steel.

Ukuhlola Nokuhlola:Kuyo yonke inqubo yokukhiqiza, ipayipi lekhabhoni elingenamthungo libhekana nezindlela zokuhlola ezihlukahlukene ezingabhubhisi nezilimazayo ukuze kuqinisekiswe ukuthi lihlangabezana nezindinganiso zekhwalithi ezidingekayo. Lokhu kungase kuhlanganise ukuhlolwa kwe-ultrasonic, ukuhlolwa kwe-hydrostatic, ukuhlolwa kwamanje kwe-eddy, nokuhlolwa okubonakalayo.

Ukuqeda kanye nokuhlanganisa:Uma ipayipi elingenamthungo lifinyelela izicaciso ezidingekayo, lingena ezinqubweni zokuqeda ezifana nokuqondisa, ukusika, nokuqeda ukuqeda. Ukwengeza, ipayipi lingase limbozwe ngezinto zokuvikela ezifana ne-varnish, upende, noma i-galvanizing ukuze kuthuthukiswe ukumelana nokugqwala, ikakhulukazi esimweni se-carbon steel.

Ukuhlola Okokugcina Nokupakishwa:Ipayipi lensimbi engenamthungo eliqediwe lihlolwa okokugcina ukuze kuqinisekiswe ukuthi lihlangabezana nazo zonke izindinganiso zekhwalithi kanye nezidingo zamakhasimende. Bese ipakishwa ngokucophelela futhi ilungiselelwe ukuthunyelwa ekhasimendeni.

I-API 5L Carbon Steel Seamless Pipe Quality Assurance and Test

Ukuhlolwa kwe-Hydrostatic

ipayipi elingenamthungo lizomelana nokuhlolwa kwe-hydrostatic ngaphandle kokuvuza ngomthungo we-weld noma umzimba wepayipi.

Ukubekezelela ububanzi, ukushuba kodonga, ubude nokuqina

| Kucacisiwe ububanzi obungaphandle | Ukubekezelela kobubanzi bepayipi le-SMLS | Ukubekezelelana okungaphandle komjikelezo | ||

| Ipayipi ngaphandle kokuphela | Ukuphela kwepayipi | Ipayipi ngaphandle kokuphela | Ukuphela kwepayipi | |

| <60.3mm | − 0.8mm ukuya + 0.4mm | − 0.4mm ukuya + 1.6mm | ||

| ≥60.3mm ukuya ku-≤168.3mm | ± 0.0075 D | 0.020 D | 0.015 D | |

| > 168.3mm kuya ku-≤610mm | ± 0.0075 D | ± 0.005 D, kodwa ubukhulu ± 1.6mm | ||

| > 610mm ukuze ≤711mm | ± 0.01 D | ± 2.0mm | 0.015 D, kodwa esiphezulu ububanzi 15 mm, kwe-D/T≤75 | 0.01 D, kodwa esiphezulu 13 mm, kwe-D/T≤75 |

| ngesivumelwano kwe-D/T>75 | ngesivumelwano kwe-D/T>75 | |||

D: OD ngaphandle ububanzi T: WT udonga ukujiya

Okunye Okuhlobene API 5L Carbon Steel Pipes

-

I-Q355 S355 Square kanye ne-Rectangular Steel Pipe Pri...

-

EN74 Isikhafu Sensimbi Esijwayelekile Esipendiwe Nesithathiwe...

-

I-Pre Gi Steel Pipe Round Hollow Isigaba esingu-60mm

-

Insiza ye-scaffolding ye-ringlock

-

I-Frame Ladders Scaffoldings Construction Scaffol...

-

Ipayipi Lensimbi Elivulwe Ngensimbi I-Grooved Ends